Superposition and Decomposition Analysis of Limbs’ Vibration

Based on 6-UPS Tibia Fracture Reduction Surgical Robot

Zhenyi Wang, Hongjian Yu

*

,

Xiangyu Shen, Dongru Xie, Hao Wang and Zhijiang Du

State Key Laboratory of Robotics and Systems, Harbin Institute of Technology, Harbin, China

Keywords: 6-UPS Parallel Robot, Tibial Fracture Reduction Robot, Linear Vibration Units, Vibration Analysis,

Dynamics Analysis.

Abstract: This article establishes the inverse kinematic model and forward kinematic model of the 6-UPS Stewart

platform. Based on the existing 6-UPS tibial fracture reduction robot, the characteristics of the linear

vibration unit and its installation on the robot limbs are analyzed. Under the condition that the moving

platform outputs vibration along the force line direction, the superposition conditions of vibration in each

limb are verified through forward kinematics, and the basic conditions for vibration synthesis are solved.

Then, based on inverse kinematics, the desired vibration of the moving platform is decomposed to obtain

the vibration equations that need to be output by the linear vibration units on each limb. Finally, combined

with the Newton-Euler method, the robot dynamics are analyzed, and the model is imported into ADAMS

for simulation verification, providing a theoretical basis for realizing the rehabilitation function of the 6-

UPS tibial fracture reduction robot by adding linear vibration units.

1

INTRODUCTION

In recent years, the incidence of traumatic

orthopedic diseases has increased. The fracture

reduction surgery robot system can assist doctors in

better realizing the accurate planning and real-time

guidance of fracture reduction so that patients have

better reduction results. The existing fracture

reduction surgery robot mainly focuses on the

reduction function (Ye, 2012). Ralf Westphal et al.

from Germany developed a surgical reduction robot

system for long bone fractures (Westphal R -

Liodakis E). The robot adopts a typical industrial

robot structure to operate on the fractured part of the

patient. Terry K.K. Koo et al. proposed a computer-

assisted fracture reduction method in 2006, which

was powered by a unilateral external fixator to

reduce long bone fractures (Koo, 2006). Hu Lei's

team from Beihang University and the Chinese

People's Liberation Army General Hospital jointly

developed a fracture reduction robot system for the

lower extremity tibia (Li C, 2016). However, the

above studies do not consider postoperative

rehabilitation. Cai Chenxu's research on mechanical

vibration promoting bone cell growth shows that

low-amplitude high-frequency vibration, as a non-

invasive and safe treatment method, can effectively

shorten fracture healing time, promote fracture

healing, and have good effects on early-stage

fracture healing (Cai C, 2023). But there has been no

suitable solution for effectively combining fracture

reduction with functional rehabilitation.

This article presents the inverse kinematic model

and forward kinematic model for the 6-UPS Stewart

platform. It analyzes the characteristics of a linear

vibration unit and its installation on a 6-UPS tibial

fracture reduction robot. The article verifies the

superposition conditions of vibration in each limb

through forward kinematics when the moving

platform outputs vibration along the force line

direction. It solves the basic conditions for vibration

synthesis. Using inverse kinematics, the desired

vibration of the moving platform is decomposed to

determine the vibration equations that need to be

output by the linear vibration units on each limb.

The robot dynamics are then analyzed using the

Newton-Euler method and the model is simulated

and verified in ADAMS. The findings provide a

theoretical basis for incorporating linear vibration

units to achieve the rehabilitation function of the 6-

UPS tibial fracture reduction robot.

86

Wang, Z., Yu, H., Shen, X., Xie, D., Wang, H. and Du, Z.

Superposition and Decomposition Analysis of Limbs’ Vibration Based on 6-UPS Tibia Fracture Reduction Surgical Robot.

DOI: 10.5220/0012274600003807

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Seminar on Artificial Intelligence, Networking and Information Technology (ANIT 2023), pages 86-92

ISBN: 978-989-758-677-4

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

2

KINEMATIC ANALYSIS OF

THE STEWART PLATFORM

2.1 Inverse Kinematics of the Stewart

Platform

Simplifying the 6-UPS fracture reduction surgical

robot shown in Fig. 1, we obtain the robot

coordinate system depicted in Fig. 2, where the

hinge points on the moving and static platforms are

positioned on two planes. The hinge points of the

static platform are represented by 𝐵

𝑖1,2, ⋯,6

,

the hinge points of the moving platform are

represented by𝐴

𝑖1,2, ⋯,6

.

