MOTION PLANNING APPROACH OF A MULTI-FINGERED

ROBOT FOR CARTON FOLDING OPERATIONS

Hidetsugu Terada, Takayuki Kobayashi

Graduate School of Medical and Engineering,Department of Mechanical System Engineering, University of Yamanashi

Takeda4-3-11,Kofu, Yamanashi, 4008511, JAPAN

Keywords: Robot, Multi, Finger, Carton, Folding, Motion, Planning

Abstract: The motion planning approach of a multi-fingered robot for carton flap folding operations has been newly

develop

ed. This approach considers the loci of the tool center point for carton flap folding operations. Also

that considers the pushing or fixing points of the carton flap. This approach is calculated from the rotating

angle for carton flap folding and the position of a robot finger tip in contact with the carton surface, using

inverse kinematics. And this approach can be adapted to changes of a carton size or a folding position. In

cases in which the carton flap is folded using this approach, the robot finger tip touches the carton surface

without slipping and moves along circular continuous path. Therefore in case of the rectangular carton box

folding, each robot finger moves in each 2.5-dimensional Cartesian frame. In this report, the proposed

approach is verified using a prototype robot system. This prototype system consists of two pairs of the robot

fingers and rotating mechanism for carton paper. Each finger has a 3-DOF SCARA type robot and a 1-DOF

linear motion system. The testing carton boxes can be folded to the desired shape.

1 INTRODUCTION

An industrial robot for assembling is used in various

fields, for example mechanical or electrical parts

assembling and circuit board testing. Especially, in

recent years, the industrial robots are used to handle

soft products like a cloth or a paper (Buckingham,

1996). However, for the assembling of carton box

which is the one of the soft products operations, the

use of robot system is not yet popular.

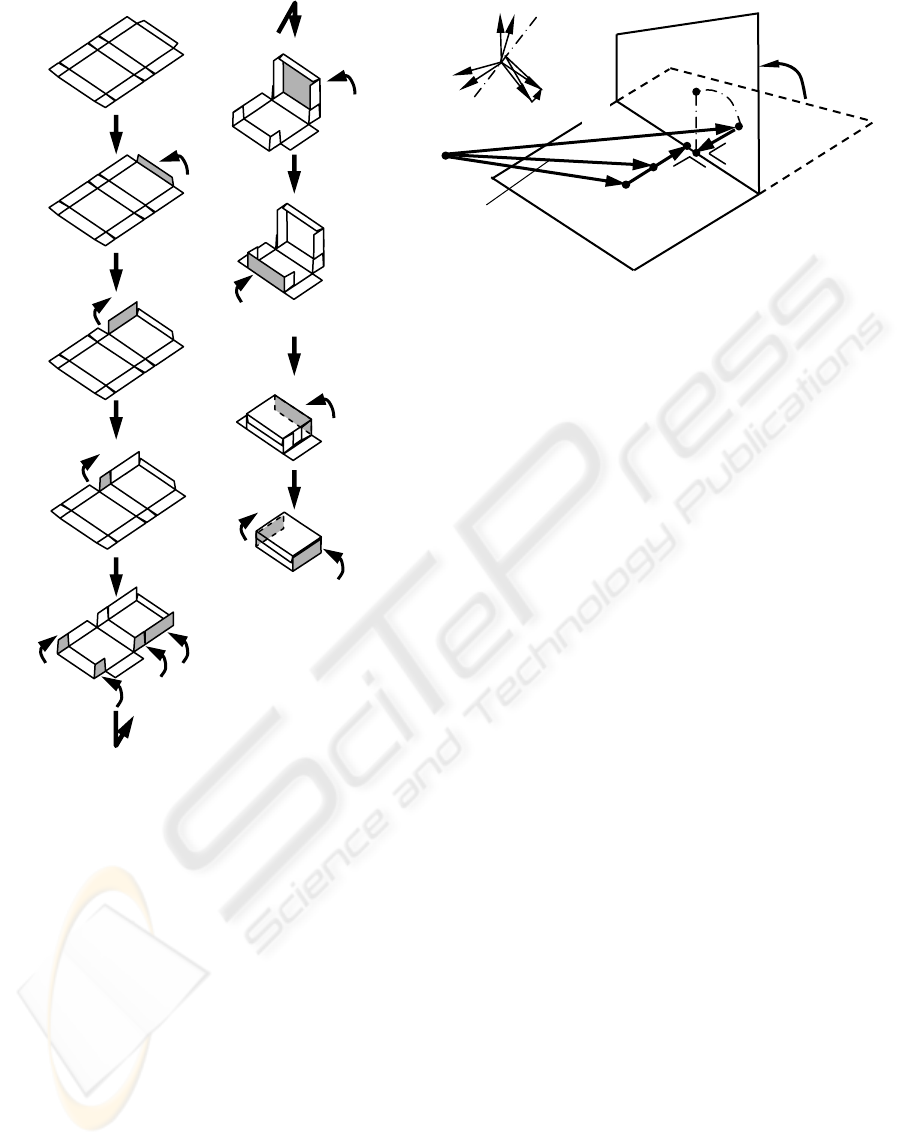

The carton box is usually assembled with

ben

ding some carton flaps and lid, as shown in

Figure 1. The carton box is assembled with bending

on the various positions and to various directions,

even like this simple rectangular shape. So in

general, a carton is assembled using the special

assembling machine (Kyoto-seisakusho, 2004).

Also, the packaging carton is often desired the

complex shape or folding procedure based on

industrial or artistic design. Therefore, it is difficult

to adapt the various kinds of the carton using the

conventional assembling machine. So, the robot

system with higher dexterity is needed.

