Digital Transformation of an OEM Development Process from a

Socio-Technical Perspective: A Case Study

Ekin Uhri

1,2 a

, Christoph Matz

2

and Ingrid Isenhardt

1b

1

Chair of Production Metrology and Quality Management & Institute for Information Management in Mechanical

Engineering (WZL-MQ & IMA), RWTH Aachen University, Dennewartstr. 27, 52068, Aachen, Germany

2

BMW Group, Department of Total Vehicle Development, Petuelring 130, 80788, Munich, Germany

Keywords: Function-Oriented Development, Socio-Technical Systems, Knowledge Management, OSTO® System Model,

Model-Based Systems Engineering.

Abstract: Based on the RFLP concept (requirements, functions, logic, product) of model-based systems engineering, a

function-oriented approach can enable a universal, data and model-driven knowledge management system for

product development. Additionally, this approach can automate development steps and ease communication

between disciplines. However, the impact of function-orientation on the established organizational structures

remains unexplored. This case study investigates the effects of digital transformation towards function-

orientation on the knowledge management system of a large corporation from a socio-technical perspective.

OSTO® system model (open, socio-technical, economic) is employed to analyse and redesign the socio-

technical system to observe the possible effects. The results show that the main limitations of the development

department lie within the information and decision-making systems. RFLP-based function-oriented

development can address these limitations, resulting in an efficient, universal, data-driven knowledge

management system.

1 INTRODUCTION

The automotive industry currently faces multiple

challenges regarding new technologies, including

electromobility and autonomous driving. Vehicles as

products are changing considerably to address these

challenges, which results in increased complexity,

where multiple disciplines (mechanics, electronics,

software) are intertwined. These changes in the

product necessitate the development process to adapt

to the improved product, increasing the complexity of

the process as well (Udo Lindemann, Maurer, &

Braun, 2009). The organizational structure of an

original equipment manufacturer (OEM) plays a

significant role in the process complexity (Kreimeyer

& Lindemann, 2011). A shift in mindset where the

development focus is on the vehicle functions can

provide an adequate solution. Function-oriented

development offers a new approach where the focus

is on the functions as opposed to components. Such

an approach can help designers manage the product

a

https://orcid.org/0000-0003-3491-7987

b

https://orcid.org/0000-0002-5645-5341

and process complexities by (among others) a

universal data-driven data structure and enabling easy

communication between disciplines (Albers et al.,

2019; Jacobs et al., 2022).

Function-oriented product development methods

are being explored in research and industry (Albers et

al., 2019; Albers et al., 2020; Denger, Fritz, Kissel,

Parvan, & Zingel, 2013; Jacobs et al., 2022; Politze

& Dierssen, 2008; Renner, 2007). However,

introducing and implementing such an approach in an

established organization is not yet fully understood.

This shift in development approach also indicates a

digital transformation because function-orientation

can only be implemented if the existing knowledge

management system is remodelled accordingly.

Information systems play a significant role in

knowledge management, as they facilitate the

information and knowledge capture, storage,

organisation, and retrieval in the organization. It is

important to analyse the existing socio-technical

system to understand how a function-oriented

52

Uhri, E., Matz, C. and Isenhardt, I.

Digital Transformation of an OEM Development Process from a Socio-Technical Perspective: A Case Study.

DOI: 10.5220/0012230600003598

In Proceedings of the 15th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2023) - Volume 3: KMIS, pages 52-61

ISBN: 978-989-758-671-2; ISSN: 2184-3228

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

concept can be implemented and its possible effects.

Hence, this paper aims to uncover the effects of the

digital transformation towards function-oriented

development on an OEM (specifically its knowledge

management system) using a socio-technical system

model. This is done by analysing the current state of

the development department, defining the ideal

function-oriented development approach, redesigning

the organization in a way to accommodate function-

oriented development, and observing the possible

effects. The results of this case study provide valuable

insights for knowledge management systems and the

organizational development of OEMs.

2 STATE-OF-THE-ART FROM AN

HTO PERSPECTIVE

Function-oriented development in this case study

refers to a development approach where the focus is

on product functions that result in a certain product

behaviour expected by the customer. In this context,

function-oriented development is used for complex,

mechatronic products. The complexity of a product

stems from the number of components and

interdependencies between them. Mechatronic

products consist of a significant number of

mechanical, software and electronic components.

Due to the complexity of the product, this approach

necessitates a well-suited and -structured knowledge

management system.

There are multiple approaches to function-

oriented development. RFLP (requirements,

functions, logic, product) approach of model-based

systems engineering is the most common (Jacobs et

al., 2022). There is no standardized definition of

function-oriented development. However, there are

some technological characteristics that the most

prominent approaches have in common: model-based

approach, solution neutrality, and functions as a

communication basis (Uhri & Isenhardt, 2023).

