Real-Time Material Identification Using Light Spectroscopy and

Support Vector Machine (SVM)

Masoud Shaloo and Gábor Princz

University of Applied Sciences Wiener Neustadt, Johannes-Gutenberg-Straße 3, 2700 Wiener Neustadt, Austria

Keywords: Industry 4.0, Smart Manufacturing, Light Spectroscopy, Support Vector Machine, Artificial Intelligence.

Abstract: Material identification is vital in diverse industries such as automotive and aerospace, and industrial

applications including machining, robotics, and smart manufacturing. Aerospace and automotive sectors deal

with machining, drilling, pressing, or grinding of multi-material parts, requiring manual process parameter

adjustments based on each material due to various inherent material properties causing delays in setup time

resulting in extended throughput times, decreasing production rates and increasing costs. In addition, manual

adjustment may lead to a decrease in the quality of the final part. Thus, there is a need for an automated system

that can detect the material type in real-time and employ that information to dynamically adjust the machining,

drilling, pressing, or grinding parameters. This paper focuses on merging a low-cost light spectroscopy sensor

in the wavelength range of 410 nm (UV) to 940nm (IR) and support vector machine (SVM) to facilitate

material identification on automated production lines. Various materials including aluminum, acrylonitrile

butadiene styrene (ABS), wood, polyvinyl chloride (PVC), plain carbon steel, polyamide (PA), polylactic

(PLA), and galvanized plain carbon steel were examined. The findings revealed that, except for PLA and

aluminum, all materials achieved very high accuracy, recall, precision, and F1-score of 100%. PLA showed

90% accuracy and recall, along with 100% precision and 94.7% F1-score. Similarly, aluminum attained 95%

accuracy and recall, 100% precision, and a 97% F1-score.

1 INTRODUCTION

The importance of material identification is evident

across various industries such as automotive and

aerospace, and industrial applications including

machining, robotics, and the implementation of smart

manufacturing systems (Lutz et al., 2021). In certain

industries, such as aerospace or automotive, the

requirement often arises to drill numerous holes,

machine, or grind parts made from multiple materials.

Due to the inherent differences in material properties,

it becomes necessary to adjust manually various

machining, drilling, pressing or grinding parameters

for each specific material. This manual adjustment

not only leads to extended throughput times but also

results in increased costs and a reduction in

production rates (Araujo et al., 2021; Denkena et al.,

2019; Deshpande et al., 2023). Furthermore, the

application of uneven manufacturing process

parameters can lead to a deterioration in the quality of

the final parts (Denkena et al., 2019). Therefore, there

is a need for an automated system that can detect the

material type in real-time and employ that

information to dynamically adjust the machining,

drilling, pressing or grinding parameters. Various

sensor technologies are combined with machine

learning techniques, such as support vector machines

(SVM), k-nearest-neighbor (KNN) and convolutional

neural network (CNN) for the identification of

different material types. These techniques encompass

the examination of surface images through camera

systems, as well as the analysis of force, torque,

vibration signals (Lutz et al., 2021), and using

spectroscopy technique (Vašková, 2011).

Spectroscopy is a non-destructive testing technique

that captures qualitative and quantitative elemental

data from materials through emitted or received

wavelength or frequency spectrum of energy. This

data emerges due to the interaction between

electromagnetic radiation and the particles of the

material. Within the context of the spectroscopy

technique, particular wavelengths are emitted by an

energy source, such as a lamp, directed onto the

material's surface. As an outcome of this interaction,

the atoms and molecules within the material absorb a

discrete amount of energy and subsequently reflect

Shaloo, M. and Princz, G.

Real-Time Material Identification Using Light Spectroscopy and Support Vector Machine (SVM).

DOI: 10.5220/0012254400003543

In Proceedings of the 20th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2023) - Volume 2, pages 227-235

