Analysis of Finite Element Analysis of Steel Concrete Conversion

Beam Tip Node

Wenhua Liu

Fujian Chuanzheng Communications College, Fuzhou, China

Keywords: Type Steel Concrete Beam, Girder Tansfer, Finite Element Analysis.

Abstract: With the continuous expansion of my country's urban rail transit, the construction projects on the subway

have been widely used in recent years. The beam -type conversion structure is widely used in subway projects

due to its clear path transmission path, convenient construction, and low cost. The connection nodes of the

steel concrete conversion beam and wall of a project in this article are research objects. The ABAQUS

software analyzes the stress strain and deformation of the node. The results of the finite element analysis

indicate that the design of the type steel concrete conversion beam can meet the engineering needs. Some

suggestions on the measures for strengthening nodes are put forward, which can provide reference for similar

projects.

1 INTRODUCTION

In order to improve the utilization rate of urban land

and make full use of the subway vehicle section and

the upper space of the vehicle base, the converter

structure is usually used. The commonly used

conversion structures include beam -type conversion

and thick plate conversion. The beam -type

conversion is widely used in the subway projects due

to its clear path transmission path, convenient

construction, and low cost.

Based on a subway roof project, this paper uses

ABAQUS finite element analysis software to

calculate and analyze the connection joints of steel-

reinforced concrete transfer beams and frame-

supported wall columns. At the same time, according

to the stress-strain results calculated by ABAQUS,

some strengthening measures of transfer beams and

frame-supported wall columns are proposed.

2 PROJECT OVERVIEW

Fuzhou a metro covered with a layer of garages layer,

the cover of the next layer of the subway out of line,

the throat area, the run-time library and the

maintenance of the library, garage-layer upper for

residential layer or business layer it. The project

according to the vertical using functions from the

lower to the upper divided into: under the cover of

Metro operational layer, cover with a garage layers,

the upper portion of the residential layer or business

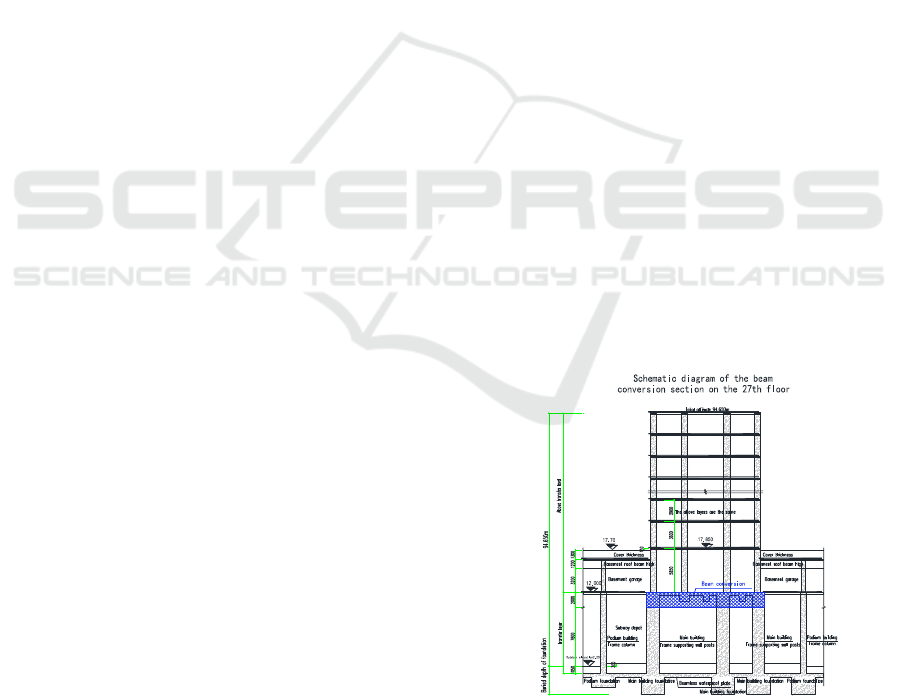

layer, the cross-sectional view is shown in Figure 1.

The project is a multi-column frame supported

shear wall structure, the Metro cover a total of 39,

building high-rise residential and other centralized

commercial and matching floor, the cover with a total

construction area of about 45208.6 Square meter. The

basis of the use of 800~1000 millimeter diameter of

the concrete strength for the C35 perfusion pile.

Figure 1. The structure cross-sectional view.

In order to meet cover the following functional

requirements, while ensuring that the structure is safe,

suitable, economically, the conversion layer using a

Liu, W.

Analysis of Finite Element Analysis of Steel Concrete Conversion Beam Tip Node.

