Inventory Demand Prediction Based on Gated Recurrent Neural

Network and Fuzzy Time Series

Xin Wu

Zhongxun Post and Telecommunications Consulting and Design Institute, Chengdu, China

Keywords: Inventory Demand, Gated Recurrent Neural Network, Fuzzy Time Series.

Abstract: Current situation of auto parts inventory management based on VMI management mode, parts suppliers do

not fully consider the influence factors of the parts themselves and the vague external influence factors such

as environment, region and economy. To improve the forecasting accuracy of auto parts inventory demand,

this paper proposed a combined forecasting model based on advantage matrix combined with gated

recurrent neural network and fuzzy time series model (CRU_FTS_AM). Firstly, the gated recurrent neural

network (GRU) is used to learn the multi-dimensional features of auto parts. Then, fuzzy time series model

(FTS) is used to learn fuzzy and uncertain external factors that affects parts inventory demand. Finally,

obtains the optimal weight coefficient of a single model by introducing the advantage matrix, and forecasts

parts inventory demand through the weighted combined model. Compared with four models used in

previous studies on three real data sets, the experimental results show that the proposed model improves

RMSE by about 18%.

1

INTRODUCTION

The existing inventory management mode is mostly

VMI management mode, which breaks the

disadvantages of separate inventory management in

the traditional supply chain, and allows upstream

organizations to plan the inventory strategy and

ordering strategy of downstream organizations. The

supplier mainly analyzes the inventory and demand

data of downstream distributors, and then exercises

the decision-making power of inventory

management. It fully mobilizes the flexibility of the

supply chain and avoids the "bullwhip effect" caused

by the continuous amplification of market demand.

The setting of traditional inventory is often based

on the historical demand data of parts, the same

supply strategy is adopted for all dealers, and set

high safety inventory, resulting in a serious

inventory backlog of parts in the peak season of

vehicle sales. This not only increases inventory

costs, but also causes unnecessary losses due to parts

past their expiration dates. Reasonable inventory

settings help to improve customer satisfaction and

reduce capital costs, and inventory settings rely on

the prediction of inventory demand.

The demand of auto parts inventory will also be

affected by environmental, regional, economic and

other external factors, when a new product has just

been released or a certain type of vehicle sales surge,

the demand for related parts will increase, and the

demand for the same parts by dealers in different

regions is also different. Therefore, the study of auto

parts inventory needs to consider the influence of

both internal and external factors of auto parts.

The research on inventory demand forecasting is

as follows. Kumar et al. (A. Kumar, 2015] aiming at

the problem that traditional safety inventory setting

relies on random summation method with

excessively high data requirements, proposed to use

multiplication method to estimate variance without

specifying data relations in advance. Beutel et al. (A.

L. Beutel, 2012) proposed two ways to set safety

inventory, the first method is to use regression

model to predict inventory demand and use error to

set safety inventory, another method is to optimize

the target inventory function with linear

programming under different service level

constraints. Dennis et al. (P. Dennis, 2017) derived

the correct method for determining safety inventory

when the mean and variance of demand are

uncertain. Juan et al. (R. Juan, 2018) proposed the

kernel density estimation method and the

autoregressive conditional heteroscedasticity model

GARCH(1,1) to calculate the safety inventory. Liao

et al. (W. Z. Liao, 2020) proposed a spare parts

inventory forecasting method based on long and

172

Wu, X.

Inventory Demand Prediction Based on Gated Recurrent Neural Network and Fuzzy Time Series.

DOI: 10.5220/0012276800003807

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Seminar on Artificial Intelligence, Networking and Information Technology (ANIT 2023), pages 172-177

ISBN: 978-989-758-677-4

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

short term memory in order to predict spare parts

inventory. This method can accurately predict the

spare parts inventory with large amount of data and

short replacement cycle. Chen et al. (Y. Chen,

2010)

used auto-regressive moving average (ARMA)

model to forecast the demand for auto parts. Li et al.

