Conceptualizing a Digital Twin Model for Natural Gas Retailing in a

Geographic Area in India

Asim Prasad

1

, Anita Kumar

2

and Pratyush Prasad

3

1

Amity Business School, Amity University, Noida, India

2

CII School of Logistics, Amity University, Noida, India

3

Data Science and Engineering, Manipal University, Jaipur, India

Keywords: Digital Twin, Natural Gas, Gas-Based Economy, Climate Change, City Gas Distribution.

Abstract: In the fourth Industrial Revolution context, various industries are embracing advanced technologies such as

artificial intelligence, machine learning, big data analytics, and the Internet of Things to facilitate Net Zero

transition with digital transformation. A notable development in this field is the Digital Twin (DT), a virtual

representation of the physical system. Digital transformation enhances process management, elevates business

performance, and facilitates the advancement of sustainable energy transition as a viable solution for the

challenges arising from climate change. India's strategic goal of achieving a gas-based economy by 2030, by

providing widespread access to a local distribution network for cleaner natural gas serving 98% of the

population has motivated the study of integrating advanced digital technology into gas retailing as a viable

solution for decarbonized economic growth. Accordingly, this exploratory study presents a novel conceptual

model of a Digital Twin for natural gas retailing. The model aims for efficient real-time management of city

gas operations in India to enhance natural gas retail consumption for accelerating a gas-based economy

transition. This supports India’s commitment to providing affordable access to cleaner fuels under its SDG 7

framework. The research has practical implications for society to manage local climate change issues

effectively.

1 INTRODUCTION

Digitalization has emerged as a prominent aspect of

the Industrial Revolution (IR) that originated in the

18

th

century. It has progressed to its present state,

witnessing rapid automation of global production and

supply chains having smarter networks for efficient

working(Status & Trends, 2020). The contemporary

period characterized by the widespread adoption of

digital technologies is commonly called the "Fourth

Industrial Revolution" or "Industry 4.0". The Fourth

Industrial Revolution (4IR) comprises a range of

state-of-the-art sophisticated technologies, including

cyber-physical systems (CPS), the Internet of Things

(IoT), the Industrial Internet of Things (IIoT), cloud

computing, cognitive computing, artificial

intelligence (AI) and machine learning (ML). CPS are

intelligent systems where computer algorithms

control any mechanism. The IoT constitutes a

network of physical objects like sensors and devices

that exchange data over the internet. The IIoT

comprises interconnected instruments and sensors for

industrial applications. Cloud Computing involves

availing computing services over the internet.

Cognitive computing is the simulation of the

functioning of the human brain on a computer system.

AI involves delivering human intelligence by

machines. ML is an AI subdomain where the machine

continuously learns from past data. Deployment of

these advanced technologies significantly influences

several product life cycle stages (Ali et al., 2022).

At the forefront of this 4IR technological

upheaval is the concept of the Digital Twin

(Aheleroff et al., 2021; Mckinsey and Company,

2023). The Digital Twin (DT) is a highly developed

simulation model representing a physical product's

twin. Unlike static 3D models, the DT is a dynamic,

data-driven simulation model that evolves in real time

based on insights from its physical counterpart

(Aheleroff et al., 2021). Its core objective is to

provide a comprehensive perspective of a physical

entity, from design and manufacturing to operation

and after-sale services (Melesse et al., 2020). Serving

as a digital replica, the DT facilitates simulation,

Prasad, A., Kumar, A. and Prasad, P.

Conceptualizing a Digital Twin Model for Natural Gas Retailing in a Geographic Area in India.

DOI: 10.5220/0012531600003792

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st Pamir Transboundary Conference for Sustainable Societies (PAMIR 2023), pages 947-956

ISBN: 978-989-758-687-3

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

947

prediction, decision-making, optimization, and new

product development. By using the DT, engineers and

operators can assess the impact of design choices on

product quality and functionality before committing

to costly physical prototypes. A defining feature of

the DT is its ability to offer a holistic view of a

physical entity throughout its life cycle (Melesse et

al., 2020). The DT concept finds applications in

diverse fields (Jones et al., 2020), including

Transportation (aircraft and automobiles), healthcare,

and urban planning (smart cities) underpinning

Digital Transformation.

Offlate, DT is becoming increasingly valuable as

an enabler in Oil and Gas Pipeline Systems(Bo et al.,

2021) for enhancing upstream production,

efficiencies, and customer experience to reduce

carbon footprints. The Oil and Gas Systems generate

large amounts of complex data that is challenging to

process and handle. These data relate to Exploration

and Production(E&P), Refining, Transportation,

Distribution, Pipeline Hydraulics Management,

Marketing, and Sales. The data sets manifest

characteristics of Big Data (volume, variety, velocity,

veracity, value, and complexity), so they require

powerful and innovative processing technologies for

their management(Mohammadpoor & Torabi, 2020).

