Design of Automatic Fire Extinguisher System for Electric Vehicles

Milan Sonnad

1 a

, Mohammed Saqhib

1 b

, Mohammed Hussain Khan

1 c

, Himanshu Jha

1 d

and P. Sudhakar

1 e

1

Department of Mechanical Engineering, Dayananda Sagar College of Engineering, Bangalore,India

iamhimanshhh@gmail.com, Sudhakar-me@dayanandasagar.edu

Keywords: Electric Vehicle, Battery, Fire, Safety Factors, Explosions and Prevention.

Abstract: Electric vehicles are best alternatives for the internal combustion engine powered vehicles but there is

increased concern among people about safety in electric vehicles due to increased number of EV battery fire

reports. The growing popularity and adoption of electric vehicles (EVs) have led to an increased need for

advanced safety systems, especially in fire prevention and extinguishing. Electric vehicle fires present unique

challenges due to the high energy density of their battery packs and the potential for thermal runaway. This

study introduces an automated fire extinguisher system specifically designed for electric vehicles, aiming to

enhance safety and mitigate fire-related risks.In this work, an automatic fire extinguishing system is designed

using CATIA software and a program coding to detect battery temperature using Arduino software was carried

out. This system helps in minimizing huge property damage, injuries, losses and also system to alert rider

about the fire so rider can reach safe distance from the vehicle and escape from fatal injuries. This study also

aims to minimize the chances of battery explosion and save the vehicle from destruction in case of battery

fire.

1 INTRODUCTION

The rise in air pollution from fossil fuel-driven

vehicles and the depletion of fossil fuel reserves have

led to a growing demand for alternative energy

sources in the automobile industry. Electric vehicles

(EVs) are emerging as one of the prominent

alternatives to traditional fossil fuel vehicles and have

been gaining popularity in recent years. In 2015,

approximately 380,000 EVs were produced, and the

demand for electric vehicles growing rapidly more

than the expected rate.

As the automobile sector in India experiences

significant growth in EV adoption, the reliability and

safety of battery-powered electric vehicles present

additional challenges for focus on safety and security

becomes increasingly vital. Studies conducted by

various organizations indicate a

a

https://orcid.org/ 0009-0007-4409-0692

b

https://orcid.org/ 0009-0001-4439-7682

c

https://orcid.org/ 0009-0004-2129-6311

d

https://orcid.org/ 0009-0007-6877-1900

e

https://orcid.org/ 0000-0002-6381-2490

noticeable increase in the number of reported electric

vehicle fire accidents. These incidents have caused

considerable property damage, injuries, and even

casualties due to thermal self-ignition, battery

explosions, and fires caused by vehicle batteries. The

concerns surrounding the firefighting and emergency

rescue operations. Consequently, numerous research

efforts have been undertaken to address the

technology of lithium battery fire prevention and

control prevention and control the disturbances in

battery can cause fire (David, 2018).

The objective of this study is to design an

automatic fire extinguishing system using CATIA

software and a program coding to detect battery

temperature using Arduino software was carried out.

With considering all the reasons mentioned in fig1.,

the were conducted. The fig 1. shows different

reasons why Electric Vehicles catch fire. It can be

seen that many electric bikes catch fire during

charging and many incidents occur at charging

stations. There are also many other reasons for this as

mentioned improper wiring can also result in this. It

can also consider accidents as main reason during

collision study aims that it can prevent from property

damage, injuries and improve safety.

Sonnad, M., Saqhib, M., Khan, M., Jha, H. and Sudhakar, P.

Design of Automatic Fire Extinguisher System for Electric Vehicles.