(F. Li, 2023) proposed a point forecasting model

based on long short-term memory network and a

quantile forecasting model based on quantile Long

short-term memory, which captured the uncertainty

of sales and improved the accuracy of inventory

forecasting. Huo et al. (X. Huo, 2022) proposed an

inventory forecasting method G-FTS based on

gaussian mixture model and fuzzy time series (FTS).

Singh et al. (P. Singh,

2012) combined particle

swarm optimization with fuzzy time series model for

inventory forecasting. Erol et al. (E. Erol, 2012)

applied intelligent algorithms such as genetic

algorithm and artificial neural network to fuzzy time

series to forecast inventory demand. Zhang et al. (M.

Zhang, 2022) used histogram algorithm and gradient

one-sided sampling algorithm to reduce the number

of features, and used LightGBM model based on

bayesian optimization for coal inventory prediction.

Boukhtouta et al. (A. Boukhtouta, 2018) used the

support vector machine (SVM) method to predict

spare parts inventory requirements of the canadian

armed forces. Hasmin et al. (E. Hasmin, 2020) used

the double exponential smoothing method to predict

frozen food inventory demand. Cheng et al. (F.

Cheng, 2017) proposed a combined model of grey

correlation analysis and time series neural network.

Grey correlation analysis method is used to select

the influencing factors, and then inventory

forecasting is carried out by time series neural

network. Wang et al. (J. Wang, 2008) proposed a

combination model of support vector machine and

markov chain for supply chain inventory forecasting.

As can be seen from the existing related

research. (1) The forecasting model based on

mathematical theory and hypothesis has a simple

structure, which is difficult to describe the complex

changing trend of inventory demand, and cannot

fully obtain its inherent characteristics. (2) The

model is relatively single, regarding the different

characteristics of inventory demand forecasting

using the same kind of prediction method. (3)

Mainly consider the impact of single features, lacks

the consideration of multi-dimensional features.

Therefore, based on the characteristics of auto parts

inventory demand, this paper introduces the

advantage matrix combination gating recurrent

neural network and fuzzy time series model, which

can reflect the superposition influence of various

laws more comprehensively and improve the

accuracy of inventory demand prediction.

