Low-Cost Synchronization Techniques for KUKA Robots and External

Axes in Low-Dynamic Processes

Patrick Kaufmann

a

, Holger Weber

b

and Michael Vistein

c

German Aerospace Center, Center for Lightweight Production Technology, Augsburg, Germany

Keywords:

Robots, Automation, Synchronization, Cost-Efficient, KUKA.

Abstract:

Many industries, including electronics, automotive, aviation, and food, are increasingly using industrial robots

to automate processes and improve quality, efficiency, and cost-effectiveness. High-volume industries like

electronics and automotive can automate complex tasks very cost-efficient, while industries with lower vol-

umes, such as aviation, require flexible and reliable automation solutions to remain competitive while keeping

a closer eye on the costs. One important task is the synchronization of robot movements with an external axis.

While there are very accurate synchronization options available, these can be very complex and costly. In par-

ticular in research or process development where requirements are changing frequently, more flexible and also

low-cost solutions are required. This paper analyzes several cost-effective alternatives for the synchronization

of a KUKA robot with an external axis.

1 INTRODUCTION

Industrial robots are in widespread use in many dif-

ferent industries nowadays. Particularly in industries

with large volumes such as automotive or electronics,

even highly complex tasks can be automated, often

with a combination of highly specialized production

machines and industrial robot. The initial cost for set-

ting up the system is very small compared to the run-

ning cost of the regular production.

In other industries which much lower volumes, for

example in aviation, the use of industrial robot may

not be that straight forward. Highly specialized pro-

duction cell would often be used sparingly due to the

low volume. Therefore, it is highly desirable to be

able to use the robots for the production of many dif-

ferent parts, which requires a very flexible system(Bi

et al., 2015).

In particular in the research area for automation

of novel production processes, fast changing require-

ments are common. Therefore, it can be desirable

to have low-cost and easy-to-implement solutions at

hand, even if these solutions provide an inferior per-

formance. A common task on designing a robotic

end-effector is the necessity to synchronize actions of

a

https://orcid.org/0000-0003-1181-7211

b

https://orcid.org/0009-0007-5666-2889

c

https://orcid.org/0000-0001-6998-0017

the end-effector with the motions of the robot. While

this is quite easy if only switch operations (such as

turning a welding gun on or off) are required, it be-

comes much more difficult if continuous motions e.g.

for feed need to be synchronous. One example would

be an end-effector that has been developed at the Ger-

man Aerospace Center (DLR), which deposits wide

textiles for the production of carbon fiber reinforced

plastics (CFRP)(Kaufmann et al., 2019). In this case,

the material is actively fed by the end-effector at a

speed that must match the robot’s velocity.

While it is possible to integrate the additional

drives into the main robot control and thus achieve

the best possible synchronization, this is usually nei-

ther easy to do, nor a very flexible solution if end-

effectors need to be switched regularly or adjusted to

new requirements.

In this paper, low-cost techniques that allow the

synchronization of end-effector drives controlled by

a Beckhoff TwinCAT PLC/NC with a KUKA robot

are investigated. The paper is organized as follows:

In section 2, the current state-of-the-art is explained.

Section 3 describes the various techniques that are

available on KUKA robots for retrieving either the

current position or velocity of the robot. Section 4

explains the experimental setup and introduced the

different synchronization approaches that have been

tested. The results for each approach are provided in

section 5 and finally discussed in section 6.

Kaufmann, P., Weber, H. and Vistein, M.

Low-Cost Synchronization Techniques for KUKA Robots and External Axes in Low-Dynamic Processes.

DOI: 10.5220/0012207900003543

In Proceedings of the 20th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2023) - Volume 1, pages 711-718

ISBN: 978-989-758-670-5; ISSN: 2184-2809

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

711

2 STATE OF THE ART

Complex production facilities often include robots in

addition to manufacturing machines, which require

synchronization of their movements. This synchro-

nization can be achieved in various ways and is de-

pendent on the robot and machine control, as well

as their synchronization capabilities. For tasks that

require a rather simple end-effector, it is common

practice to control the complete end-effector using

the built-in functionality of the robot controller. For

more complex cases, coordination can be performed

by the machine’s PLC up to the extend that the robot

is considered being an integral part of the machine

with no user access to the underlying robot controller

anymore. KUKA’s KR C4 robot control offers both

options.