DOI: 10.5220/0012525900003808

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Intelligent and Sustainable Power and Energy Systems (ISPES 2023), pages 125-130

ISBN: 978-989-758-689-7

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

125

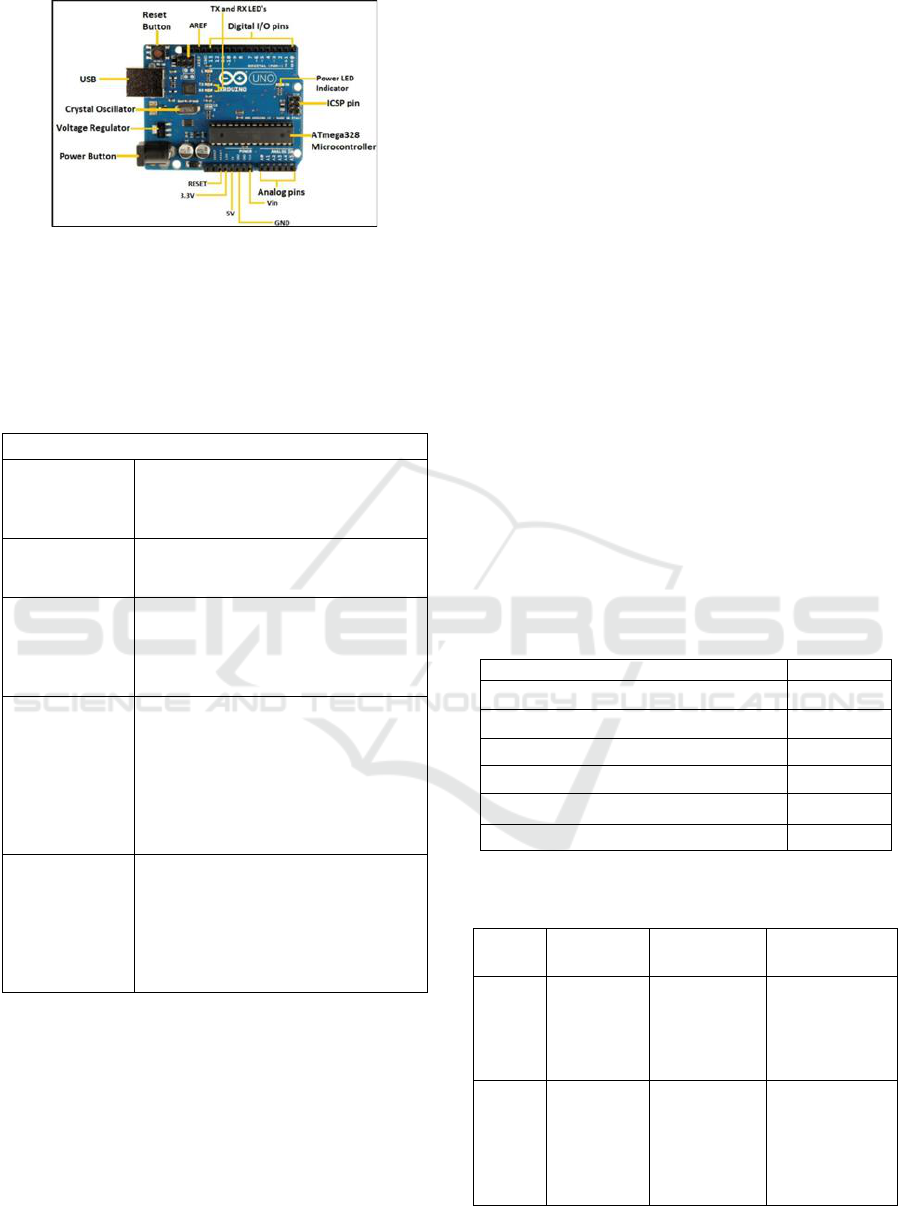

Fig. 1: Parts of Arduino UNO.

In consideration of fire in battery of EV, two types

of fire namely Class B and C are present in this fire

detection in lithium batteries and their brief

information of each fire is listed below:

Table 1: TVS bike details.

Why EVs Catch Fire

Short circuit

A short circuit brought about from a wiring

fault to even a puncture in the cells can

cause a rise in temperature and

subsequently a fire.

