Gearbox Fault Diagnosis Based on Polynomial Chirplet Transform

and Support Vector Machine

Qing Xu and Zhongyan Li

*

North China Electric Power University, Beijing, China

Keywords: Polynomial Chirplet Transform, Transformation Kernel Parameters, Feature Extraction, Fault Diagnosis.

Abstract: In order to effectively extract gearbox signal features from complex vibration signals with interference from

small samples and diagnose faults, this article proposes a gearbox fault diagnosis method based on polynomial

chirplet transform and support vector machine. Firstly, via the polynomial chirplet transform for time-

frequency analysis of vibration signals, a set of transformation kernel parameters that can centrally and

accurately represent the time-frequency characteristics of the vibration signal are proposed as features to

distinguish different states of the gearboxes. Secondly, this research combines the transform kernel parameters

with time-domain and frequency-domain features to form feature vector groups. Then we use the feature

vector group as the input set of the support vector machine to classify the feature vector group and obtain the

state judgment of gearbox vibration signals. It’s found that transformation kernel parameters have a significant

positive effect on improving the accuracy of model faults diagnosis after multiple experimental comparisons

and this algorithm has generalization.

1 INTRODUCTION

Gearbox fault diagnosis (Zhuang Ye, 2021), as a

current research hotspot, attracts widespread attention

in multiple fields, and gearbox is a mechanical device

widely used in mechanical equipment to increase

output torque or change motor speed. In recent years,

algorithms based on feature extraction and pattern

recognition have been widely used for gearbox fault

diagnosis. Using time-frequency analysis methods

such as short-time Fourier transform and wavelet

transform to process the original signal, and the

obtained time-frequency images were used as the

input set of the neural network to form a gearbox fault

diagnosis model (Yiwei Cheng - Jianhua Zhou) based

on a combination of non parametric time-frequency

analysis methods and machine learning methods.

However, the non parametric time-frequency analysis

methods (Anand Parey, 2019), such as short-time

Fourier transform, wavelet transform, and Wigner-

Ville distribution, have time-frequency resolution

independent of the signal. It is prone to errors when

reflecting the time-frequency characteristics of

complex signals, and the extracted features do not

yield relatively accurate pattern recognition results. In

addition, the application of neural networks in

intelligent fault diagnosis (Zhuang Ye - Mingjing

Yao) requires a large amount of fault data, but in

reality, collecting a large amount of fault data can

sometimes be cumbersome and difficult.

The parameterized time-frequency analysis

methods (Yang Yang, 2013) construct a matching

transform kernel function for the signal model and

iteratively select the appropriate transform kernel

parameters to obtain a high-precision and cross term

interference free time-frequency representation,

which is beneficial for analyzing non-stationary

signals and extracting useful information. In

parameterized time-frequency analysis methods,

polynomial chirplet transform (PCT) essentially uses

polynomial functions to approximate the true time-

frequency characteristics of the signal, thereby

obtaining an accurate time-frequency representation

of the polynomial phase signal. According to the

Weierstrass approximation theorem, any continuous

function on a closed interval can be uniformly

approximated by a polynomial series. Therefore,

compared to other parameterized time-frequency

analysis methods, polynomial chirplet transform is

suitable for analyzing non-stationary signals with

finite and short lengths. Support vector machine

(SVM) is a commonly used machine learning

algorithm. Support vector machine adopts the

principle of structural risk minimization to select

models, therefore it has strong generalization ability.

468

Xu, Q. and Li, Z.

Gearbox Fault Diagnosis Based on Polynomial Chirplet Transform and Support Vector Machine.

DOI: 10.5220/0012286100003807

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Seminar on Artificial Intelligence, Networking and Information Technology (ANIT 2023), pages 468-473

ISBN: 978-989-758-677-4

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

In addition, support vector machine adopts the

principle of maximizing interval to classify samples,

so it can effectively handle small sample data (Bin Li,

2019).