Then the coordinates of the hinge point on the

fixed platform in the fixed coordinate system can be

expressed as:

𝐵

𝑏

𝑏

0

𝑅

cos𝜑

R

sin𝜑

0

𝑖1

,

2

,

⋯

,

6

(1)

Then the coordinates of the hinge point on the

moving platform in the moving coordinate system

can be expressed as:

𝐴

𝑎

𝑎

0

𝑅

cos

𝜑

R

sin

𝜑

0

𝑖1

,

2

,

⋯

,

6

(2)

The pose of the moving platform relative to the

fixed platform is represented by a homogeneous

transformation matrix 𝑇:

(3)

Figure 1: Robot Integration Diagram.

The expression of hinge point coordinates in the

static coordinate system is as follows:

𝐴

𝑃𝑅⋅ 𝐴

(4)

Figure 2: Coordinate System of Stewart Platforms.

The rod length of each drive rod of a parallel robot

can be expressed as:

𝐿

𝑛

→

𝑃

𝑅⋅ 𝐴

−𝐵

(5)

In the equation:

𝑛

⃗

—— the direction vector of the drive rod𝐵

𝐴

;

𝐿

——The length of the drive rod

𝐵

𝐴

.

The inverse expression that can obtain the robot rod

length is:

𝑙

|

𝐴

𝐵

|

𝑃

𝑅⋅ 𝐴

−𝐵

(6)

The specific expression of the inverse rod length

can be obtained:

(7)

2.2 Positive Kinematics of the Stewart

Platform

To improve the operation speed of kinematics when

controlled by parallel robots, the solution of positive

kinematics is iteratively solved by Newton's method

(Liang, 2022).

For a given pose of a parallel robot 𝑞

𝑥

𝑦

𝑧

𝛼𝛽𝛾

, the inverse kinematics

equation can be converted to:

(8)

Combine the equations of the six rods to get a

system of equations:

𝐹𝑞

𝑓

𝑞

𝑓

𝑞

𝑓

𝑞

𝑓

𝑞

𝑓

𝑞

𝑓

𝑞

0

(9)

𝑇=

𝑐𝑜𝑠𝛽𝑐𝑜𝑠𝛾 𝑠𝑖𝑛𝛼𝑠𝑖𝑛𝛽𝑐𝑜𝑠𝛾−𝑐𝑜𝑠𝛼𝑠𝑖𝑛𝛾 𝑐𝑜𝑠𝛼𝑠𝑖𝑛𝛽𝑐𝑜𝑠𝛾+ 𝑠𝑖𝑛𝛼𝑠𝑖𝑛𝛾 𝑥

0

𝑐𝑜𝑠𝛽𝑠𝑖𝑛𝛾 𝑠𝑖𝑛𝛼𝑠𝑖𝑛𝛽𝑠𝑖𝑛𝛾+ 𝑐𝑜𝑠𝛼𝑐𝑜𝑠𝛾 𝑐𝑜𝑠𝛼𝑠𝑖𝑛𝛽𝑠𝑖𝑛𝛾−𝑠𝑖𝑛𝛼𝑐𝑜𝑠𝛾 𝑦

0

−𝑠𝑖𝑛𝛽 𝑠𝑖𝑛𝛼𝑐𝑜𝑠𝛽 𝑐𝑜𝑠𝛼𝑐𝑜𝑠𝛽 𝑧

0

00 01

𝑙

𝑖

=

(𝑎

𝑥𝑖

𝑟

11

+ 𝑎

𝑦𝑖

𝑟

12

+ 𝑥

𝑝

−𝑏

𝑥𝑖

)

2

+(𝑎

𝑥𝑖

𝑟

21

+ 𝑎

𝑦𝑖

𝑟

22

+ 𝑦

𝑝

−𝑏

𝑦𝑖

)

2

+(𝑎

𝑥𝑖

𝑟

31

+ 𝑎

𝑦𝑖

𝑟

32

+ 𝑧

𝑝

)

2

𝑓

𝑖

(𝑞)=(𝑎

𝑥𝑖

𝑟

11

+ 𝑎

𝑦𝑖

𝑟

12

+ 𝑥

𝑝

−𝑏

𝑥𝑖

)

2

+. . (𝑎

𝑥𝑖

𝑟

21

+ 𝑎

𝑦𝑖

𝑟

22

+ 𝑦

𝑝

−𝑏

𝑦𝑖

)