The communication between the robot and PLCs

is done through real-time interfaces provided by

the manufacturer. KUKA offers software such as

KUKA.PLC mxAutomation, which sends elementary

motion commands from an PLC to the robot’s path

planning. An implementation of the robot into the

machine control is offered with KUKA’s KUKA.CNC

Sinumerik software, allowing the robot to be con-

trolled via Sinumerik functions. Communication be-

tween the robot and machine control is achieved using

the Profinet IRT (isochronous real-time) interface.

If the robot and machine control should remain

separate, synchronization must be implemented us-

ing the interfaces provided by both systems. An al-

ternative approach is to use general interfaces such as

TCP or UDP, which are offered by most manufactur-

ers. Ultimately, the ideal synchronization method de-

pends on the process to be executed and a cost-benefit

analysis.

Using communication protocols to synchronize an

external axis with a robots trajectory is rather un-

common, most applications are modifying the robot

motion. KUKA’s Robot Sensor Interface (RSI) is

used e.g. to switch position control to torque con-

trol (Winkler and Such

`

y, 2013) or the most common

use case, manipulating moving objects by synchro-

nizing the robot with a conveyor belts (Stogl et al.,

2017). In time critical applications precise timing

and accurate control are key. While costly solu-

tion like KUKA.PLC mxAutomation and KUKA.CNC

Sinumerik ensure real-time response there is research

for budget solution like controlling KUKA robots via

Kukavarproxy or RSI using ROS (Arbo et al., 2020).

Adapting to fast changing circumstances especially

for manufacturing in small lot sizes or research con-

text while open the need of low-budget methods. Syn-

chronizing external axes to assure process quality is

especially crucial in the aerospace sector producing

airplane parts (Kaufmann et al., 2019). Extending the

concept of manipulating external axis (Mindermann

et al., 2021) is the next step of cooperating robots

without the use of technologies e.g. KUKA.RoboTeam

(M

¨

ollensiep et al., 2021), (Kochoski et al., 2022).

Making technologies affordable elevates acceptance

especially for SME whilst acceleration degree of au-

tomation(Kaiser et al., 2022) using the robot as an ex-

ternal coordinator (Bilancia et al., 2023).

3 REAL-TIME ACCESS TO

ROBOT POSITION

A key requirement for the synchronization of a tool

axis with the robot is the availability of the robot’s

velocity in real-time. If the velocity is not available

directly, alternatively the current position can be used

to derive the velocity. However, this approach already

introduces a certain latency since at least two robot

positions with a precisely known time-difference are

required. In the following section, various methods

for accessing the position or velocity of a KUKA

robot using the KRC4 controller are explained.

3.1 Submit-Interpreter

The submit interpreter is a task running parallel to the

robot program on the robot controller. It is intended

for simple control tasks to spare an external PLC in

simple use cases. The submit interpreter can access

the system variables as well as inputs and outputs of

the robot control and therefore can read the current

robot speed. Using a field-bus such as Profinet or

EtherCAT, the values read by the submit interpreter

can be transmitted to an external controller. No ad-

ditional technology package is required for this ap-

proach and therefore no additional costs occur. As

the submit interpreter is executed in parallel to the

motion task with a lower priority, no hard real-time

guarantees for its execution can be given. The behav-

ior may not be strictly deterministic and depend on

the complexity of the motion planning tasks for the

main robot program.

3.2 Ethernet KRL

Ethernet KRL enables direct integration of data ex-

change into the robot’s control program using KUKA-

provided functions. Communication occurs via the

Ethernet KRL Interface (EKI), which can establish

and terminate connections, read and write data, and

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

712

send and receive data telegrams. However, the time

behaviour of Ethernet KRL varies depending on the

programming of the robot program, and KUKA does

not guarantee deterministic behavior or recommend it

for real-time communication.

Additionally, adapting existing robot programs to

implement regular send instructions for cyclic com-

munication would require significant time and ef-

fort, which could also decrease program readability.

Overall, Ethernet KRL is more suited for irregular or

program-dependent data exchange, rather than for fast

and cyclical communication, such as in axis synchro-

nization.

3.3 OPC UA

OPC stands for Open Platform Communications and

is a platform-independent communication standard

used in industrial automation. OPC Classic includes

several specifications for data access, alarms and

events, and historical data. The OPC Foundation de-

veloped a new standard called OPC UA (Unified Ar-

chitecture), which is based on the server-client model

and includes the standards from OPC Classic. OPC

UA offers flexibility and platform-independent imple-

mentation and is a fundamental requirement for In-

dustry 4.0. However, being based on standard net-

work protocols, OPC UA does not by itself meet the

requirements of real-time applications and reaches its

limits in complex processes. (Kritsch, 2018) There-

fore, the OPC Foundation introduced OPC UA Pub-

Sub over TSN (Time Sensitive Networks) which en-

able real-time processes to be implemented.