ISBN: 978-989-758-670-5; ISSN: 2184-2809

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

227

the remaining energy. The energy that is reflected is

then collected by a spectrometer. The captured

spectrum by the spectrometer is meticulously

analyzed with wavelength, wavenumber, or

frequency to get elemental information of the

inspected material (Scotter, 1997). There are various

spectroscopy techniques e.g. visible and near-infrared

(Vis-NIR), near-infrared (NIR), mid-infrared (MIR),

Laser induced break down (LIBS), Raman,

fluorescence, and terahertz (THz) spectroscopy

(Koujelev et al., 2010; Ma et al., 2023). However,

most previous work has either focused on expensive

sensors or could not be integrated into real-time

production environments (Pease et al., 2017). This is

a significant barrier especially for SMEs (small and

medium enterprises) that may not have access to

high-end machines and need a scalable, low-cost

solution (Failing et al., 2023). Despite numerous

researches on combining machine learning and sensor

technologies for real-time material detection, a gap in

understanding persists about the applicability and

performance of using light spectroscopy and SVM in

automated production lines. The novelty of this

project lies in its approach of using low-cost light

spectroscopy sensors for a wide range of materials, as

well as in its integration directly into the production

line, which allows immediate feedback and

adjustment of the manufacturing parameters. The

primary aim of this research is to combine a low-cost

light spectroscopy sensor in the wavelength range of

410 nm (UV) to 940 nm (IR) with the SVM method

for the real-time and inline identification of material

types including aluminum, acrylonitrile butadiene

styrene (ABS), wood, polyvinyl chloride (PVC),

galvanized plain carbon steel, polyamide (PA),

polylactic (PLA), and plain carbon steel on automated

production lines. This information will then be

transmitted to the Programmable Logic Controller

(PLC) to enable the intelligent adjustment of process

parameters specifically for further smart

manufacturing. The subsequent sections of this paper

are structured as follows. In the next section, we

provided the theoretical background of SVM. In

section two, we review related literature on the

subject and introduced the knowledge gap. This will

particularly highlight the limited studies that focus on

low-cost spectroscopy solutions in production.

Section three presents the employed methodology.

Section four provides an analysis of the obtained

results. Finally, a summary of this work and its

conclusion are presented.

2 SUPPORT VECTOR

MACHINES

SVM provide a robust classification framework based

on the pursuit of optimal hyperplane separation across

different data categories (Winters-Hilt et al., 2006). In

its linear form, the SVM theoretically determines a

hyperplane for a given data set (x

1

, y

1

) , (x

2

,y

2

), ..., (x

n

,

y

n

), where each xi represents a feature vector and y

i

is

its label. The decision function is expressed as f(x)=

(w, x) + b, where “w” and “b” denote the weight

vector and bias, respectively. In practice, data are

often non-linear. This non-linearity is addressed by

SVM with the kernel technique, which projects data

into a higher-dimensional space to achieve linearity.

Kernels used are linear, polynomial, and radial basis

functions (RBF).

SVM is characterized by maximizing the span

between classes, which increases its resistance to

overfitting (Han & Jiang, 2014). SVM is originally

developed for binary classification, however, it can be

adapted to multiclass problems using one-versus-one

and one-versus-all techniques (Rodriguez-Pérez et

al., 2017). In SVM, the regularization parameter C is

crucial as it determines the trade-off between margin

width and misclassification penalty (Nakayama et al.,

2017). A high C value focuses on limiting

misclassification, often resulting in a narrower

margin, while a low C value favours maximising the

margin, possibly at the expense of increasing

misclassification. This adjustability of C strengthens

the SVM's resilience to outliers and demonstrates its

usefulness for a wealth of supervised learning

applications.

SVM is ideal for supervised learning applications,

especially text classification, image recognition,

bioinformatics tasks such as gene classification,

financial prediction and speech recognition, as it

handles high-dimensional data very well, is versatile

in different domains and fine-tuning is adjustable

(Abdullah & Abdulazeez, 2021).

3 LITERATURE REVIEW

The utilization of machine learning techniques for

material identification has gained substantial interest

due to its potential for enhancing efficiency and

accuracy in various industrial applications. Denkena

et al. (Denkena et al., 2019) investigated various

machine learning models including a neural network,

a k-nearest-neighbor model, a support vector

machine, and a decision tree to determine the

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

228

materials in hybrid components during the CNC

machining process. The findings revealed that among

the models evaluated, only the k-nearest-neighbour

(kNN) model demonstrated acceptable results,

making it suitable for online identification purposes.

The trained decision tree model did not yield

satisfactory outcomes in terms of material separation.

However, both the neural network (NN) and support

vector machine (SVM) models exhibited promising

capabilities in accurately identifying one of the two

materials. Penumuru et al. (Penumuru et al., 2020)

conducted a study that integrated machine vision

techniques with the extraction of red, green, and blue

(RGB) color values in the RGB color space, along

with the use of Support Vector Machine (SVM) for

automatic detection of distinct materials such as

aluminum, copper, medium-density fibreboard

(MDF), and mild steel. The findings indicated that

SVM achieved a remarkable accuracy level of 100%.