Model-based approach, in contrast to document-

based, proposes that the information exchange should

be based on models instead of documents during

development (Jacobs et al., 2022). Advantages of a

model-based approach include visualization of the

design problem, decreased susceptibility to errors,

higher system reliability, improved comprehension of

the system, easier design reuse, real-time

collaboration on a model, and potentially reduced

development cost and time (Bergmann, 2014).

Solution neutrality is the definition of functions

independent of a solution alternative where functions

and solutions are considered separately. This allows

for out-of-the-box thinking and the reuse of existing

functions for different products (Renner, 2007).

Additionally, the solution neutrality of the functions

helps the descriptions of the functions to be domain-

independent and thus, serve as a communication basis

for multiple disciplines (Albers et al., 2019). The

complexity and interdisciplinarity of mechatronic

products necessitate strong interdisciplinary

communication. Functions should be formulated in a

discipline- and solution-independent manner to be

comprehensible to all relevant disciplines. This will

allow the designers to understand the system they

develop and its context within the product and

communicate between different domains (Denger et

al., 2013; Jacobs et al., 2022).

While technological aspects of function-

orientation have been explored, the research on

human and organizational factors is limited (Uhri

& Isenhardt, 2023). Yet the importance of the human,

technological, and organizational (HTO) factors

(Eklund, 2000) for the success of a new technology

or process are emphasized in function-orientation

(Albers et al., 2020; Politze & Dierssen, 2008;

Renner, 2007) and in socio-technical design research

(Mumford, 2000). Designers are encouraged to

include the customer perspective of the functions to

develop a user-oriented product (Albers et al., 2020).

Product ontologies can help to achieve this (Politze

& Dierssen, 2008). Understanding the system and its

adaptability are integral to the success of the product

(Renner, 2007). Organizational barriers between

teams, non-standardized and ambiguous terminology

for development artefacts (within an organization or

the industry), differing structures and workflows and

emphasis on data protection that hinders data flow are

some of the significant challenges faced during the

implementation. Differentiating between users and

decision-makers and adapting strategies for both

(including change management strategies) can help

with these challenges (Renner, 2007).

Factors that could support the digital

transformation towards function-oriented

development from an HTO perspective include

mindset change, user-friendly interfaces, step-by-step

transformation, alignment with the existing

structures, and management support (Uhri

& Isenhardt, 2023). Designers should be open to new

development approaches for a successful

implementation. This can be done by adapting change

management methods and showing the importance of

the transformation for the survival of the company.

User-friendly design of not only the tools but also the

methods, structures and processes can help the

Digital Transformation of an OEM Development Process from a Socio-Technical Perspective: A Case Study

53

implementation. Step-by-step transformation towards

function-orientation is essential for the acceptance of

the new methods. Alignment to the existing structures

also helps with the acceptance, allowing the reuse of

existing structures. Without management support, no

new process can be implemented. They must be

shown the benefits and necessity of function-oriented

development. (Uhri & Isenhardt, 2023)

3 RESEARCH GOAL

The current state of research in function-oriented

development states the benefits of such a framework

on the development process, which include customer-

oriented products, shorter development times,

stronger cross-disciplinary collaboration, fostering

innovative solutions, complexity management, data

consistency and traceability, and remaining market-

competitive (Uhri & Isenhardt, 2023). However, the

research mainly focuses on the technological side of

the framework.

According to the socio-technical design research

(Eklund, 2000; Mumford, 2000), as well as the human

factors research in engineering design (Ernst, 2014),

the success of a new framework within a company

mainly depends on the considerations of human and

organizational aspects as well as technological

factors. Implementation of a new development

framework heavily relies on the existing processes

and organization, yet the effects of function-

orientation on the established socio-technical system

are not yet known. Hence, this case study aims to

predict the potential implications of the

transformation towards function-oriented

development on the company for its successful

implementation. This research paper aims to answer

the following research question (RQ):

RQ: What are the possible effects of the digital

transformation towards function-oriented product

development on an established OEM (specifically on

its knowledge management system) from a socio-

technical perspective?

4 METHODOLOGY

OSTO® is a cybernetic system model where

organizations are considered open systems with

closed feedback loops (Hanna, 1988). The model is

helpful to analyse existing systems and observe the

possible effects of a change at any stage of the system.

Additionally, the model allows the designers to

consider multiple design elements as well as their

interdependencies. Thus, they can depict and analyse

a complex system. The model was initially

formulated by Hanna (1988) and further developed by

Rieckmann and Weissengruber (1990) and Henning

and Marks (1996).