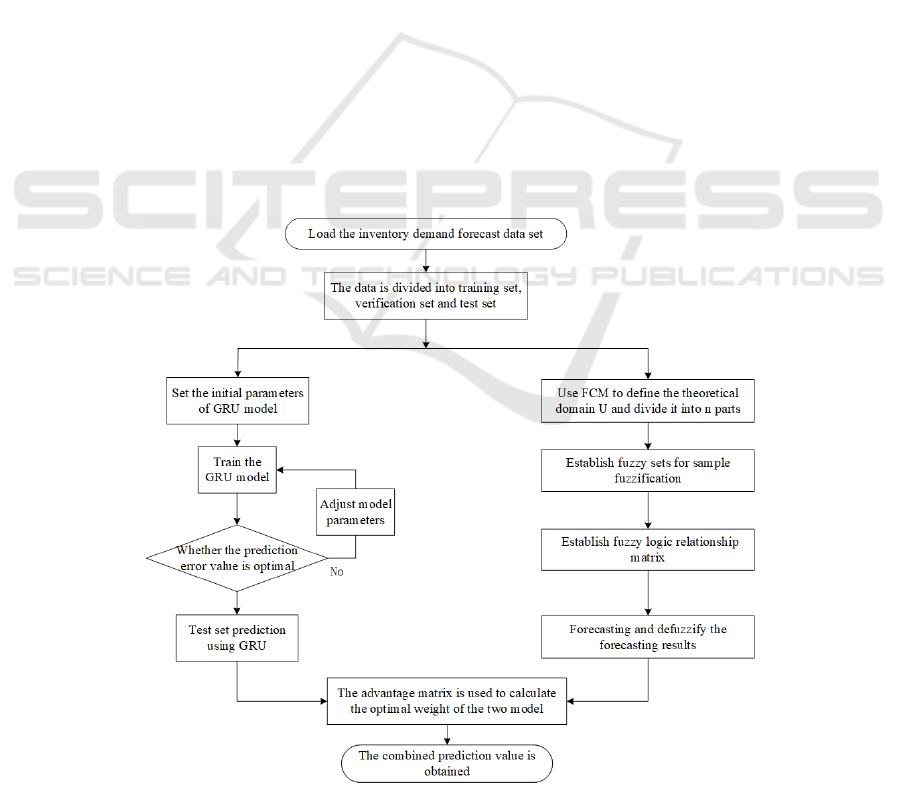

Figure 1: Frame diagram of GRU_FTS_AM combination model.

Inventory Demand Prediction Based on Gated Recurrent Neural Network and Fuzzy Time Series

173

2

PROPOSED MODEL

Based on VMI inventory management model, a

combination model of gated neural network and

fuzzy time series model based on advantage matrix

is proposed to forecast auto parts inventory demand

in multi-value chain. While fully considering

inventory influencing factors, the influence of

interference and parameter changes on forecasting

effect is reduced, and the robustness of forecasting

model is enhanced. The frame diagram of the

proposed model is shown as figure 1.

2.1 Gated Recurrent Neural Networks

Due to the large time interval for auto parts suppliers

to supply parts, the size of inventory demand data is

mostly small sample data and there are many factors

affecting inventory demand, so GRU model is used

to forecast. GRU, a variant of LSTM(K. Greff,

2016), was proposed by cho et al. (K. Cho, 2014) in

2014. It can not only solve the problem of gradient

disappearance in recurrent neural networks, but also

has higher computational efficiency, simpler

structure and better prediction effect for small data

sets. GRU has two gates, one is the update gate,

which mainly controls how much state information

is saved at the previous time. The second is the reset

door, which mainly controls how much information

needs to be forgotten. The operation process of GRU

is shown in equations (1) - (4).

𝑧

= 𝑠𝑖𝑔𝑚𝑜𝑖𝑑

𝑊

·

ℎ

· 𝑥

+ 𝑏

(1)

𝑟

= 𝑠𝑖𝑔𝑚𝑜𝑖𝑑(𝑊

·[ℎ

· 𝑥

]+𝑏

)

(2)

ℎ

= 𝑡𝑎𝑛ℎ(𝑊

·

[

𝑟

∗ℎ

· 𝑥

]

+ 𝑏

) (3)

ℎ

=

(

1 −𝑧

)

∗ℎ

+ 𝑧

∗ℎ

(4)

𝑧

is the update gate, 𝑟

is the reset gate, ℎ

is

the activation status at time 𝑡−1, 𝑥

is the input

value at time 𝑡. 𝑊

, 𝑊

, 𝑊

, represents the

parameters in the training process, ℎ

is the state at

time t, "·" represents the multiplication of matrix

sample points, "*" represents the multiplication of

matrices, 𝑠𝑖𝑔𝑚𝑜𝑖𝑑 and 𝑡𝑎𝑛ℎ are activation function.

2.2 Fuzzy Time Series

There are many factors that affect the inventory

demand, among which the inaccurate and ambiguous

phenomena such as environment, region and

economy cannot be described by accurate data. To

overcome these defects, fuzzy time series model is

used to forecast inventory demand. Fuzzy sets can

effectively reflect the continuous transition state

between objects, and have natural advantages in

dealing with fuzzy small sample data. Fuzzy time

series model can reduce the influence of interference

and parameter change on prediction effect, enhance

the robustness of prediction model, and make

effective prediction while learning the uncertainty of

data set. The general prediction steps of fuzzy time

series are as follows. (1) Determine and divide the

theoretical domain. (2) Fuzzify the actual data. (3)

Establish fuzzy relationship. (4) Defuzzifying the

predicted value.