As the global debate on Net Zero Transition has

intensified(IEA, 2021a), the application of Big Data

Analytics to accelerate Energy Transition has gained

momentum, with many countries aiming to achieve

their decarbonization targets by 2050. In this

direction, IEA argues that innovative solutions and

digital transformation will be necessary to achieve

this(IEA, 2021b). Further, MIT Technology Review

Insights; & Shell Inc;, 2022 research finds that digital

technology will be the backbone of Net Zero

Transition. With mounting pressure on developing

countries to combat Climate Change, the Indian

Government has set ambitious targets to augment the

share of clean energy in India's primary energy

consumption (PEC) mix. One of the aspirations is to

raise the contribution of Natural Gas (NG) in India’s

PEC mix from 6% to 15% by 2030, aiming for

climate management and decarbonized sustainable

economic growth. NG is the cleanest fossil fuel. It

burns entirely without leaving any particulate

matter(EIA, 2022), hence the global choicest fuel.

While NG constitutes 24.2% of the global PEC mix,

it only amounts to 6.3% in India(BP, 2022). The

Indian focus is shifting from conventional liquid fuels

to cleaner NG, aiming to curtail GHG emissions. This

transition towards a gas-based economy(GBE)

necessitates substantial investments, including a $60

billion commitment to develop gas infrastructure like

Liquified NG(LNG) import terminals, NG Pipeline

Networks, and local distribution networks under City

Gas Distribution(CGD) Projects (PTI, 2019). Such

infrastructure will ensure NG door delivery and

affordable access to retail customers for meeting SDG

7 targets.

Presently, 11 million households use Piped

Natural Gas(PNG), while over 5700 Compressed

Natural Gas(CNG) stations dispense cleaner NG fuel

to the transport segment(PPAC, 2023). Under normal

conditions, the CGD operators monitor the gas flow,

pressure, and temperature to manage demand and

supply. However, several Supply Chain

Management(SCM) issues related to Marketing,

Operations, Maintenance, and Safety arise while

dealing with PNG household customers. These must

be tactically managed in real-time to enhance

customer experience and service while ensuring that

the continuity of gas supply to domestic kitchens is

safely maintained. Also, PNG consumption data is

essential to calculate the reduction in carbon dioxide

emission when NG replaces polluting fossil fuels.

The development of the CGD Network is

progressing fast to attain extensive coverage of the

local distribution Supply Chain (SC) network,

encompassing 88% of the land area (2.89 million sq

km) to achieve the stated objective of enhancing NG

consumption. This network aims to provide NG

access to 98% of the population (1.4 billion) residing

in 295 Geographic Areas (GA's) spanning over 600

districts of the country(PNGRB, 2023). Nevertheless,

managing CGD operations on a vast scale presents

intricate and challenging situations. Not a single

nation has hitherto undertaken such an endeavor

globally. Nevertheless, AI and ML techniques

involving digital technology are powerful enough to

handle large volumes of real-time data comparable to

those produced during CGD operations. However,

DT models involving AI, ML, and big data analytics

have not yet been applied for gas retailing in CGD

projects. Considering these, the research question

(RQ) that comes to the researcher's mind is as

follows:

RQ: Can a Digital Twin Model with AI, ML, and

Big Data Analytics manage the complex and

intricate CGD operations to promote Net

Zero Transition?

Based on the above argument, this research aims

to develop a Conceptual Digital Twin Model for PNG

Retailing in a GA in India. The deployment of AI and

ML tools and techniques within the DT frameworks

may effectively imitate the behavior of physical

systems. This approach proves beneficial in

monitoring and remotely controlling CGD network

PAMIR 2023 - The First Pamir Transboundary Conference for Sustainable Societies- | PAMIR

948

operations. Implementing DT solutions that

effectively address real-time challenges will enhance

the customer experience significantly. The rest of the

article is structured as follows. Section 2 is the

literature review involving (i) the supply chain for

NG retailing, (ii) safety considerations during NG

transportation, and (iii) DT concepts and use case

applications. Section 3 presents the Conceptual DT

model. The article ends with a conclusion and future

research directions.

2 LITERATURE REVIEW

An integrative concept-centric review was

undertaken first to present the physical elements of

the CGD Network underpinning its SC and then to

understand the technicalities and associated

requirements for the deployment of DT for PNG

retailing and CNG dispensing within a GA.

2.1 Supply Chain for NG Retailing

The retail sector comprises domestic, industrial, and

commercial customers whose daily NG requirement

is less than 50,000 SCMD(PNGRB, 2018) and the

CNG transport segment, where vehicles use the NG

as fuel. The PNGRB authorizes entities to build, own,

and operate the CGD network over its

lifecycle(PNGRB, 2008). The entire GA is divided

into small charge areas, the potential load or demand

centers for gas consumption. All the demand centers

are connected with the CGD network to maintain a

continuous supply of PNG and CNG. The authorized

CGD entity, the SC owner, is therefore responsible

for building, owning, and operating the SC network,

satisfying the demand and expectations of retail

customers. The physical network is designed as per

PNGRB T4S regulations for CGD. The network

comprises City Gate Station(CGS), an odourization

unit, underground carbon steel externally coated and

Polyethylene (PE) pipelines, cathodic protection (CP)

systems for corrosion control, optical fiber cables to

transmit data, regulator stations, gas meters, flow and

pressure control valves, isolation valves, pressure,

and temperature transmitters. Further, the

Supervisory Control and Data Acquisition (SCADA)