Nonetheless, it was noted that this approach may not

be entirely suitable for real-world applications as the

lighting conditions is dynamic and fluctuate. Ding et

al. (Ding et al., 2020) employed capacitive proximity

sensors and various machine learning-based

techniques, ranging from simple k-nearest-neighbor

(k-NN) methods to more complex artificial neural

networks, such as feed-forward neural networks

(FFNN) and convolutional neural networks (CNN),

for the detection of ten different materials. The study's

findings suggest that converting the 1D spectra data

into images and utilizing image-based Convolutional

Neural Networks (CNNs) allow for the successful

identification of materials with closely related

electrical characteristics. Lutz et al. (Lutz et al., 2021)

reviewed various material identification methods and

reported that the analysis of surface images (using

camera systems), force measurements, torque

analysis, and vibration signals are commonly

employed techniques. In their study, spectroscopy

technique was not discussed. Koujelev et al.

(Koujelev et al., 2010) successfully combined Laser-

Induced Breakdown Spectroscopy (LIBS) with an

Artificial Neural Network (ANN) to detect a diverse

range of materials, encompassing metal alloys,

marble, granite, soil, clay, rocks, sediments, and

silicon oxide. They achieved a remarkable 100%

detection rate for mineral samples in scenarios where

the reference set of materials comprised five distinct

classes. In a different study, conducted by W.H.A.M.

van den Broek et al. (Van Den Broek et al., 1998), an

NIR spectroscopy system was employed in

conjunction with an Artificial Neural Network

(ANN) to identify plastic materials. Their findings

indicated a high detection rate of 80%. Despite the

extensive research on applying machine learning

techniques with various sensor technologies for real-

time material detection, there remains a knowledge

gap regarding the applicability and performance of a

combination of light spectroscopy and SVM

technique in automated production lines. This study

seeks to address this gap by developing an intelligent,

low-cost, in-line and real-time SVM-based machine-

learning model that utilizes light spectroscopy to

identify materials.

4 METHODOLOGY

This section provides a comprehensive description of

the experimental configuration, and the statistical

techniques utilized.

4.1 Experimental Setup

The experimental procedures were carried out using

the laboratory production line- FESTO FMS 50

didactics system, consisting of five distinct stations:

incoming goods, manufacturing, assembly and

quality control, storage, and outgoing goods. This

study focused on the manufacturing station. The

manufacturing process at this station can be described

as follows: Initially, the part was transported from the

incoming goods station to the manufacturing station.

Subsequently, a couple of sensors were employed to

verify the availability of the part by detecting the

workpiece carrier. Once its presence was confirmed,

the manufacturing process commenced. A gantry

system equipped with a vacuum gripper facilitated the

transfer of the part onto the turntable. The turntable

executed three rotations, followed by a 3-second

pause for material detection. Figure 1 illustrates a

schematic of the implemented system architecture.

Figure 1: A schematic of the implemented system

architecture.

An algorithm implemented in Python on the

Raspberry Pi was responsible for detecting the

Real-Time Material Identification Using Light Spectroscopy and Support Vector Machine (SVM)

229

material and transmitting the results to the

programmable logic controller (PLC) Siemens S7-

1500 (Siemens AG, 2023) via Profinet. Based on the

identified material, various pressing and grinding

parameters could be configured. The pressing

process, along with the subsequent grinding

operation, was completed within a duration of 2

seconds. Once these processes were concluded, the

turntable rotated one step, allowing the gantry system

to transfer the finished part onto the workpiece carrier

on the conveyor. This study employed a Sparkfun

triad spectroscopy sensor AS7265x (SparkFun

Electronics, 2023). The sensor allows for the precise

measurement of 18 individual light frequencies,

reaching an impressive sensitivity of 28.6 nW/cm2

and an accuracy level of +/-12%. The sensor was

integrated with a Raspberry Pi 3B (Raspberry Pi 3,

2023) using I

2

C communication. Figure 2 illustrates a

variety of materials that were examined, namely

aluminum, acrylonitrile butadiene styrene (ABS),

wood, polyvinyl chloride (PVC), galvanized plain

carbon steel, polyamide (PA), polylactic (PLA), and

plain carbon steel.

Figure 2: Used materials for experiments.