DOI: 10.5220/0012285500003807

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Seminar on Artificial Intelligence, Networking and Information Technology (ANIT 2023), pages 437-441

ISBN: 978-989-758-677-4

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

437

Girder tansfer solution. Girder tansfer structure of the

power transmission path is clear, the construction is

convenient, the cost is relatively low (Wang C Y.-

Cheng X H).

Connection cover and under the cover of the

converted beam is passed loads of important

structural member, and the“strong node of the weak

member”so that the node design is especially

important.

3 FINITE ELEMENT MODELING

3.1 Conversion Member Location

Select

Selected to take the structure in the most adverse

conditions typical steel transfer beams and frame

branch wall column of connected nodes for ABAQUS

analysis and calculation, the conversion of the beam

position as shown in Figure 2 shown. Steel beam

cross-sectional dimensions as shown in Figure 3 is

shown for 1200x2000(300x1500x32x32), the most

unfavorable conditions of the beam span is 11. 4m.

Figure 2. Conversion of the beam position of the figure.

Figure 3: Conversion of the beam size chart.

3.2 Element Types and Meshing

Concrete using eight-node linear hexahedral elements

and reduced integration, hourglass control the format

of the three-dimensional solid elements (C3D8R)

were simulated. The longitudinal reinforcement and

stirrups of the selection of the two-node linear three-

dimensional Truss element T3D2 simulation. Type of

steel using tetrahedral shell element S4R simulation.

In the meshing is required prior to first determine

to meet the accuracy of the mesh density, the use of

finite element software to provide the structured

meshing technique for the finite element model for

cell division.The grid is divided as Figure 4 shows.

Figure 4. Meshing diagram.

3.3 Material Constitutive Relationship

Conversion beams concrete used C40 strength, in-

the-wall concrete used C30 strength, the elastic stage

of the Poisson's ratio υ 0. 2, the density is taken

2400kg/m

3

. Steel pipe adopts Q345, reinforced the

use of HRB400. The steel used to meet the Mises

yield criterion of the elastic-plastic model, the

concrete using shaping injury model.

Concrete consists of two types of concrete

components, one is the stirrups constraints of the

concrete, and another for the stirrups outside

unconstrained concrete, two types of inconsistent,

which means that the stress-strain relationship of the

model used must be targeted. Stirrups constraints

concrete takes into account the distribution of the

Hoop characteristic value of the concrete stress-strain

relationship model, the model of the mathematical

formulas expressed as follows (Qian J R - Han L H).

11-87.01/

10223

y

2

2.0

32

xxxBx

xxAxAAx

(1)

The formula parameters are defined in detail in the

literature (Han L H, 2016).

3.4 Contact Interface Analog

Through the Embedded region (built-in area of the

longitudinal reinforcement and stirrups of the steel

skeleton embedded into the concrete below. Steel

beams with lap walls of the node selected binding Tie)

constraints.

Steel and concrete between the along the normal

to the direction of use is considered normal contact

300

Steel reinforced

concrete beam

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

438

stress in the steel tube and the concrete completely

passed the“hard”contact, and by the force of the

process, allowing the steel and concrete in contact

with each other after separation; along the tangential

direction using the Coulomb friction model.

3.5 Boundary Conditions

The wall base is applied to the solid end of the

constraint, limiting its six directions of the degrees of

freedom. The walls of the ring to the constraint, floor

lateral support as a safety Reserve will not be

considered.

3.6 Load

Load: material parameters, beam, floor permanent

loads and variable loads are by design take the value

1.3 D+1.5 L; the weight of the load by density and

acceleration of gravity finish is applied; a conversion

layer of the upper shear wall load by extracting YJK

big shock to calculate the bottom of the column force

data obtained, regardless of the adjustment factors.

4 CALCULATION RESULTS

AND ANALYSIS

4.1 Concrete Stress Analysis

Figure 5 visible wall in concrete the maximum

compressive stress is 64.46MPa, is greater than the

concrete tensile strength design value, in the corner

near the place; the maximum tensile stress of

2.10MPa, is greater than the concrete compressive

strength design value, in the beams of the wall node

position.Figure 6 visible beam in concrete the

maximum compressive stress is 14.61MPa, less than

the concrete compressive strength design value; the

maximum tensile stress of 2.0MPa, is greater than the

concrete tensile strength design value, in the beams of

the wall node position. Concrete plastic strain as

shown in Figure 7, the maximum plastic strain value

is 0.0246, located in the beam and the wall at the

junction of the neighborhood. The maximum plastic

strain value is very small, the material does not occur

destroyed.

Figure 5. Wall in concrete stress cloud diagram.

Figure 6. Beams in concrete stress cloud diagram.