OSTO is an acronym for open (offen), socio-

technical (soziotechnisch), and economic

(ökonomisch) aspects of a system. The system is

open, enabling it to interact with its environment. The

social part of the model refers to the parts with human

involvement, which comprises the organizational

structure, information and decision process, reward

and control system, motivation of the employees and

the organizational culture. The technical part refers to

the physical and material parts of the system, which

include the tools, methods, machinery, infrastructure,

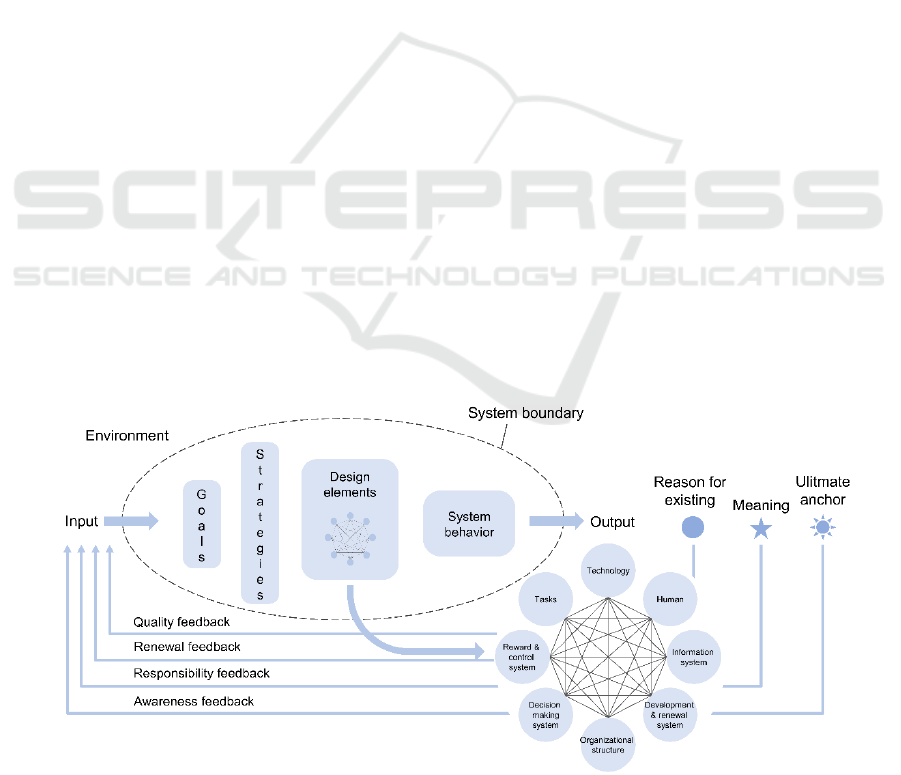

Figure 1: An overview of the OSTO® system model (based on Henning & Marks, 1996; Rieckmann & Weissengruber, 1990).

KMIS 2023 - 15th International Conference on Knowledge Management and Information Systems

54

and processes. The economic parts of a system

comprise all the activities that result in the economic

efficiency of the system, such as budgeting,

investments, revenue trends, and controlling.

Figure illustrates the OSTO® system model in

the structure variation (Henning & Marks, 1996;

Rieckmann & Weissengruber, 1990). Less relevant

components, (meaning, ultimate anchor), and their

feedback loops (responsibility and awareness) are not

considered in this case study. An organization

includes a significant number of components (for

instance in input, output, and system behaviour). It is

important to only focus on the components that are

relevant to the goal of the analysis. Sections 4.1 and

4.2 describe the OSTO® system model used in this

study (Henning & Marks, 1996; Rieckmann

& Weissengruber, 1990).

4.1 OSTO® System Model

Components

System Boundary: The system boundary separates

the system and its environment and can be physical,

temporal, social or psychological. Correct

identification of the system border is essential to

defining and describing the system accurately. Since

the system is open, it can interact with its

environment.

Environment: Anything that is outside of the

system boundary and the system interacts with is

defined as the environment. In terms of an

organization, the environment can include customers,

political conditions, the market, and society in

general.

Reason for Existing: The reason for existing

describes the purpose of a system. It describes why

the system exists and which environmental need is

fulfilled by the existence and output of the system.

Input: The input of the system comes from its

environment and its feedback loops and can include

both material and immaterial items.

Goals and Strategies: The goals of a system are

derived from the reason for existing. The strategies

are derived from the goals and aim to describe the

steps to achieve the goals.

System Behaviour: The system behaviour

describes all the actions that result in the system

output and outcome. The behaviour can be altered by

changing the design elements.

