AN INTEGRATED ENVIRONMENT FOR

MACHINE SYSTEM SIMULATION,

REMOTE MONITORING AND FAULT DETECTION

Amos Ng, Leo De Vin, Martin Sundberg, Fredrik Oldefors,

Centre for Intelligent Automation, University of Skövde, PO Box 408, SE-541 28 Skövde, Sweden

Philip Moore, Sanho Yeo

Mechatronics Research Group, De Montfort University, Leicester, LE1 9BH, U.K.

Keywords: Simulation, remote monitoring, model-based fault detection

Abstract: Machine service and maintenance is an intricate specialist task and machine builders often have to provide

worldwide service at short notice. Machine builders would benefit enormously from the possibility to

monitor and diagnose equipment operating at distant locations – both for condition-based preventive

maintenance and for diagnostic purposes before flying in qualified maintenance personnel and spare parts.

This paper introduces an innovative virtual engineering framework that extends the kinematics modelling

and dynamics modelling capability of advanced machine simulation systems to incorporate remote

monitoring and fault detection features. Specifically, it addresses the software environment that is designed

to facilitate the tight integration between virtual engineering tools (machine system simulation), machine

controllers (real/simulated) and model-based fault detection schemes. The underlying real-time

communication framework based on the publish-subscribe model and applications interfacing techniques

are also presented.

1 INTRODUCTION

In the past, cyclically or sporadically occurring

faults, which could not be identified automatically

and monitored directly by fault messages of the

controllers, had to be detected by visual observation

(Groll 2001). In this era of globalisation, this is not

desirable if the service and maintenance support is

provided in a worldwide basis. It is also not

applicable to machine failures for which the error

symptoms cannot be repeated for observation. Video

diagnosis systems and corresponding fast off-line

video transmission technologies, can be seen as an

enhancement to provide visual information to

improve the analysis capability (Wolfram and

Isermann 2002). However, this incorporates high

additional cost in installing and running the video

systems. Furthermore, monitoring by video can only

be applied to observe a very limited number of

views of an individual machine so that it falls short

of the applicability for monitoring the complex

machine system as a whole, where faults may occur

in different locations with different components.

Alternatively, advanced kinematics modelling with

realistic three-dimensional (3-D) animation feature

that is nowadays commonly supported by many

advanced machine simulation systems, is promising

to provide users with highly visualised, meaningful

and easily comprehensible information. This

approach is considered to be also highly economical

if the same set of simulation models, developed

incrementally during the machine design and

development lifecycle, can be reused. As a matter of

fact, our previous research conducted in the ESPRIT

project VIR-ENG (Adolfsson et al. 2000, VIR-ENG

2001, Moore et al. 2003), has proposed and

successfully demonstrated the use of virtual

engineering to support the entire development

lifecycle of modular manufacturing machine

systems, from conceptual design during negotiation

and quotation stage, to the final machine

commissioning phase. Depending on the level of

details and equipment types, both robot simulation

(RS) and discrete event simulation (DES) have been

used for developing the machine system simulations

that are integrated with real/simulated machine

150

Ng A., De Vin L., Sundberg M., Oldefors F., Moore P. and Yeo S. (2004).

AN INTEGRATED ENVIRONMENT FOR MACHINE SYSTEM SIMULATION, REMOTE MONITORING AND FAULT DETECTION.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 150-157

DOI: 10.5220/0001129701500157

Copyright

c

SciTePress

controllers for testing and verifying the logic control

software. It has been envisaged that the graphical

simulation models developed incrementally during

the machine development stage can be effectively

applied to the operational monitoring and

maintenance phase as well. In addition to the

modelling capability and validity of the simulation

models, the applicability and effectiveness of such

an approach rely also heavily on a framework that

tightly integrates virtual engineering tools (machine

system simulations), machine controller (real and

simulated) and model-based fault detection schemes

with high-performance devices/applications

communication and interfacing techniques.

