Cycle Life Prediction of Lithium-Ion Batteries Using Deep Learning

Yu Fujitaki and Hiroyuki Kobayashi

Osaka Institute of Technology, Osaka, Japan

Keywords:

Lithium-Ion Batteries, Deep Learning, LSTM, Prediction.

Abstract:

To improve the accuracy of lithium-ion battery life prediction, we decided to train multiple LSTMs separately,

as each battery may have its own unique characteristics. When verifying the results, we found similarities

between the verification and training batteries and used LSTMs to predict the verification battery, but we show

that the results were not successful.

1 INTRODUCTION

I am surrounded by a plethora of portable electronic

devices, including smartphones, all of which rely on

lithium-ion batteries (abbreviated as LIBs). It has

been a quarter of a century since LIBs were first com-

mercialized. In particular, LIBs have become a ubiq-

uitous electronic component in our daily lives, espe-

cially in mobile devices, owing to their high energy

and power density, long lifespan, cost-effectiveness,

and reliable safety when compared to other commer-

cially available batteries. However, accidents involv-

ing LIBs continue to occur, and their incidence has

been on the rise in recent years.To ensure the reliable

and safe usage of LIBs in electric vehicles and other

devices equipped with these batteries, it is crucial to

monitor various parameters, including voltage, tem-

perature, state of charge (SOC), state of health (SOH),

remaining capacity, and cycle life. While some of

these parameters, such as voltage and temperature,

can be directly measured using sensors, others like

SOC and SOH need to be estimated using algorithms

based on measurement characteristics. Predicting cy-

cle life is essential, but traditional prediction methods

are highly complex, relying on physics-based mod-

eling techniques and having to account for a wide

range of operating conditions and significant device

variability, even among batteries from the same man-

ufacturer.In recent years, there has been a growing

focus on machine learning-based methods to empir-

ically learn and predict battery behavior. Accurate

early prediction of battery cycle life not only enables

rapid validation of new manufacturing processes but

also allows end-users to identify performance degra-

dation and replace failing batteries with ample time to

spare. (Schmush, 2018).

2 RELATED RESEARCH

LIB life prediction methods include, in addition to

simple empirical methods, physical models in which a

person hypothesizes degradation phenomena and nu-

merically solves electrochemical reaction equations,

etc., and more recently, data-driven models that use

machine learning to predict life based on charge-

discharge cycle data. In particular, the data-driven

method I am focusing on here has been evaluated for

its ability to estimate LIB capacity, remaining service

life, and cycle life. This method is based on limited

test data, either empirical or mechanical, and does

not consider modes of degradation. In Severson’s

study, the battery Severson’s study used information

from the first 100 cycles, when the battery is barely

degraded, to predict the cycle life of the LIB, They

achieved a very low testing error of 9.1%. This study

is a promising data-driven approach for predicting the

behavior of complex nonlinear systems. This study

shows the promising power of data-driven methods

for predicting the behavior of complex nonlinear sys-

tems.The goal of my research is to use data-driven

deep learning to produce more accurate predictions

than his. (Severson, 2019)

3 PRINCIPLE

The discharge characteristic data of the LIB is time

series data. Therefore, LSTM, which is special-

ized for learning time-series data, is adopted in this

study. Therefore, LSTM, which specializes in learn-

ing time-series data, was used in this study. Long

Short-Term Memory (LSTM) is a specialized recur-

Fujitaki, Y. and Kobayashi, H.

Cycle Life Prediction of Lithium-Ion Batteries Using Deep Learning.

DOI: 10.5220/0012233500003543

In Proceedings of the 20th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2023) - Volume 2, pages 307-310

ISBN: 978-989-758-670-5; ISSN: 2184-2809

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

307

rent neural network (RNN) architecture designed for

handling sequential data. Unlike traditional RNNs,

which struggle with maintaining long-term dependen-

cies, LSTMs are adept at capturing and utilizing infor-

mation over extended sequences.LSTMs achieve this

by introducing memory cells and gating mechanisms.

The memory cell can store information over time,

while the gates control the flow of data into and out

of the cell. The forget gate decides what to retain or

forget from the previous cell state, the input gate man-

ages new information input, and the output gate con-

trols the information passed as output. LSTMs have

become a crucial tool for tasks requiring the model-

ing of complex dependencies in sequential data.The

model proposed in this study is a ”dedicated LSTM.