KUKA offers an OPC Server package

KUKA.DeviceConnector that allows an OPC

client to read and write – among many other infor-

mation – the system and program variables of the

robot. It is based on the traditional OPC UA client

server model and does not (at this time) implement

PubSub and TSN. Variable access can be done either

using the subscription mechanism of OPC/UA or by

actively polling the OPC/UA server for new data.

Subscriptions are limited to a sampling rate of 40 ms

and for polling, no guarantees for the reply times can

be given, in particular for large numbers of variables.

Therefore, the current OPC/UA implementation is

not ideal for real-time synchronization purposes.

3.4 RSI

Robot Sensor Interface (RSI) is a technology pack-

age developed by KUKA for cyclic data exchange

between a robot controller and a sensor system. It

allows the robot program to be influenced based on

sensor signals. RSI is configured with a data-flow

graph containing pre-defined function blocks. Com-

munication with the sensor system can either be done

using the robot controller’s IO system or over Ether-

net using UDP packets. RSI has a fixed cycle time of

either 4 or 12 ms, which provides a deterministic be-

havior. A small selection of predefined data is avail-

able, amongst others the current position of the robot

in Cartesian and in joint space. The current veloc-

ity of the TCP however is not available directly but

must be calculated by using two robot positions and

the fixed time span between both. The sensor sys-

tem can either receive data only, or may influence the

trajectory of the robot by providing correction values

in real-time. For the application of axis synchroniza-

tion, a read-only connection is sufficient. While the

data aggregation and calculation within RSI is done

in hard real-time, the Ethernet interface does not pro-

vide any such guarantees. In general small Ethernet

segments however achieve latencies lower than 1 ms

with no package loss and therefore are sufficient for

the use of RSI.

3.5 FSD

The technology package Fast Send Driver (FSD) was

developed for non-destructive material testing to pro-

vide fast and accurate trigger signal for external de-

vices like e.g. cameras. The robot control commu-

nicates with an evaluation system, the Data Acqui-

sition System (DAS), via a real-time interface. The

main feature is a simulated encoder interface (provid-

ing, among others, A, B,

¯

A,

¯

B signals) which can trig-

ger the DAS either with fixed travel distances or fixed

time intervals. The encoder signals are generated us-

ing digital output terminals connected to the KUKA

Extension Bus using the EtherCAT protocol. Addi-

tionally, for each trigger pulse a UDP packet can be

transmitted to the DAS containing the position of the

robot at the time of the trigger pulse. While the trigger

pulses are available in hard real time, the UDP pack-

ages are sent over Ethernet which generally does not

guarantee deterministic behavior. A maximum fre-

quency of 1 kHz is achievable using FSD for trigger

pulses. While the structure of the transmitted UDP

packets can be configured, it is not possible to in-

clude the current Cartesian velocity of the robot. To

use FSD for synchronization issues, the transmitted

robot’s Cartesian position data must be differentiated

over the cycle time in order to calculate the robot

speed. The software package is quite expensive, but

FSD is the fastest communication method KUKA of-

fers without exchanging Hardware components.

Low-Cost Synchronization Techniques for KUKA Robots and External Axes in Low-Dynamic Processes

713

3.6 Further Options

Like mentioned in section 2, the software modules

KUKA.CNC Sinumerik and KUKA.PLC mxAutoma-

tion are aimed at controlling and positioning a robot

through the machine control system, achieving high

precision between the robot and end-effector through

real-time interfaces. Another option would be the use

of additional hardware to add external axes into the

KUKA robot controller. Either as KUKA Axis if the

movement of the external axis should be part of the

robot control path planning, or as MCFB Axis (Mo-

tion Control Function Block) which is used to syn-

chronize asynchronous external axes. These technol-

ogy packages are, in regards of synchronization tasks,

considered more to be the state of the art. But they are

also quite complex, very expensive and inflexible.

4 APPROACH

Considering our application example, there are some

limitations in regard of realizing a synchronization

as cost-effective as possible. The first one would be

the existing infrastructure, the KUKA robot control

system KR C4 and the Beckhoff IPC CX2040. The

considered process is comparatively slow and has no

highly dynamic movements. Therefore, the require-

ments for a synchronization are quite low.