Output & Outcome: The output of a system

describes all the desired and non-desired items a

system produces. Output includes both work results

of a system, as well as immaterial outputs such as

motivation of the employees or amount of workload.

Outcome refers to the financial output of the system.

Feedback Loops: Feedback loops are an essential

part of the model. The loops ensure that the time

dimension is considered, and the system adapts,

develops, and stabilizes according to its output and

reason for existing. Quality feedbacks respond to the

quality of the output. Renewal feedback gives the

response from the environment on the reason for

existing.

Design Elements: Design elements are the core

of the model and describe the individual components

that make up the system. They are interconnected and

a change made in one element has consequences on

all the other elements and the system as a whole.

The human element comprises all the personnel

of an organization as well as their roles and

relationships. The technology element includes all

the material equipment needed to produce the system

outcome (e.g., infrastructure, materials, property…).

Organizational structure refers to the procedures and

processes of the organization for its operations. The

tasks element describes the tasks the organization

must finish and their structure and division into

subtasks for the organization to function. The

decision-making system describes all the

mechanisms that are relevant to the decision-making

process (e.g., relevant roles, hierarchies, tools,

processes etc.). Information system comprises all

the relevant mechanisms for information retrieval,

storage, transformation, display and communication

with their reasons. Reward and control system

regulates the human, process, and technical behaviour

of a system with reward and control mechanisms

(e.g., monetary incentives, acknowledgements,

responsibility, personal development etc.).

Development and renewal system controls the

performance and adaption capacities of a system and

helps an organization to develop further.

4.2 Study Design

The analysis of the system was done using the

OSTO® system model with method (OSTO) and

field (vehicle development) experts. The workshop

format is taken from Rieckmann and Weissengruber

(1990) and adapted for this study. Two workshops

were conducted to analyse the system. The diagnosis

workshop was done “backwards”, i.e., starting from

the system boundary and output, working through the

reason for existing, system behaviour and design

elements, and concluding in system goals and

strategies. In contrast, in the redesign workshop, the

Digital Transformation of an OEM Development Process from a Socio-Technical Perspective: A Case Study

55

goals and strategies were defined first, and the system

output was predicted at the end.

In this case study, the system was the

development department of an OEM, which produces

vehicles (a complex mechatronic product).

Specifically, the knowledge management system was

analysed within the socio-technical context. Since the

investigated subject is a major corporation with tens

of thousands of employees, the analysis gives an

overview of the company structure and does not

represent the intricacies of all departments.

Additionally, the analysis focus lay on the areas that

required improvement, and not on the organization as

a whole. Thus, the many (positive) aspects were

overlooked.

The goal of the diagnosis workshop was to

determine the limitations within the development

department of the company that can be addressed by

function-oriented development. Based on the results

from the diagnosis, the system was redesigned to

accommodate function-oriented development. The

ideal system was described, and the organization was

adapted to achieve this ideal. The model also allowed

the experts to predict the possible behaviours and

outcomes of the system when the changes are

implemented.

5 RESULTS AND DISCUSSION

5.1 Results of the System Diagnosis

The diagnosis began with the definition of the

system boundary. In this case study, the system

boundary was set as the entire vehicle development

department. The department includes structures that

encompass requirements management through to

integration and testing of the virtual product.

Departments that lie outside of the system are other

departments of the company, government policies,

market, end customers and society in general. The

company and product strategy and production

planning departments are in direct contact with the

system through inputs and outputs.

The next step was to determine the system

inputs and outputs. The system gets its input from

the end customers through the product strategy

department, which determines the customer

requirements. Additionally, the previous product

concepts are also taken in as input, as well as the

quality feedback and quantity predictions from the

production planning. The main system output is the

description of a production-ready product and all the

relevant data for its production. However, there are

also unintentional outputs. One noteworthy output is

the insufficient interdepartmental information

transfer. This causes the production planning

department to generate a certain amount of

information again, which results in redundant work

and possible errors in the system.

Afterwards, the reason for existing was defined.

The reason for existing of the development

department is to fulfil the need of the production

planning department for the production-ready

product description. This description meets the

product requirements provided by the company

strategy department (regarding market value,

sustainability, feasibility, cost-effectiveness etc.).