For carton box assembling, the robot system

wi

th higher dexterity can be adapted to the various

changes of carton size, shape or carton folding

procedure. In other words, the many parameters of

robot control have to be decided for the motion

planning. These parameters are the folding or fixing

positions, the folding angles with directions and the

order of folding operations. Although it is difficult to

teach the carton box assembling procedure using

conventional robot system, that procedure has to be

taught directly, using the "Direct teaching method"

(Rosheim, 1994). When that parameter which is the

position or the order of folding is changed using that

conventional method, it is necessary to teach all

motion again. So the conventional method is not

useful. Also, some researches have shown the

quantification method of a carton assembling

procedure (Song, 2001, and Dubey, 2003). In that

method, the robot motion locus was not considered

with a folding procedure. So the robot motion

control method had to be generated, using other

procedure.

In this report, the simplified motion planning

approach, which realizes

the quantification of carton

box assembling operations, is newly proposed. And

the locus of robot motion is considered to this

approach. And the structure of robot system and the

353

Terada H. and Kobayashi T. (2004).

MOTION PLANNING APPROACH OF A MULTI-FINGERED ROBOT FOR CARTON FOLDING OPERATIONS.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 353-360

DOI: 10.5220/0001126203530360

Copyright

c

SciTePress

robot motion loci are investigated. Then, the

prototype robot system, which consists of two pairs

of the robot fingers and the rotating mechanism of

carton paper, is tested. Each finger has a SCARA

type robot and a linear motion system. And the test

carton boxes are folded to verify the validity of that

proposed approach and the robot system.

2 MOTION PLANNING FOR

CARTON FOLDING

OPERATIONS

In general, a carton paper for the packaging box is

made from a hard paper, which has similar plastic

deformation characteristics like an aluminium

bending. Also, it is different from a soft paper like a

newspaper. In addition, the outline of that carton

paper is usually blanked using cutting machine. And

that is usually embossed with folding-lines. Then,

the conventional special assembling machine

assembles the carton paper which is fixed on the

base plate using a vacuum-Chuck or a fixture. In this

research, it is assumed that these conditions are

applied to investigate the quantification of

assembling carton box using the robot system.

When we assemble a carton box by folding, we

often push the flap using our fingers which slip on

that flap. However, the influences of a friction

fluctuate by the environment and paper material etc..

In industrial fields for carton box assembling, we

should eliminate an influence of that friction. Also

the conventional special assembling machine can

fold the carton paper without slipping. So it is

assumed that the robot finger moves without

slipping, too.

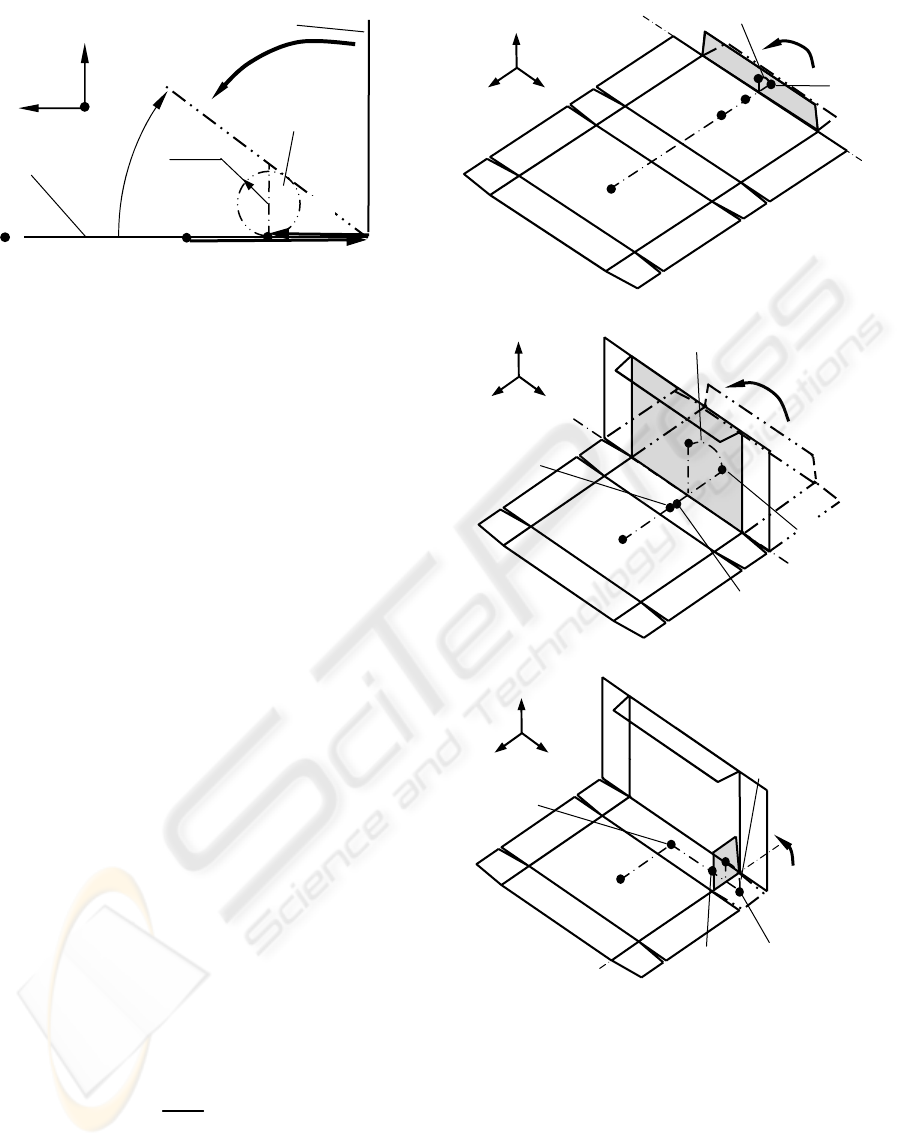

A motion of the carton flap folding on the

arbitrary position and pose is defined using the polar

vector analysis (Makino, 1998) as shown in Figure 2.