On the basis of the above analysis, this article

studies the problem of gearbox fault diagnosis. Using

polynomial chirplet transform for time-frequency

analysis of vibration signals, a set of transformation

kernel parameters that can centrally and accurately

represent the time-frequency characteristics of

vibration signals was proposed as features to

distinguish different states of gearboxes. Analyze the

time-domain and frequency-domain, and combine the

extracted time-domain and frequency-domain

features with the transformation kernel parameters to

form a feature vector group. Using the feature vector

group as the input set of support vector machine, a

gearbox fault diagnosis model based on PCT and

SVM is obtained. Compare and analyze the model

accuracy obtained from the feature vector groups

before and after adding transformation kernel

parameters, and conduct generalization experiments

on the gearbox fault dataset publicly available at

Southeast University.

2 POLYNOMIAL CHIRPLET

TRANSFORM

2.1 Definition of Polynomial Chirplet

Transform

Generally, for the analytical signal z(t) of the

frequency modulation signal s

(

t

)

, let the transform

kernel function

𝜅

(

t

)

=c

t

Here

c

,c

,c

,...,c

is the polynomial

coefficients, which is the transformation kernel

parameters. The definition of polynomial chirplet

transform is as follows:

𝑃𝐶𝑇

(𝑡

,𝜔;c

,c

,c

,...,c

)= 𝑧

(

𝜏

)

Ψ

,

,

,...,

(

𝜏

)

Ψ

,

,

,

,...,

(

𝜏

)

𝑔

∗

(𝜏−𝑡)𝑒𝑥𝑝(−𝑗𝜔𝜏)𝑑𝜏

Ψ

,

,

,...,

(

𝜏

)

=exp−j

1

i

c

𝜏

Ψ

,

,

,

,...,

(

𝜏

)

=expj

c

t

𝜏

g

(

t

)

is a Gaussian window function with a time

window of 𝜎,

g

(

t

)

=

1

2

√

𝜋𝜎

exp(−

t

4𝜎

)

2.2 Parameter Estimation of

Polynomial Chirplet Transform

According to the mathematical definition of

polynomial chirplet transform, by selecting

appropriate transformation kernel parameters

c

,c

,c

,...,c

, the transformation kernel function

matches the time-frequency characteristics of the

signal more closely. So, the higher the concentration

of the representation of time-frequency, the more

accurate the representation of the time-frequency

characteristics of the signal. From the above, it can be

seen that the selection of transformation kernel

parameters

c

,c

,c

,...,c

determines the

analytical performance of the polynomial chirplet

transform method, which in turn affects its accuracy

in characterizing the time-frequency characteristics of

non-stationary signals. Therefore, suitable

transformation kernel parameters can be used as

features of vibration signals for fault diagnosis and

detection research. In summary, estimating the

appropriate transformation kernel parameters

c

,c

,c

,...,c

is crucial for the study of gearbox

fault diagnosis.

Polynomial chirplet transform utilizes a

polynomial function to iteratively approximate the

time-frequency characteristics of signals, thereby

obtaining suitable polynomial transformation kernel

parameters. Based on this idea, a method for

parameter estimation has been developed based on

the definition of polynomial chirplet transform.

Without losing generality, it is assumed that the time-

frequency characteristics of the signal are any

function of time IF

(

𝑡

)

. In the 𝑖-th iteration process,

polynomial chirplet transform is first used to obtain

the time-frequency representation of the signal, i.e.

𝑃𝐶𝑇

(𝑡

,𝜔;c

,c

,c

,...,c

)= 𝑧

(

𝜏

)

Ψ

,

,

,...,

(

𝜏

)

Ψ

,

,

,

,...,

(

𝜏

)

𝑔

∗

(𝜏−𝑡)𝑒𝑥𝑝(−𝑗𝜔𝜏)𝑑𝜏

Among them, 𝜅

(

t

)

is the transformation kernel

function defined by parameters P

when the number

of iterations is 1. Make P

=0. When using

initialization kernel parameters to match the time-

frequency characteristics of signals, the effect is poor.

Therefore, further iterative optimization of

polynomial kernel parameters is needed.