The model proposed in this study is a ”dedicated

LSTM, In order to compare the performance of the

two models, I will explain the two models, ”conven-

tional LSTM” and ”dedicated LSTM. The following

is a comparison of the performance of the two models,

”conventional LSTM” and ”dedicated LSTM.

Figure 1: Conventional LSTM.

In figure1, N training batteries and 1 validation

battery are used. That is, the LIB has N training bat-

teries and 1 validation battery, each containing 5 vari-

ables. Step (1) uses N data to train one LSTM with

data from the first to the Mth cycle of the LIB; the

form of the data to be trained into the LSTM is N ×

M × 5. In step (2), the data from the first cycle to

the Mth cycle of the test LIB is input to the learned

LSTM. The form of the data here is 1 x M x 5. In

step (3), the predicted values of the five features are

output for the M+1st cycle. Incidentally, when pre-

dicting the life span, the number of cycles when the

predicted value of the discharge capacity falls below

a value of 0.88 is used as the life span.

Figure2 above shows the verification of data for

testing using a dedicated LSTM. First, dedicated

LSTM means that each battery is considered to be

Figure 2: Dedicated LSTM.

different and predicted by its own LSTM after gu-

rupturing from the initial cycle. In (1), N LSTMs

are prepared for N training LIBs, and each battery

is trained; in (2), the similarity between the training

LIBs and the test LIBs is determined; and in (3), the

similarity between the training LIBs and the test LIBs

is determined. The difference between the discharge

capacities of the 100th and 10th cycles of the test LIB

is judged to be closer to the difference between the

discharge capacities of the training LIB. In (3), cycle

data is input to the LSTM that has learned the training

LIB, which is similar to the test LIB in (2). In (4), the

five predicted values for the M+1th cycle are output

in the same way as in the conventional method.

4 DATA CONTENTS

This data set was used in the ”Data-driven prediction

of battery cycle life before capacity degradation”. The

data set consists of 124 commercial lithium-ion bat-

teries that have been cycled 150 to 2300 times using

72 fast charge conditions for a total data set of approx-

imately 96,700 cycles. Table 2 shows the 15 variables

of the data set.

Manufactured by the A123 system

(APR18650M1A), these lithium phosphate lithium

ion (LFP)/graphite cells are circulating in a horizon-

tal cylindrical fixture on a 48-channel Alvin LBT

potentiometer in a forced convection temperature

chamber set at 30 °C. Table 3.2 presents the battery

specifications. The goal of this work is to optimize

the rapid charging of lithium-ion batteries. Therefore,

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

308

Table 1: Data set variables.

Data Point Test Time

Date Time Step Time

Step Index Cycle Index

Current Voltage

Charge Capacity Charge Energy

Discharge Capacity Discharge Energy

dV/dt Temperature

fff Internal Resistance

all cells in the dataset of are charged with a one-step

or two-step fast charging policy. The format of this

policy is ”C1(Q1)-C2”, where C1 and C2 are the

first and second constant current steps, respectively,

and Q1 is the state of charge (SOC, %) at which

the current switches; the second current step ends

at 80% SOC and the cells are then charged at 1C

CC-CV. The upper and lower cutoff potentials are

3.6 V and 2.0 V, respectively. These cutoff potentials

are fixed for all current steps, including fast charging.

After some cycling, cells may hit the upper cutoff

potentials during fast charging, leading to significant

constant voltage charging. All cells are discharged

at 4C. The data set is divided into three ”batches”,

each representing approximately 48 cells. Each batch

is defined by the ”batch date,” or the date the test

was initiated. Each batch has some irregularities,

as detailed on the individual batch pages. Temper-

ature measurements are taken by attaching a T-type

thermocouple to the exposed cell can with thermal

epoxy (OMEGATHERM201) and Kapton tape after

a small piece of plastic insulation has been removed.

It should be noted that temperature measurements are

not completely reliable. Thermal contact between

the thermocouple and the cell can vary widely, and

the thermocouple may lose contact during cycling.

Internal resistance measurements were obtained dur-

ing charging at 80% SOC by an average of 10 pulses

of ± 3.6C with pulse widths of 30 ms (2017-05-12

and 2017-06-30) or 33 ms (2018-04-12). Table 3.3

presents the cycle life statistics.