4.1 Focus and Restrictions

If aiming at the best possible performance, the

software modules KUKA.CNC Sinumerik and

KUKA.PLC mxAutomation would be the way to go.

However, both methods are quite complex and cost

intensive to realize, which make them less suitable

for the current task. Using MCFB or using a KUKA

axis requires integration of the motor to the KUKA

control cabinet. In many cases this requires additional

hardware (e.g. KUKA servo amplifier).

The remaining options are not directly made for

synchronizing an external axis, but might be worth

further investigations. Ethernet KRL is not suited

for fast and cyclical communication (cf. section 3.2).

Neither is OPC UA without TSN. TSN would require

new hardware and is not available for the KUKA con-

trol system yet.

Therefore, we decided to take on further investi-

gations using RSI, FSD and the submit interpreter. A

short summary of the their main features are shown in

Table 1.

4.2 Experimental Setup

Figure 1 depicts the experimental setup utilized to in-

vestigate the distinct behaviors and limitations of the

Robot Sensor Interface (RSI), Fast Send Driver (FSD)

and submit interpreter. A test rack (1), equipped with

a vertical linear axis (4), was constructed for this pur-

pose. A laser distance sensor was affixed to the slide

of the linear axis (3), while a KUKA KR240 (2) with

an aluminum plate positioned on axis A6 (5) served as

the counterpart. The test rack and robot were aligned

such that the robot’s movement in the Z direction was

parallel to the vertical linear axis of the rack.

Figure 1: Experimental Setup.

Following the calibration of the laser sensor and

the generation of a robot program designed to move

with a consistent velocity in the Z direction, our mea-

surements commenced. To initiate this process, we

positioned the aluminum plate (5) at a distance of

50 mm beneath the laser sensor, which corresponds

to the center of its measurement range. Furthermore,

we initiated the robot’s movement and transmitted

the positional data to a Beckhoff IPC via one of the

aforementioned communication methods. Therein,

we leveraged Cartesian coordinates and the supplied

time stamp or cycle time to calculate the velocity of

the robot’s Tool Center Point (TCP). The stepper mo-

tor of the linear axis was regulated by the IPC via a

motor controller (EL7041). The latencies caused on

the drive side were neglected for these tests, since they

have no significant influence on the qualitative com-

parison of the transmission technologies. Both robot

and linear axis should move at the same speed. The

variance in acceleration, velocity, and response time

was indirectly measured via the laser distance sensor.

In order to evaluate the synchronization quality of the

various communication methods, we performed mul-

tiple measurements at differing robot speeds, repeat-

ing each measurement ten times.

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

714

Table 1: technology overview.

Submit Interpreter RSI FSD

cycle time 12 ms 4 ms 1 ms

original purpose small cyclic tasks ext. trajectory correction triggering ext. measurments

timing behavior best effort mostly deterministic (mostly) deterministic

4.2.1 Submit Interpreter

To establish communication with the robot via the

submit interpreter, it is necessary to connect the IPC

to the robot controller using a field-bus. On the robot

side, the internal variable $ACT VEL, which contains

the speed of the TCP of the robot, is written on digital

outputs. Some care must be taken for the data format,

such as endianness or floating point number represen-

tation. The TCP speeds that have been tested were

100 mm s

−1

and 200 mm s

−1

.

4.2.2 RSI

In the case of RSI, the Beckhoff PLC is connected to

the KUKA Line Interface (KLI) on port X66 via Eth-

ernet. The communication details, such as the RSI

output format, connection properties, and XML struc-

ture for data transmission, are specified in a rsix file.

Since RSI does not provide direct access to velocity,

we choose the actual position as the output and inter-

polate the velocity. We establish unidirectional com-

munication, as only the robot needs to send data.

To implement synchronization in KRL code, the

RSI configuration must be loaded, along with the se-

lection of the corresponding coordinate system (TCP

- Tool Center Point) and signal processing mode (in

this case, a 4ms communication cycle). The PLC is

responsible for translating the robot’s trajectory into

linear axis motion. We tested speeds of 100 mm s

−1

and 200 mm s

−1

.

For reception, Beckhoff’s standard UDP module

is utilized. The received message is a XML string

with a predefined format (XML structure for data

transmission) and a timestamp known as IPOC (in-

terpolation counter).