Recently, research and implementation of such a

new approach is undergoing in a Swedish project

called MASSIVE – MAchine Service Support using

Innovative Virtual Engineering at the University of

Skövde with a number of major Swedish industrial

companies (see Acknowledgments for the list of

participants). This paper aims at presenting an

overview of the MASSIVE project. Specifically, it

addresses the system architecture that is designed to

incorporate the tight integration between machine

system simulation and other system components for

remote monitoring and fault detection. It also

addresses the underlying real-time communication

framework that supports the interaction of the

system components.

The rest of this paper is organised as follows:

Section 2 briefly introduces the important modelling

concepts and techniques when using virtual

engineering tools for manufacturing machine system

lifecycles. Section 3 reveals the designed system

architecture. The underlying real-time

communication framework based on the publish-

subscribe model is presented in Section 4.

Conclusions and outlook are given in Section 5.

2 VIRTUAL ENGINEERING FOR

MANUFACTURING MACHINE

SYSTEM LIFECYCLES

Other than the advanced kinematics modelling and

realistic 3-D animation feature as mentioned

previously, the capability of virtual engineering tools

for the modelling of machine system logic as well as

the system dynamics required for both system

development and maintenance purposes should not

be underestimated. The core concept behind the new

approach proposed here is the separation of a

simulation model into a number of sub-models

including machine/environment logic models and the

machine dynamics models. These sub-models can

then readily be linked to the logic control models

and/or real/simulated machine controllers using

hardware-in-the-loop (HIL) techniques for testing

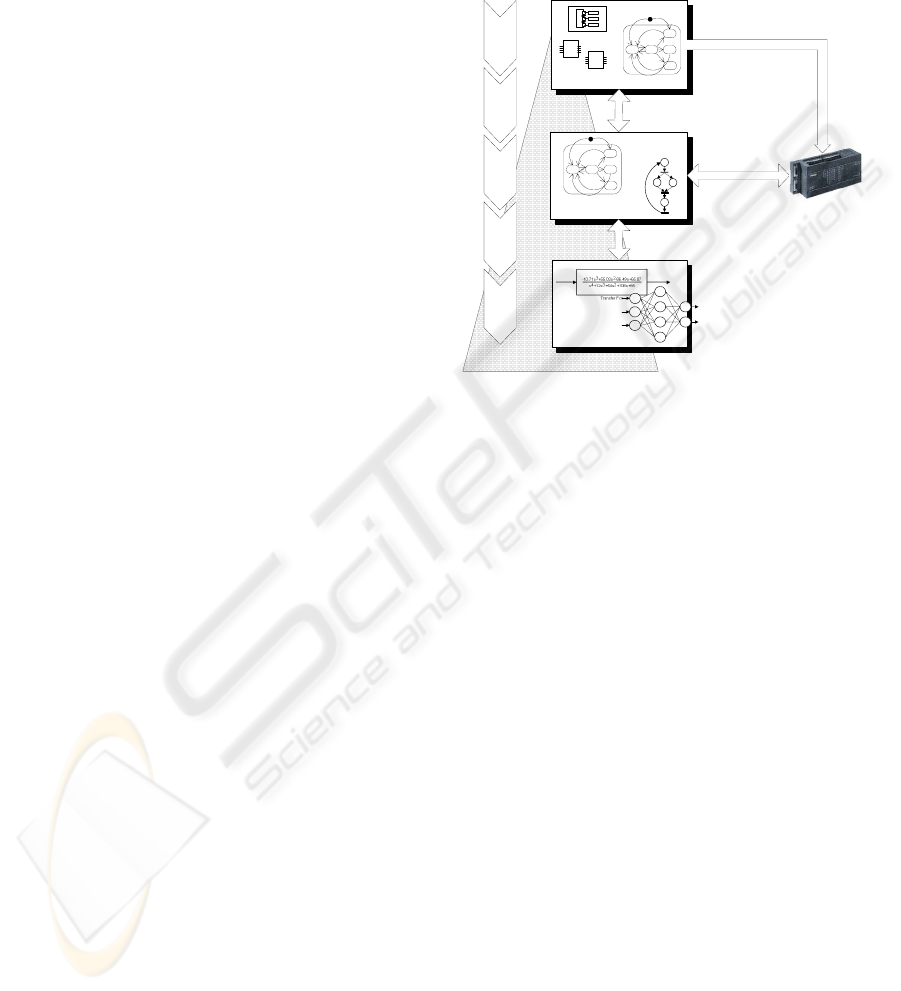

and verification. Figure 1 illustrates this concept and

proposes some suitable modelling formalisms for

different types of models.