5 DATA PREPROCESSING

First, standardization was performed to keep the val-

ues within a certain range. Next, the data was ana-

lyzed to improve the prediction accuracy. I examined

the relationship between the cycle life and four vari-

ables: discharge capacity, discharge energy, charge

capacity, and charge energy. The correlation coef-

ficient for all four variables was approximately 0.6,

which is not a very high correlation coefficient, but

I considered that it would improve the accuracy of

cycle life prediction, so I used these as characteristic

quantities.

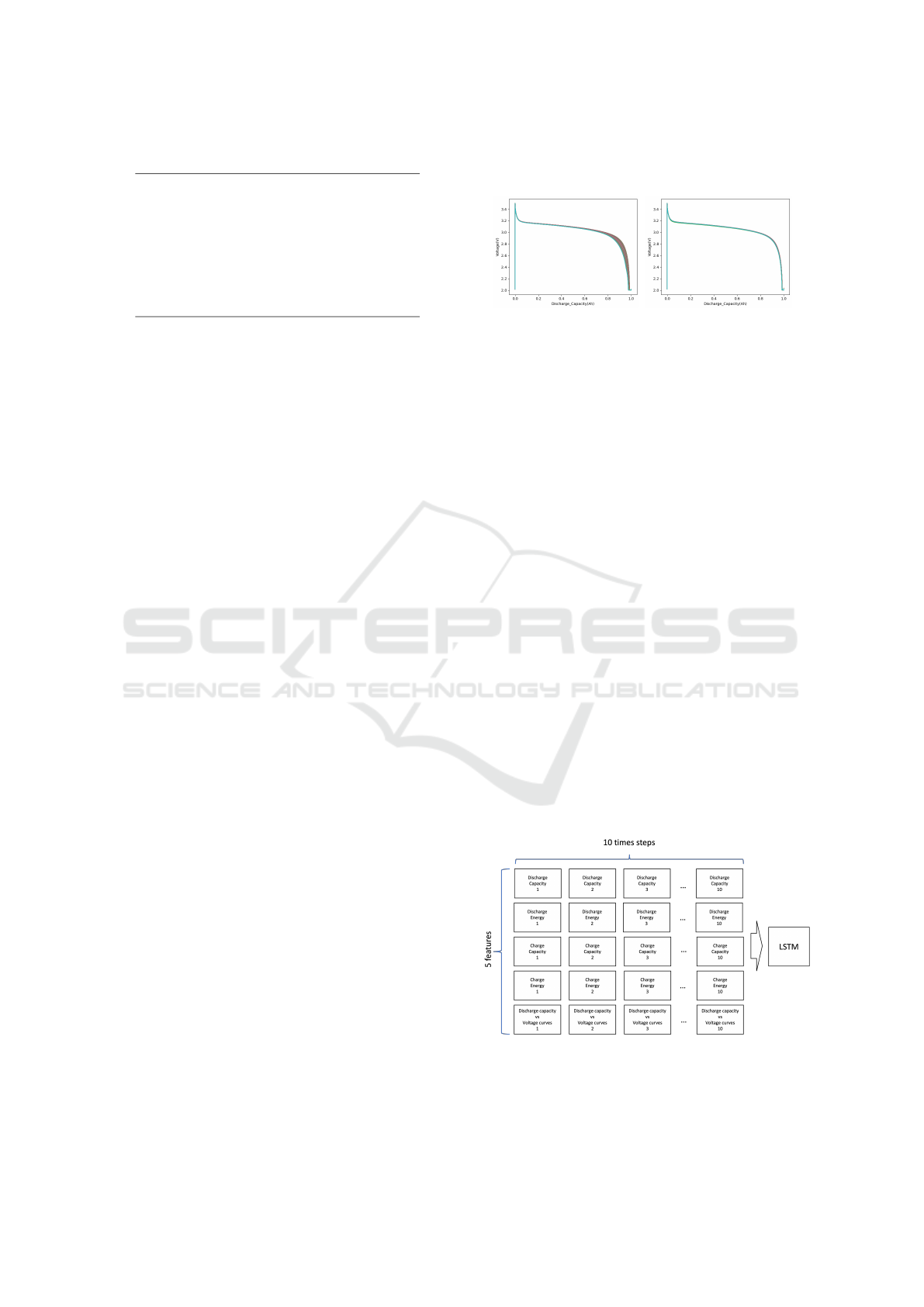

(a) short life span (b) log life span

Figure 3: Short and long life difference by discharge curve.