2

+(𝑎

𝑥𝑖

𝑟

31

+ 𝑎

𝑦

𝑖

𝑟

32

+ 𝑧

𝑝

)

2

−𝑙

𝑖

2

=0 (𝑖=1⋯6)

Superposition and Decomposition Analysis of Limbs’ Vibration Based on 6-UPS Tibia Fracture Reduction Surgical Robot

87

Newton’s method for solving a system of

nonlinear equations can be expressed as:

𝑞

= 𝑞

−𝐹

’

(𝑞

)

𝐹(𝑞

) (10)

where 𝐹

’

(𝑞) is the equation derivation of each

element, which can be expressed as:

𝐹

′

(𝑞)=

⎣

⎢

⎢

⎢

⎢

⎢

⎡

()

()

⋯

()

()

()

⋯

()

⋮⋮⋱⋮

()

()

⋯

()

⎦

⎥

⎥

⎥

⎥

⎥

⎤

(11)

After giving the member length of the six rods of the

parallel robot, given the initial pose 𝑞

of the

iteration, and specifying the iteration accuracy 𝜀 and

the maximum number of iterations 𝑁, the posture

that meets the requirements is obtained through

iterative operation.

3

DYNAMICS ANALYSIS OF

6-UPS STEWART PLATFORM

The linear vibration unit can directly convert

electrical energy into mechanical energy, driving the

spring-mass block for linear motion, and avoiding

radial vibrations. It provides delicate vibrations, fast

startup speed, controllable direction, and obvious

advantages. It is suitable for use as a vibration unit

in fracture rehabilitation. Its internal structure is

shown in

Fig. 3

. We can design a flange fixture as

shown in

Fig. 4

to install the linear vibration motors

in the limbs. As shown in

Fig. 5

, we have installed

the motors fixture designed in the limbs.

The general idea of using the Newton-Euler

method to establish the dynamic model of the 6-UPS

platform is: assuming that the motion acceleration

and angular acceleration of the required upper

platform are known, the vector relationship in the

fixed coordinate system is represented by the

rotation matrix and the coordinate transformation

matrix; Through the analysis of the kinematics and

dynamics of the outrigger, the Newton-Euler

dynamic equation of the outrigger is established, and

the force of each leg on the upper platform is

substituted into the Newton-Euler equation

established on the upper platform, and the closed-

loop dynamic equation of the entire platform is

simplified and finally obtained. Performing dynamic

analysis on a single rod as shown in Fig. 6.

Figure 3: Internal Structure of Linear Motor.

Figure 4: Linear Motor Connectors.

Figure 5: Linear Motor Physical Object.

Figure 6: Single Branch Limb Force Analysis.

Taking the first 𝑖leg as the research object, the force

analysis is shown in Figure 2, and the force balance

equation is as follows:

𝑚

𝑠

⋅𝑎

= 𝐹

+ 𝑚

𝑠

⋅𝑔−𝑓

,(𝑖=1,⋯,6) (12)

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

88

In the equation:𝐹

is the driving force of the limb

motor end; 𝑚

is the mass of the limb pusher; 𝑠

is

the direction vector of the limb; 𝑔 is the

gravitational acceleration; 𝑎

is the acceleration of

the pusher end of the limb; the force of the platform

on the limb is 𝑓

.

Taking the moving platform as the research

object, the dynamic equilibrium equation is:

𝑚

𝑎

= 𝑚

𝑔+ 𝐹

+

∑

𝑓

(13)

In the equation:𝑚

is the mass of the moving

platform; the center of mass acceleration of the

moving platform is; the external force acting on the

moving platform is 𝐹

. Substituting equation (12)

into equation (13), we obtain:

∑

𝐹

=

𝑚

𝛼

−𝑚

𝑔−𝐹

+

∑ (

𝑚

𝑠

⋅𝑎

−

𝑚

𝑠

⋅𝑔

)

(14)

Similar to force balancing, the moment balance

equation for the first limb is as follows:

(

𝑚

𝑟

+ 𝑚

𝑟

)

× 𝑔−𝐿

𝑠

× 𝑓

−𝑚

𝑟

⋅

𝑎

−𝜔

×

(

𝐼

+ 𝐼

)

−

(

𝐼

+ 𝐼

)

𝛼

−

𝜔

𝑚

𝑟

× 𝑎

=0 (15)

In the equation: 𝑚

is the mass at the motor end

of the limb; 𝐿

is the length of the limb motor end;

𝑟

and 𝑟

are position vectors from point 𝐵

to the

fixed part and the movable part of the motor,

respectively. 𝐼

and 𝐼

are the inertia matrices of

the fixed part and the movable part of the limb

around the point 𝐵

, respectively. 𝜔

and 𝛼

are the

angular velocity and angular acceleration of the

limb, respectively.