Figure 1: Modelling techniques for manufacturing

machine system lifecycles.

A machine/environment logic model is a logic

model that mimics the logical behaviour of the

machine or process as well as part of the

surrounding environment (e.g. auxiliary devices or

human operators) in response to the commands sent

from the logic control models/machine controllers.

In return, based on the interaction of the logic model

and the machine dynamics models, inputs to the

logic control models/machine controllers are

changed to imitate the events/signals from the

feedback devices and any observable state variables

of the machine system. In other words, the

machine/environment logic model behaves as the

virtual actuators and sensors of the controlled

process. Hence, the interface for the connection to a

logic control model is called virtual I/O (VIO).

After the logic control models has been fully

tested and verified, control components that control

the physical machines can be generated seamlessly

using the VIR-ENG approach (Moore et al. 2003) or

transferred to real machine controllers such as

programmable logic controllers (PLCs). It is also

possible to carry out tests with the real controllers

against the virtual machines by replacing the virtual

sensors and actuator interfaces (i.e. VIO) with the

physical I/O devices, normally in a piecewise basis.

It has been noticed that an identical concept has been

proposed as the methodology for using the emerging

IEC 61499 function blocks modelling standard to

Design

Production &

Maintenance

Manufacturing

& Assembly

Comissioning

Integration

& Testing

FB

FB

Detail and validity of the models

Logic Control Models

e.g.

IEC 61131-3

IEC 61499

UML Statecharts

Machine/Environment

Logic Models

e.g.

UML Statecharts

Petri nets

Machine Dynamics

Models

e.g.

Linear transfer functions

Neural networks

Machine system development lifecycle

Real controller

e.g.

PLCs

Hardware-in-the-loop

techniques

Code generation

e.g. VIR-ENG approach

AN INTEGRATED ENVIRONMENT FOR MACHINE SYSTEM SIMULATION, REMOTE MONITORING AND

FAULT DETECTION

151

develop next-generation state-machine controllers

(Lewis 2001).