The position of the ridge in the time-frequency

representation of a signal can represent its time-

frequency feature IF

(

𝑡

)

, and under noise conditions,

the energy of the signal is mainly concentrated near

the ridge. Therefore, by performing peak detection

along the time axis in the time-frequency

representation of the signal, the corresponding ridge

position can be obtained. Call it the approximate

time-frequency characteristic of the signal 𝐼𝐹

(

𝑡

)

.

Gearbox Fault Diagnosis Based on Polynomial Chirplet Transform and Support Vector Machine

469

The approximate time-frequency feature 𝐼𝐹

(

𝑡

)

obtained from the 𝑖-th iteration is

𝐼𝐹

(

𝑡

)

=argmax

|

𝑃𝐶𝑇

(

𝑡,𝜔;𝑃

)|

Using the least squares method and the necessary

conditions for finding extreme values of multivariate

functions to fit and approximate the approximate

time-frequency characteristic curve,

𝑃

=min

𝐼𝐹

(𝑡)−𝐼𝐹

(

𝑡

)

Where 𝐼𝐹

(𝑡) is the polynomial fitting curve of

the approximate time-frequency characteristics after

the i-th iteration. 𝑃

is the estimated value of the

transformation kernel parameter in the i-th iteration.

If 𝑃

=𝑃

, then the new transformation kernel

function is

𝜅

(

t

)

=𝐼𝐹

(𝑡)

The judgment basis for iteration termination is

Λ

=𝑚𝑒𝑎𝑛

|

(

)

(

)

|

|

(

)

|

<𝛼 (1)

When 𝑖=1,𝐼𝐹

(

𝑡

)

=0.

3 EXPERIMENTATION

3.1 Dataset Introduction

In order to verify the feasibility of this method, during

the operation of the gearbox, vibration signals were

collected by installing an acceleration sensor for

gearbox fault diagnosis. This article collected

vibration signals of the gearbox under 5 different

states, namely normal state and 4 fault states, with a

sampling frequency of 6.4kHz. Select 20 sets of

experimental data from different states for gearbox

fault diagnosis.