That folding motion is replaced to the rotational

motion around the arbitrary axis. And that motion

includes the translational motion from origin point.

Also for this operation, it is assumed that the carton

flap is folded with pushing on the single point. The

quantification of a carton paper folding operation

which considers these assumptions is investigated.

At first, the initial orientation frame of a carton

paper is converted using arbitrary axis rotation E

-

ω

0

θ

0

.

In that figure, the rotating axis of a flap folding is

rotated to the j-axis on the Cartesian frame. And the

folding motion is replaced to the rotating motion of

the center of gravity (CGr) of each flap. Each CGr

on flap is calculated from each area. In that figure,

each CGr is defined as the polar vector C

i

0

and C

i

1

from the origin point O

p

. The CGr on a flap is

defined as the tool center point (TCP) of a folding

operation. In that figure, the pushing point conforms

to the C

i

1

. Then the distances between the CGr and

Figure 1: Example of an assembling procedure for

rectangular carton box

Lid Folding

Flap Folding

Flap Folding

Flap Folding

Each flap folding

Flap Folding

Flap Folding

Flap Folding

Flap Folding

Lid Folding

Figure 2: Geometry of a carton flap folding

O

p

1

θ

j

E

i

0

C

i

1

C

i

0

A

i

1

A

i

0

F

Folding

w

k

u

i

v

j

θ

0

ω

0

ICINCO 2004 - ROBOTICS AND AUTOMATION

354

9

θ

j

E

i

8

C

i

9

C

the folding-line are defined as

A

i

0

and A

i

1

. So the

folding operation is shown as follows:

(

)

i

j

ii

1111

1

00

AEACEP

θ

θω

−+=

−

(1)

In case of a rectangular carton box assembling,

each folding axis conforms to the principal axis of

the Cartesian frame. And the end point of

A

i

0

conforms to the end point of

A

i

1

. And each distance

is same. So, the folding operation is simplified as

follows:

i

j

ii

1111

1

AEACP

θ

−+=

(2)

In cases in which the carton paper is folded

without slipping, the fixing point for carton flap

folding should be near the folding axis line as shown

in Figure 3. And when the carton paper is folded

along the embossed folding-line, the fixing point and

the push point need to be symmetrical with respect

to the folding-line, in general. And the fixing point

holds a constant point during a folding operation.

Also, these points are operated simultaneously. In

other words, the two fingers need to co-operate to

fold a carton flap.

In general, the carton flap is often folded over 90

degrees. When the robot fingers which are just like a

human finger are used, the collision avoidance

between the carton flap and the carton fixing robot

finger has to be considered. So, it is assumed that the

robot end-effector has a ball shape to simplify that

procedure. This imaginary radius is defined as r.

And

τ

is the supplemental angle of the flap folding

as shown in Figure 3. And the fixing point is defined

as follows:

(

)

iiii

00000

0000

BACEFEF −+==

−−

θωθω

(3)

T

i

r

⎟

⎠

⎞

⎜

⎝

⎛

= 0,0,

tan

0

τ

B (4)

There are two procedures to approach this fixing

point. To avoid the collision, each robot finger is

approached from the same side as an initial finger

position with respect to the carton paper. In case of

the example which shows in Figure 3, the robot

finger for fixing approaches from left side. And the

robot finger for folding approaches from right side.

However, in case of the carton lid folding, the carton

paper is folded over itself. There is the possibility

that the collision between robot finger and carton lid

will occur. In this case, the carton paper is fixed

using a fixture or a vacuum-Chuck, instead of a

fixing finger. This fixture is similar to the

conventional special assembling machine. Using

Flap folding

i

8

F

O

p

i

j

k

i

0

C

i

7

C

i

8

C

8

θ

j

E

Lid folding

i

7

F

O

p

Figure 4: Geometry of a fixed point on carton flap

(a) Flap folding

(b) Carton lid folding

i

j

k

(c) Side flap folding

i

7

C

j

10

C

10

θ

i

E

Side flap

folding

j

10

F

O

p

i

j

k

Folding

p

O

i

0

A

i

0

B

i

0

F

Imaginary ball

Flap

Fixed carton

τ

j

i

k

r

Figure 3: Geometry of a fixing point on carton flap

MOTION PLANNING APPROACH OF A MULTI-FINGERED ROBOT FOR CARTON FOLDING OPERATIONS

355

these definitions and conditions, all folding motions

can be quantified.

Figure 4 shows the example of a carton flap

folding, that carton box has a rectangular shape. The

CGr of each flap is defined as

C

m

n

. And the carton

fixing point using robot finger is defined as

F

m

n

. And

for the flap folding, the rotation of each CGr on a,

flap is defined as the rotation matrix

E

m

θ

n

. Also the

distance between CGr and folding-line is defined as

the vector

A

m

n

. It is assumed that fixing point using

vacuum-Chuck conforms to the origin point of a

carton paper. The m shows the axis direction on the

Cartesian frame, and the n shows the number of flap.