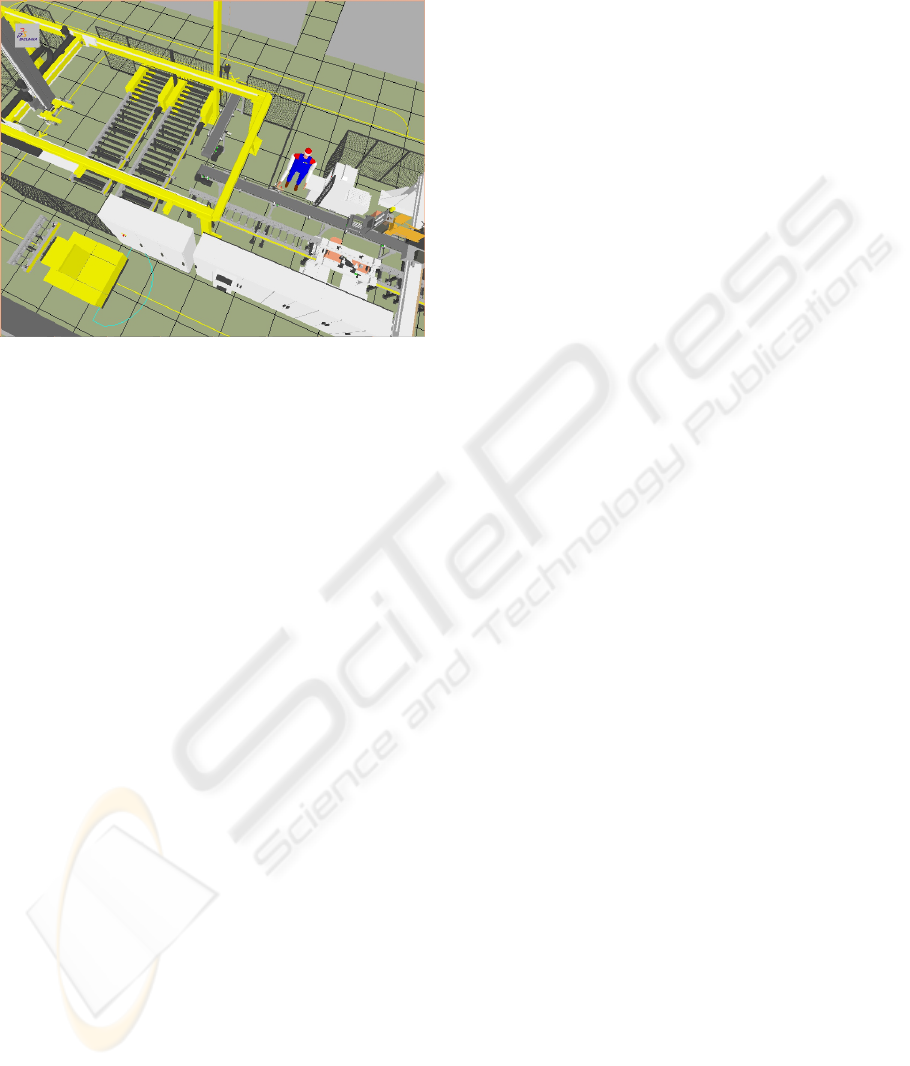

Figure 2: A simulation model for the industrial test-

bed – a flexible assembly cell for automotive engines.

The above-said approach has been partially

demonstrated to shorten the machine system

development time significantly based on the

experience from an industrial test-bed (VIR-ENG

2001) in which simulation models have been

developed using RS system IGRIP, DES system

QUEST supplied by DELMIA (2003)(see Figure 2).

To extend the model for valid and robust fault

detection further, an accurate machine dynamics

model is paramount. With an observation that

accurate machine dynamics is difficult to model by

using physical principles, especially during the

system development stage, applying system

identification techniques is proposed. Linear models

(Ljung 1999) or non-linear models, e.g. using neural

network (Nelles 2001) can be identified using

observed input-output data acquired during the

machine commissioning or initial operational stage.

These models can then be embedded into the

machine simulation and link to a

machine/environment logic model that governs

which dynamics model should be invoked based on

the predetermined logical structure. In a remote

monitoring setting, these dynamics models act as the

reference models to generate the nominal dynamic

response of the system with the input data from the

sampled data acquired remotely and allow

comparison to actual output from the real system

using residual analysis. The residual signal is useful

for fault detection, as well as to isolate and assist

diagnostic tasks when tracing the root cause of the

fault using various residual evaluation techniques –

an approach that is commonly known as model-

based fault detection. While significant efforts have

already been paid to address model-based fault

detection and isolation (FDI), particularly for the

process industry (Chen and Patton 1999, Isermann

and Ballé 1997), MASSIVE is intended to contribute

a new virtual engineering framework so that existing

generic or machine-specific FDI algorithms or

schemes, can be tightly integrated with graphical

machine simulations to provide an unique service

and maintenance environment for builders of

discrete manufacturing machine systems.