Faulty charging

Using incorrect and/or faulty cables or wall

outlets can also trigger a fire with an

incorrect amount of electricity

Cell quality

Even a single contaminated cell can spark a

massive fire, igniting itself and then leading

to the dreaded thermal runway igniting

subsequent cells thanks to the temperature

rise.

BMS issues

The key safety task in any battery

management system (BMS) is temperature

control. This entails carefully managing

both charge and discharge speed and

cycles, any fault here can raise the battery

temperature sufficient enough to combust

and high ambient temperatures exacerbate

the issue.

Accidental damage

Though protected very well, a battery

getting punctured or even dented in an

accident can lead to cell ruptures and thus

ignition. An accident can also spill oil - yes

EVs have oil for lubrication and cooling -

onto hot electrical components which can

ignite and lead to a bigger blaze

Class B Fire:

Class B fires are ignited by flammable liquids or

gases such as alcohol, kerosene, paint, gasoline,

methane, oil-based coolants, or propane. Water is

ineffective for extinguishing Class B fires. Instead,

Carbon Dioxide (CO

2

) or dry chemical agents are

typically used to combat these fires.

Class C Fire:

Class C fires are characterized by live electrical

currents or electrical equipment as their source of

fuel. These could include electric tools, appliances,

motors, and transformers. Such fires are prevalent in

industrial settings dealing with energy or electrically

powered quipment, such as wind turbines. Water is

unsuitable for fighting electrical fires and can worsen

the situation. Non-conductive chemical agents,

including clean agents, are recommended for

extinguishing the flames (Yang, 2018).

In this case, the study deals with an Iqube (TVS

make) bike battery with a capacity of 24Ah and

battery details are stated in table 1.

1.1 Fire Suppression Agents for

Battery Fire

Table 2 shows some of the fire suppression agents and

its effectiveness to the fire. This indicates that various

compounds have various suppressing effects and that

various agents are effective for various battery kinds.

In some agents the re-ignition which might be danger

sometimes. So, careful consideration of parameters

related to selection of agent which is used in the

system (Yang, 2018).

Table 2: Battery specification.

Nominal Capacity

24 Ah

Capacity

24 Ah

Nominal Voltage

60 V

Maximum Charging Current

5 Amp

Warranty

2 yrs.

Model Name/Number

IQube

Minimum Order Quantity

1

Table 3: Different fire suppression agents for different

batteries.

Agent

Battery type

Release

moment

Suppression

effectiveness

CO

2

LiNi

03

Co

0.2

Mn

0.3

O

2

/Grap

hite

Safety valve is

opened

It took 30sec to

suppress the fire

but reignition was

observed during

releasing

HFC-

227ea

LiNi

03

Co-

0.2

Mn

0.3

O

2

/Gr

aphite

Safety valve is

opened

It took 22 s to

suppress the fire,

but re-ignition

was observed

during the releasi

ng

ISPES 2023 - International Conference on Intelligent and Sustainable Power and Energy Systems