In case of a flap folding around the j-axis at 90

degrees as shown in Figure 4(a), the folding motion

is defined as follows:

i

j

ii

9991

9

AEACP

θ

−+=

(5)

And the fixing point is defined as the constant vector

F

i

8

. And in case of a carton lid folding around the j-

axis at 90degrees as shown in Figure 4(b), the

folding motion is defined as follows:

i

j

ii

8882

8

AEACP

θ

−+=

(6)

The fixing point is defined as the constant vector

F

i

7

.

Also, in case of a side flap folding around the i-axis

at 90degrees as shown in Figure 4(c), the folding

motion is defined as follows:

j

i

jj

1010103

10

AEACP

θ

−+=

(7)

In this case, the fixing point is shifted to the j-axis

direction from

C

i

7

. So the fixing point is defined as

the constant vector

C

i

7

+F

j

10

.

These vector equations show the folding motions

and the operating procedure of carton assembling

conforms to the execution order of these equations.

It can be adapted to the change required by replacing

the order of those equations. In other words, the

motion planning approach of a carton assembling

can be quantified using some equations and the

order of those equations.

3 FINGER MOTION LOCI FOR

CARTON FOLDING

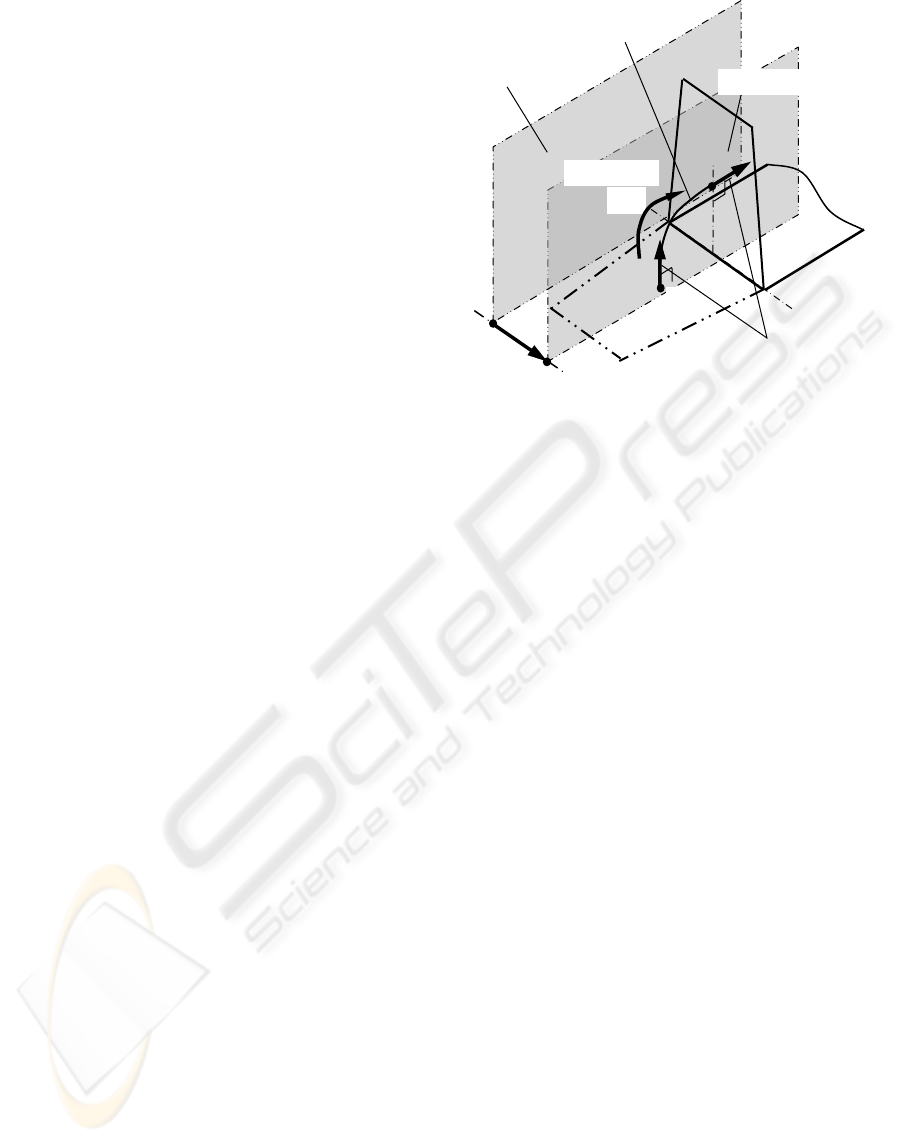

The motion planning approach for carton box

assembling has been proposed using a newly

developed quantification approach of carton flap

folding. Next, the loci of robot fingers are

investigated using this approach.

The point touched with the TCP of robot finger

rotates around the folding-line at the required angle.

This motion locus has a circular locus, in any

folding operations. And all motions of a robot finger

are regarded as the planar motion. This plane is

defined as "Folding-plane". Especially for

rectangular carton box assembling, the Folding-

plane is moved linearly to include each TCP’s locus,

as shown in Figure 5. And in case that the carton

flap folds around the arbitrary folding-line, that

plane can conform to the motion locus by translating

along some axes and by rotating around some axes.

Then, the carton box is assembled by robot finger,

the influence of a finger slip on a carton paper needs

to eliminate as much as possible. So, the robot finger

maintains the perpendicular pose to the carton flap

during the folding operation. And the robot finger

needs to avoid a collision at the other section of a

carton paper. So it is the most simplified and useful

approach to conform the pose of a robot finger tip

and the tangent direction of a motion locus.