1) Determine and divide the theoretical domain

Divide the theoretical domain U=[ 𝐷

- 𝐷

,

𝐷

+𝐷

], 𝐷

and 𝐷

are the maximum and

minimum values of the historical time series dataset

{ 𝑥

, 𝑥

,..., 𝑥

}, respectively. FCM (K. Li, 2009)

algorithm is used to calculate membership degree

and find cluster center {𝑐

, 𝑐

,...,𝑐

}, then divide the

domain of discourse, where 𝐷

=

, 𝐷

=

.

Finally, the domain of theoretical is divided into n

subintervals {𝑢

, 𝑢

,…𝑢

}.

2) Fuzzify the actual data

Data fuzzification, based on the subintervals

{ 𝑢

, 𝑢

,… 𝑢

}. The fuzzy sets defined on the

theoretical domain is shown as follows.

𝐴

=

(

)

+

(

)

+ ⋯+

(

)

(5)

Where, k =1,2,...,n . 𝑓

is the membership

function of the fuzzy set 𝐴

, 𝑓

(𝑢

) represents the

membership value belonging to the fuzzy set,

𝑓

(𝑢

)∈[0,1].

3) Establish fuzzy relationship

Form fuzzy relation based on the calculated fuzzy

sets, and then establish a fuzzy matrix. Let the first-

order fuzzy relation 𝐴

be obtained by 𝐴

, and

their fuzzy relation be expressed as 𝑅

(

𝑘, 𝑘−1

)

,

therefore 𝐴

= 𝐴

· 𝑅(𝑘, 𝑘−1) , Let 𝑅(𝑘, 𝑘−1)

be 𝑟

,

, the calculation formula of fuzzy relation

matrix R is as follows.

R=

𝑟

…

𝑟

…

𝑟

𝑟

……

𝑟

…

…

𝑟

(6)

4) Defuzzifying the predicted value

The predicted value is obtained by defuzzification. If

the membership degree value of the fuzzy prediction

has only one maximum value, the center of the

cluster is selected as the predicted value of the

defuzzification. If the membership degree value of

the fuzzy prediction has two or more maximum

values, the arithmetic mean value of the

corresponding cluster center is selected as the

defuzzification prediction value, set 𝑓

(𝑢

)= 𝑓

, as

shown in equation (7).

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

174

𝐹

(

𝑖+1

)

=

∑

𝑐

(𝑓

∑

𝑓

⁄

)

(7)

Where, 𝐹

(

𝑖+1

)

is the predicted value, 𝑐

is the

center value of the interval, also the midpoint of 𝐴

.

2.3 Advantage Matrix

The commonly used methods of combination

prediction model include least square method, voting

method, weighted average method, etc. (L. W. Ling,

2019) .In this paper, Advantage matrix (Y. L. Bai,

2020) is used to determine the weight coefficients of

a single prediction model. Assuming that there are

two prediction models 𝑚

and 𝑚

, a single model is

trained separately to obtain the predicted value, and

then a comparison matrix of model prediction error

is established according to the calculated RMSE of

prediction, as shown in equation (8).

𝑅𝑀𝑆𝐸

𝑅𝑀𝑆𝐸

𝑅𝑀𝑆𝐸

𝑅𝑀𝑆𝐸

…

𝑅𝑀𝑆𝐸

…

𝑅𝑀𝑆𝐸

(8)

According to the error comparison matrix,

advantage matrix can be obtained, if 𝑅𝑀𝑆𝐸

less

than 𝑅𝑀𝑆𝐸

, 𝑅𝑀𝑆𝐸

is 1, otherwise it is 0. If the

two errors are equal, it is 0.5. The advantage matrix

is shown in equation (9).

1

1

0

0

…

0

…

1

(9)

Then calculate the weight coefficients of 𝑚

and

𝑚

, where 𝑛 is the number of rows of the matrix, 𝑛

is the sum of the first column of the advantage matri

x, and 𝑛

is the sum of the second column of the adv

antage matrix. The calculation formula is as follows.