The next step was to observe the system

behaviour that leads to the system output. It should

be emphasized that this list is not exhaustive and only

the relevant behaviour patterns were examined that

require improvement. A significant amount of

development-relevant information exchange happens

on an informal level and is not always systematically

documented. The information storage and sharing are

heavily dependent on the individuals and not

standardized. A personnel change may indicate that

the information and expertise are partially lost, and

additional effort is needed to gather the information

again. Another behaviour observed was in the

decision-making system. Some decisions are mainly

based on the expertise of the employees. While

domain expertise is very valued, major changes in

product requirements and boundary conditions show

that expertise alone may not always result in optimal

decision-making. Thus, among expertise, multiple

factors must be considered for the decision-making

system. The company produces a commercially very

successful, high-quality, and reliable product. Thus,

up until recently, next-generation products have been

heavily based on previous products. While this is a

successful path to produce similarly high-quality

products, changing requirements and boundary

conditions must be considered for a successful market

launch and competitiveness. Therefore, over-reliance

on previous projects may not be enough to create a

successful, customer-oriented, innovative product.

Innovative ideas can initially meet with scepticism,

especially if similar projects were unsuccessful

before.

The subsequent step was to determine the design

elements that caused the system behaviour. The

design elements were focused on the identified

behaviour patterns and mainly aimed to solve the

limitations of the company. It is not an exhaustive list

and only the most significant findings are listed here.

The information systems are not consistent and

KMIS 2023 - 15th International Conference on Knowledge Management and Information Systems

56

universal within the company. While this is to be

expected to some degree (different departments

utilize domain-specific databases and tools), the

interfaces are not always sufficiently defined and

structured. The system is specifically designed in this

way for data privacy. This results in information

being shared only when asked and with a valid

reason, and not automatically shared with the

necessary parties (need-to-know principle). There is a

focus on expert knowledge, which is very valuable

but not always accessible and discoverable. This

results in a loss of knowledge when the expert

switches their role, department, or company. Informal

yet significant information exchange is not always

documented and thus can be lost easily. There can be

a somewhat risk-avoidant culture within the

company, where the previous product design is taken

as the benchmark and improved upon when

necessary. This is a valid approach, as long as the next

generation of products still fulfils the customer

requirements. Since the requirements are changing

rather rapidly, this approach alone is not enough to

remain market competitive.

The final step of the diagnosis was the

identification of the goals and strategies of the

system. The main goal of the development

department is to create a high-quality product. Other

related goals include using and optimizing the

existing concepts, and the safety and security of the

product, process, and company. The strategies to

reach these goals include using successful previous

product concepts as the basis for next product

iterations, using proofs-of-concept for all innovative

ideas, using standards for quality measurement, IT

security through company hardware and software and

the need-to-know principle for all data.

The OSTO® model helped to understand the

relevant and critical underlying mechanisms of the

organization and structure the system components of

the development process. The chain of events and

information were observed and categorized. A

structured look at the system highlighted the parts that

need to be improved. The redesign workshop helped

to reorganize and improve the system in the right

direction.

5.2 Results of the System Redesign

The redesign workshop began with the definition of

the ideal system. The expectations and goals for

function-oriented development were listed. In the

redesign workshop, the system was adapted in a way

to fulfil the listed goals. Function-oriented

development aims to create transparent and

permeable systems and use functions as a

communication basis across different disciplines,

potentially resulting in (semi-) automated workflows.

The automation shall help decrease the workload,

thus creating time that can be used to generate

innovative ideas. With different creativity techniques,

a mindset for new, innovative solutions and

transparency between subsystems and disciplines can

be achieved. These goals can also help to evaluate

different solution ideas objectively, thus increasing

the number of innovative ideas incorporated into the

product.

After defining the ideal system, the system

boundary was set. In this case, the boundary

remained the same, the entire development

department. The next step was to define the reason

for existing. The reason for existing was improved to

not only include the product quality and efficiency

but also the process and company quality. The new

reason for existing of the development department is

to fulfil the needs of the top management of the

company, which is a product development process

that fulfils the determined quality, cost, and efficiency

criteria. By shifting the focus from production

planning to top management, the entire company is

aimed to be shaped to be efficient, in terms of costs,

quality, and time. This not only includes the product

but also the processes and structures within the

company.

The next step was to identify the goals and

strategies. Not all goals and strategies were irrelevant

or required alteration, so some of them remained

unchanged. The main goal is still to generate a high-

quality product. Additional goals that were defined

here were producing innovative products, as well as

an efficient and flexible development process.

Similarly, the strategies that fulfil the existing goals

were kept. The old strategies that do not fulfil the new

goals were removed. The new set of strategies

includes the reuse of existing concepts if necessary;

reducing workload for generating time for

innovation; generating a cost, quality, and time-

efficient development process; using standards for

quality measurement (and defining these standards if

they do not yet exist); and traceability and

transparency on the process, product, and

organization.

Afterwards, the new design elements were

identified. These design elements were added to the

existing elements (unless concurrent). RFLP-based

function-oriented product development can be

implemented within the company to address many of

the goals and strategies. This has implications for

many design elements, mainly on the information

Digital Transformation of an OEM Development Process from a Socio-Technical Perspective: A Case Study

57

system, human, tasks, and technology. The concept

aims to establish a consistent, universal, model- and

data-driven knowledge management system within

the company (by remodelling the existing system).

