Estimating Technical Efficiency of Crude Palm Oil in Malaysia

Mariah Binti Sabar

1

and Anton Abdulbasah Kamil

2

1

School of Mathematical Sciences, Universiti Sains Malaysia, Penang 11800, Malaysia

2

Faculty of Economics, Administrative and Social Sciences, Istanbul Gelisim University, Istanbul, Turkey

Keywords:

SFA, TE, Cobb-Douglas Functional Form, Translog Functional Form, CPO.

Abstract:

The main purpose of this study is to apply parametric techniques in evaluating the technical efficiency (TE) of

crude palm oil (CPO) production by the states in Malaysia. To achieve this, the parametric stochastic frontier

analysis (SFA) approach was applied. This study involves a panel data consisting of 12 CPO producing states

in Malaysia, over a 18 year time period from year 1999 to 2016. The output variable chosen was the annual

CPO production and the input variables considered were plantation area, fruit mill capacity, labour and time

variable. We found fruit mill capacity, labour and time as input variables that significantly affect the level of

CPO output. Plantation area was proven to be statistically insignificant. Technical efficiency was found to be

increasing over time. It was also found that the inefficiencies in the industry were mainly caused by ‘pure’

technical inefficiency rather than scale inefficiency. The overall mean TE of SFA is 0.79. Selangor is the top

efficient state according to SFA. We concluded that the state of Malacca is overall the least efficient state due

to their low ranking.

1 INTRODUCTION

Malaysia is one of the biggest palm oil producers

in the world (Basiron, 2007). The country accounts

for 44% of the world’s exports of palm oil making

the industry the fourth major revenue for the nation

(M.P.C., 2014). The industry plays a huge role in the

development of the country by reducing poverty rate

from 50% in the 1960s, to less than 5% today. The

success of the Malaysian palm oil industry, however,

did not come without a price. From health campaign

claiming the oil increased risk of heart diseases, al-

leged land grabs, deforestation and the extinction of

the orang utan to the recent resolution by the Euro-

pean Parliament calling for the EU to phase out the

use of palm oil in biodiesel that are allegedly pro-

duced in an unsustainable way, leading to deforesta-

tion.

With the continuous pressure and controversies

surrounding the manufacturing of palm oil, it is only

ideal that the Malaysian palm oil industry demon-

strate sustainability by being more efficient in the us-

age of resources. Measuring efficiency is important

not only to have a reliable record of the industry’s

progress, but also to be able to investigate the im-

pact of any new and already existing implemented

policies. Methods for estimating efficiency can be

categorized into two, parametric approach and non-

parametric approach. These approaches can either

be deterministic or stochastic (Bogetoft et al., 2011).

Among the various methods developed, parametric

stochastic frontier analysis (SFA) is the most com-

monly used technique for estimating technical effi-

ciency (Baten et al., 2009), (Hassan et al., 2012). The

SFA technique involve mathematical programming

and econometric methods, respectively (Coelli et al.,

2005). To our knowledge, no study has yet used the

most applied parametric SFA technique to find the ef-

ficiency of producing CPO by the states in Malaysia.

The result could be an indicator to where each state

stands in terms of producing CPO efficiently among

the states in Malaysia. This can serve as a planning

aid for management and policy makers to draw con-

clusion on existing and new regulations.

2 METHODOLOGY

Efficiency Measurement According to (Farrell, 1957),

the efficiency of a firm could be looked at from two

components; technical efficiency and allocative effi-

ciency. Technical efficiency is the ability of a firm to

produce the maximum amount of output from a given

set of inputs. Meanwhile, allocative efficiency repre-

198

Sabar, M. and Kamil, A.

Estimating Technical Efficiency of Crude Palm Oil in Malaysia.

DOI: 10.5220/0012446800003848

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 3rd International Conference on Advanced Information Scientific Development (ICAISD 2023), pages 198-203

ISBN: 978-989-758-678-1

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

sents the firm’s ability to use the optimal proportions

of inputs given their respective prices and the produc-

tion technology. This study focuses on technical effi-

ciency (TE).

The following notations are used: i, j = 1,...,N

the collection of decision making units (DMU), t =

1,...,T study period, k,l = 1, ...,K number of inputs.