The primary objective in selecting these materials

was to encompass a diverse range of commonly used

materials in the industry. This allowed the analysis of

the developed model's performance across a spectrum

of materials, each with both similar and distinct

material characteristics, ranging from plastics to

metals. Additionally, a category labelled "No part"

was defined to signify the unavailability of a specific

part. An algorithm was employed to read the light

sensor TSL2951 (Adafruit TSL2591, 2023) lux

values. To obtain accurate readings, the TSL2591

light sensor was calibrated using a Voltcraft LX-10

(Voltcraft LX-10, 2023) as a reference light sensor

with an accuracy of +/- 4%. Table 1 indicates an

example of the captured raw dataset (spectral

responsivity from the sensor) for investigated

materials. To gather raw data for training the model,

a Python algorithm was developed. This algorithm

scanned each material and recorded its raw spectrum

for a duration of 4 minutes (2 minutes under a light

intensity of approximately 100 lux and 2 minutes

under a light intensity of approximately 300 lux). The

captured data was then saved as a .csv file. Notably,

350 scans were performed for each material to ensure

comprehensive data collection.

Table 1: An example of the captured raw dataset (spectral

responsivity from the sensor) for investigated materials.

4.2 Training Procedure of the SVM

Model

A multi-class Support Vector Machine (SVM)

classifier was implemented to identify different

materials based on their features. The necessary

Python (Python, 2023) libraries were imported. These

include scikit-learn (Scikit-Learn, 2023) for SVM,

pandas (Pandas, 2023) for data handling, matplotlib

(Matplotlib, 2023) and seaborn (Seaborn, 2023) for

data visualization, and numpy (NumPy, 2023) for

numerical operations. Next, the dataset was loaded

containing all raw data from a CSV file named

"Data.csv" using pandas. We then perform data

cleaning to ensure that the dataset does not contain

any missing values. Any rows with NaN or NULL

values are dropped from the dataset. The dataset was

split into three sets: the train set, the test set, and the

validation set. The train set contains 80% of the data,

while the test set comprises 20%. The test set further

was divided equally to create the test and validation

subsets, each containing 50% of the test data. Next,

the data was pre-processed by separating the target

variable "Material" which represents material types

or classes from the feature variables in all three

datasets (train, test, and validation). An SVM

classifier with a linear kernel was created and trained

using the training dataset. Once the model is trained,

we evaluate its performance on different datasets. The

accuracy metric on the train, validation, and test

datasets was calculated to gauge how well the model

generalizes to unseen data. Finally, the trained SVM

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

230

model was exported using the joblib (Joblib, 2023)

library, making it ready for deployment in Raspberry

Pi to predict the material class of new samples.

4.3 PLC Configuration

PUT/GET communication was activated to enable the

program to write (PUT) or read (GET) data to and

from specific memory locations within the data block

through Profinet protocol. As shown in

Figure 3

, a data

block was defined to allocate a specific memory area

within the PLC for storing information related to

different materials. A bit for each material type was

defined within the data block, to show the presence or

absence of a particular material using a binary state.

Deactivating optimized block access might be

necessary to ensure direct and reliable access to

individual bits within the data block.

Figure 3: Defined bits for each material inside the data

block called “Material Detection”.

4.4 Implemented Code on Raspberry

Pi

Figure 4 indicates the flowchart of the developed

algorithm on raspberry Pi to identify different types

of materials and send corresponding signals to the

PLC for further control actions.

Figure 4: Flowchart of the implemented code onto

raspberry pi.