𝑤

=

(10)

𝑤

=

(11)

Let 𝑦

(t=1,2,3,…,n) represents the predicted value

at time 𝑡, then the weighted combined predicted valu

e of the two models based on the dominance matrix i

s as follows.

𝑦

=

∑

𝑤

∗𝑦

+ 𝑤

∗𝑦

(12)

The GRU_FTS_AM algorithm is as follows.

Model GRU_FTS_AM

Input

Parts stock demand forecast datasets X={𝑥

, 𝑥

,…,𝑥

};

Output

Parts stock demand forecast value 𝑦

;

1 Load X;

2 Initialize GRU;

3 Execute GRU use equations(1)-(4);

4

Save 𝑦

;

5 Preprocess X;

6 Using FCM algorithm to divide the domain;

7 Fuzzify the data use equation(5);

8 Establish the fuzzy relationships use equation(6);

9 Defuzzify the forecasting results use equation(7);

10

Save 𝑦

;

11

Calculate 𝑦

use equations(8)-(12);

12

Return 𝑦

;

3

EXPERIMENT

This paper takes the multi-value chain data of 𝐴

automobile manufacturing as the experimental data

set, takes the parts suppliers as the research object,

and uses three real data sets of "transmission

components", "radiator assembly" and "license

mounting plate" supplied by them for example

analysis and model comparison. Due to the large

time interval of parts supply, the fitting is processed

in months, the time range is from January 2017 to

December 2021, and the training set and test set are

divided according to 8:2. The influencing factors of

auto parts inventory demand mainly come from the

part itself. Based on the real data of parts and the

existing research literature, the three influencing

factors of historical sales data of part, vehicle

ownership of part and life of part are selected.

"License mounting plate" part of the data set are as

shown in table 1.

Table 1: "License mounting Plate" part dataset.

Date

Historical

sales data

Total vehicle

ownership

Life

span

January 2017 3275.00 167.4 3.7

February 2017 3740.00 169.8 4.2

March 2017 3560.00 172.3 3.8

… … … …

December 2021 4001.00 281.2 3.4

In this paper, root mean square error, mean

absolute error and coefficient of determination are

used as the evaluation indicators of the model. The

formulas are as follows:

(1) Root Mean Square Error:

RMSE =

∑

(𝑌

−𝑌

)

(13)

(2) Mean Absolute Error:

MAE =

∑

|𝑌

−𝑌

|

(14)

(3) R-squard:

𝑅

=1−

∑

(

)

∑

(

)

(15)

Where, 𝑌

is the real inventory demand, 𝑌

is the

forecast inventory demand. RMSE and MAE

calculate the prediction error, the smaller the value,

the smaller the error from the true value. 𝑅

calculate the correlation coefficient, the larger the

value, the more representative the real data.

After experiments, the optimal parameters of the

GRU model are shown in the table 2. The historical

sales data of auto part is used as the input of FTS

model, and fuzzy C-means clustering algorithm with

Inventory Demand Prediction Based on Gated Recurrent Neural Network and Fuzzy Time Series

175

cluster center 16 is used to divide the theoretical

domain.

Table 2: The parameters of the GRU.

Paramete

r

Optimal Value

Hidden laye

r

1

Units 8

Time steps 4

Batch size 4

Epochs 50

In order to verify the rationality of

GRU_FTS_AM model, it was compared with GRU,

FTS (X. Huo, 2022), SVM (Boukhtouta, 2018) and

ARMA(Y. Chen,

2010) prediction models. Based on

the 12 months starting from 2021 of the

"Transmission components" dataset, the weight

coefficient of GRU and FTS is 0.589 and 0.411,

respectively, calculated by the advantage matrix.

Based on the 12 months starting from 2021 of the

"Radiator Assembly" dataset, the weight coefficient

of GRU and FTS is 0.624 and 0.376, respectively,

calculated by the advantage matrix. Based on the 12

months starting from 2021 of the "License mounting

plate" dataset, the weight coefficient of GRU and

FTS is 0.547 and 0.453, respectively, calculated by

the advantage matrix. The experimental results are

shown in the figure 2.