2.1 Theoretical Stochastic Frontier

Model

The model used was the production model for panel

data proposed by (Battese and Coelli, 1992) ex-

pressed as:

lnyit = X

it

β + (v

it

− u

it

, (1)

u

it

= u

i

exp −η[−(t − T ],i = 1,..., N,t = 1, ...,T (2)

where y

it

is the output of the i-th unit in the t − th

time period, x

it

is a (K x 1) vector of transformation

of the input quantities of the i − th unit in the t − th

time period, β is a vector of unknown parameters to

be estimated, v

it

are random variables assumed to be

independent and identically distributed N(0,σ

2

v

) and

are independent of u

it

, η is a unknown parameter to

be estimated and u

i

are non-negative random variables

which are assumed to be independent and identically

distributed as truncations at zero of the N(0,σ

2

v

) dis-

tribution and are assumed to represent the technical

inefficiency in production.

The inefficiency model (2) can be in the form of a

truncated normal distribution, half normal distribution

or an exponential distribution (Hossain, 2013). How-

ever, in this study only the truncated normal or half-

normal distributions were considered. (Battese and

Corra, 1977) parameterized σv

2

and σ

2

u

by replacing

them with:

σ

2

= σ

2

v

+ σ

2

u

(3)

γ = σ

2

u

/σ

2

(4)

Gamma (γ) is an unknown parameter that lies be-

tween zero and one. It explains the presence of the

inefficiency component in the total error term (Coelli

et al., 2005). The technical efficiency (TE) of the

i − th unit at the t − th time period can be measured

by:

T E

it

= y

it

/y

it∗

= exp(x

it

β + v

it

− u

it

)/exp(x

it

β + v

it

)

= exp(−u

it

)

(5)

where y

it

is the observed output and yit∗ is the cor-

responding stochastic frontier output.

The measurement of technical efficiency is the ob-

served output of a unit relative to the output that po-

tentially could be produced by a fully-efficient unit

using the same amount of input (Coelli et al., 2005).

The value can range between zero and one.

2.1.1 Application

Empirical Stochastic Frontier Model After the out-

put and input variables involved were made clear, the

functional form of translog production model (Battese

and Coelli, 1992) was applied that can be defined as:

lnCPO

it

= β

0

+ β

1

lnArea

it

+ β

2

lnMC

it

+β

3

lnLabour

it

+ β

4

t + 1/2[β

11

(lnArea

it

)

2

+

β

22

(lnMC

it

)

2

+ β

33

(lnLabour

it

)

2

+ β

44

t

2

+β

12

lnArea

it

∗ lnMC

it

+ β

13

lnArea

it

∗ lnLabour

it

+ β

14

lnArea

it

∗ t +β

23

lnMC

it

∗lnLabour

it

+ β

24

lnMC

it

∗ t

+β

3

4lnLabour

it

∗ t +v

it

− u

it

(6)

where i = 1, 2, ..., 12 and t = 1, 2, ..., 18,

ln refers to the natural logarithm, CPO

it

is the

amount of crude palm oil production by the i−th state

at t − th period,

Area

it

is the area under oil palm plantation in the i−th

state at t − th period,

MC

it

denotes the total fruit mill capacity available in

the i − th state at t − th period,

Labour

it

is the number of plantation employee work-

ing in the i− th state at the t − th period, t is the study

period from the value of 1 to 18 (year 1999 to 2016),

β, v

it

and uit are as defined in the previous section.

The most used functional forms are the Cobb-

Douglas model and the transcendental logarithmic

(trans-log) model. According to (Ferdushi, 2013),

choosing the most appropriate model for our analysis

is crucial as the functional form would significantly

affect our results. Hence, to test whether the trans-log

model above is the appropriate functional form for our

model, the likelihood ratio test was conducted which

would be explained in the next section. The time vari-

able in the stochastic frontier model (6) was included

to allow for Hicksian neutral technological change

(Baten et al., 2009), while in the inefficiency model

(2) the time variable is associated with the change

in inefficiency as the time period increases (Coelli

and Battese, 1996a). In model (6), the time-squared

and the time interaction with each (log) input variable

Estimating Technical Efficiency of Crude Palm Oil in Malaysia

199

were considered to allow for non-monotonic technical

change and non-neutral technical change respectively

(See and Coelli, 2012). Hypothesis Test Several hy-

potheses would be tested to verify the validity of the

results, to find the most appropriate functional form

for the model and to select the distribution of the ran-

dom variables assumed to represent the technical in-

efficiency (Ferdushi et al., 2011), (Mustapha, 2011).