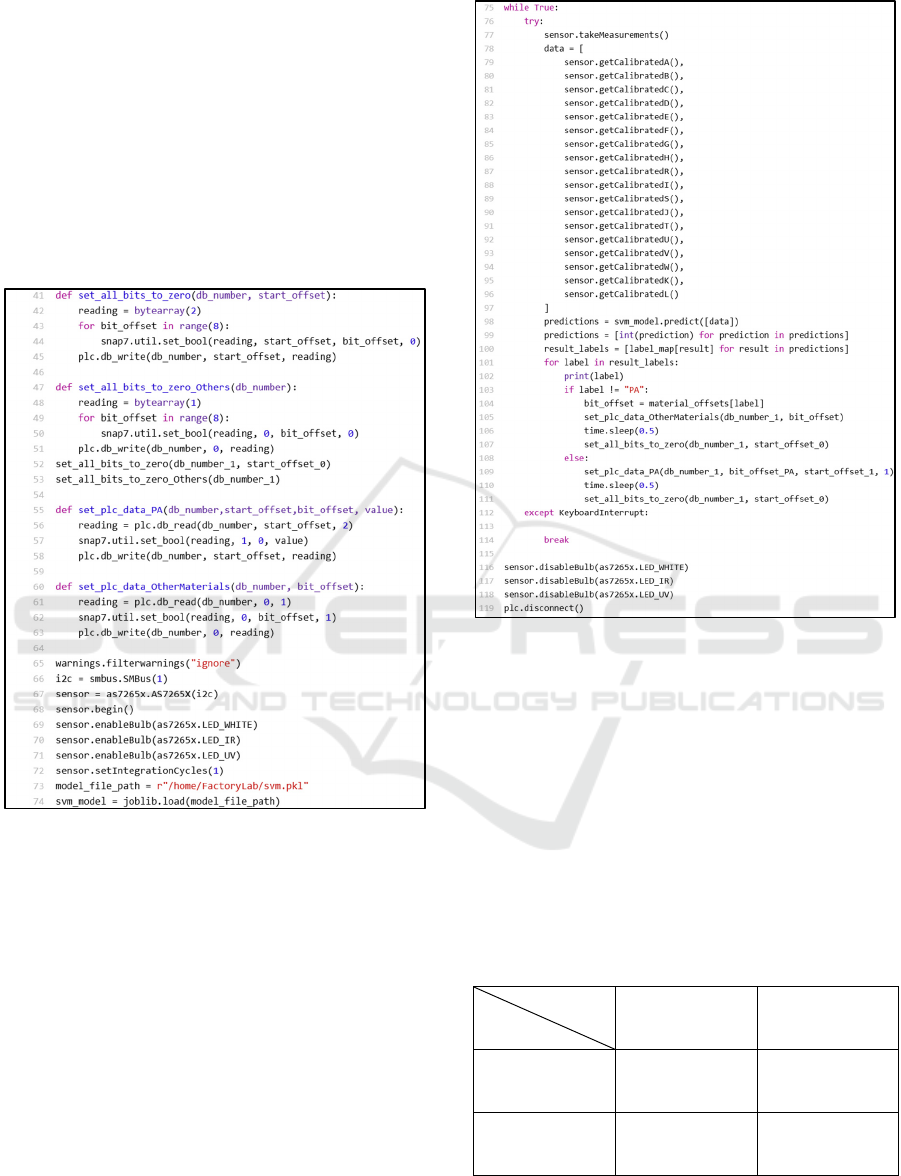

As shown in Figure 5, the code imports various

Python libraries that are required for different tasks,

such as handling CSV files (CSV library), working

with sensors (AS7265X library), performing

mathematical operations (numpy and math libraries),

managing joblib models (Joblib library), handling

warnings (warnings library), communicating with a

Siemens PLC (via Snap7 library), and managing time

(time library). The code establishes a connection with

a Siemens PLC using its IP address. It specifies the

PLC's data block numbers and various offsets for

different Materials. A mapping is created that

associates material types with specific bit offsets.

This mapping is used to set the appropriate bits in the

PLC to control the materials. Another mapping is

created that associates numeric labels with human-

readable material types.

Figure 5: Imported libraries, PLC initialization, material

and bits-mapping in the developed algorithm in python.

This mapping is used to convert the numerical

predictions from the SVM model into meaningful

material labels. As shown in Figure 6, the code

defines functions to set bits to zero in the PLC's data

blocks. These functions are used to reset plc variables

Start

Import

required

libraries

PLC

initialization

Label

mapping

Material

offsets

PLC utility

functions

Loading

machine

learning

model

Main loop

Cleanup and

termination

End

Real-Time Material Identification Using Light Spectroscopy and Support Vector Machine (SVM)

231

before setting new values. In addition, two functions

are defined to set bits based on the detected material.

The code initializes the AS7265X sensor, enabling

specific LED bulbs, setting integration cycles, and

configuring the sensor. Classification, especially

using the SVM model, involves training a model to

assign input examples to one of several classes. This

is done based on a previous set of examples where the

correct class assignments are known. In this context,

the code loads the already trained SVM model from

the predefined directory. This model is used to predict

the material type based on sensor measurements.

Figure 6: Defined PLC functions, sensor configuration and

imported developed SVM model in the python program.

Then, as shown in Figure 7, the code enters a

continuous loop where it performs the following

steps: Takes measurements from the sensor, uses the

SVM model to predict the material type based on the

measurements, converts the numerical predictions

into human-readable material labels using the label

mapping. Depending on the material type, it sets the

appropriate bit in the PLC for the detected material

type and clears other material bits. Repeats the loop

with a short delay of 0.5 second between iterations.