As can be seen from the figure 2, the red line is

the prediction result of GRU_FTS_AM. Where the

prediction error of GRU and FTS models is large,

GRU_FTS_AM can achieve better prediction

results. In order to further understand the prediction

accuracy of each model, the three evaluation

indicators proposed above are used for evaluation.

Table 3: Error comparison between different models.

Model

“Transmission

component”

“Radiator assembly”

“License mounting

p

late”

RMSE MAE

𝑅

RMSE MAE

𝑅

RMSE MAE

𝑅

ARMA 247 154 0.752 186 122 0.741 416 224 0.786

SVM 208 128 0.851 138 83 0.881 312 189 0.861

GRU 187 113 0.874 132 81 0.887 284 168 0.887

FTS 212 132 0.846 146 91 0.869 302 187 0.873

GRU_FTS_A

M

171 106 0.915 126 75 0.904 267 152 0.907

It can be seen from the evaluation results in the

table 3 that the GRU_FTS_AM model is better than

the other four prediction models in the three

evaluation indicators of RMSE, MAE and 𝑅

. The

experiment proves that GRU_FTS_AM model can

effectively and fully consider the influencing factors

of parts inventory demand, and improve the

forecasting accuracy of parts inventory demand.

4

CONCLUSION

Based on the VMI inventory management mode, this

paper takes the auto parts suppliers as the research

object, fully considers the influencing factors of

inventory demand, and proposes the GRU_FTS_AM

combination forecasting model.

(a) (b)

(c)

Figure 2: Values predicted by different models.

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

176

The model uses GRU to learn the internal

features of auto parts and FTS to learn the fuzzy

external features of parts inventory, which not only

improves efficiency but also has a simple structure.

Finally, the validity of the GRU_FTS_AM model

was verified through three data sets. Compared with

the four existing single prediction models, the

prediction accuracy of GRU_FTS_AM model is

significantly improved in each evaluation index.

REFERENCES

A. Kumar, P. T. Evers. Setting Safety Stock Based on

Imprecise Records[J]. International Journal of

Production Economics, 2015, 169:S09. https://doi.org/

10.1016/j.ijpe.2015.07.018

A. L. Beutel, S. Minner. Safety Stock Planning under

Causal Demand Forecasting[J]. International Journal

of Production Economics, 2012, 140(2): 637-645.

https://doi.org/10.1016/j.ijpe.2011.04.017

P. Dennis, R. Teunter, A. Syntetos. On the Calculation of

Safety Stocks When Demand is Forecasted[J].

European Journal of Operational Research, 2017,

256(2). https://doi.org/ 10.1016/j.ejor.2016.06.035

R. Juan, Trapero, M. Cardós, N. Kourentzes. Empirical

Safety Stock Estimation Based on Kernel and GARCH

Models[J]. Omega, 2018, 32(06):91-98.

https://doi.org/ 10.1016/j.omega.2018.05.004

W. Z. Liao, G. L. Ye, Y. C. Yin, et al. The inventory of

spare parts Prediction Based on LSTM for large data

and a short replacement cycle[J]. IEEE International

Conference on Computer Systems and Applications,

AICCSA, 2020, 1-5. https://doi.org/10.1109/

AICCSA50499.2020.9316488

F. Li, L. Sun, N. Kong, H. Zhang and L. Mo. Sales

Forecasting Method for Inventory Replenishment

Systems of Vehicle Energy Stations Without

Stockouts[J]. in IEEE Transactions on Engineering

Management, 2023, 1-13. https://doi.org/10.

1109/TEM.2023.3274544

X. Huo, K. Hao, L. Chen, X. Cai, X. Liu and L. Ren.

Missing Data Dynamic Forecasting of Fuzzy Time

Series Based on Gaussian Mixture Model[C]. 2022

IEEE International Symposium on Advanced Control

of Industrial Processes, 2022, 222-227. https://

doi.org/10.1109/AdCONIP55568.2022.9894178

P. Singh, B. Borah. Forecasting stock index price based on

M-factors fuzzy time series and particle swarm

optimization[J]. International Journal of Approximate

Reasoning, 2014, 55(3):812-833. https://doi.org/10.