4.2.3 FSD

To initiate the FSD protocol, a connection is estab-

lished between the PLC and the KUKA system bus

at port X47 via Ethernet UDP. For transmission and

receiving of byte-encoded UDP messages, an internal

Beckhoff UDP module is utilized.

The client needs to register with the Kuka Server

and initiate data exchange by sending a message with

the following parameters: transmission type (time-

based mode), format (position excluding orientation),

frame (TCP-frame), and time interval (1ms).

Since a message with the identifier (packet

counter) and position is sent every millisecond, it be-

comes possible to interpolate the velocity and adjust

the speed of the linear motors to follow the robot’s

trajectory. The packet counter is essential for identi-

fying sequential positions. The trajectory and speed

are defined in standard KRL code.

5 VALIDATION

This section shows the results of the measurements

and findings regarding the different communication

technologies.

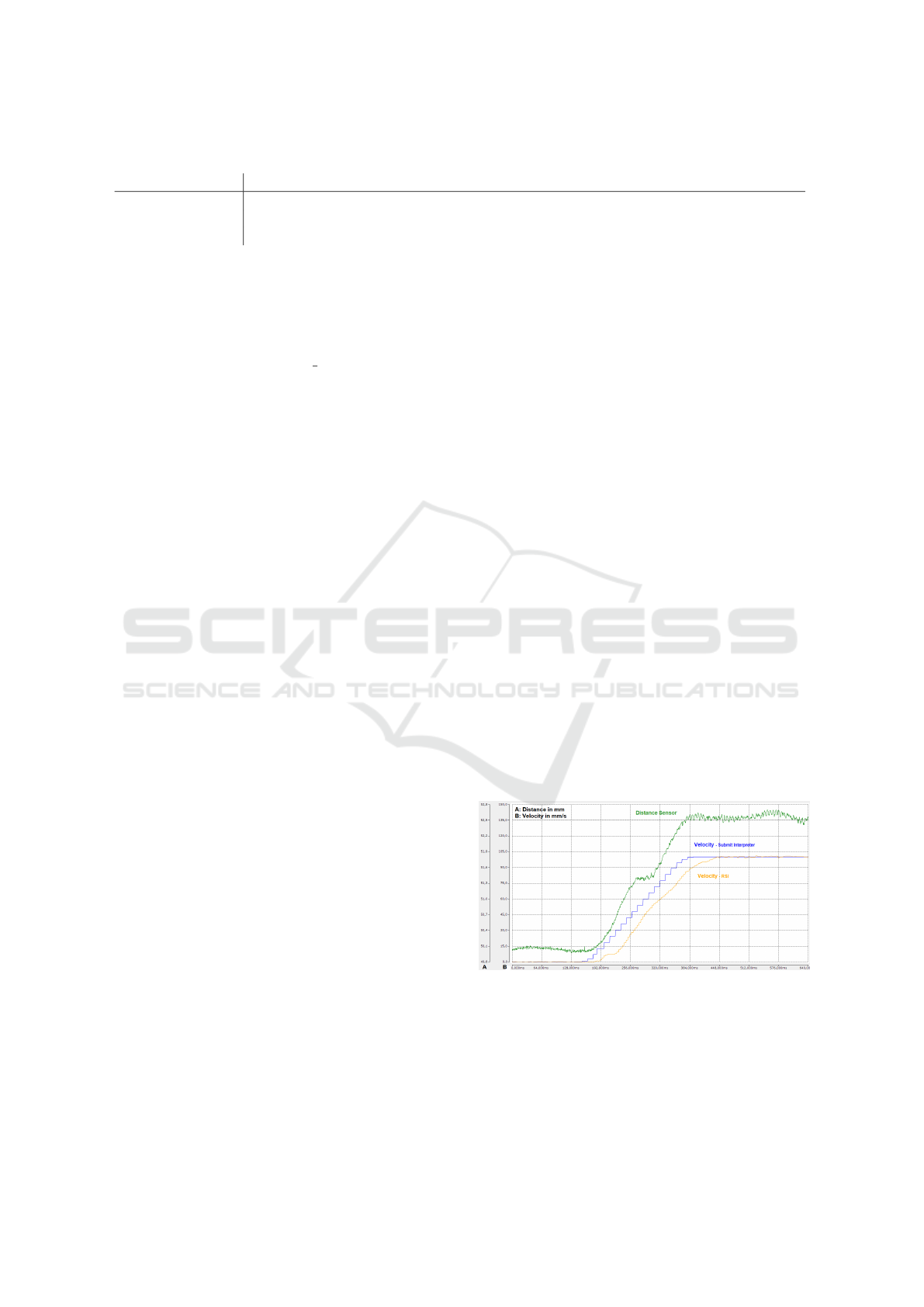

5.1 Submit Interpreter

The initial measurements were conducted using the

submit interpreter. In figure 2, a section of the

recorded measurement is presented, displaying the ac-

celeration ramp. The green line represents the po-

sition data from the laser sensor, the blue line indi-

cates the velocity value transmitted via the submit in-

terpreter, and the orange line represents the velocity

calculated using the RSI position data as a reference.