Figure 7. Concrete equivalent plastic strain figure.

4.2 Reinforced with Steel Stress

Analysis

Analysis of reinforced and steel using the Mises yield

criterion, i.e., the Fourth of the yield strength of the

theory.Figure 8 shows the type of steel, the maximum

stress is 345MPa, and the stress is mainly

concentrated in the beam bottom tension and

and frame branch wall connecting the nodes

around.Figure 9 visible reinforced the maximum

stress of 360 MPa, the mid-span position of the beam

and bottom beam surface of the longitudinal

reinforcement of a larger force, and frame branch wall

connected to the node position of the beam reinforced

by the force is also larger.Overall, the block support

walls and conversion beam connecting node of stress

throughout the stage are more than their yield stress.

Greater

than f

c

Greater

than f

t

Analysis of Finite Element Analysis of Steel Concrete Conversion Beam Tip Node

439

Figure 8. Type steel Mises stress cloud diagram

Figure 9. Reinforced Mises stress cloud diagram.

4.3 Summary

In the most unfavorable load combination, the

conversion beams and frame branch wall of the

connection node of the concrete local damage, the

concrete portion enters the plastic State, but the

magnitude is small. Steel and rebar are not the yield,

the structure is subjected to slight damage, the overall

node in the rare case of an earthquake under the force

of good performance, meet the needs of large

earthquakes do not pour the principles.

5 NODE PROCESSING

MEASURES

5.1 Frame Branch Wall Column and

the Conversion of Beam-Column

Node Practices

Follow the “strong node of the weak member”of the

principle of frame branch wall column and the

conversion of beam-column node to take the

corresponding reinforcement measures, steel beam

inside the steel and rebar connection sample detailed

in Figure 10, the frame supported the wall of the

column and convert the beam node a large sample

detailed in Figure 11.

Figure 10. A large section of steel beam.

Figure 11. Large sample of frame support wallcolumn and

transfer beam joint

5.2 Conversion Member Construction

Technical Measures

Steel splice should be member of the welding surface

of the oil, rust removal. Bear welding work, welder,

according to the leading industry standard for the

steel structural welding code stipulates that

certificates.

Steel structure installation should be strictly

according to the drawings specified axis and the

position of the positioning, force and holes should be

correct; the lifting process should use the relevant

equipment strict calibration of vertical, and timely

positioning. Installation of the vertical degree, field of

lifting the error range should be consistent with the

national standards of the steel structure engineering

construction quality acceptance criteria of GB50205

the provision.

Steel plate hole, you should use the factory lathe

prepared hole, forbidden to live with oxygen cutting

openings.

Pegs before welding, should be a member of the

welding surface of the oil, rust removal, welding

inspection after the peg height of the allowable

deviation should be within±2mm, at the same time,

according to the relevant provisions of the sampling

check its quality of welding.

Steel reinforced concrete member within the steel

without coating processing.

screw

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

440

6 CONCLUSIONS

The present text to a subway on the cover of the

project as the basis for steel reinforced concrete

transfer beams of the wall node to the ABAQUS finite

element calculation and analysis. Results showed that

the conversion of the beam and frame branch wall in

a large earthquake case of a partial concrete into a

plastic State, but the number was smaller, rebar and

steel are not to exceed the respective yield

stress.Verify in the most adverse conditions and still

maintain good mechanical performance, can meet

large earthquake conditions performance

requirements. This article for conversion beams and

frame branch wall design calculation of ideas and the

node processing measures may be for the same

project reference.

REFERENCES

Wang C Y. The Research and Contrast on RC 、 SRC

Transfer Beam and the Combined Action With Upper

Short-Pier Shear Wall (D). Xi'an University of

Architecture and Technology, 2009.

Dong K, Sun Y. Discussion on the practical design method

of girder transfer floor for high-rise

building(J).Industrial Construction, 2009, 39:265-269.

Cheng X H, Ma F .Beam Frame Supported Shear Wall

Structure Based on the ANSYS Finite Element Static

Analysis of Beam-Type Transfer Floor (J).Advanced

Materials Research, 2013, 788: 508-510.

https://doi.org/10.4028/www.scientific.net/AMR.788.5

08.

Qian J R, Cheng L R, Zhou D L. Behavior of axially loaded

concrete columns confined with ordinary hoops (J).

Journal of Tsinghua University: Natural Science Edition,

2002, 42(10):5.

Han L H. Concrete-filled Steel Tube Structure-Theory and

Practice (3rd Edition) (M). Beijing: Science Press, 2016.

Analysis of Finite Element Analysis of Steel Concrete Conversion Beam Tip Node

441