1109/ComComAp.2012.6154806

E. Erol. A New Time-Invariant Fuzzy Time Series

Forecasting Method Based on Genetic Algorithm[C].

Advances in Fuzzy Systems, 2012(2012):2. https://

doi.org/10.1155/2012/785709

M. Zhang, Y. Song, Z. Zhang and L. Lu. Power Plant Coal

Inventory Forecasting Based on LightGBM with

Bayesian Optimization[C]. 2022 5th International

Conference on Power and Energy Applications 2022,

560-565. https://doi.org/10.1109/ICPEA56363.2022.

10052407.

A. Boukhtouta and P. Jentsch,. Support Vector Machine for

Demand Forecasting of Canadian Armed Forces Spare

Parts[C]. 2018 6th International Symposium on

Computational and Business Intelligence (ISCBI), 2018,

59-64. https://doi.org/ 10.1109/ISCBI.2018.00021

E. Hasmin and N. Aini. Data Mining For Inventory

Forecasting Using Double Exponential Smoothing

Method[C]. 2020 2nd International Conference on

Cybernetics and Intelligent System (ICORIS), 2020, 1-5.

https://doi.org/ 10.1109/ICORIS50180.2020.9320765

F. Cheng and R. Sun. Inventory demand forecast based on

gray correlation analysis and time series neural network

hybrid model[C]. 2017 13th International Conference

on Natural Computation, Fuzzy Systems and Knowledge

Discovery, 2017, 2491-2496. https://doi.org/10.1109/

FSKD.2017.8393167

J. Wang, W. Zhu, D. Sun, and H. Lu. Application of SVM

Combined with Mackov Chain for Inventory Prediction

in Supply Chain[C]. In Wireless Communications,

Networking and Mobile Computing, 2008, 1-4.

https://doi.org/ 10.1109/WiCom.2008.1543

K. Cho, V. Merrienboer, C. Gulcehre, et al. Learning

Phrase Representations using RNN Encoder-Decoder

for Statistical Machine Translation[C]. Proceedings of

the 2014 Conf. on Empirical Methods in Natural

Language Processing. Doha, Qatar: Association for

Computational Linguistics, 2014: 1724-1734. https://

doi.org/10.3115/v1/D14-1179

K. Greff, R. K. Srivastava, J. Koutník, et al. LSTM: A

search space odyssey[J]. IEEE transactions on neural

networks and learning systems, 2016, 28(10): 2222-

2232. https://doi.org/10.1109/TNNLS.2016.2582924

K. Li, Z. Cao, L. Cao, and R. Zhao. A novel semi-

supervised fuzzy c-means clustering method[C].

Chinese Control and Decision Conference, 2009, 3761–

3765. https://doi.org/10.1109/CCDC.2009.5191706

L. W. Ling, D. D. Zhang. Summary of Research on

Construction Methods and Application of Combination

Forecasting Model[J]. Statistics and Decision, 2019, 35

(01): 18-23(in Chinese). https://doi.org/10.13546/j.cnki

.tjyjc.2019.01.004

Y. L. Bai, L. H. Tang, M. H. Fan, et al. Fuzzy First Order

Transition Rules Trained Hybrid Forecasting System for

Short Term Wind Speed Forecasts[J]. Energies, 2020,

13(13): 1-18. https://doi.org/10.3390/en13133332.

Y. Chen, H. Zhao, L. Yu. Demand Forecasting in

automobile Aftermarket Based on ARMA Model[C].

Proceedings in International Conf. on Management and

Service Science, 2010, 1-4. https://doi.org/10.1109/

ICMSS.2010.5577867

Inventory Demand Prediction Based on Gated Recurrent Neural Network and Fuzzy Time Series

177