One notable observation is that the data transmitted

via the submit interpreter appears to be ahead of the

data transmitted via RSI, despite RSI having a faster

transmission rate.

Figure 2: Measurement with SUB - 100 mms

−1

.

Another intriguing finding pertains to the dis-

tance measured by the laser sensor. Typically, one

would expect to observe a decrease in the distance be-

tween the robot’s aluminum plate and the laser sensor

mounted on the external axis. However, in this case,

an increase in distance is observed rather than a de-

Low-Cost Synchronization Techniques for KUKA Robots and External Axes in Low-Dynamic Processes

715

crease. This implies that the external axis is advanc-

ing ahead of the robot’s movement. The only plausi-

ble explanation for this phenomenon is that the veloc-

ity data transmitted via the submit interpreter repre-

sents the expected target speed rather than the current

speed of the robot’s TCP.

5.2 RSI

Subsequent measurements were performed using the

Robot Sensor Interface (RSI). In figure 3, a section of

the recorded measurement is presented, also display-

ing the acceleration ramp. The green line likewise

represents the position data from the laser sensor, the

orange line represents the velocity calculated using

the RSI position data, and the blue line indicates the

velocity value transmitted via the submit interpreter

as a reference. In this case, it is also noticeable that

the data transmitted via the submit interpreter appears

to be ahead of the data transmitted via RSI. However,

the distance measured by the laser sensor exhibits the

expected behavior.

Figure 3: Measurement with RSI - 100 mms

−1

.

During acceleration, the distance measured by the

laser sensor decreases (green line in figure 3), while

during deceleration, it increases. Additionally, it is

evident that the RSI transmission rate (orange) results

in a smoother signal compared to the submit inter-

preter (blue), highlighting the faster transmission rate

of RSI.

5.3 FSD

Unfortunately, we were unable to complete our mea-

surements with the FSD. During the initial test, we

observed a significant delay between the movement of

the robot and the response of the axes. This delay was

unexpected, as we had previously experienced much

lower delays in data transmission during our measure-

ments with the submit interpreter or RSI which have a

lower transmission rate. However, this time, the delay

was much more pronounced and varied depending on

the target speed. For instance, when the speed was set

at 100 mm s

−1

, we noticed a loss of 7.2 mm (as shown

by the green line in figure 4), which almost exceeds

the measurement range of ±10 mm. The delay be-

tween the robot and axis movements was so substan-

tial that we became concerned about the possibility

of a collision between the robot and the laser sensor.

Consequently, we decided to halt our series of tests.

Figure 4: Measurement with FSD - 100 mms

−1

.

Nevertheless, we were able to make some inter-

esting observations. Firstly, we noticed that the trans-

mission delay via FSD is significantly higher com-

pared to the delay via RSI. Secondly, despite the fact

that the FSD data (orange) in figure 4 appears to be

coming in at the intended rate of 1 ms, it frequently

lacks updates. In contrast, the data stream from the

submit interpreter (blue) shows a similar update rate,

with updates occurring every 12 ms. This suggests

that the update rate of the FSD Position Data is much

slower than the transmission rate of 1 ms. The combi-

nation of the considerable delay in data transmission

and the slow update rate can explain the poor perfor-

mance of FSD in this particular use case.

5.4 Submit Interpreter vs. RSI

When comparing these two methods, it is important

to note the difference in the received data. With the

Robot Sensor Interface (RSI), the current position

data of the robot is obtained, allowing for the calcu-

lation of the actual robot velocity. On the other hand,

the submit interpreter directly transmits the robot ve-

locity. However, it is essential to highlight that the

received data from the submit interpreter does not rep-

resent the actual velocity of the robot, but rather the

expected target velocity as mentioned in section 5.1.