3.2 Model Design

Time frequency analysis can further extract effective

information from signals. Perform time-frequency

analysis on each group of data using polynomial

chirplet transform. The basis for terminating the

iteration is shown in equation (1). The threshold is set

to 1%. Extract the optimal transformation kernel

parameters corresponding to each group of data

separately. Taking the first set of data in fault state 4

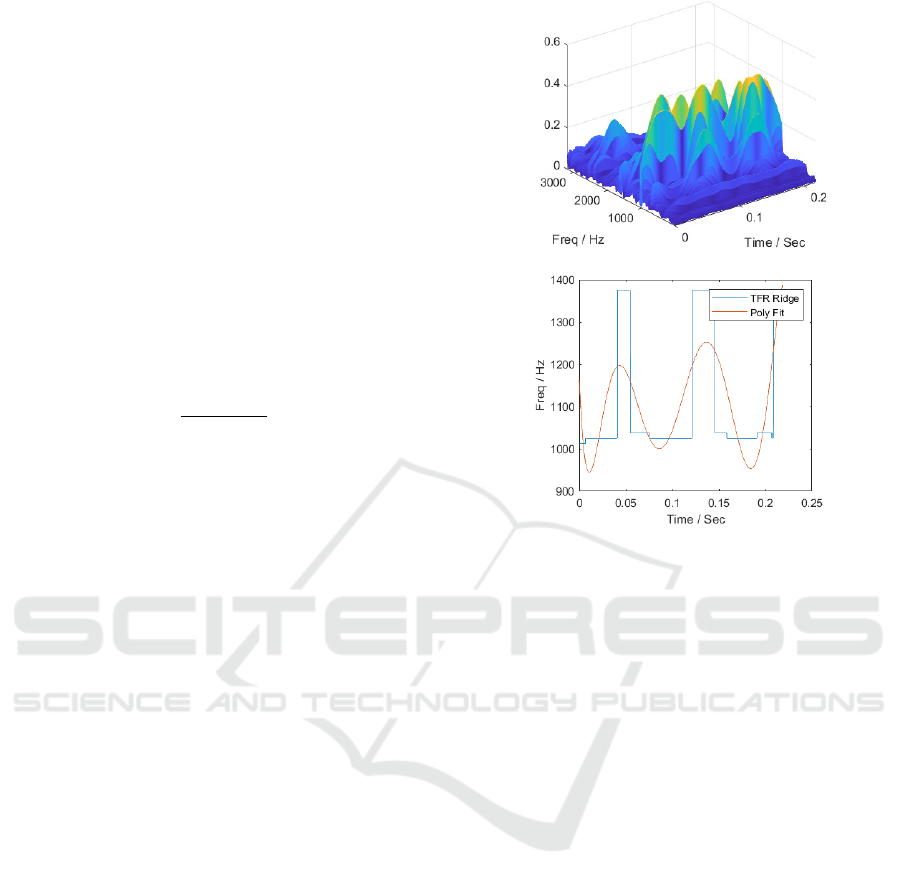

as an example. Fig. 1 shows the time-frequency

analysis and polynomial fitting effect when using the

initialization transformation kernel parameters (i.e.

𝑃=0). In fact, it is the short-time Fourier transform.

Due to noise interference, the position of the ridge

line deviates greatly from the true time-frequency

characteristics.

(a)

(b)

Figure 1. Initial time-frequency representation and

polynomial fitting effect diagram.

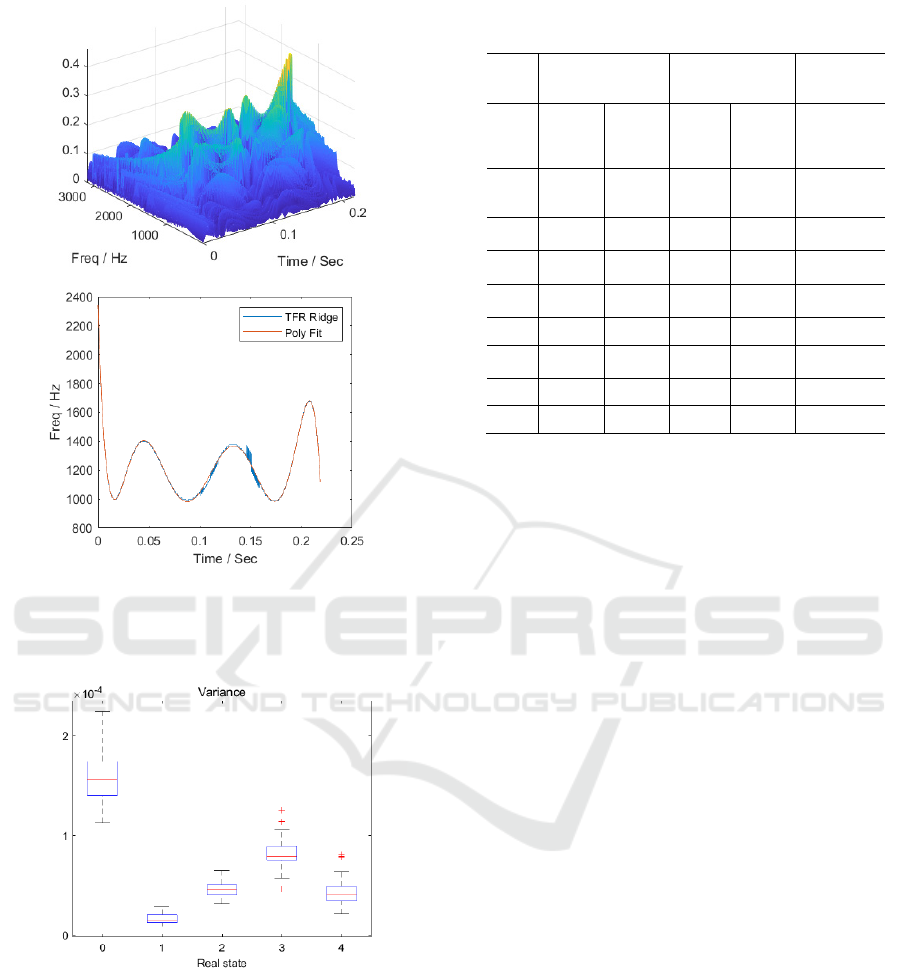

Until the end of the iteration cycle, as shown in

Fig. 2, the aggregation of time-frequency

representation has been greatly improved, and the

fitted polynomial curve is very close to the time-

frequency characteristics of the signal.