126

Water

mist

LiNi

03

Co-

0.2

Mn

0.3

O

2

/Gr

aphite

Safety valve is

opened

No flame

appeared

Water

Ni

oxide/graphit

e

Temperature of

battery up

to 650 "C

Extinguished fire

within 20 s

CO

2

Ni

oxide/graphit

e

Temperature of

battery up

to 650 "C

Having no effect

on

reduced the temp

erature

Foam

Ni

oxide/graphit

e

Temperature of

battery up

to 650 "C

Extinguished fire

within 20 s

Water

mist

Ni

oxide/graphit

e

Temperature of

battery up

to 650 "C

No effect on

reducing the

temperature

Dry

power

Ni

oxide/graphit

e

Temperature of

battery up

to 650 "C

No effect on

reducing the

temperature

CO

2

LFP

Battery occurs

fire

Re-ignition

happened

HFC-

227ea

LFP

Battery occurs

fire

Suppressed the

fire Explosion

and thermal

runaway occurred

Super

fine

power

LFP

Battery occurs

fire

Explosion and

thermal runaway

accord

CO

2

13S5P

18650-TYPE

LiCoO

2

Cell

15 s after fire

occurred

Re-ignition

occurred at 10 s

after the

suppression

of open fire

Dry

powder

13S5P

18650-TYPE

LiCoO

2

Cell

15 s after fire

occurred

Re-ignition

occurred at 8s

after the

suppression

of open fire

3% AFFF

13S5P

18650-TYPE

LiCoO

2

Cell

15 s after fire

occurred

Re-ignition

occurred at 45 s

after the

suppression

of open fire

Aqueous

agent

5 18650-type

UBs

First battery

occur TR

None of the cells

propagated

Gaseous

agent

5 18650-typ e

UBs

First battery

occur TR

All of the cells

propagated

2 MATERIALS AND METHODS

The Automatic fire extinguisher system for EVs has

following components:

• Arduino UNO

• MQ 2 sensor

• RTD Sensor (temperature sensor)

• Solenoid valve

• Pressure cylinder for CO

2

• IR flame sensor

2.1 Arduino Uno

The Arduino Uno is a microcontroller board based on

the Microchip ATmega328P microcontroller (MCU)

and it is an open-source platform equipped with sets

of digital and analog input/output (I/O) pins, enabling

connections to various expansion boards (shields) and

circuits. The board features 14 digital I/O pins, with

six of them capable of PWM

(Pulse Width Modulation) output, and 6 analog I/O

pins. For programming the Arduino Uno, Arduino

IDE (Integrated Development Environment) with a

type B USB cable is used in this study. Power can be

supplied through either a USB cable or a barrel

connector that supports voltages between 7 and 20

volts, like a rectangular cross section 9-volt battery.

Fig. 2: MQ2 smoke sensor.

2.2 MQ2 Smoke Sensor

The Fig. 3 shows MQ2 smoke sensor, belonging to

the family of MQ sensors, operates based on Metal

Oxide Semiconductor (MOS) technology. It requires

a 5V DC supply and consumes approximately

800mW of power. This sensor can detect various

gases, including smoke, hydrogen, alcohol and

carbon monoxide with concentrations ranging from

200 to 10,000 parts per million.

Fig. 3: RTD Sensor.

Design of Automatic Fire Extinguisher System for Electric Vehicles

127

2.3 RTD Sensor

A RTD (Resistance Temperature Detector) is a

temperature sensor that exhibits a change in

resistance corresponding to fluctuations in

temperature. Fig. 4 shows the sensor used here. This

resistance-temperature relationship is widely

understood and remains consistent over time,

ensuring repeatability. It's important to note that an

RTD functions as a passive device (Wang, 2015).

Fig. 4: 160 Bar High pressure stainless-steel solenoid valve.

2.4 Solenoid Valve

Application of the solenoid valve maintains flow of

CO

2

, the valve product name is BRANDO SH as

shown in fig. 5 and the details are mentioned

below.Specifications of valve:Make/manufacturer:

BRANDO

1. Model no: SH

2. Working medium: air, water, gas, liquid, etc

3. Max Working Pressure: 160 bar

4. Seal Material: PTFE

5. Body Material: Stainless Steel 304

6. Port Size: 3/8'', 1/2'', 3/4'', 1''

7. Orifice Size: 1mm to 25mm

8. Operation: Direct Acting (DN1 to 5),

Piston Pilot Operated (DN10 to 25)

9. Voltage: 12VDC, 24VDC, 24VAC,

110VAC, 220VAC (50/60Hz)

Fig. 5: Technical Data of valve.