For the assembling of rectangular carton box as

shown in Figure 1, the degree of freedom (DOF) of a

robot finger needs the 2-DOF of the position and the

1-DOF of the pose on a Folding-plane. And the

Folding-plane needs to include the motion locus. So

the translation and the rotation mechanism on a

robot base section are needed. However when that

robot system consists of the robot finger without the

rotating mechanism, that robot system needs two

pairs of robot fingers to realize the same carton

folding operation. These pairs should be assigned on

the perpendicular location.

On the other hand, a robot finger fixes a carton

paper to avoid the releasing of the carton paper from

fixed base which is caused by the elastic

deformation of that paper, during that paper fixed

operation. A robot finger should avoid the collision

with other sections of carton paper during that

operation. So, the pose of the robot finger which

fixes a carton paper needs to consider a folding

Robot finger motion

direction

1

θ

j

E

i

1

C

Flap folding

Folding axis

Folding-plane

Carton flap

TCP motion circular locus

O

p

O

p

’

Figure 5: Geometry of a tool center point (TCP)

motion and a "Folding-plane"

ICINCO 2004 - ROBOTICS AND AUTOMATION

356

angle. In cases in which the robot finger folds the

carton flap at 90 degrees, as shown in Figure 5, the

robot finger with vertical pose of that finger tip can

fix that carton paper.

However, the carton paper usually has the

"Spring-Back" characteristic which is just like

stainless-steel. So, the supplemental angle for the

flap folding is defined as the 45-90degrees. And the

robot end-effector has a ball shape. So, this

condition and Equation (4) should be considered to

the pose of the robot finger which fixes the carton

paper. Also, to adapt to the various folding

operations each robot finger has a same finger

structure. And they are installed to make face to face

location. Then, they are symmetrical with respect to

the carton paper or working-area. And the Folding-

plane of a folding motion conforms to that plane of a

fixing motion. Both translational mechanisms move

simultaneously.

4 KINEMATICS OF A ROBOT

FINGER

Considering the proposed motion planning approach,

and the robot finger motion on that Folding-plane,

the robot finger consists of a 3-DOF serial link and a

translational mechanism. On that Folding-plane, the

SCARA robot folds a carton flap as shown in Figure

6. That robot finger has the simplest structure that is

the minimum DOF. The position

P and pose E of a

robot finger are defined using the polar vector

analysis shown as Equation 8 and 9.

(

((

iji

j

i

j

i

j

kj

4321

00

321

BECECECE

CLP

α

θ

θθ

++++

+=

)

))

(8)

α

θθθ

j

jjj

EEEEE

321

=

(9)

Each linkage length is defined as

C

k

0

, C

i

1

, C

i

2

and

C

i

3

. Also each robot joint rotation is defined as E

j

θ

1

,

E

j

θ

2

and E

j

θ

3

. The origin point Op conforms to the

start point of the translational motion

L

j

0

. The robot

finger tip has a spherical shape. When that robot

finger folds a carton flap, the contact point is on the

extended vector of the

C

i

3

. And in cases in which the

robot finger fixes a carton paper, this finger tip has

an inclined pose at

τ

’. In other words, the contact

point on each finger tip is different. So the contact

point from a finger center is defined as

E

j

α

B

i

4

. Also

the spherical shape radius of a robot finger is defined

as

B

i

4

. In case of a folding operation, the contact

point is on the extended vector of the

C

i

3

, it is

α

=0.

And in case of a carton fixed operation, that is

α

=

τ

'.

The folding operation is independent of the

translational operation for the Folding-plane. So, the

kinematics of that robot system can be regarded as

the two individual analyses; the one is the robot

finger section and the other is the translational

mechanism section. For the forward and inverse

kinematics of the robot finger as shown Figure 6, the

3-DOF type SCARA robot and the 1-DOF linear

motion mechanism are analyzed. In general, the

SCARA robot has two solutions which are the

"Right hand solution" and the "Left hand solution"

(Furuya et al., 1983). The robot finger for the carton

fixing operation usually uses the opposite solution to

that folding operation. And the solution doesn’t

change during the folding or fixing operation.

In cases in which the carton flap folds on the

arbitrary position and the pose, the carton paper

rotates to conform that folding-line to the motion

direction of that translational mechanism; the

position and pose shown as Equation 8 and 9, rotate

around the arbitrary axis. In case that carton paper is

rotated around k-axis of the Cartesian frame that is

popular for carton folding, the position and posture

of a robot finger are changed to the

P' and E', shown

as Equation 10 and 11.

PEP

λ

k

=

′

(10)

EEE

λ

k

=

′

(11)