System is deployed to enable real-time remote data

collection and control. NG characteristics, flow rates,

operational pressures, and the surrounding

environment are all considered during the CGD

network design. According to the pressure

requirement, the SC design consists of primary

(medium-pressure distribution system),

secondary(low-pressure distribution system), and

tertiary (service pressure distribution systems)

networks. The pressure regulator station is the

(i) district regulator station (DRS) at demand

centers with provision to reduce pressure

(ii) individual pressure regulating station(IPRS)

at customer premises

(iii) service regulator station(SRS) to maintain

supply pressure.

The design ensures the supply of NG at constant

volume with varying pressure and gas at constant

pressure at the consumer end.

The retail SC comprises upstream gas suppliers, the

CGD entity, and different segments of retail

customers connected to the network. The major

functions of retail SC are to:

(i) serve in market mediation to create product

variety i.e. PNG (domestic, commercial, and

industrial) and CNG;

(ii) safely deliver PNG continuously at

contractual conditions to all segments of end

consumers,

(iii) safely deliver CNG uninterruptedly at the

required pressure at CNG outlets.

The typical retail SC for the CGD is in Figure 1, and

the CGS is in Figure 2.

Figure 1: SC for CGD network.

Figure 2: CGS Design (Garg, 2019).

Conceptualizing a Digital Twin Model for Natural Gas Retailing in a Geographic Area in India

949

The flowchart showing different network

components and pressure ratings is in Figure 3. Each

load center has CNG stations with multiple dispensers

and a number of customers. Real-time data relating to

total gas receipt by the CGD entity from the gas

supplier at CGS(flow rate), gas consumed by each

customer within the load center, gas dispensed at each

CNG station, along with gas pressure, gas

temperature etc., are paramount to manage demand

and supply. SCADA, an industrial control system,

monitors and manages field services at off-site

locations. It provides access to real-time data.

Different sensors like pressure and temperature

transmitters are installed along the CGD network to

record pressure and temperature data. The IoT

devices connect and exchange these field data over

the internet or other communication channels. NG

metering system reconciles gas received at CGS by

the CGD entity and the total gas sold. These help

monitor the pipeline hydraulics, demand, supply

management, gas leakage, etc. The associated parties

directly connected to the CGD network in a load

center and related data points of interest are in Table

1.

Figure 3: CGD Flowchart(Rajput et al., 2022).

Table 1: Associated Parties and Data Point.

Parties

Data Point

Gas Supplied to CGD entity

at City Gate Station(CGS)

Flow rate, Pressure,

Temperature, Gas

Composition

PNG domestic customers

Flow rate; Gas

Pressure

PNG commercial customers

PNG industrial customer

CNG Stations

Quantity of gas sold

per dispenser

2.2 Safety in NG Transportation

NG is a hazardous, category 1, extremely flammable

mixture of methane, ethane, propane, butane, and

higher hydrocarbons(IGL, 2022). It is lighter than air

and compressible. It is a simple asphyxiant. It ignites

with static charge and sparks. It is colorless and

odorless, so it is dozed with mercaptan when injected

into the CGD network to provide a pungent order to

detect its leak with the smell. Safety during pipeline

transportation through the CGD network is

paramount for ensuring safety. Different standards

and guidelines published by PNGRB, OISD, and

ASME are followed during the CGD network's

design, operation, and maintenance, as depicted in

Figure 4.

Figure 4: PNG distribution system (Garg, 2019).

2.3 Digital Twin Concepts and Use

Case Application

2.3.1 What Is Digital Twin

DTs are based on the idea that there should be a one-

to-one real-time correspondence between a real-

world product and its digital counterpart (Bo et al.,

2021). Any actions taken in the virtual world can have

repercussions in the real world and vice versa.

Inversely, information gathered about the physical

system can be used to refine and perfect the virtual

model. The effectiveness of any DT deployment

depends on the degree to which the digital and

physical worlds are in synchronization. DT has

emerged as a critical subject within Industry 4.0. DT

is "a realistic digital representation of assets,

processes, and systems that connects data between

the real world and its digital representation" (CDBB,

2020). It provides a micro and macro-level accurate

virtual description of a physical system(Jones et al.,

2020). DT shows how a real thing acts and keeps

changing throughout its lifecycle (Opoku et al.,

2021). It is a connected and synchronized digital

replica of physical assets representing the elements

and the dynamics of how systems and devices operate

within their environment and live throughout their

lifecycle. It is a synchronized, interconnected digital

representation of physical assets that captures the

aspects and dynamics of how systems and equipment

function in their surroundings and progress through

their lives(Borth et al., 2019). It is associated with 4IR

PAMIR 2023 - The First Pamir Transboundary Conference for Sustainable Societies- | PAMIR

950

(Negri et al., 2017) as one of its enabling

technologies(Melesse et al., 2020).