Finally, the script disables the sensor's LED bulbs and

disconnects from the PLC.

Figure 7: Developed main loop to perform real-time

material identification and sending the results to the PLC.

4.5 Statistical Analysis

To evaluate the performance of the trained model and

thus validate the application of low-budget light

spectroscopy in an industrial environment, each

material was tested 20 times under the same light and

environmental conditions. Afterwards, the confusion

matrix (Chen & Shiu, 2022) was calculated. The

structure of the confusion matrix is presented in

Table 1.

Table 2: Confusion matrix.

Actual

Predict

Actually

defective

(positive)

Actually non-

defective

(negative)

Predicted

defective

(p

ositive

)

True Positive

(TP)

False Positive

(FP)

Predicted non-

defective

(

ne

g

ative

)

False Negative

(FN)

True Negative

(TN)

True Positives (TP) signify the number of cases

accurately identified as members of the positive class.

On the other hand, True Negatives (TN) denote the

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

232

count of cases correctly identified as members of the

negative class. False Positives (FP) represent

instances incorrectly classified as belonging to the

positive class, while they actually belong to the

negative class. Similarly, False Negatives (FN)

indicate instances wrongly classified as belonging to

the negative class, when they indeed belong to the

positive class. Besides the confusion matrix, various

commonly used metrics in machine learning,

particularly in classification tasks, were computed to

gauge the model's performance. These metrics

include accuracy, precision, recall, and F1-Score

(Chen & Shiu, 2022; Vu et al., 2023; Zheng et al.,

2021) . They were calculated using the following

formulas:

Accurac

y

TP TN

TP TN FP FN

(1)

Precision

TP

TP FP

(2)

Recall

TP

TP FN

(3)

F1 Score

2 ∗ Precision ∗ Recall

Precision Recall

(4)

5 RESULTS AND DISCUSSION

Table 3 presents the calculated confusion matrix.

Table 3: Calculated confusion matrix.

Material TP FP TN FN

ABS 20 0 0 0

Wood 20 0 0 0

PVC 20 0 0 0

PLA 18 0 0 2

Aluminium 19 0 0 1

Plain carbon steel 20 0 0 0

Galvanized carbon

steel

20 0 0 0

PA 20 0 0 0

No part 20 0 0 0

Table

4

indicates the performance metrics of the

multi-class Support Vector Machine (SVM) classifier

for material identification based on the calculated

confusion matrix. The SVM classifier achieved very

good results for ABS, Wood, PVC, Aluminium, Plain

carbon steel, Galvanized carbon steel, PA, and No

part, with 100% precision, recall, F1 score, and

accuracy. This indicates that the model correctly

identified all instances of these materials and made no

false positive (FP) or false negative (FN) predictions.

Table 4: Calculated statistical metrics to evaluate the

performance of the trained SVM model.

Material Recall Precisio

n

F1-score Accurac

y

ABS 100,0% 100,0% 100,0% 100,0%

Wood 100,0% 100,0% 100,0% 100,0%

PVC 100,0% 100,0% 100,0% 100,0%

PLA 90,0% 100,0% 94,7% 90,0%

Aluminiu

m

95,0% 100,0% 97,0% 95,0%

Plain

carbon

steel

100,0% 100,0% 100,0% 100,0%

Galvaniz

ed carbon

steel

100,0% 100,0% 100,0% 100,0%

PA 100,0% 100,0% 100,0% 100,0%

No part 100,0% 100,0% 100,0% 100,0%

The high accuracy on these materials

demonstrates the capability of the SVM classifier in

distinguishing between them based on their features.

In the case of PLA, the SVM classifier achieved high

performance on PLA as well, with 18 true positive

predictions and 2 false negative predictions. This

resulted in a recall of 90.0% and a precision of

100.0%. The F1 score for PLA is 94.7%, which

indicates a good balance between precision and

recall.

Figure 8: A comparison of the reflectance intensity of PA

and PLA at light intensity of 100 lux.

However, the accuracy for PLA is slightly lower

at 90.0%, mainly due to the two false negative

predictions. As shown in Figure 8, the high similarity

in the spectrum range of raw data of PLA to PA might

have caused the model to incorrectly detect some

Real-Time Material Identification Using Light Spectroscopy and Support Vector Machine (SVM)

233

PLA instances as PA. Aluminum achieved an

accuracy and recall of 95%, perfect precision of

100%, and an F1-score of 97%. The lower accuracy

and recall may be attributed to the highly reflective

surface and uneven light reflectance of the aluminum

material. The developed SVM classifier

demonstrated excellent performance for material

identification across most materials, achieving high

accuracy for the majority of them. The model's ability

to differentiate between various materials based on

their features highlights its robustness and potential

for real-world applications.