This, along with function, system, property, and

product libraries, can help with the reuse of previous

product concepts as well as solution ideas

systematically. This development framework also

allows the designers to have a better understanding of

the system they are developing, specifically within

the context of the product. Using the framework,

tasks can be (semi-) automated and interfaces can be

clearly defined. It also helps to create a traceable and

transparent development process where relevant

information can be accessed easily. Relevant

responsible roles for each RFLP element can be easily

identified. Along with the solution-neutral

description of the functions, these roles help with the

communication between different teams, roles, and

disciplines. Instead of a need-to-know principle, a

publisher and subscriber concept can help with the

interface definitions and ease information access for

those to whom it is relevant. The innovative spirit of

the company can be increased by using idea collectors

and innovation days.

The subsequent step was to observe the system

behaviour. The system behaviour at this stage was

mainly a prediction and cannot be deduced explicitly

due to the abstraction of the system and the lack of

external validation. Given the design components, the

reliance on previous concepts, mainly expert-based

decision making and the tendency to reject innovative

ideas will most likely no longer be observed.

Additionally, the amount of informal information

exchange was also expected to be decreased due to

the more structured knowledge management system.

Lastly, the system output was predicted. The

main output of the system (description of a

production-ready product and all relevant data) will

likely remain, possibly with more innovative product

concepts. The main improvement of the output should

be the interdepartmental information transfer and the

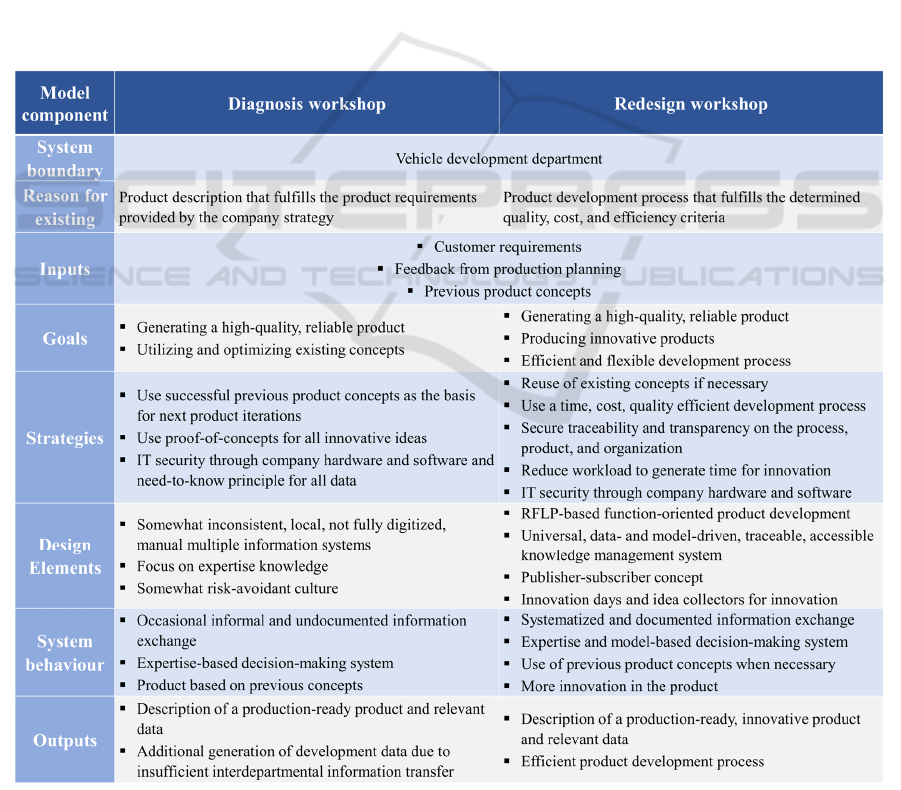

Figure 2: Summary of the most significant findings from the workshops.

KMIS 2023 - 15th International Conference on Knowledge Management and Information Systems

58

resulting redundant work, which will be improved

upon with the proposed items. The efficient

development process will also likely be an output.

Figure summarizes the most significant (not all)

findings of the OSTO® system model diagnosis and

redesign.

5.3 Discussion

The OSTO® system model was very beneficial for

the examination of the organization in a structured

and systematic manner. The workshop format was

rather unconventional for the field experts, who have

a technical background. The case study improved the

system understanding from a socio-technical

perspective. While the company provides a state-of-

the-art product, humans play a crucial role in the

development process and the organizational structure,

which is not usually, explicitly addressed. Providing

a human-centred process and socio-technical system

thinking can support the development of an efficient

knowledge management system. This can increase

employee satisfaction and identification with the

company. These effects can help retain experienced

employees and attract new talents, which can mitigate

the effects of the skilled worker shortage.