Taking the moving platform as the research

object, the moment balance equation of the moving

platform is listed:

𝐼

𝑎

+ 𝜔

×

(

𝐼

𝜔

)

−𝑀

−𝑟× 𝐹

=

∑

(

Rb

)

× 𝑓

(16)

In the equation: 𝑚

is the quality of the moving

platform; 𝐼

is the inertia matrix of the moving

platform; 𝑀

is the external moment acting on the

moving platform; 𝜔

, and 𝑎

are angular velocity

and angular acceleration of the moving platform; 𝑅

is the transformation matrix for the coordinate

system. Substituting equation (15) into equation

(16), we obtain:

∑

Rb

×

(

𝑚

𝑠

⋅𝑎

−𝑚

𝑠

⋅𝑔

)

+ 𝐼

𝑎

+

𝜔

× 𝐼

𝜔

−𝑀

−𝑟× 𝐹

=

∑

(

𝑅𝑏

)

× 𝐹

(17)

Combining the force balance equation (14) and

the moment equilibrium equation (17) gives a

dynamic equation of the following form:

𝐻⋅𝐹= 𝐾 (18)

In the equation :

(19)

(20)

4

SUPERPOSITION AND

DECOMPOSITION OF LIMB

VIBRATIONS

4.1 Superposition of Vibrations

After the completion of the fracture reduction

surgery, assuming the posture of the moving

platform is known, we can obtain the direction

vectors of the six branches. Based on the forward

kinematics model, assuming that the vibration

transmission time from the six branches to the

moving platform is the same, we multiply the

vibrations of the six branches by the decomposition

of the unit direction vectors of each branch. This

yields the vibrational components in the x, y, and z

directions. By representing these components in

three-dimensional space, we can observe the

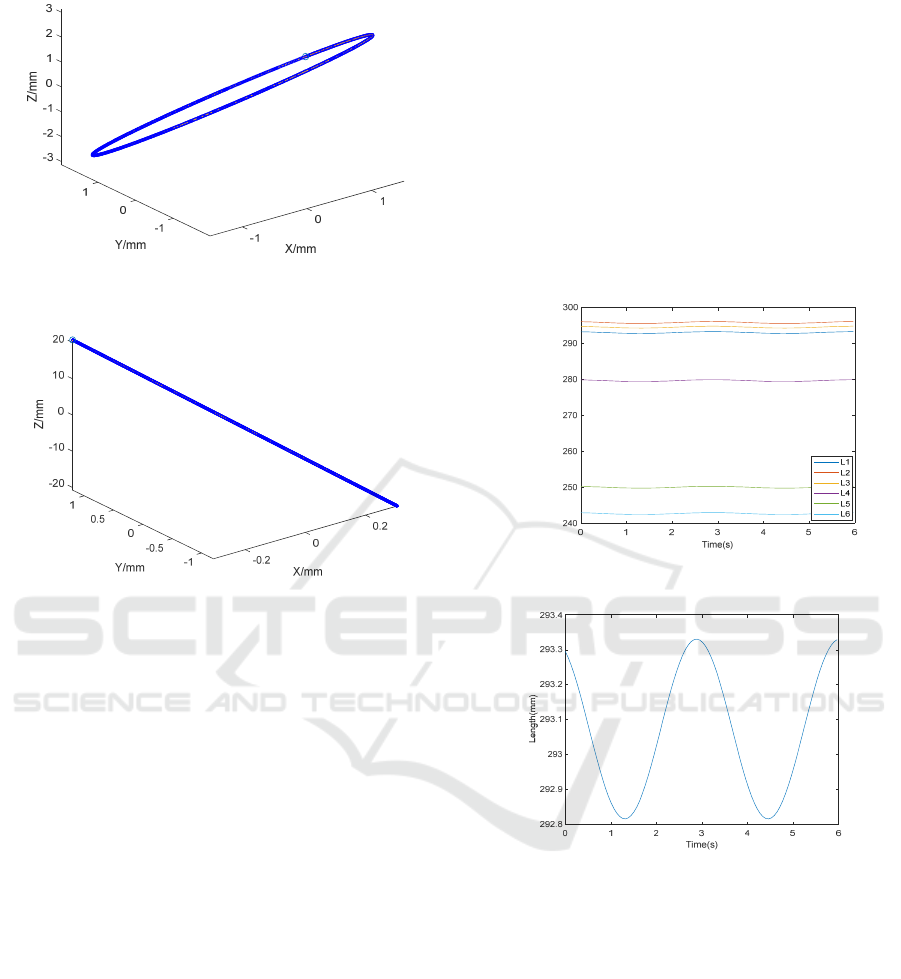

following laws as shown in Fig. 7.