2.3.2 Parts of Digital Twin

DT comprises three parts, namely (i) the physical

system in real-world settings, (ii) the virtual

counterpart, which is the virtual entity, and (iii) the

two-way link between the real and virtual

entity(Pregnolato et al., 2022). Data, information, and

knowledge are exchanged between the real and

virtual systems that require computers, IoT, IIoT,

high-speed internet, and advanced analytics (Rosen et

al., 2015). High-end technologies like the AI and ML

are deployed to conduct big data analytics,

simulation, and forecasting.

2.3.3 DT Application

DT finds different applications, namely (i) demand-

supply management, (ii) predictive maintenance and

disaster preparedness, (iii) asset management (iv)

simulating real situations and scenario planning in

different conditions. The DT can be developed for the

design, production, and service phases(Semeraro et

al., 2021). It provides real-time awareness of the

situation, data management, better visualization,

planning, prediction, integration, and collaboration

(Shahat et al., 2021). DT fosters innovation and

enhances productivity, security, safety,

dependability, decision-making, and

adaptability(Jones et al., 2020; Negri et al., 2017). It

decreases costs, risks, and design time. In machines,

it enhances its visibility. It connects business

processes and helps in supply chain activities, aiding

financial decisions(Melesse et al., 2020). It gains

importance when its design captures user-diverse

experiences at the operator level. It enhances the

organization's environmental sustainability, builds

capabilities, and helps learn from behavior

data(Mckinsey and Company, 2023). Considering

these, the literature reveals that the DT model has

potential use case application (Semeraro et al., 2021)

for a wide variety of real-life problems of diverse

nature:

(i) Aviation, Precise Medicine,

Manufacturing(Barricelli et al., 2019)

(ii) Intelligent Transportation comprising

operations of Electric Vehicles(Ali et al.,

2022)

(iii) Smart Cities and Infrastructure(Aheleroff et

al., 2021; Pregnolato et al., 2022; Shahat et al.,

2021)

(iv) Industrial Operation applications like

predictive maintenance, production, and after-

sales(Errandonea et al., 2020; Melesse et al.,

2020)

(v) Construction Industry(Opoku et al., 2021)

(vi) Smart Grid and Smart Lightning(Borth et al.,

2019)

(vii) Product Design (Tao et al., 2019)

(viii) Human Health, Farming (Jones et al., 2020)

(ix) Oil and Gas Industry(Bo et al., 2021)

(x) Transportation and Storage of Hazardous

Chemicals(Li et al., 2022)