“All organizations are perfectly designed to get

the results they get” (Hanna, 1988). The output of the

system has been optimized well in the last decades.

With the volatility of the automotive industry, the

output must be tailored to match the expectations of

the market and the customer. This also means that the

organization itself must work on its limitations to

remain market competitive and fulfil its reason for

existing. The goals of the system must change to

achieve different results (Hanna, 1988). By adopting

the goal to incorporate an efficient development

process, the organization can generate an adequate,

market-competitive, and innovative product. RFLP-

based function-oriented development can help the

company achieve this goal by addressing the

limitations in the information systems and providing

an adequate knowledge management system. The

knowledge management system must be remodelled

to accommodate the RFLP model, considering the

specific requirements of the organization (regarding

the product, structures, and processes…).

Some of the HTO-relevant factors of function-

oriented development (Uhri & Isenhardt, 2023) were

addressed in the redesign workshop. Specifically, the

mindset changes in both designers and decision-

makers, alignment to the existing structures, and user-

friendly interfaces were considered. The redesign

workshop set mindset change as a goal for the way

towards function-oriented development. New design

elements were added to incorporate function-oriented

development in the existing organizational structures.

The redesign workshop focused on the needs of the

designer to generate a user-friendly process. Elements

such as improving system understanding, traceability

and transparency of the systems, and easier

communication between disciplines can help to

develop a human-centred process. Though not

explicitly addressed, management support and step-

by-step transformation towards function orientation

are essential and must be considered in the further

development of the approach.

This case study includes the development

department of only one OEM. Therefore, the results

have limited generalizability and applicability.

Nevertheless, the results contribute to the

development of function-orientation with

consideration of HTO factors. The interdependencies

between the design elements create a hard-to-predict

system behaviour and output. Changes to multiple

design elements at once may result in chaotic and

unpredictable system behaviour. Thus, it is important

to not alter too many elements at once to keep the

system in check. The inclusion of RFLP-based

function orientation may be at the limits of this rule.

Hence, the interdependencies between design

elements must be inspected further.

The redesign workshop can be seen as a

systematic and thorough yet abstract creative exercise

to predict the possible effects. The effects are merely

posited by the experts and not empirically tested.

These effects may differ when the approach is

implemented within the context of the organization.

6 CONCLUSION AND OUTLOOK

This case study aims to observe the possible effects

of the digital transformation caused by the

implementation of function-orientation on an

established OEM and its knowledge management

system. The limitations of the system were

determined through a systematic analysis of the

existing organizational structures. Subsequently, the

ideal system that utilizes function-orientation was

defined. The existing system was redesigned in a way

to accommodate function-orientation and its effects

on the company were observed.

It is concluded that the information systems and

the designer and decision-maker mindsets are the

main areas that can be improved upon. RFLP-based

function-oriented development can be used to create

an accessible, traceable, data-driven, universal

Digital Transformation of an OEM Development Process from a Socio-Technical Perspective: A Case Study

59

knowledge management system. This approach

enables the easy communication of different

disciplines on a systematically documented model,

which can support the decision-making process

(along with expert knowledge). In addition to the

existing goal of generating a high-quality product, the

company can aim to generate a time, cost, and

quality-efficient development process to incorporate

and sustain function-orientation within the

organization. The socio-technical and systematic look

at the organization was crucial to discovering the

limitations of the system and providing solution

alternatives.

This research contributes valuable insights for the

further development of the function-oriented

approach and the knowledge management systems

including the technological, human, and

organizational perspectives. Further research is

needed to concretize and empirically test the results.

Additionally, further organizations and products can

be analysed to validate the results.

ACKNOWLEDGEMENTS

We thank our colleagues Dr.-Ing. Anas Abdelrazeq,

Lea Daling, Cathrin Deutz, Dr. rer. nat. Frank Hees,

Johanna Lauwigi and Dr. rer. nat. Sarah Müller-

Abdelrazeq at WZL-MQ & IMA for their

contributions during the two workshops.

This case study was funded by BMW Group.