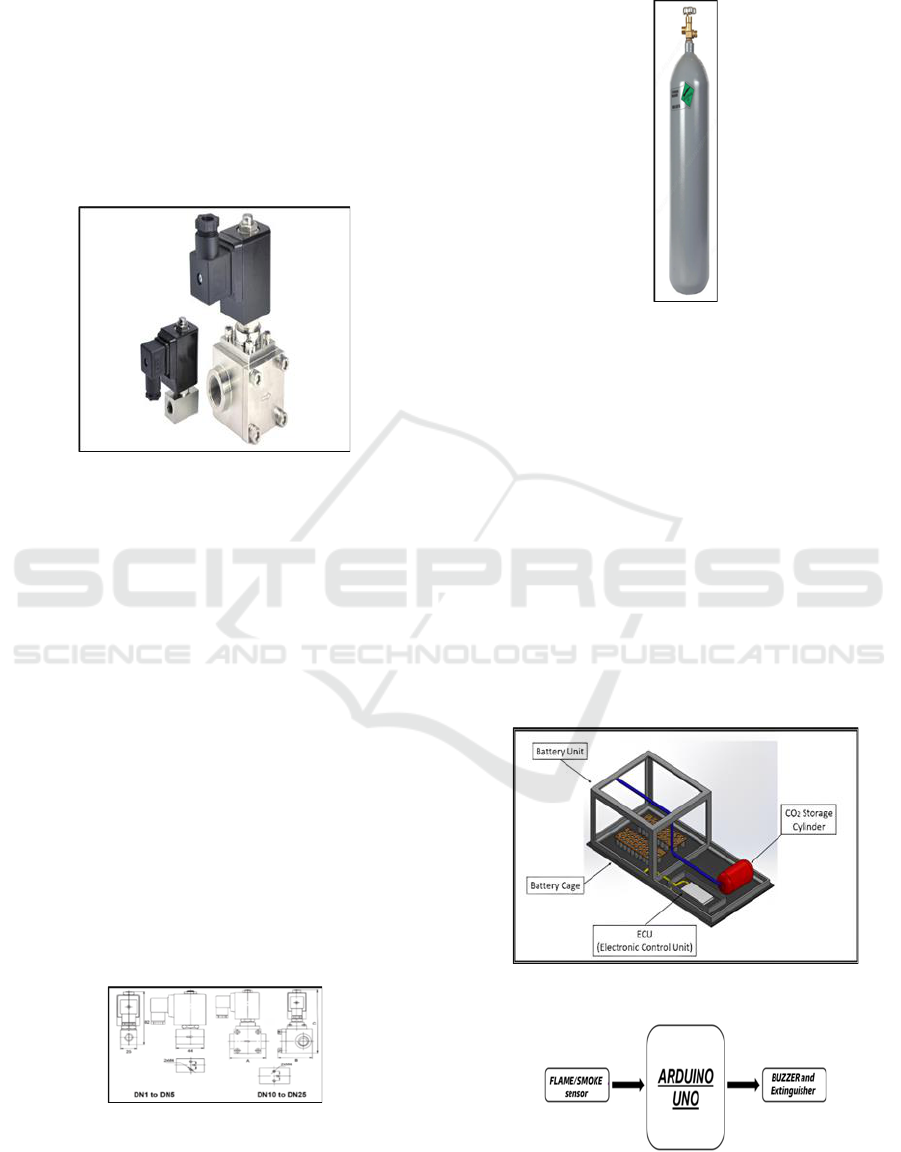

2.5 Pressure Cylinder for CO

2

Fig. 6: Pressure cylinder for CO2.

Fig. 7 shows bulk low-pressure carbon dioxide and

high-pressure canister CO

2

(Liu, 2003). Material and

Weight: CO

2

bulk tanks and cylinders are available in

various sizes depending on their intended use, and the

two most common materials used are aluminum and

steel. The weight of these tanks differs based on their

material and whether it is empty or filled. Bulk tanks

are stationary and typically constructed from 100%

stainless steel, and are prepared in various sizes to suit

specific requirements. The size and capacity offer

increased distribution flexibility and reduce the need

for frequent refilled cylinders. On the other hand, CO

2

canisters or cylinders are high-pressure tanks

designed for exchange of fluid. It is weighed over 100

lbs when empty and up to 200 lbs when filled.