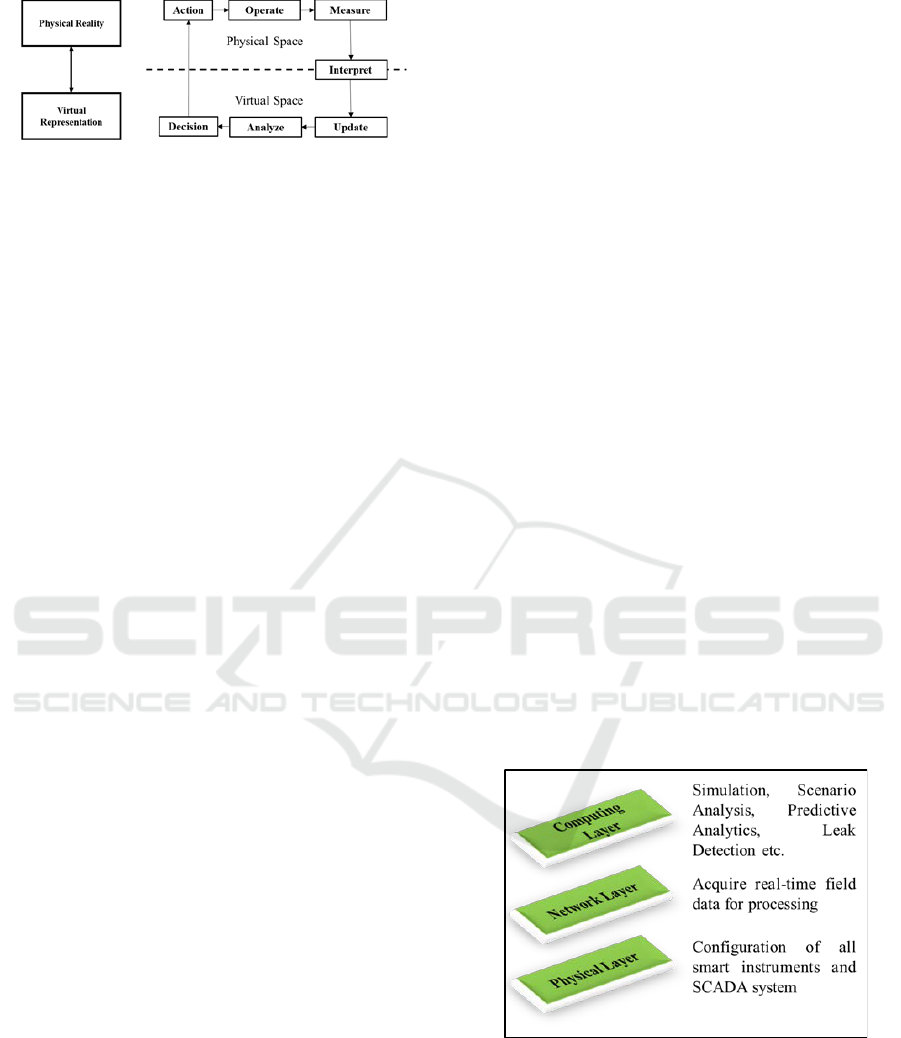

2.3.4 DT Component and Architect Layers

The DT components and architect comprise three

different layers, namely:

(i) Physical layer: This layer comprises sensors

and devices plugged into the physical system

to collect real-time data

(ii) Network Layer: To transmit the data and

information from the physical system to the

virtual system

(iii) Computing Layer: Consists of the virtual

model to mimic or mirror the corresponding

physical entity.

The critical elements in the design of a DT model are:

(i) Physical Entity/Twin(Negri et al., 2017)

(ii) Virtual Entity/Twin(Bo et al., 2021)

(iii) Data Collection and IoT(Ali et al., 2022)

(iv) Cloud Computing and Big Data(Aheleroff et

al., 2021)

(v) Realization and Synchronization(Schleich et

al., 2017)

(vi) Simulation and Analytics(Jones et al., 2020)

Different platforms are commercially available to

implement DT, like IBM Watson, Microsoft Azure,

Simens PLM etc..

2.3.5 Platforms to Implement DT and Its

Dimensions

The three dimensions of the DT relate to its life cycle

phases, hierarchical levels, and the intent of its

implementation(everyday use). Accordingly, the DT

involves different hierarchical levels like information

sharing, components, products, systems, and multiple

systems. Its life cycle phases are design, build,

operate, maintain, optimize, and decommission.

Some of its everyday use relate to digitalization,

visualization, simulation, mirroring, extraction, asset

interoperability, maintenance, orchestration, and

prediction. A typical DT process and component are

in Figure 5.

Conceptualizing a Digital Twin Model for Natural Gas Retailing in a Geographic Area in India

951

Figure 5: DT process and component (VanDerHorn &

Mahadevan, 2021).

2.3.6 DT for Pipeline Service

The implementation of DT as a critical enabling

technology toward achieving an intelligent pipeline

system has been reported for China Russia East Line

for achieving long-term goals(Bo et al., 2021). DT for

a pipeline service has been defined as "a digital model

constructed in virtual space, which is precisely

mapped, consistent in behavior, growing together,

and iteratively optimized with the actual pipe

system"(Bo et al., 2021). According to this definition,

the DT features are precise mapping, consistent

behavior, time consistency(growing together), and

iterative optimization.

The objective of DT is driven by (i) data analysis

and visualization, (ii) IoT or Industrial Internet, and

(iii) Simulation. However, the intelligent system

requires the integration of (i) information and

technology, (ii) information and automation (iii)

human-computer decision-making to achieve its

intended objectives. As such, the domain of DT for a

pipeline system requires the integration of multiple

technologies from different fields, such as IoT, data

transmission, big data analytics, data visualization,

simulation, prediction, knowledge networks, and

other technologies. A DT design concept for Oil and

Gas Pipelines proposed by Bo et al., 2021comprises

entity end and application end under "two ends" with

a data model and virtual model under "two core".

2.3.7 IT/OT Convergence

Deploying an industrial internet would be the key to

IT and OT convergence to merge business processes,

provide new insights, and implement controls into a

single platform. While IT systems are used for data

-

based computing, OT systems manage and control

physical devices. It focuses on behavior and

outcomes, watching events, processes, and devices to

change business and industry operations.

Concurrently, the ML and AI techniques in the Oil

and Gas Sector process a large amount of real-time

data to improve safety, performance and ease of

decision-making (Sircar et al., 2021).

In light of the above deliberations, the Conceptual

Digital Twin model for managing the complex and

intricate CGD operations to promote Net Zero

Transition for PNG retailing within a GA is presented.

3 CONCEPTUAL DIGITAL TWIN

MODEL

Digital Transformation is vital for implementing a DT

facilitating 4IR principles underpinning data

management of the physical system, big data

analytics, AI and ML. The researcher followed the

following steps to design the DT model (Tao et al.,

2019):

(i) Creation of Virtual System (or product) of

Physical System (or product)

(ii) Data collection, analysis, integration, and

visualization

(iii) Simulation of product behavior in the

virtual environment

(iv) Behaviors control

(v) Establish two-way real-time

communication between the physical and

virtual system or product.