There are many different combinations and alterna-

tive models types to choose from. For the stochastic

frontier model, the most common used are the Cobb-

Douglas model or the trans-log model. For the ineffi-

ciency model, one can assume whether the inefficien-

cies follow a half-normal distribution or a truncated

normal distribution. Since our data is a panel data, we

also had to decide whether to assume time-varying or

time invariant efficiencies. To solve this problem, a

number of alternative models were estimated and then

the likelihood ratio tests were carried out to select the

most appropriate model (Coelli and Battese, 1996a).

We would be testing 4 hypotheses:

1. H

0

: γ = 0, testing the significance of the γ param-

eter is basically testing whether it is necessary to

apply the stochastic frontier production function.

From equation (4), we could see that if the null

hypothesis is true, then the value of σ

2

u

would also

be equal to zero meaning there is no technical in-

efficiency present. Thus, the uit term should be

removed, turning the model into an ordinary lin-

ear regression model that could be solved using

the ordinary least squares (OLS) method.

2. H

0

: β

k

l = 0(k ≤ l = 1,2,3,4), the null hypothesis

specifies that the coefficients of the squared

input and the interaction between input variables

of the stochastic frontier function are simulta-

neously zero. This means that the parameters

β

11

,β

22

,β

33

,β

44

,β

12

,β

13

,β

14

,β

23

,β

24

,andβ

34

are restricted to the value of zero. If this is

accepted, then the Cobb-Douglas functional form

is more appropriate than the translog functional

form.

3. H

0

: µ = 0, this particular hypothesis is to test

whether the distribution for the inefficiency is a

half-normal distribution or a truncated normal dis-

tribution. The null hypothesis implies that the

mean of the inefficiency distribution is equal to

zero, making it a half-normal distribution which

is a special case of the truncated normal distribu-

tion.

4. H

0

: η = 0, implies that the technical inefficiencies

are time invariant.

As we can see from equation (2), if the null hy-

pothesis η = 0 is accepted then it would mean that

the technical inefficiencies are not affected by time.

All of these hypotheses were tested using the like-

lihood ratio test. The generalized likelihood ratio

(LR) test statistic is defined by:

LR = −2ln [L(H

0

)/L(H

1

)]

= −2ln [L(H

0

)] − ln [/L(H

1

)]

(7)

where ln[L(H

0

)] and ln [L(H

1

)] are the values of

the log-likelihood function of the production frontier

model under the null and the alternative hypotheses

respectively. Under the null hypothesis, the LR statis-

tic is assumed to be a Chi-square (or a mixed Chi-

square) distribution with the degree of freedom equal

to the number of restrictions involved (Coelli and Bat-

tese, 1996b). If the value of the LR test statistic ex-

ceeds the critical value, then the null hypothesis is re-

jected (Taymaz and Saatci, 1997).

3 RESULTS AND DISCUSSION

3.1 Maximum Likelihood Estimates of

the Translog Stochastic Frontier

Production Function

The maximum likelihood estimates for the parame-

ters of the translog crude palm oil production model

is shown in Table 1.

Table 1: Maximum likelihood estimates for the parameters

of the translog production function.

Variable Parameter Coefficient Standard Error t-ratio

Constant β

0

19.21489*** 3.11286 6.17274

Area β

1

-0.00817 1.23538 -0.00661

MC β

2

-2.83437*** 1.02815 -2.75677

Labour β

3

1.49079** 0.59092 2.52283

t β

3

0.18653*** 0.04569 4.08262

... ... ... ... ...

Variance Pa-

rameter

Sigma-

Squared

σ

2

0.05309** 0.02437 2.17910

Gamma γ 0.71642*** 0.12953 5.53094

Eta η 0.04956*** 0.01445 3.42982

Looking at the maximum likelihood estimates of

the coefficient of the first order variables, it is clear

that all the variables except plantation area signifi-

cantly affect the level of crude palm oil production.

Fruit mill capacity and time both yield coefficient that

are highly statistically significant at 1% level of sig-

nificance. The coefficient of time is estimated to be

0.187 meaning that as time increases by a year, then

crude palm oil production would increase by 0.187

tonnes if the effects of all other predictors are held

ICAISD 2023 - International Conference on Advanced Information Scientific Development

200

constant. It also implies that technical progress in-

creases on average of 18.7% per year. Meanwhile,

the coefficient of fruit mill capacity is - 48 2.834. The

negative sign of the coefficient could possibly indi-

cate that the current existing mills are not fully uti-

lized to their full capacity. This could also suggest

that smaller size fruit mills are more productive com-

pared to the larger fruit mills because they are easier

to manage and monitor. Labour yield a significant

coefficient at 1.491 implying that the labour variable

influences crude palm oil output positively. The value

of the coefficient for plantation area is approximated

at -0.008.