Fig. 7: Prototype design.

Fig. 8: Working principle.

ISPES 2023 - International Conference on Intelligent and Sustainable Power and Energy Systems

128

Fig. 9: Circuit diagram.

2.5 Prototype Design for Fire

Extinguishing System

Various components, such as the flame sensor, gas

sensor, buzzer, and water pump, are connected to the

Arduino using jumper cables (fig. 10). These sensors

and components are linked to their respective pins, as

specified in the program that was uploaded to

Arduino. Power for the Arduino board comes from a

laptop, while the other components receive power

from the 5V pin on the Arduino.

Fig. 10: Temperature sensor output readings.

The IR flame sensor and MQ2 gas sensors

continuously monitor for the presence of flames or

smoke near the battery. If either sensor detects flame

or smoke, it sends a value of 1 to the Arduino,

indicating the presence of fire or smoke. The

Arduino, in turn, triggers the buzzer, and the water

pump floods the battery compartment with water until

the fire is extinguished.

The design of the automatic fire extinguisher

system is intended for the “IQube”, which features a

3.04kWh Lithium-Ion battery with a curved shape.

The structure is constructed using materials capable

of withstanding higher temperatures and is less prone

to catching fire, unlike steel. The design incorporates

breathing holes to facilitate battery cooling. The

flame sensor has an effective range of 30cm, and

smoke sensors are strategically placed in each corner,

approximately 50cm apart from one another, mainly

oriented towards the terminals to cover the entire

battery area as seen in fig. 8. In the event of flame or

smoke detection, the buzzer and solenoid valve are

activated as seen in fig 9, allowing the flow of AVD

(Automatic Vapor Dispenser) stored in the boot

space. Within 25 seconds of detection, the curved

structure is flooded with AVD, preventing further

damage to components, and avoiding battery

explosions (Roy, 1970).

3 RESULTS AND DISCUSSION

Results are discussed in this section.

3.1 Results

Outputs of sensors are discussed.

3.1.1 IR Sensor Output

The output of an IR (infrared) sensor can vary

significantly depending on its specific type. It will

manifest in various forms, such as digital signals that

signify the presence or absence of an object. Analog

signals that correspond to the intensity of detected

infrared radiation, pulse width modulation (PWM)

signals that change based on proximity or intensity,

or serial communication protocols that offer detailed

information, including calibrated values or distance

measurements. To successfully integrate an IR sensor

with microcontrollers or other electronic components

for further processing and decision-making, it is

crucial to consult the sensor's datasheet or relevant

literature. Fig. 10 shows the temperature variation for

the given period of time. The reference value for

initiation of flame considered is 1500 C, it is seen in

the fig. 10 the designed system detects in 20 seconds.

Maximum upper limit and minimum upper limit is

160 and 1060 C in the temperature management of

fire detection is considered.

3.1.2 MQ2 Sensor Output

The MQ2 smoke sensor will detect the presence of

smoke or flammable gases within a range of 300 ppm

to 10000 ppm. Its output typically takes the form of

an analog signal, with variations in voltage or current

proportional to the quantity of smoke or flammable

Design of Automatic Fire Extinguisher System for Electric Vehicles

129

gases detected. Higher concentrations of smoke or

gas leads to an increase in the output signal, while

lower concentrations result in a decrease in signal

strength. In areas where there is a potential risk of

smoke or combustible gases, this analog output can

be further processed or utilized in conjunction with

microcontrollers or other electronic devices to trigger

alarms, activate safety features, or assess the air

quality.