NG being hazardous, the safety aspects are

considered vital during the design of the physical

system that facilitates monitoring the safety

parameters remotely on the virtual system. As

depicted in Figure 6, three layers are created to set up

the DT.

Figure 6: DT Layers.

(i) Physical Layer: This layer constitutes the

pipeline network, different instruments,

devices, sensors, and equipment that are

installed at identified locations on the CGD

network. They capture real-time pressure,

flow, and temperature data. The SCADA

PAMIR 2023 - The First Pamir Transboundary Conference for Sustainable Societies- | PAMIR

952

system transmits data remotely to the central

control room.

(ii) Network Layer: A network layer is created

to acquire all the field data for processing

through the IT system. At the unit level, this

constitutes

(a) the NG received at the CGS, its pressure,

composition, and temperature

(b) PNG consumed by each customer

(c) CNG dispensed through CNG dispensers

(d) Data from each regulator station

(e) Current and voltage data from the CP

system

(f) Data from the automated odorization unit

(g) Data from gas detectors installed at

critical locations

(h) real-time audio/visual data, if required,

from the CGS station or any other

installation

(iii) Computing Layer: A virtual model of each

charge area is to be created that comprises

segment-wise individual PNG customers and

CNG stations. Then, the virtual model for all

charge areas within the GA is integrated to

form the virtual SC for the CGD network.

Different dashboards are created within the

IT system to display and monitor various

parameters related to pipeline hydraulics,

mass balancing, leak detection etc. The

convergence of IT/OT systems is vital to

mimic the physical system in the virtual

world precisely. Smart field instruments and

devices enable real-time data acquisition and

transmission. Other decisions that the CGD

entity needs to take relate to data security,

data storage, platforms to set up the DT, tools

for simulation and predictive analytics etc.

The data-driven models assist in making

different operational decisions related to

demand-supply management,

mass/volume/energy balancing, leak

detection, business decisions related to

demand forecasting for gas sourcing, pricing,

billing, sales revenue, enhancing operating

margins etc.

Accordingly, the Conceptual DT Model is shown in

Figure 7. The virtual model can be superimposed into

the physical map of the district where the SC for CGD

network will operate.

4 CONCLUSIONS

Digital Transformation is the global buzzword

believed in providing real-time solutions to real-life

business and social problems that impact the quality

of life, well-being, climate change, and energy

transition (EIA, 2022). Though the Indian model for

GBE transition and ecological modernization is

available in the literature(Prasad & Kumar, 2022),

alongside physical models for CGD (Rajput et al.,

2022; Yadav & Sircar, 2022), intelligent models

suiting Indian conditions based on AI, ML and Big

Data Analytics underpinning 4IR are scanty. As such,

the conceptual digital twin model in Figure 7 proposed

in this research is the first innovative step to promote

the digital transformation of the Indian NG retail

sector, leveraging Industry 4.0 standards.

Source: Authors Analysis

Figure 7: Conceptual Digital Twin Model for NG Retailing within a GA.

Conceptualizing a Digital Twin Model for Natural Gas Retailing in a Geographic Area in India

953

This paves the path for smarter societies since the

DT model precisely measures the decrease in

emissions when NG replaces carbon-intensive fossil

fuels at the household level. Even though the Indian

NG sector witnesses challenges in the speedy

execution of pipeline projects(Prasad, 2011), a SCM

framework to overcome such challenges exists that

has the potential to manage delays in establishing

CGD network, tackle time and cost overrun,

adversely impacting delivered NG price(Prasad et al.,

2023).

As the GOI aspires to achieve a GBE, the instant

model will help CGD entities expand their gas

retailing business with real-time accurate demand

forecasting for gas supply to different segments of

retail customers. This will increase NG consumption

because the NG will likely replace fuels like petrol,

diesel, furnace oil, light distillate oil, etc., owing to

its positive attributes and environmentally friendly

nature(EIA, 2022). Other advantages that the

conceptual model shall provide the CGD entity relate

to :

(i) Timely and accurate billing for all segments

of retail customers

(ii) Quick realization of gas bills

(iii) Transparent dispute resolution in billing

(iv) Accurate gas reconciliation

(v) Minimize operating system gas loss

(vi) Quick Demand forecasting

(vii) Gas load management between different

load centers

(viii) Increase operating margin and sales revenue

(ix) Tool for detecting gas leakage in real-time

(x) Improved operations safety

(xi) Better control in operations and maintenance

of CGD grid.

(xii) Real-time scenario analysis for demand

forecasting

(xiii) Real-time predictive analysis for price

affordability range for retail industrial and

commercial customers

(xiv) Real-time data for NG that replaces

commercially available liquid fuels like

petrol and diesel

(xv) Promote gas-based economy transition.

(xvi) Promote smart societies with ecological

modernization.

The instant research is the first in delivering a

Conceptual Digital Twin Model for gas retailing

supporting global decarbonization aspirations to

achieve SDG targets for 2030. Further scope of

research exists in dovetailing multiple such models

for different GA's in India to establish a DT for CGD

networks at the country level. Other emerging and

developing economies may refer to this model to gain

insights on the steps to be followed in developing

such a model and tailor the current model to suit their

local requirement.