The figure3 shows the discharge curves for the

short-life and long-life, both of which graph the

change in discharge capacity and voltage after 100

charge/discharge cycles. Comparing the voltages near

the discharge capacity of 0.8 in this figure, it can be

seen that the short-life LIBs have progressively lower

voltages. The correlation coefficient between the volt-

age dispersion by the discharge curve and the cycle

life of the LIB is 0.8. Since a high correlation co-

efficient was obtained, this relationship is one of the

characteristic quantities.

∆Q = variance(Q

0

− Q

i

)(i = 1, 2, 3 · · · 100) (1)

The equation(1) generates time series data for 100

cycles based on 0 cycles, where the voltage dif-

ference due to the discharge curve is distributed.

(Pengcheng Xu, 2022)

6 EXPERIMENT

Before training, data is generated for each time step

using 10 data to train LSTM on the feature-extracted

data to predict the next value. The data generated for

each time step was used to train the system.

Figure 4: Time step.

The figure4 illustrates the time steps.This experi-

mental evaluation will be conducted using RSME and

MPE. In addition, the verification of training data for

Cycle Life Prediction of Lithium-Ion Batteries Using Deep Learning

309

”conventional LSTM” is omitted because ”dedicated

LSTM” is difficult to verify for training data, and the

main focus is on ”dedicated LSTM.

Table 2: Inspection result.

convention dedicated

RSME 0.145 RSME 0.440

MPE 0.110 MPE 0.470

The results show that ”conventional LSTM” is

more accurate than ”dedicated LSTM. The results

show that the prediction accuracy of ”conventional

LSTM” is higher than that of ”dedicated LSTM”.

Possible causes One possible reason is that similarity

judgment by ”Dedicated LSTM” may not be so effec-

tive with the discharge volume. The reason may be

that the similarity judgment by ”Dedicated LSTM” is

not so effective for the discharge volume. In feature

extraction, a high correlation coefficient between cy-

cle life and If the dispersion of the discharge curve

with a high correlation coefficient with the cycle life

is used for feature extraction, it may be possible to

obtain more accurate results. It is thought that more

accurate results could have been obtained if the vari-

ance of the discharge curve with a high correlation

coefficient with the cycle life was used for feature ex-

traction. In addition, instead of using 100 initial cy-

cles, it may be better to use 100 initial cycles. It is also

necessary to verify the results using 500 initial cycles

instead of 100 initial cycles. It may also have been

necessary to verify the results using an initial cycle of

500 instead of the initial cycle of 100. The results of

this study were more accurate than those obtained by

using the dispersion of discharge curves with a high

correlation coefficient.

7 FUTURE DEVELOPMENT

As mentioned in the discussion, as a future develop-

ment, I will examine the initial cycle as 500 as the

initial cycle. I am also considering other uses for

”dedicated LSTMs. One is to use the data from the

test LIBs in the study LIBs instead of using a single

LSTM for similarity determination. One is to use all

the LSTMs learned in the training LIB instead of us-

ing a single LSTM to determine similarity of the data

in the test LIB. One is to use all LSTMs learned in the

training LIB and average them as predictions, instead

of using a single LSTM for similarity determination

of the data in the test LIB. The other is to look at

the predicted value as averaged over all the LSTMs

studied in the training LIB. The other is to use the

averaged cycle change (change in 6th-order features)

predicted by all models to obtain the cycle life. The

other is to calculate the cycle life by averaging the cy-

cle changes (changes in 6D features) predicted by all

the models.

ACKNOWLEDGEMENTS

I would like to thank my teachers and school for sup-

porting my research and for giving me this opportu-

nity.

REFERENCES

Pengcheng Xu, Y. L. (2022). Predicting li-ion battery cycle

life with lstm rnn.

Schmush, Richard, e. a. (2018). Performance and cost

of materials for lithiumbased rechargeable automotive

batteries. Nature Energy 3.4, page 267.

Severson, K. (2019). Data-drivenpredic- tion of battery cy-

cle life before capacity degradation. Nature Energy

4.5, pages 383–391.

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

310