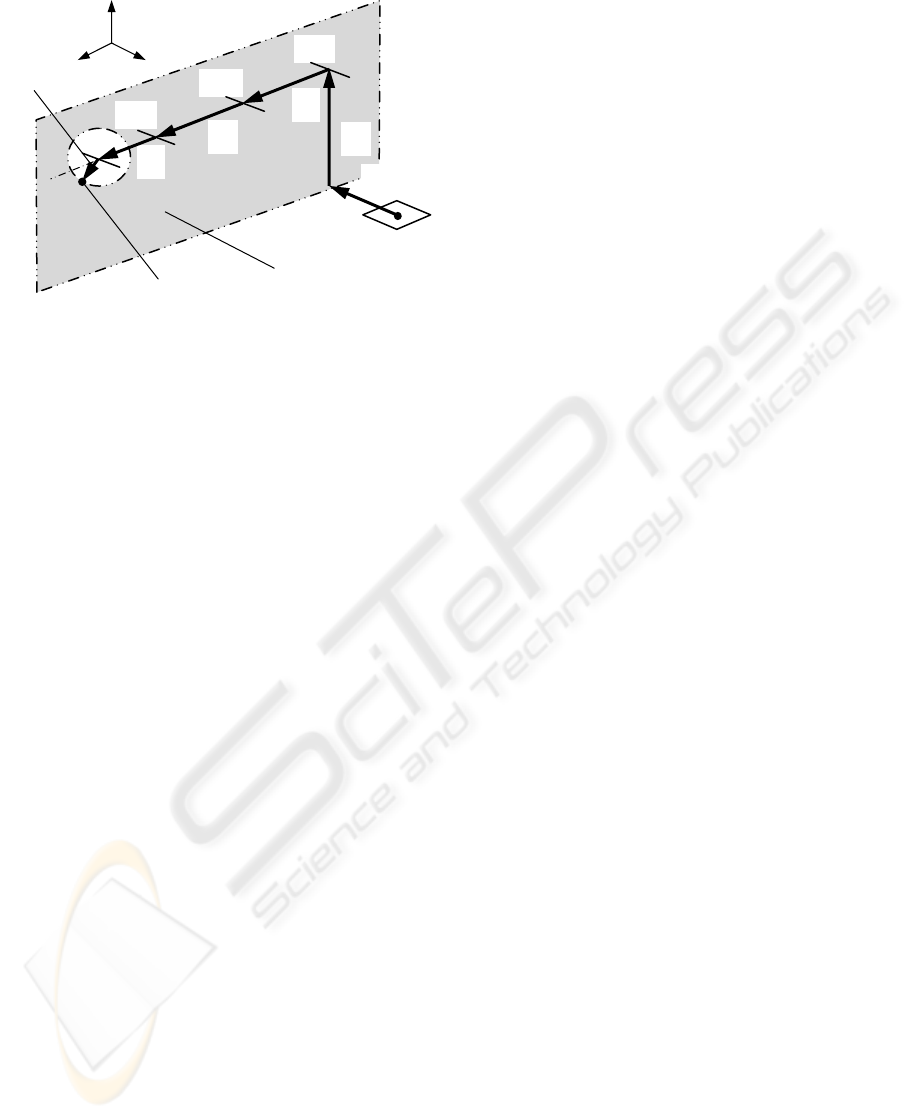

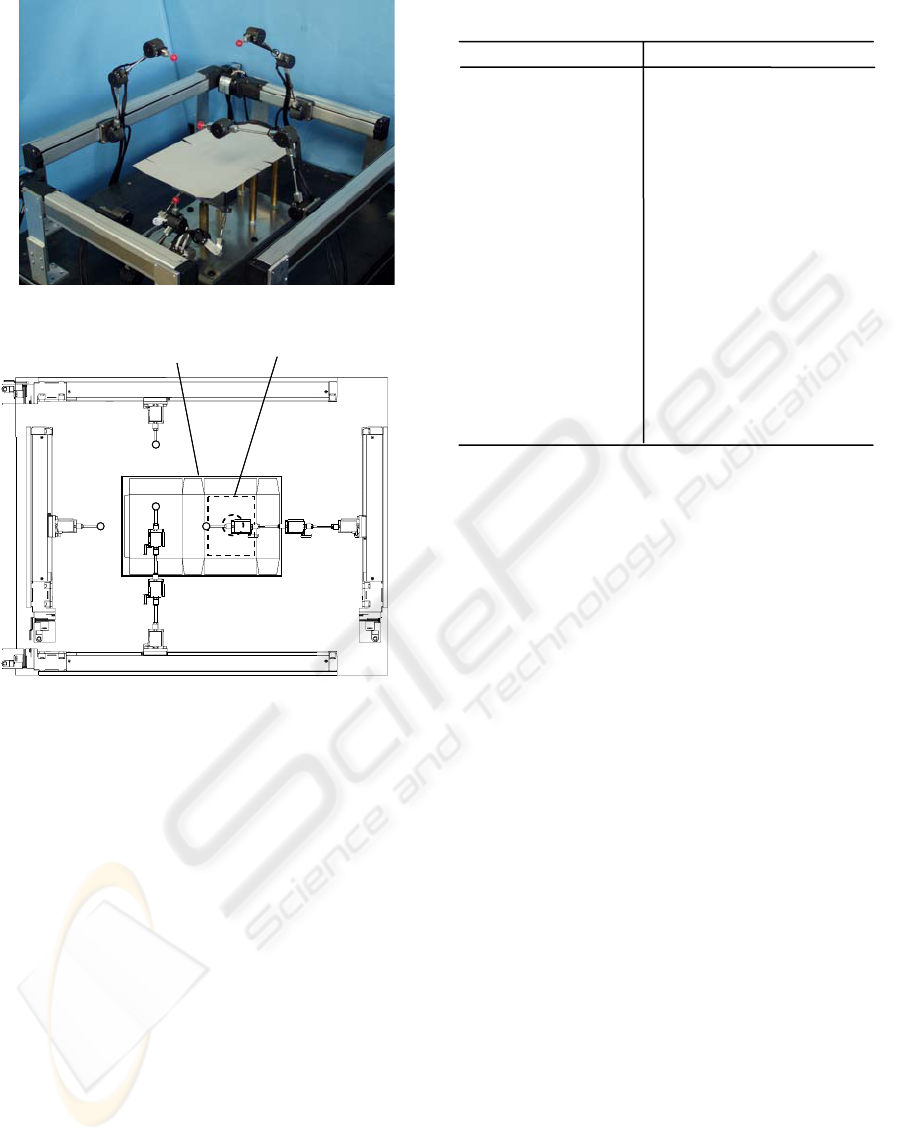

5 PROTOTYPE ROBOT SYSTEM

Considering the proposed motion planning approach

for carton box assembling and the circular motion

for robot fingers, the prototype of a robot system has

been made. That system consists of two pairs of the

3-DOF SCARA robot fingers with the 1-DOF

translational motion mechanism and rotating

mechanism of carton paper, as shown in Figure 7(a).