Figure 7a: Frequency is different, but amplitude and phase

are the same.

𝐾=

⎣

⎢

⎢

⎢

⎢

⎡

𝑚

𝑝

𝑎

𝑝

−𝑚

𝑝

𝑔−𝐹

𝐸

+

(

𝑚

𝑢

𝑠

𝑖

⋅𝑔−𝑚

𝑢

𝑠

𝑖

⋅𝑎

𝑢𝑖

)

6

𝑖=1

𝑅𝑏

𝑖

×

(

𝑚

𝑢

𝑠

𝑖

⋅𝑎

𝑢𝑖

−𝑚

𝑢

𝑠

𝑖

⋅𝑔

)

+ 𝐼

𝑝

𝑎

𝑝

+ 𝜔

𝑝

× 𝐼

𝑝

𝜔

𝑝

−𝑀

𝐸

−𝑟× 𝐹

𝐸

6

𝑖=1

⎦

⎥

⎥

⎥

⎥

⎤

𝐻=

𝑠

1

𝑠

2

𝑠

3

𝑠

4

𝑠

5

𝑠

6

𝑏× 𝑠

1

𝑏

2

× 𝑠

2

𝑏

𝑏

× 𝑠

3

𝑏

4

× 𝑠

4

𝑏

5

× 𝑠

5

𝑏

𝑏

× 𝑠

6

Superposition and Decomposition Analysis of Limbs’ Vibration Based on 6-UPS Tibia Fracture Reduction Surgical Robot

89

Figure 7b: Phase is different but amplitude and frequency

are the same.

Figure 7c: Amplitude is different, but phase and frequency

are the same.

It can be seen from the analysis that if you want the

robot moving platform to vibrate in the direction of

the force line, it is necessary to control the vibration

phase and frequency of each limb consistently and

adjust the direction of vibration by changing the

amplitude. Calculating the amplitude of each limb

needs to use the previously derived inverse

kinematics formula.

4.2 Decomposition of Vibrations

Vibration decomposition assumes that the moving

platform vibrates along the direction of the force line

after fracture reduction. It decomposes the desired

linear vibration of the moving platform. One

approach is to move the moving platform a small

distance along the force line direction and then study

the coordinate changes of each branch, calculate the

distance between the hinge points of the moving

platform and the fixed platform, and observe the

changes in the length of the branches. Another

approach is to add the displacement of the moving

platform to the initial pose of the robot, substitute

the new pose into the previously calculated inverse

kinematics model, and calculate the difference

between the branches before and after to obtain the

change in rod length. The results obtained by these

two methods are consistent.

Pair pose X=2; Y=2; Z=2; ROLL=pi/15;

PITCH=pi/12; YAW=pi/18. To facilitate the

observation of the magnitude of the amplitude, we

adjust the amplitude to 1μm, assume that the

dynamic platform vibrates along the force line, and

its vibration equation is 0.001sin(2t+2*pi/3). The

rod length change of each rod calculated by the two

methods is shown in Fig. 8, and the vibration of a

single axis can be found to be close to sinusoidal, as

shown in Fig. 9.

Figure 8: The length of the six limbs varies.

Figure 9: The length of a single limb varies.

5

DYNAMIC SIMULATION

BASED ON ADAMS

Simplify the model and import it into ADAMS. Set

the material properties and designate the push rod as

the driver. Substitute the vibration equations of each

supporting branch obtained in the previous chapter

into the drivers of each rod. Conduct simulations and

measure the force status of each rod component to

obtain Fig. 10. Compare the results of dynamic

numerical calculations with the results obtained

from ADAMS simulations, as shown in Fig. 11. It

can be observed that the numerical calculations and

Length(mm)

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

90

Figure 10: ADAMS simulation interface and results.

Figure 11: Comparison between ADAMS simulation and numerical calculation..