3.2 Discussions

In the realm of fire suppression, innovative solutions

tailored specifically for electric vehicles (EVs) are

emerging. These solutions encompass various

methods such as foam, inert gases, water mist, and

even solid-state extinguishing substances. In

comparison to traditional fire suppression systems,

these cutting-edge technologies offer numerous

advantages, including enhanced effectiveness in

extinguishing battery fires, reduced environmental

impact, and simplified installation and maintenance

processes. The integration of fire suppression

systems with other vehicle safety features is a

possibility in the future. This could involve

combining them with existing safety mechanisms like

airbags and battery management systems. Such

connectivity would enable the fire suppression

system to activate automatically in the event of a fire

or be manually triggered by the driver or passenger

during emergency situation (Wang, 2002).

As EV technology continues to gain wider

adoption, it becomes imperative to establish new

criteria for EV fire safety. These standards must

account for the diverse range of fire suppression

devices available and consider the unique

characteristics of EV batteries. By doing so, it is

ensured the utmost safety and protection as electric

vehicles become more prevalent on the roads.

4 CONCLUSION

After conducting an extensive review of various

literature papers and developing an automatic fire

extinguisher system for electric vehicles, the study

arrives the conclusion that the designed model

exhibits excellent capabilities in detecting and

extinguishing fires. Moreover, it can be seamlessly

integrated into production electric vehicles, thereby

significantly reducing the occurrence of electric

vehicle fire accidents. The inclusion of infra-red

flame sensors and MQ2 smoke sensors ensures a

swift response to battery fires. In the event of a fire,

these sensors will promptly trigger the fire

extinguisher system and alarm, effectively containing

the fire's spread, minimizing component damage, and

reducing the risk of explosions. The alarm system

serves as a crucial warning mechanism, alerting riders

and bystanders to evacuate to a safe distance before

any potential dangers escalate. To ensure continuous

monitoring of battery temperature, a temperature

sensor module is incorporated. In situation where

battery's temperature exceeds a certain threshold,

indicating a high likelihood of fire or explosion, the

system takes preventive measures. It immediately

disconnects the battery from circuits and charging to

prevent any potential fire, and the cooling system is

activated to mitigate temperature rise (Yang, 2018).

In the literature, Advanced vehicle diagnostics

(AVD) was mentioned as the most efficient fire

extinguishing agents for lithium-ion battery fires,

though a complexion in design, intended not to

include them in this field of study. Also, several

reasons integrated for excluding AVD in design for

eliminating increasing complexity, programming

requirements, and associated component costs.

Nonetheless, the designed system with its array of

sensors and fire extinguishing mechanisms is proven

to be highly effective and addresses the critical need

for enhanced fire safety in electric vehicles.

REFERENCES

David Wagman (2018). Powerplant run on CO

2

.

Yang, Z., Lian, Z., Xiong, J., Miao, Z., Yu-hui, A., & Chen,

A. (2018). Feasibility study on applying the mist-

spraying cooling to improve the capacity of ultra-large

container ships for loading reefers. Ocean

Engineering, 163, 377–390.

https://doi.org/10.1016/j.oceaneng.2018.06.009

Liu, Jianghong & Liao, Guangxuan & Li, Peide & Fan,

Weicheng & Lu, Qiang. (2003). Progress in research

and application of water mist fire suppression

technology. Chinese Science Bulletin. 48. 718-725.

10.1007/BF03187040.

Wang Xishi, Liao Guang-xuan, Jun, Q., & Fan Weicheng.

(2002). Experimental Study on the Effectiveness of the

Extinction of a Pool Fire with Water Mist. 20(4), 279–

295. https://doi.org/10.1177/073490402762574730

Wang, Z. L., Chen, J., & Lin, L. (2015). Progress in

triboelectric nanogenerators as a new energy

technology and self-powered sensors. Energy &

Environmental Science, 8(8), 2250–2282.

https://doi.org/10.1039/c5ee01532d

Roy Chowdhury, Joydeb & Banerjee, Tribeni Prasad &

Das, Swagatam & Abraham, Ajith & Snasel, Vaclav.

(1970). Fuzzy Rule Based Intelligent Security and Fire

Detector System. 10.1007/978-3-642-04091-7_6.

ISPES 2023 - International Conference on Intelligent and Sustainable Power and Energy Systems

130