REFERENCES

Albers, A., Fahl, J., Hirschter, T., Haag, S., Hunemeyer, S.,

& Staiger, T. (2020). Defining, Formulating and

Modeling Product Functions in the Early Phase in the

Model of PGE — Product Generation Engineering. In

2020 IEEE International Symposium on Systems

Engineering (ISSE) (pp. 1–10). IEEE.

https://doi.org/10.1109/isse49799.2020.9272222

Albers, A., Haug, F., Heitger, N., Fahl, J., Hirschter, T., &

Binz H., Bertsche B., Bauer W., Riedel O., Spath D.,

Roth D. (2019). Entwicklungsgenerationen zur

Steuerung der PGE - Produktgenerationsentwicklung:

Von der Bauteil- zur Funktionsorientierung in der

Automobilentwicklung. In Stuttgarter Symposium für

Produktentwicklung SSP 2019 (pp. 253–262).

Stuttgart: Stuttgart : Fraunhofer-Institut für

Arbeitswirtschaft und Organisation IAO.

https://doi.org/10.18419/opus-10394

Bergmann, A. (2014). Benefits and Drawbacks of Model-

based Design. KMUTNB International Journal of

Applied Science and Technology, 7(3), 15–19.

https://doi.org/10.14416/j.ijast.2014.04.004

Denger, A., Fritz, J., Kissel, M., Parvan, M., & Zingel, C.

(2013). Potentiale einer funktionsorientierten Lenkung

mechatronischer Produkte in der Automobilindustrie.

In M. Maurer & S.-O. Schulze (Eds.), Tag des Systems

Engineering (pp. 405–414). München: Carl Hanser

Verlag GmbH & Co. KG. https://doi.org/

10.3139/9783446436039.040

Eklund, J. (2000). Towards a Framework for Quality of

Interactions between Humans, Technology and

Organization. Proceedings of the Human Factors and

Ergonomics Society Annual Meeting, 44(12), 2-463-2-

466. https://doi.org/10.1177/154193120004401207

Ernst, J. (2014). Humanfaktoren in der

Produktentwicklung. In M. Eigner, D. Roubanov, & R.

Zafirov (Eds.), Modellbasierte virtuelle

Produktentwicklung (pp. 349–367). Berlin, Heidelberg:

Springer Berlin Heidelberg; Imprint: Springer Vieweg.

https://doi.org/10.1007/978-3-662-43816-9_15

Hanna, D. P. (1988). Designing organizations for high

performance. Addison-Wesley series on organization

development. Reading, Mass.: Addison-Wesley.

Henning, K., & Marks, S. (1996). Kommunikations- und

Organisationsentwicklung. Aachen:

Augustinusbuchhandlung.

Jacobs, G., Konrad, C., Berroth, J., Zerwas, T.,

Höpfner, G., & Spütz, K. (2022). Function-Oriented

Model-Based Product Development. In D. Krause & E.

Heyden (Eds.), Design Methodology for Future

Products: Data Driven, Agile and Flexible (1st ed.,

pp. 243–263). Cham: Springer.

https://doi.org/10.1007/978-3-030-78368-6_13

Kreimeyer, M., & Lindemann, U. (2011). Complexity

Metrics in Engineering Design. Berlin, Heidelberg:

Springer Berlin Heidelberg. https://doi.org/10.

1007/978-3-642-20963-5

Lindemann, U., Maurer, M., & Braun, T. (2009). Use case:

Automotive safety development. In U. Lindemann, M.

Maurer, & T. Braun (Eds.), Structural complexity

management: An approach for the field of product

design (pp. 155–170). Berlin: Springer.

https://doi.org/10.1007/978-3-540-87889-6_10

Mumford, E. (2000). A Socio-Technical Approach to

Systems Design. Requirements Engineering, 5(2), 125–

133. https://doi.org/10.1007/PL00010345

Politze, D. P., & Dierssen, S. (2008). A functional model

for the function oriented description of customer-

related functions of high-variant products. In

NordDesign 2008 Conference. Symposium conducted

at the meeting of Design Society, Tallinn, Estonia.

Renner, I. (2007). Methodische Unterstützung

funktionsorientierter Baukastenentwicklung am

Beispiel Automobil (PhD). TUM, München.

Rieckmann, H., & Weissengruber, P. (1990). Managing the

Unmanagable? Oder: Lassen sich komplexe Systeme

überhaupt noch steuern? - Offenes Systemmanagement

mit dem OSTO®-Systemansatz. In H. Kraus & N.

Kailer (Eds.), Management-Development im Wandel

(pp. 27–96). Wien: Manz.

KMIS 2023 - 15th International Conference on Knowledge Management and Information Systems

60

Uhri, E., & Isenhardt, I. (2023). Function-oriented

development of complex mechatronic products from an

HTO perspective: A systematic literature review. In

Proceedings of the International Conference on

Engineering Design (ICED23), Bordeaux, France.

DOI:10.1017/pds.2023.203

Digital Transformation of an OEM Development Process from a Socio-Technical Perspective: A Case Study

61