At this point, polynomial chirplet transform

accurately characterizes the time-frequency

characteristics of the signal. Therefore, the

transformation kernel parameters at this time can be

extracted as a set of features for this group of signals.

In order to demonstrate the effectiveness of

transforming kernel parameters in gearbox fault

diagnosis, experiments were conducted to extract time-

domain and frequency-domain features. Compare and

analyze the accuracy of model classification before and

after adding kernel parameters to the feature vector

group. As the Box-plot is not affected by outliers, it can

accurately and stably depict the discrete distribution of

data, and visually display the distribution of each group

of data. Therefore, Box-plot was used to filter out 12

commonly used features (Yajing Xiao, 2019) in fault

diagnosis, including maximum, variance, average

frequency, etc. Take the variance of the signal as an

example. There are significant differences in the

variance distribution range of each group's data under

different states in Fig. 3. Therefore, it is feasible to use

variance as a feature to distinguish different state data.

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

470

(a)

(b)

Figure 2. The optimal time-frequency representation and

polynomial fitting effect diagram when reaching the

threshold.

Figure 3. Box-plot of variance.

From this, the feature vector group of the gearbox

vibration signal is obtained. Taking data one under

normal conditions as an example. Its feature vector

group is shown in Table 1. Preprocess the feature

vector group. Using feature vector groups as input

sets for support vector machine, a gearbox fault

diagnosis based on PCT and SVM was established as

shown in Fig. 4.

Table 1. The feature vector group of the first set of data in

normal state.

Number

Time Domain

Features

Frequency domain

features

Transform

kernel

p

arameters

1

Waveform

factor

1.2587256

Root

mean

square of

fre

q

uenc

y

1732.1435 1.088673E+03

2

Root

mean

S

q

uare

0.0317237

Center of

gravity

fre

q

uenc

y

1539.9500 1.019567E+05

3

Minimum

value

-0.094641

Average

fre

q

uenc

y

0.0009844

-

5.757793E+06

4

Maximum

value

0.1042190 1.283804E+08

5

Peak

value

0.1988596

-

1.399988E+09

6 Skewness 0.0348320 7.905804E+09

7 Kurtosis 2.9740948

-

2.213817E+10

8 Variance 0.0010068 2.423154E+10

9 Margin 9.3294435

Using the model obtained in Fig. 4, classify the

feature vector groups. In order to observe the

classification ability of the model in more detail, a

confusion matrix is used to represent the

classification results. As shown in Fig. 5, the

horizontal axis represents the model's prediction of

the state of the gearbox, while the vertical axis

represents the true state of the signal. 0 represents

normal state, 1 represents fault state one. The (0,0)

coordinate value represents that the predicted state of

the model is normal, and the true state of the signal is

also normal, which means that the classification is

accurate. The (1,0) coordinate value represents that

the predicted state of the model is fault one, and the

true state of the signal is normal, which means that

the classification is incorrect. And so on.

From the figure, it can be seen that before adding

transformation kernel parameters to the feature vector

group, the accuracy of this model in state

classification is 95%. After adding transformation

kernel parameters to the feature vector group, the

accuracy of this model in state classification is 100%.

3.3 Generalization Experiment

To further verify the universality of this method, this

article uses the publicly available gearbox dataset

from Southeast University (Chao Chen, 2020) for

experiments. This dataset contains two sub datasets:

bearing data and gear data. This article selects gear

data, which includes normal state and four fault

states, namely Chipped tooth, Missing tooth, Root

fault and Surface fault. The speed load configuration

is set to 20-0. Take the Y-direction vibration signal of

Gearbox Fault Diagnosis Based on Polynomial Chirplet Transform and Support Vector Machine

471

Figure 4. The gearbox fault diagnosis based on polynomial chirplet transform and support vector machine.