REFERENCES

Aheleroff, S., Xu, X., Zhong, R. Y., & Lu, Y. (2021).

Digital Twin as a Service (DTaaS) in Industry 4.0: An

Architecture Reference Model. Advanced Engineering

Informatics, 47(December 2020), 101225.

https://doi.org/10.1016/j.aei.2020.101225

Ali, W. A., Roccotelli, M., & Fanti, M. P. (2022). Digital

Twin in Intelligent Transportation Systems: a Review.

2022 8th International Conference on Control,

Decision and Information Technologies, CoDIT 2022,

May, 576–581.

https://doi.org/10.1109/CoDIT55151.2022.9804017

Barricelli, B. R., Casiraghi, E., & Fogli, D. (2019). A survey

on digital twin: Definitions, characteristics,

applications, and design implications. IEEE Access,

7(Ml), 167653–167671.

https://doi.org/10.1109/ACCESS.2019.2953499

Bo, L., Jiannan, G., & Xiangdong, X. (2021). The Digital

Twin of Oil and Gas Pipeline System. IFAC

PapersOnLine, 53(5), 710–714.

Borth, M., Verriet, J., & Muller, G. (2019). Digital Twin

Strategies for SoS. 2019 14th Annual Conference

System of Systems Engineering (SoSE), 164–169.

https://ieeexplore-ieee-

org.ukzn.idm.oclc.org/stamp/stamp.jsp?tp=&arnumber

=8753860

BP. (2022). BP Statistical Review of World Energy.

CDBB. (2020). The approach to delivering a National

Digital Twin for the United Kingdom.

https://www.cdbb.cam.ac.uk/files/approach_summaryr

eport_final.pdf

EIA. (2022). Carbon Dioxide Emissions Coefficients by

Fuel. U.S. Energy Information Administration.

https://www.eia.gov/environment/emissions/co2_vol_

mass.php

Errandonea, I., Beltrán, S., & Arrizabalaga, S. (2020).

Digital Twin for maintenance: A literature review.

Computers in Industry, 123.

https://doi.org/10.1016/j.compind.2020.103316

Garg, S. P. (2019). Safety Practices for CGD. Workshop on

Safety in CGD Industry. https://ngsindia.org/safety/

IEA. (2021a). Net Zero by 2050. In IEA.

https://doi.org/10.1787/c8328405-en

IEA. (2021b). Unlocking Net Zero in Cities Through

Sustainable Digital Transformation and Innovative

Solutions. IEA. https://www.iea.org/events/iea-at-

cop26-unlocking-net-zero-in-cities-through-

sustainable-digital-transformation-and-innovative-

solutions

PAMIR 2023 - The First Pamir Transboundary Conference for Sustainable Societies- | PAMIR

954

IGL. (2022). Material Safety Data Sheet Natural Gas. IGL.

https://www.iglonline.net/uploads/files/Material_Safet

y_Data_Sheet-_Natural_Gas.pdf

Jones, D., Snider, C., Nassehi, A., Yon, J., & Hicks, B.

(2020). Characterising the Digital Twin: A systematic

literature review. CIRP Journal of Manufacturing

Science and Technology, 29, 36–52.

https://doi.org/10.1016/j.cirpj.2020.02.002

Li, X., Zhang, Y., Li, C., Wang, T., & Xi, C. (2022).

Application of Digital Twin in Handling and

Transportation of Hazardous Chemicals. Applied

Sciences (Switzerland), 12(24).

https://doi.org/10.3390/app122412746

Mckinsey and Company. (2023). What is digital-twin

technology ? (Issue July).

Melesse, T. Y., Di Pasquale, V., & Riemma, S. (2020).

Digital twin models in industrial operations: A

systematic literature review. Procedia Manufacturing,

42(2019), 267–272.

https://doi.org/10.1016/j.promfg.2020.02.084

MIT Technology Review Insights;, & Shell Inc; (2022).

Digital technology : The backbone of a net-zero

emissions future. In MIT Technology Review Insights.

https://www.shell.com/energy-and-

innovation/digitalisation/digitalisation-accelerating-

the-energy-transition/digitalisation-and-

decarbonisation-mit-

report/_jcr_content/root/main/section/call_to_action/li

nks/item0.stream/1678207879539/34a35ef0e6176ff3e

b255

Mohammadpoor, M., & Torabi, F. (2020). Big Data

analytics in oil and gas industry: An emerging trend.

Petroleum, 6(4), 321–328.

https://doi.org/10.1016/j.petlm.2018.11.001

Negri, E., Fumagalli, L., & Macchi, M. (2017). A Review

of the Roles of Digital Twin in CPS-based Production

Systems. Procedia Manufacturing, 11(June), 939–948.

https://doi.org/10.1016/j.promfg.2017.07.198

Opoku, D. G. J., Perera, S., Osei-Kyei, R., & Rashidi, M.