Figure 5 shows an example of a complete mea-

surement. The Start position (1) and End position (2)

marked in red are the mean values of the sensor sig-

nal. The position data during the motion show an un-

expected drift. In order to evaluate the data, also the

mean value was determined marked with (3). This is

further discussed in (cf. section 6)

Table 2 displays the measured mean values ob-

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

716

Figure 5: Measurement with RSI - 100 mms

−1

.

Table 2: Measurement with sensor data in [mm].

Mean value and standard deviation

Start Motion End

RSI 100 50.291 48.320 49.717

0.072 0.162 0.284

RSI 200 50.311 46.274 49.694

0.073 0.196 0.471

Sub 100 50.251 52.073 49.809

0.069 0.150 0.213

Sub 200 50.293 53.072 49.693

0.023 0.411 0.478

tained from the laser distance sensor. The second

value represents the standard deviation calculated for

each set of measurements. As can be observe, the

standard deviation is relatively low, indicating a valid

set of measurements. However, what stands out is the

increase in the standard deviation during motion. The

first value, labeled as ’start,’ refers to the distance at

the beginning of the respective test. The value labeled

as ’motion’ represents the distance during the robot

movement, and the last value, marked as ’end,’ sig-

nifies the distance at the end of the respective test.

Throughout this process, an increase in the standard

deviation can be observed. This deviation can be at-

tributed to the accuracy of our employed external lin-

ear axis and the use of a stepper motor. A similar

observation can be made in table 3. Here one can see

the mean values of the distance lost during the accel-

eration (∆ acc.) and deceleration (∆ dec.) as well

Table 3: Table of measurement with deltas in [mm].

Mean value and standard deviation

∆ acc. ∆ dec. ∆ motion

RSI 100 -1.971 1.397 0.574

0.217 0.185 0.333

RSI 200 -4.037 3.420 0.617

0.293 0.363 0.504

Sub 100 1.823 -2.264 0.441

0.197 0.168 0.244

Sub 200 2.779 -3.378 0.599

0.409 0.168 0.473

as between the start and the end of the robot move-

ment (∆ motion). At the last category, accuracies in

the range of 0.5 mm are noted, whereas an industrial

robot should typically achieve accuracies of 0.2 mm

or even 0.1 mm.

Comparing the mean values of our measurements

in table 3, two interesting observations can be made,

despite the reversal in algebraic sign (expected veloc-

ity vs. actual velocity). Firstly, the distance lost be-

tween the Robot and the laser sensor is quite similar

for both RSI and submit interpreter. This suggests that

in our use case with low speeds and dynamics, both

methods would be relatively equal in performance.

Secondly, when comparing the two different veloci-

ties, RSI 100 and 200, a doubling of the lost distance

is observed (−1.971 mm to −4.057 mm). This result

is expected, considering the doubling in robot speed.

Conversely, when comparing submit interpreter 100

and 200, less than a doubling is observed. This im-

plies that the robot, due to its higher dynamic and

torque compared to our external axis, is able to gain

ground during acceleration and deceleration.

To gain further insights into the comparison of

these methods, we propose conducting an additional

experiment. This experiment would involve a larger

and more capable external axis to determine the dy-

namics at which the submit interpreter or RSI would

experience a breakdown in accuracy. Furthermore, it

would be intriguing to examine the behavior when the

external axis possesses the ability to match the robot’s

torque and dynamics. In such a scenario, it may be

feasible to calculate acceleration delays for the robot

and external axis, thereby compensating for the for-

ward motion of the external axis. This compensation

could potentially enhance the accuracy of the submit

interpreter significantly.

6 DISCUSSION

The results obtained from the various communication

methods were quite similar, with the transmission via

submit interpreter surprisingly able to keep up with

the low speed values used. However, the experimental

setup which was presented are rather to be considered

as preliminary tests helping to create a better plan-

ning for our main experiment. Therefore, we want to

mention some major issues we want to improve be-

fore taking the next step.

Unfortunately, technical limitations associated

with the linear axis and the stepper motor prevented

testing at higher speeds. Which resulted in robot

speeds not sufficient enough to push either RSI or

the submit interpreter to their limits. Therefore, we

Low-Cost Synchronization Techniques for KUKA Robots and External Axes in Low-Dynamic Processes

717

want to use a much more capable linear axis and more

suited and powerful servo motor to achieve similar

speeds and accelerations like the industrial robot. To

take further investigations regarding some quality is-

sues with our data from the distance sensor, we will

use a servo motor with a build in motor encoder for

tracking slippage or the loss of motor steps. The rea-

son further improvements for the test setup are nec-

essary is a unexpected jump in the sensor data of the

distance sensor clearly visible in figure 2 and figure 3.