Figure 12: The vibration conditions of each component

after ma

g

nification.

simulations yield similar results. Perform separate

analysis and comparison of the dynamic calculation

results for each bar, and obtain Fig. 12 . The

calculation results indicate that within a margin of

error not exceeding 0.7%, it can be reasonably

assumed that the model is accurate.

6

CONCLUSION

This paper establishes the inverse kinematic model

Superposition and Decomposition Analysis of Limbs’ Vibration Based on 6-UPS Tibia Fracture Reduction Surgical Robot

91

and forward kinematic model of the 6-UPS Stewart

platform to solve the vibration repair function

required for tibial fracture reduction in the current 6-

UPS robot. Based on the existing 6-UPS tibial

fracture reduction robot, the installation of the linear

vibration device on the limbs is analyzed. Under the

condition of force-line direction vibration output by

the motion platform, the synthesis of the limbs'

vibration is achieved through forward kinematics,

and the vibration conditions of each limb are

verified under different vibration conditions. If the

motion platform of the robot needs to undergo linear

vibration along the force line, it is necessary to

control the phase and frequency consistency of each

limb vibration and adjust only the amplitude to

change the vibration direction. Then, based on the

inverse kinematics, the linear vibration set on the

motion platform is decomposed, and the vibration

equation of the linear vibration unit installed on each

limb is obtained. Finally, based on the Newton-Euler

method, the analysis of the 6-UPS tibial fracture

reduction robot is completed, and the model is

validated using ADAMS. The calculation results

show that within an error range of not exceeding

0.7%, the model can be reasonably considered

accurate. This paper provides a theoretical basis for

improving the rehabilitation function of tibial

fracture reduction robot through vibration.

ACKNOWLEDGMENTS

This work was financially supported by the Key-

Area Research and Development Program of

Guangdong Province (No.2020B0909020002) and

Self-Planned Task (No.SKLRS202211B) of State

Key Laboratory of Robotics and System (HIT).

REFERENCES

Ye R, Chen Y, Yau W. A simple and novel hybrid robotic

system for robot-assisted femur fracture reduction[J].

Advanced Robotics, 2012, 26(1-2): 83-104.

https://doi.org/10.1163/ 016918611x607383

Westphal R, Winkelbach S, Gösling T, et al. A surgical

telemanipulator for femur shaft fracture reduction[J].

The International Journal of Medical Robotics and

Computer Assisted Surgery, 2006, 2(3): 238-

250.https://doi.org/10.1002/rcs.81

Westphal R, Winkelbach S, Wahl F, et al. Robot-

assisted long bone fracture reduction[J]. The

International Journal of Robotics Research, 2009,

28(10): 1259-1278. https://doi.org/10.1177/

0278364909101189

Oszwald M, Westphal R, Bredow J, et al. Robot‐

assisted fracture reduction using three‐dimensional

intraoperative fracture visualization: An experimental

study on human cadaver femora[J]. Journal of

Orthopaedic Research, 2010, 28(9): 1240-

1244.https://doi.org/10.1002/ jor.21118

Liodakis E, Chu K, Westphal R, et al. Assessment of the

accuracy of infrared and electromagnetic navigation

using an industrial robot: Which factors are influencing

the accuracy of navigation? [J]. Journal of Orthopaedic

Research, 2011, 29(10): 1476-

1483.https://doi.org/10.1002/jor.21429

Koo T K K, Chao E Y S, Mak A F T. Development and

validation of a new approach for computer-aided long

bone fracture reduction using unilateral external

fixator[J]. Journal of Biomechanics, 2006, 39(11):

2104-2112.

https://doi.org/10.1016/j.jbiomech.2005.06.002

Li C, Wang T, Hu L, et al. A novel master–slave

teleoperation robot system for diaphyseal fracture

reduction: a preliminary study[J]. Computer Assisted

Surgery, 2016, 21(sup1): 162-167.

https://doi.org/10.1080/24699322.2016.1240304

Cai C, Zheng X, Shi M, et al. Bone collision detection

method for robot assisted fracture reduction based on

vibration excitation[J]. Computer Methods and

Programs in Biomedicine, 2023, 229:

107317.https://doi.org/10.1016/j.cmpb.2022.107317

Liang F, Tan S, Zhao X, et al. Kinematics and Dynamics

Simulation of a Stewart Platform[C]. Journal of

Physics: Conference Series, 2022, 2333(1):012026.

https://doi.org/10.1088/1742-6596/2333/1/012026

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

92