(2021). Digital twin application in the construction

industry: A literature review. Journal of Building

Engineering, 40(April), 102726.

https://doi.org/10.1016/j.jobe.2021.102726

PNGRB. (2008). PNGRB (Technical Standards and

Specifications including Safety Standards for City or

Local Natural Gas Distribution Networks) Regulations,

2008. PNGRB.

PNGRB. (2018). PNGRB CGD in India. In PNGRB.

PNGRB. (2023). PNGRB 12th CGD Bidding Round.

PNGRB, 93.

https://www.pngrb.gov.in/OurRegulation/pdf/Gazette-

Regulation/English/GSR808(E)-E.pdf

PPAC. (2023). PPAC Archive. PPAC, MoPNG.

https://ppac.gov.in/archives

Prasad, A. (2011). Risks and challenges in the speedy

execution of pipeline projects. Premium Pipeline

International Digest, October, 5–9.

Prasad, A., & Kumar, A. (2022). Supply Chain

Performance Measurement Methodology for COVID-

19 Disruption Recovery- Natural Gas Retailing in

India. Pacific Business Review International, 15(1),

41–55.

Prasad, A., Kumar, A., & Chatnani, N. N. (2023). Carbon

Neutrality with Sustainable Supply Chain Project

Management Framework for Affordable Access to

Natural Gas in India. Pacific Business Review

International, 15(12), 1–17.

Pregnolato, M., Gunner, S., Voyagaki, E., De Risi, R.,

Carhart, N., Gavriel, G., Tully, P., Tryfonas, T.,

Macdonald, J., & Taylor, C. (2022). Towards Civil

Engineering 4.0: Concept, workflow and application of

Digital Twins for existing infrastructure. Automation in

Construction, 141(July), 104421.

https://doi.org/10.1016/j.autcon.2022.104421

PTI. (2019). $60 billion investment coming in gas

infrastructure: Dharmendra Pradhan. The Economic

Times.

https://economictimes.indiatimes.com/industry/energy

/oil-gas/60-billion-investment-coming-in-gas-

infrastructure-dharmendra-

pradhan/articleshow/71566401.cms?from=mdr

Rajput, S., Sabharwal, N., Singh, A., Shingan, B., & Yadav,

B. P. (2022). City Gas Distribution Incident Analysis in

India using Pareto Principle: A Comprehensive

Analysis. Journal of Failure Analysis and Prevention,

22(3), 899–911. https://doi.org/10.1007/s11668-022-

01422-9

Rosen, R., Von Wichert, G., Lo, G., & Bettenhausen, K. D.

(2015). About the importance of autonomy and digital

twins for the future of manufacturing. IFAC-

PapersOnLine, 28(3), 567–572.

https://doi.org/10.1016/j.ifacol.2015.06.141

Schleich, B., Anwer, N., Mathieu, L., & Wartzack, S.

(2017). Shaping the digital twin for design and

production engineering. CIRP Annals - Manufacturing

Technology, 66(1), 141–144.

https://doi.org/10.1016/j.cirp.2017.04.040

Semeraro, C., Lezoche, M., Panetto, H., & Dassisti, M.

(2021). Digital twin paradigm: A systematic literature

review. In Computers in Industry (Vol. 130).

https://doi.org/10.1016/j.compind.2021.103469

Shahat, E., Hyun, C. T., & Yeom, C. (2021). City digital

twin potentials: A review and research agenda.

Sustainability (Switzerland), 13(6), 1–20.

https://doi.org/10.3390/su13063386

Sircar, A., Yadav, K., Rayavarapu, K., Bist, N., & Oza, H.

(2021). Application of machine learning and artificial

intelligence in oil and gas industry. Petroleum

Research, 6(4), 379–391.

https://doi.org/10.1016/j.ptlrs.2021.05.009

Status, C., & Trends, F. (2020). Industry 4.0 - Current

Status and Future Trends. In Industry 4.0 - Current

Status and Future Trends.

https://doi.org/10.5772/intechopen.86000

Tao, F., Sui, F., Liu, A., Qi, Q., Zhang, M., Song, B., Guo,

Z., Lu, S. C. Y., & Nee, A. Y. C. (2019). Digital twin-

driven product design framework. International

Journal of Production Research, 57(12), 3935–3953.

https://doi.org/10.1080/00207543.2018.1443229

Conceptualizing a Digital Twin Model for Natural Gas Retailing in a Geographic Area in India

955

VanDerHorn, E., & Mahadevan, S. (2021). Digital Twin:

Generalization, characterization and implementation.

Decision Support Systems, 145(June 2020), 113524.

https://doi.org/10.1016/j.dss.2021.113524

Yadav, K., & Sircar, A. (2022). Modeling parameters

influencing city gas distribution sector based on factor

analysis method. Petroleum Research, 7(1), 144–154.

https://doi.org/10.1016/j.ptlrs.2021.07.003

PAMIR 2023 - The First Pamir Transboundary Conference for Sustainable Societies- | PAMIR

956