Each robot finger moves simultaneously in a single

working area as shown in Figure 7(b). Each finger is

installed to make face to face location. And each

i

1

C

1

θ

j

E

k

0

C

j

0

L

i

2

C

i

3

C

2

θ

j

E

3

θ

j

E

ija

4

BE

Folding plane

Contact point

O

p

i

j

k

Figure 6: Vectors geometry of a robot finger

MOTION PLANNING APPROACH OF A MULTI-FINGERED ROBOT FOR CARTON FOLDING OPERATIONS

357

pair of that finger is placed to make perpendicular

location. Also, each pair of translational motion

mechanism which is installed to make parallel

location moves simultaneously, too. The rotating

mechanism around k-axis on Cartesian frame with

the vacuum-Chuck which fixes a carton paper on

carton base section is installed under that working

area. Therefore, we can test two approaches using

this prototype system. The one is the approach of

two pairs of robot fingers, and another is the

approach of a pair of robot fingers with a rotating

mechanism.

Each finger has small and light-weight joint

actuators which consist of an AC servo-motor,

encoder and Harmonic-drive reducer (Umetsu

et.al.1993). And that size is 30mm diameter with

length 30mm and the weight is the 70gf. That

actuator uses to the rotating mechanism for carton

paper, too. Then, each link of a robot finger has a

cylindrical shape made from steel to minimize a

collision at the other section of carton paper. That

diameter is the 4mm; it is smaller than the joint

diameter. Also, the finger tip has a ball shape which

is made from the Butadiene rubber to eliminate the

slipping on a carton paper. That diameter is the

6.5mm. And also the translational mechanism

consists of a ball screw with an AC servo-motor and

a linear guide slide system (THK, 2004). The

specifications of these actuators are shown in Table

1. Furthermore, all axes of the robot system are

controlled synchronously by the command PC. That

control data are communicated using a parallel

communication protocol.

Working area

(300mm× 200mm)

Robot 0

Robot 1

Robot 2

Robot 3

Carton fixture with paper

rotation mechanism

Working area

(300mm× 200mm)