However, this value is proven to be statistically in-

significant implying that plantation area does not af-

fect the output level significantly. All of the second

order variables are found to be insignificant. The co-

efficients of the product variables between plantation

area with fruit mill capacity, fruit mill capacity with

time and labour with time appear to be significant at

the 10% level of significance. The other interactions

between input variables were found to be insignificant

to production.

The parameter of error σ

2

is estimated to be 0.053

with significance level at 5%. Since σ

2

is statistically

significantly different from zero, we can say that the

model is a good fit to our data set. The parameters γ

and η are found to be significant at 1% level of signif-

icance. γ is estimated at 0.716, implying that 71.6%

of the variation in deviation is caused by technical in-

efficiency whereas 28.4% is caused by the stochastic

random error. This result shows that technical ineffi-

ciency is important in explaining the total variability

within the production of crude palm oil. The param-

eter η is approximated to be 0.05. The positive value

of η suggests that the technical inefficiency tends to

decline over time. Thus, the technical efficiency in-

creases over time.

3.2 Estimated Technical Efficiency of

Production

Table 2 displays the readings of the estimated tech-

nical efficiency for the production of crude palm oil

of each state for each year generated. The overall

mean technical efficiency in the production of crude

palm oil for the states in Malaysia from the year 1999

to 2016 is 0.792. This means that 79.2% of the po-

tential output is achieved by the palm oil industry in

Malaysia. However, this also shows that there exists

technical inefficiency of around 20.8% that can be im-

proved using the same amount of existing resources.

The lowest reading of technical efficiency is 0.4 by the

state of Malacca during 1999. On the other hand, the

highest reading is 0.986 by Selangor in 2016. None

of the states got 100% level in efficiency at any given

year.

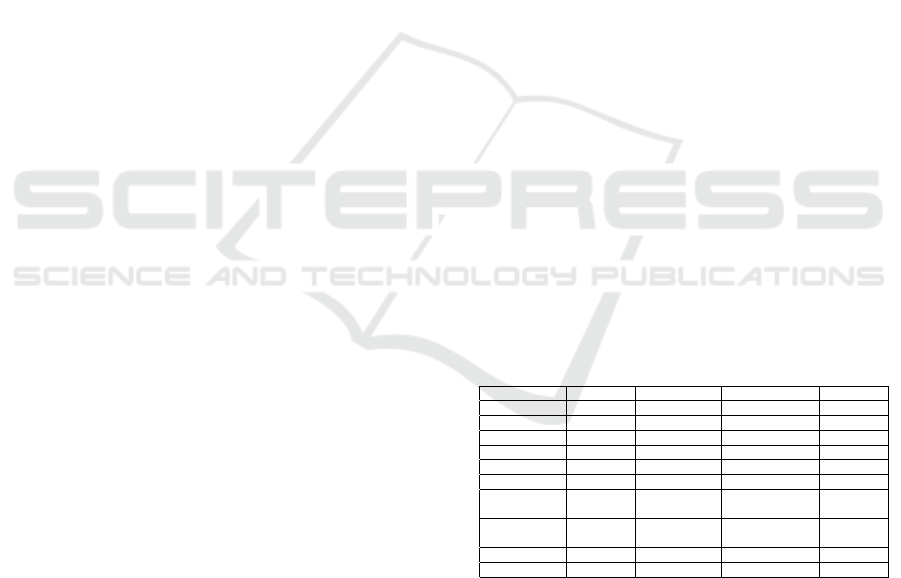

Table 2: Estimated technical efficiency of producing crude

palm oil for the states in Malaysia from 1999 to 2016 by

stochastic frontier analysis.