6 CONCLUSION

This paper combined light spectroscopy and SVM

methods for inline and real-time material

identification within automated production lines. The

experimentation encompassed a range of materials,

including aluminum, ABS, wood, PVC, galvanized

plain carbon steel, PA, PLA, and plain carbon steel.

The outcomes of the study demonstrated that:

• all materials with the exception of PLA and

aluminum, achieved accuracy, recall,

precision, and F1-score of 100%.

• PLA demonstrated a 90% accuracy and

recall, coupled with perfect precision of

100% and an F1-score of 94.7%.

• aluminum achieved a 95% accuracy and

recall, perfect precision of 100%, and an F1-

score of 97%.

In the context of future research, light

Spectroscopy will be merged with Convolutional

Neural Network and k-Nearest Neighbors models. In

addition, there is a need for further research testing

the developed model in a real industrial environment.

By using low-cost light spectroscopy in these

environments, it will be possible to test and validate

the applicability of the model in dynamically

adjusting manufacturing parameters in real time. This

practical validation is important to ensure that the

model not only works in controlled environments but

is also effective and reliable in real production

scenarios.

REFERENCES

Abdullah, D. M., & Abdulazeez, A. M. (2021). Machine

Learning Applications based on SVM Classification : A

Review. Qubahan Academic Journal, 1(2), 81–90.

https://doi.org/10.48161/Issn.2709-8206

Adafruit TSL2591. (2023). https://www.berrybase.at/

adafruit-tsl2591-high-dynamic-range-digitaler-licht-

sensor

Araujo, A. C., Landon, Y., & Lagarrigue, P. (2021). Smart

drilling for Aerospace Industry: State of art in research

and education. Procedia CIRP, 99(March), 387–391.

https://doi.org/10.1016/j.procir.2021.03.105

Chen, Y. W., & Shiu, J. M. (2022). An implementation of

YOLO-family algorithms in classifying the product

quality for the acrylonitrile butadiene styrene

metallization. The International Journal of Advanced

Manufacturing Technology, 119(11–12), 8257–8269.

https://doi.org/10.1007/s00170-022-08676-5

Denkena, B., Bergmann, B., & Witt, M. (2019). Material

identification based on machine-learning algorithms for

hybrid workpieces during cylindrical operations.

Journal of Intelligent Manufacturing, 30(6), 2449–

2456. https://doi.org/10.1007/s10845-018-1404-0

Deshpande, S., Bouzid, A., Lagarrigue, P., Landon, Y., &

Araujo, A. C. (2023). Data maps for material

identification in helical milling by spindle power

monitoring. Procedia CIRP, 117, 1–6. https://doi.org/

10.1016/J.PROCIR.2023.03.002

Ding, Y., Kisner, H., Kong, T., & Thomas, U. (2020). Using

machine learning for material detection with capacitive

proximity sensors. IEEE International Conference on

Intelligent Robots and Systems, 10424–10429.

https://doi.org/10.1109/IROS45743.2020.9341016

Failing, J. M., Abellán-Nebot, J. V., Benavent Nácher, S.,

Rosado Castellano, P., & Romero Subirón, F. (2023). A

Tool Condition Monitoring System Based on Low-Cost

Sensors and an IoT Platform for Rapid Deployment.

Processes, 11(3). https://doi.org/10.3390/pr11030668

Han, H., & Jiang, X. (2014). Overcome Support Vector

Machine Diagnosis Overfitting. Cancer Informatics,

13s1, CIN.S13875. https://doi.org/10.4137/cin.s13875

Joblib. (2023). https://joblib.readthedocs.io/en/stable/

Koujelev, A., Sabsabi, M., Motto-Ros, V., Laville, S., &

Lui, S. L. (2010). Laser-induced breakdown

spectroscopy with artificial neural network processing

for material identification. Planetary and Space

Science, 58(4), 682–690. https://doi.org/10.1016/

j.pss.2009.06.022

Lutz, B., Kisskalt, D., Regulin, D., Hauser, T., & Franke, J.

(2021). Material identification for smart manufacturing

systems: A review. In Proceedings - 2021 4th IEEE

International Conference on Industrial Cyber-Physical

Systems, ICPS 2021 (pp. 353–360). https://doi.org/10.