Robot 0

Robot 1

Robot 2

Robot 3

Carton fixture with paper

rotation mechanism

6 VERIFICATION USING THE

PROTOTYPE ROBOT SYSTEM

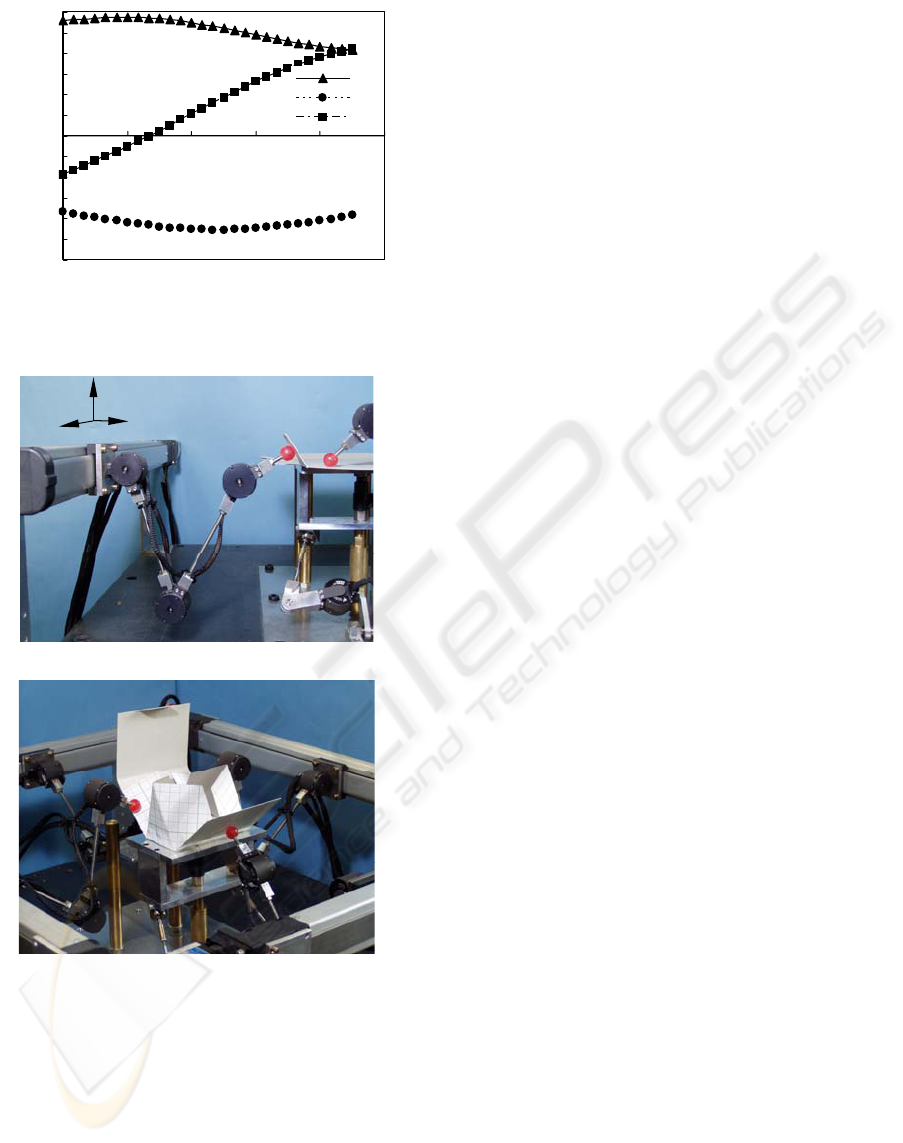

The rectangular carton box as shown in Figure 1 has

been assembled to verify the usefulness for proposed

motion planning approach and robot motion. It is

proved that the folding procedures for carton flaps

can be quantified. And the robot fingers, the

translational mechanisms and the rotating

mechanism can move simultaneously, which are

based on the proposed approach. Also, it is proved

that the carton box can be assembled.

In case of the rectangular carton box has twelve

folding operations, the mean Cycle time for carton

folding is 10.5 seconds. It is because that maximum

speed of a robot finger actuator is limited to 22.5rpm.

When it is required that robot finger moves more

quickly, the actuator of that robot finger should be

improved to adapt to higher rotation. Figure 8(a)

shows the relations of each robot finger joint angle

with the sample motion for the carton flap folding at

Figure 7: The multi-fingered robot system with carton

paper rotating mechanism

(b) Robot assignment and working area

(a) Structure

Items Values

Robot finger type 3-DOF SCARA type

Finger 1st and 2nd link 130mm

Finger 3rd link 50mm

Finger actuator Hybrid motor-reducer type

Max. speed 22.5rpm

Motor AC servo-motor, 1.4W

Encoder 128p/r

Reducer i: 1/80, Harmonic Drive

Tool head diameter 6.5mm

Tool head material Butadiene rubber

Rotating mechanism k-axis rotating

Linear actuator Ball screw type, lead 8.0mm

Max. speed 600mm/s

Motor AC servo motor, 30W

Encoder 2000p/r

Stroke Robot0, 2: 400mm,

Robot1,

3: 200mm

Table 1: Specifications of a prototype robot system

ICINCO 2004 - ROBOTICS AND AUTOMATION

358

60 degrees. Each joint angle of a robot finger for

folding operation is shown in Figure 8(b).

Considering the "Spring-back" characteristic, that

carton paper is folded to 135 degrees. Also this

proposed motion planning approach using robot

system doesn’t need a force control of a carton

folding. It is similar to the conventional special

assembling machine.

Then, this robot system based on proposed

approach, can deal with the complex shape of the

carton box like “Boy-scouts tent” in which the

conventional special assembling machine cannot be

adapted as shown in Figure 8(c). And using

proposed approach, the robot motion can be taught

by off-line. It isn't necessary to move each robot

finger to teach like a conventional robot system. It is

very useful to reducing the set-up time.

In future work, to realize the other operation for

carton packaging, we will investigate the grasping

procedure of papers or products with force control.

7 CONCLUSIONS

For carton box assembling, the carton flap folding

procedure which is quantified to simplify the motion

planning approach has been newly proposed. This

procedure considers the loci of the center of gravity

of carton flaps and the robot motion. Using the

multi-fingered prototype robot system, we have

verified the proposed approach; it is proved that the

folding procedures of the carton flaps can be

quantified. Also the carton box can be assembled.

For the sample assembling rectangular carton box,

the mean "Tact-time" for a carton flap folding is the

10.5 seconds.

In future work, to realize the work-handling of

the carton packaging that is different from the carton

flap folding, we will develop the approach of

grasping with a force control.

REFERENCES

Buckingham R., 1996, Multi-arm Robots, Industrial Robot,

vol.23, No.1.

http://www.kyotoss.co.jp/, 2004.

Rosheim M., 1994, Robot Evolution, John Wiley & Sons.

Song G. and Amato N., 2001, A Motion Planning

Approach to Folding: Form Paper Craft to Protein

Folding, Proceedings of the 2001 IEEE International

Conference on Robotics and Automation, 948.

Dubey V. and Crowder R., 2003, Designing a Dexterous

Re-configurable Packaging System for Flexible

Automation, Proceedings of the 2003 ASME Design

Engineering Technical Conferences and Computers

and Information in Engineering Conference.

Makino H. 1998, 3-dimensional Kinematics, Nikkankogyo

Sinbunsha.

Furuya N. and Makino H., 1983, Calibration of SCARA

Robot Dimensions Teaching, Journal of the Japan

Society for Precision Engineering, vol.49, No.9.

(b) Robot finger motion at the folding angle 60 degrees

Figure 8: The test motion of a carton flap folding

(a) Relation between the folding angle and each robo

t

finger joint angle to 135degrees

i

k

j

-180

-150

-120

-90

-60

-30

0

30

60

90

120

150

180

0 30 60 90 120 150

Folding angle deg

Robot joint rotating angle deg

θ1

θ2

θ3

(c) Folding motion for “Boy-scouts tent” type carton box

MOTION PLANNING APPROACH OF A MULTI-FINGERED ROBOT FOR CARTON FOLDING OPERATIONS

359

Umetsu M. and Oniki K., 1993, Compliant Control of

Arm-Hand System, Proceedings of the 1993 JSME

International Conference on Advanced Mechatronics.

http://www.thk.co.jp/, 2004.

ICINCO 2004 - ROBOTICS AND AUTOMATION

360