State 1999 2000 2001 ... 2016 Mean

Selangor 0.968 0.970 0.971 ... 0.986 0.978

Sarawak 0.931 0.934 0.937 ... 0.969 0.952

Perak 0.892 0.897 0.902 ... 0.952 0.926

N. Sembilan 0.891 0.896 0.901 ... 0.951 0.925

Penang 0.759 0.770 0.779 ... 0.888 0.831

Terengganu 0.726 0.737 0.748 ... 0.871 0.806

Kedah 0.712 0.724 0.735 ... 0.864 0.795

Sabah 0.590 0.606 0.620 ... 0.797 0.702

Johor 0.581 0.596 0.612 ... 0.791 0.695

Kelantan 0.554 0.570 0.586 ... 0.775 0.674

Pahang 0.554 0.570 0.586 ... 0.775 0.673

Malacca 0.400 0.418 0.436 ... 0.674 0.544

It was found that out of the 12 states, 7 states

yielded mean technical efficiency above the overall

average of 0.792. The most efficient state is the state

of Selangor with a mean efficiency at 0.978. This im-

plies that among all the states, Selangor is the most

efficient in managing its resources to maximize pro-

duction. It is clear that the least efficient state is

the state of Malacca with mean efficiency reading of

0.544. The difference in score of the mean techni-

cal efficiency of Selangor and Malacca is a staggering

0.434. Meanwhile, the largest state in Malaysia, the

state of Sarawak rank second with a yield mean ef-

ficiency score of 0.952. This is followed by Perak,

Negeri Sembilan, Penang, Terengganu and Kedah

with scores of 0.926, 0.925, 0.831, 0.806 and 0.795

respectively. The state of Sabah, which is the largest

producer of crude palm oil between the states, ranked

eighth following a mean efficiency score of 0.702.

This indicates that Sabah can improve their output

level by around 29.8% by fully utilizing their current

available resources. After Sabah, the state of Johor,

Kelantan and Pahang follow closely at 0.695, 0.674

and 0.673 respectively.

3.3 Selection of the Production

Function and Hypotheses Testing

To determine the form of the production function,

several hypothesis tests were carried out. The results

are shown in Table 3:

According to (Coelli, 1995), if the null hypoth-

esis involves γ = 0, then the asymptotic distribution

requires a mixed Chi-square distribution. Thus, the

critical value for the first null hypothesis is obtained

from Table 1 of (Kodde and Palm, 1986). The null

hypothesis is rejected since the value of the test statis-

Estimating Technical Efficiency of Crude Palm Oil in Malaysia

201

Table 3: Generalized likelihood ratio test of hypothesis for

the stochastic frontier production model.

Null L-

likelihood

L-

likelihood

LR

test

Critical Decision

Hypothesis Function

(H

0

)

Function

(H

1

)

Statistic Value

H

0

: γ =

0

87.1588 120.3780 66.4383 2.706* Reject

H

0

:

β

kl

= 0

70.7475 125.4358 109.3765 18.307 Reject

H

0

: µ =

0

125.3437 125.4358 0.1842 3.841 Accept

H

0

: η =

0

120.3780 125.3437 9.9314 3.841 Accept

tic exceeds the critical value. This result confirms that

technical inefficiencies exist and are significant in ex-

plaining the performance in the production of crude

palm oil by the states. The second null hypothesis

H0 : βkl = 0 which specifies that the Cobb-Douglas

production function is statistically more preferable

than the translog production function is rejected. This

indicates that the usage of translog production func-

tion is more appropriate for the data set. The third null

hypothesis H

0

: µ = 0 is accepted since the test statistic

value did not exceed the critical value. We can con-

clude that the most suitable distribution for the ineffi-

ciency is the half-normal distribution. Finally, the null

hypothesis H

0

: η = 0 implies that the technical inef-

ficiencies are time invariant. This is rejected showing

that time does significantly influence the technical in-

efficiencies in the production model. From the results

of these hypothesis tests, we can conclude that the

most preferable form of the production function for

the data set is the translog stochastic frontier produc-

tion function with the inefficiency assumed to follow

a half-normal distribution and are time-variant.

4 CONCLUSION

This study set out to estimate the technical efficiency

(TE) of producing crude palm oil (CPO) in Malaysia

by applying the parametric stochastic frontier analy-

sis (SFA) technique. The overall mean TE is 0.79.

We found that fruit mill capacity, labour and time as

input variables significantly affect the level of CPO

output. Labour and time variables have positive rela-

tionship with the output level. On the other hand, fruit

mill capacity was shown to have a negative relation-

ship with the CPO production which could possibly

indicate that the mills are not utilized to their full ca-

pacity. Plantation area was proven to be statistically

insignificant in affecting output level. 71.6% of the

variation in deviations were due to technical ineffi-

ciencies whereas 28.4% were cause by the stochastic

random error. SFA estimated the state of Selangor to

be the most efficient CPO producing state among our

population and the state of Malacca to be the least

efficient. Even though the average efficiency of the

Malaysian CPO industry seems to be increasing grad-

ually each year, there is still room for improvement.