1109/ICPS49255.2021.9468191

Ma, S., Li, Y., & Peng, Y. (2023). Spectroscopy and

computer vision techniques for noninvasive analysis of

legumes: A review. Computers and Electronics in

Agriculture, 206, 107695. https://doi.org/10.

1016/j.compag.2023.107695

Matplotlib. (2023). https://matplotlib.org/

Nakayama, Y., Yata, K., & Aoshima, M. (2017). Support

vector machine and its bias correction in high-

dimension, low-sample-size settings. Journal of

Statistical Planning and Inference, 191, 88–100.

https://doi.org/10.1016/j.jspi.2017.05.005

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

234

NumPy. (2023). https://numpy.org/

Pandas. (2023). https://pandas.pydata.org/

Pease, S. G., Conway, P. P., & West, A. A. (2017). Hybrid

ToF and RSSI real-time semantic tracking with an

adaptive industrial internet of things architecture.

Journal of Network and Computer Applications,

99(October), 98–109. https://doi.org/10.1016/j.

jnca.2017.10.010

Penumuru, D. P., Muthuswamy, S., & Karumbu, P. (2020).

Identification and classification of materials using

machine vision and machine learning in the context of

industry 4.0. Journal of Intelligent Manufacturing,

31(5), 1229–1241. https://doi.org/10.1007/s10845-019-

01508-6

Python. (2023). https://www.python.org/

Raspberry Pi 3. (2023). https://www.raspberrypi.com/

products/raspberry-pi-3-model-b/

Rodriguez-Pérez, R., Vogt, M., & Bajorath, J. (2017).

Support vector machine classification and regression

prioritize different structural features for binary

compound activity and potency value prediction. ACS

Omega, 2(10), 6371–6379. https://doi.org/10.1021/

acsomega.7b01079

Scikit-learn. (2023). https://scikit-learn.org/stable/

Scotter, C. N. G. (1997). Non-destructive spectroscopic

techniques for the measurement of food quality. Trends

in Food Science and Technology, 8(9), 285–292.

https://doi.org/10.1016/S0924-2244(97)01053-4

Seaborn. (2023). https://seaborn.pydata.org/

Siemens AG. (2023). SIMATIC S7-1500 - SIMATIC

Controller - Deutschland. https://www.siemens.

com/de/de/produkte/automatisierung/systeme/industrie

/sps/simatic-s7-1500.html

SparkFun Electronics ®. (2023). SparkFun Triad

Spectroscopy Sensor. https://www.sparkfun.com/

products/15050

Van Den Broek, W. H. A. M., Wienke, D., Melssen, W. J.,

& Buydens, L. M. C. (1998). Plastic material

identification with spectroscopic near infrared imaging

and artificial neural networks. Analytica Chimica Acta,

361(1–2), 161–176. https://doi.org/10.1016/S0003-

2670(98)00012-9

Vašková, H. (2011). A powerful tool for material

identification: Raman spectroscopy. INTERNATIONAL

JOURNAL OF MATHEMATICAL MODELS AND

METHODS IN APPLIED SCIENCES, 5(7).

Voltcraft LX-10. (2023). https://www.conrad.at/de/p/

voltcraft-lx-10-luxmeter-0-199900-lx-1662853.html?r

efresh=true

Vu, T.-T.-H., Pham, D.-L., & Chang, T.-W. (2023). A

YOLO-based Real-time Packaging Defect Detection

System. Procedia Computer Science, 217(2022), 886–

894. https://doi.org/10.1016/j.procs.2022.12.285

Winters-Hilt, S., Yelundur, A., McChesney, C., & Landry,

M. (2006). Support Vector Machine implementations

for classification & clustering. BMC Bioinformatics,

7

(SUPPL.2), 1–18. https://doi.org/10.1186/1471-2105-

7-S2-S4

Zheng, L., Wang, X., Wang, Q., Wang, S., & Liu, X.

(2021). A Fabric Defect Detection Method Based on

Improved YOLOv5. 2021 7th International Conference

on Computer and Communications, ICCC 2021, 620–

624. https://doi.org/10.1109/ICCC54389.2021.

9674548

This research is part of the project "IntelliProPS - AI-

supported planning and control for customer-

specific and multi-variant series production"

(FFG Nr. 898071) which was funded by the

Austrian Research Promotion Agency (FFG).

Real-Time Material Identification Using Light Spectroscopy and Support Vector Machine (SVM)

235