(a)

(b)

Figure 5. The confusion matrix before and after adding

kernel parameters to the feature vector group.

the planetary gearbox as experimental data, take 1024

sampling points as sample length, and take 40 sets of

samples for each state as the original dataset.

From the Fig. 6, it can be seen that the accuracy of

the gearbox fault diagnosis based on PCT and SVM

on this dataset is 98.5%, which performs well. This

result verifies the generalization of the model on

different datasets.

Figure 6. The classification effect on the gearbox fault

dataset of Southeast University.

ANIT 2023 - The International Seminar on Artificial Intelligence, Networking and Information Technology

472

4 CONCLUSION

This article proposes a gearbox fault diagnosis

method based on PCT and SVM. By studying the

application of polynomial chirplet transform in time-

frequency analysis, a set of features that can

distinguish different states of gearboxes, namely

transformation kernel parameters, has been proposed.

Through comparative analysis, it can be concluded

that this method can more effectively identify and

classify different states of gearboxes. In addition, this

article verified the generalization of the model on the

gearbox fault dataset publicly available at Southeast

University.

This method can accurately reflect the time-

frequency characteristics of complex signals, and the

extracted feature vector group containing transform

kernel parameters can obtain more accurate pattern

recognition results. In addition, this method is

suitable for small sample experimental data and has

low requirements for server configuration. Therefore,

when using this method for fault diagnosis, it is easy

to quickly collect data and perform fault diagnosis.

REFERENCES

Zhuang Ye, Jianbo Yu, Deep morphological convolutional

network for feature learning of vibration signals and its

applications to gearbox fault diagnosis (J), Mechanical

Systems and Signal Processing. 2021, 161(5): 107984.

https://doi.org/10.1016/j.ymssp.2021.107984.

Yiwei Cheng, Manxi Lin, Jun Wu, et al, Intelligent fault

diagnosis of rotating machinery based on continuous

wavelet transform-local binary convolutional neural

network (J), Knowledge-Based Systems. 2021, 216(1):

106796. https://doi.org/10.1016/j.knosys.2021.106796.

Jianhua Zhou, Pan Zheng, Shuaixing Wang, et al, Fault

diagnosis method of planetary gearbox based on

wavelet time-frequency diagram and convolutional

neural network(J). Journal of Mechanical

Transmission. 2022, 46(1): 156-163. (in Chinese).

Anand Parey, Amandeep Singh, Gearbox fault diagnosis

using acoustic signals, continuous wavelet transform

and adaptive neuro-fuzzy inference system(J), Applied

Acoustics. 2019, 147: 133-140.

https://doi.org/10.1016/j.apacoust.2018.10.013.

Zhuang Ye, Jianbo Yu, Deep morphological convolutional

network for feature learning of vibration signals and its

applications to gearbox fault diagnosis (J), Mechanical

Systems and Signal Processing. 2021, 161(5): 107984.

https://doi.org/10.1016/j.ymssp.2021.107984.

Mingjing Yao, Xuan Tang, Ang Lv, Research on fault

diagnosis of planetary gearbox based on improved

convolutional neural network (J), Manufacturing

Technology & Machine Tool. 2021, (7):141-145. (in

Chinese).

Yang Yang, Theory, methodology of parameterized time-

frequency analysis and its application in engineering

signal processing (D), Shanghai Jiao Tong University.

2013. (in Chinese).

Bin Li, Min Zhang, Heng Zhou, et al, Identifying optical

cable faults in OTDR based on wavelet packet analysis

and support vector machine (J), Laser &

Optoelectronics Progress. 2019, 56(02): 127-134. (in

Chinese).

Yajing Xiao, Research on rolling bearing fault diagnosis

and prediction method based on support vector machine

(D), China University of Mining and Technology-

Beijing. 2019. (in Chinese).

Chao Chen, Methodologies for fault diagnosis of rotary

machine based on transfer learning(D), Donghua

University. 2020. (in Chinese)

Gearbox Fault Diagnosis Based on Polynomial Chirplet Transform and Support Vector Machine

473