Inefficiencies could be reduced by managing existing

resources better, utilization of idle capacity, operat-

ing at optimal scale and applying the ways of efficient

states. The status of fruit mills in Malaysia needs to

be looked at as it was discovered to have a negative re-

lationship with output level. The existing mills possi-

bly are not fully utilized. Future study should be done

on the productivity of CPO production based on the

size of fruit mills and whether smaller fruit mills are

easier to manage and monitor. The productivity of the

whole industry decreases each year due to technologi-

cal change. Thus, investing in new technology is what

needs to be done to encourage productivity growth in

the industry. It is recommended that further study be

done on identifying the factors influencing the TE of

producing CPO in Malaysia preferably using the SFA

(Coelli, 1995) model specification. The inclusion of

environmental variables is highly suggested such as

rainfall and temperature.

REFERENCES

Basiron, Y. (2007). Palm oil production through sustainable

plantations. European Journal of Lipid Science and

Technology, 109(4):289–295.

Baten, M., Kamil, A., and Mohammad, A. (2009). Model-

ing technical inefficiencies effects in a stochastic fron-

tier production function for panel data. African Jour-

nal of Agricultural Research, 4(12):1374–1382.

Battese, G. and Coelli, T. (1992). Frontier production func-

tions, technical efficiency and panel data: With appli-

cation to paddy farmers in india. Journal of Produc-

tivity Analysis, 3(1-2):153–169.

Battese, G. and Corra, G. (1977). Estimation of a produc-

tion frontier model: with application to the pastoral

zone of eastern australia. Australian Journal of Agri-

cultural Economics, 21(3):169–179.

Bogetoft, P., Otto, L., and Boles, J. (2011). Benchmark-

ing with dea, sfa and r. In Proceedings of the Annual

Meeting (Western Farm Economics Association, New

York. Springer.

Coelli, T. (1995). Estimators and hypothesis tests for a

stochastic frontier function: a monte carlo analysis.

Journal of Productivity Analysis, 6(3):247–268.

Coelli, T. and Battese, G. (1996a). Identification of fac-

tors which influence the technical inefficiency of in-

dian farmers. Australian Journal of Agricultural and

Resource Economics, 40(2):103–128.

Coelli, T. and Battese, G. (1996b). Identification of fac-

tors which influence the technical inefficiency of in-

dian farmers. Australian Journal of Agricultural Eco-

nomics, 40(2):103–128.

ICAISD 2023 - International Conference on Advanced Information Scientific Development

202

Coelli, T., Rao, D., O’Donnell, C., and Battese, G. (2005).

An Introduction to Efficiency and Productivity Analy-

sis. Springer Science & Business Media, New York.

Farrell, M. (1957). The measurement of productive effi-

ciency. Journal of the Royal Statistical Society. Series

A (General, 120(3):253–290.

Ferdushi, K. (2013). Stochastic metafrontier production

model, flexible risk efficiency and its properties: with

application to rice croppings systems in bangladesh.

Ferdushi, K., Baten, M., Kamil, A., and Mustafa, A. (2011).

Wage augmented stochastic frontier model with trun-

cated normal distribution. International Journal of

Physical Sciences, 6(14):3288–3295.

Hassan, M., Kamil, A., Mustafa, A., and Baten, M. (2012).

Estimating stock market technical efficiency for trun-

cated normal distribution: Evidence from dhaka stock

exchange. Trends in Applied Sciences Research,

7(7):532–540.

Hossain, M. (2013). Improved data envelopment analysis

efficiency with statistical distributions: A role of envi-

ronment impact.

Kodde, D. and Palm, F. (1986). Wald criteria for

jointly testing equality and inequality restrictions.

Econometrica: Journal of the Econometric Society,

54(5):1243–1248.

M.P.C. (2014). Reducing unnecessary regulatory burdens

on business: Growing oil palm. Malaysia Productivity

Corporation, Selangor, Malaysia.

Mustapha, N. (2011). Technical efficiency for rubber

smallholders under risda’s supervisory system using

stochastic frontier analysis. Journal of Sustainability

Science and Management, 6(1):156–168.

See, K. and Coelli, T. (2012). An analysis of factors that

influence the technical efficiency of malaysian thermal

power plants. Energy Economics, 34(3):677– 685.

Taymaz, E. and Saatci, G. (1997). Technical change and ef-

ficiency in turkish manufacturing industries. Journal

of Productivity Analysis, 8(4):461–475.

Estimating Technical Efficiency of Crude Palm Oil in Malaysia

203