We were also able to measure a drift in the distance

data during the movement of the robot and the exter-

nal axis. While a lost in distance between the external

axis and the robot during acceleration and decelera-

tion was expected, it should not occur during a con-

stant motion. Possible reasons for this could be a loss

of motor steps or the alignment of the linear axis to

the robot coordinate system. Therefore, another quite

important improvement would be the use of two laser

trackers to get external measured position data of the

robot and external axis movement. This would give

us further insights of how good the synchronization

between robot and external axis really is.

Furthermore, it is important to improve the consis-

tency of our data transmission. While the data trans-

mission for RSI on the robot and PLC side is based

on real time the exchange happened through the win-

dows interface of the soft PLC which is not real time

capable. Therefore, we have to implement a real time

interface to ensure a clean data transmission.

Another surprising finding was the behavior of

the FSD technology package. As discussed in sec-

tion 5.3, FSD exhibited a much faster transmission

rate (1 ms) than RSI (4 ms). However, the transmitted

data was only updated every 12 ms, counteracting the

advantages of the fast transfer rate. Furthermore, FSD

demonstrated a significant delay time about 100 ms

between the start of the robot movement and the first

change of the internal position data. This topic needs

some further investigation to clarify if we are able to

find a working configuration for FSD or if it is really

not suitable for our use case.

REFERENCES

Arbo, M. H., Eriksen, I., Sanfilippo, F., and Gravdahl, J. T.

(2020). Comparison of KVP and RSI for control-

ling KUKA robots over ROS. IFAC-PapersOnLine,

53(2):9841–9846.

Bi, Z. M., Liu, Y., Baumgartner, B., Culver, E., Sorokin,

J., Peters, A., Cox, B., Hunnicutt, J., Yurek, J., and

O’Shaughnessey, S. (2015). Reusing industrial robots

to achieve sustainability in small and medium-sized

enterprises (smes). Industrial Robot: An International

Journal, 42(3):264–273.

Bilancia, P., Schmidt, J., Raffaeli, R., Peruzzini, M., and

Pellicciari, M. (2023). An overview of industrial

robots control and programming approaches. Applied

Sciences, 13(4):2582.

Kaiser, B., Wolf, M., and Verl, A. (2022). Modular control

architecture for reconfigurable fabrication systems for

prefabrication in construction. In ISR Europe 2022;

54th International Symposium on Robotics, pages 1–

7. VDE.

Kaufmann, P., Braun, G., Buchheim, A., and Malecha, M.

(2019). Automated draping of wide textiles on double

curved surfaces. In Proceedings of the 16th Interna-

tional Conference on Informatics in Control, Automa-

tion and Robotics - Volume 2: ICINCO, pages 50–58.

INSTICC, SciTePress.

Kochoski, F., Dukovski, V., Samak, S., Cvetkoska, D., and

Petkoska, B. (2022). Manufacturing thermoplastic

composites by laser automatic tape placement tool-

less technology with dual robot system. Interna-

tional Journal of Engineering Research & Technology

(IJERT), 11(4).

Kritsch, S. (2018). Konzeption, Entwicklung und Va-

lidierung von Methoden zur Synchronisation von

Roboterbewegung und externer Vorschubachse. Mas-

ter thesis, University of Applied Sciences Fulda.

Mindermann, P., Bodea, S., Menges, A., and Gresser, G. T.

(2021). Development of an impregnation end-effector

with fiber tension monitoring for robotic coreless fila-

ment winding. Processes, 9(5):806.

M

¨

ollensiep, D., Gorlas, T., Kulessa, P., and Kuhlenk

¨

otter,

B. (2021). Real-time stiffness compensation and force

control of cooperating robots in robot-based double

sided incremental sheet forming. Production Engi-

neering, 15:683–699.

Stogl, D., Zumkeller, D., Navarro, S. E., Heilig, A., and

Hein, B. (2017). Tracking, reconstruction and grasp-

ing of unknown rotationally symmetrical objects from

a conveyor belt. In 2017 22nd IEEE International

Conference on Emerging Technologies and Factory

Automation (ETFA), pages 1–8. IEEE.

Winkler, A. and Such

`

y, J. (2013). Robot force/torque con-

trol in assembly tasks. IFAC Proceedings Volumes,

46(9):796–801.

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

718