3 THE MSSS ENVIRONMENT

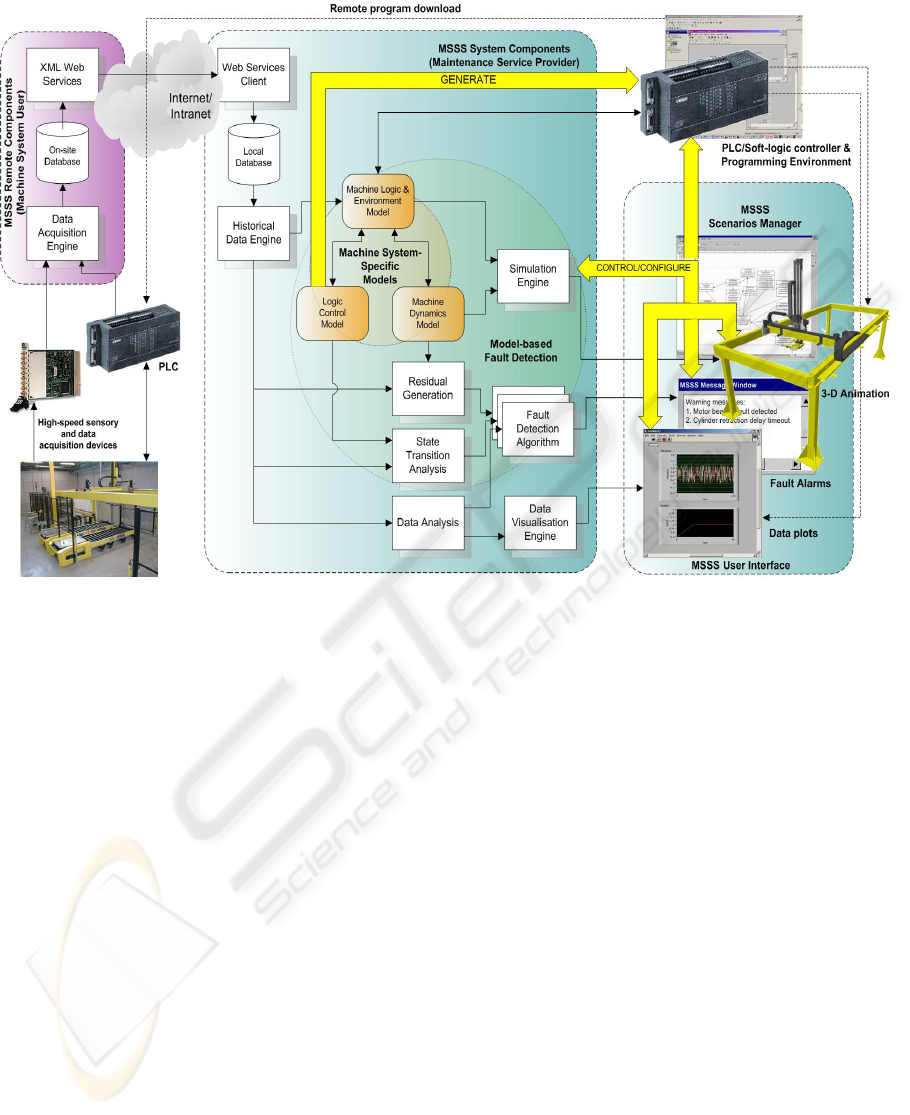

Within the MASSIVE project, the above-said

concepts are being realised through the design and

implementation of an integrated software

environment called MSSS (Machine Service Support

System), as an extended part of the machine design

and control environments developed in VIR-ENG. A

system architecture that defines various components

of MSSS and their interactions has been

preliminarily designed and is illustrated in Figure 3

on the next page.

3.1 Data Acquisition and

Transmission

MSSS is essentially a remote data acquisition and

analysis system. Therefore, it is obvious to see that

an advanced data acquisition, pre-processing and

management framework is the foundation for all

other functions. The OLE for Process Control (OPC)

technology (OPC Foundation 2003) is being used for

collecting discrete-event data and continuous data

with low sampling rate (<100Hz) from the

PLCs/soft-logic controllers or directly from the

fieldbus. As the de-facto standard for application

interface to control devices in the industrial

automation sector, OPC is supported by virtually all

automation suppliers and therefore offers seamless

data access solution without the need of developing

customised software drivers. Nevertheless, dedicated

sensory and high-speed data-acquisition devices

might be required if high sampling rate is required

for collecting continuous data such as electric

current.

The data acquisition system can be remotely

configured so that specified parameters, machine

process variables, discrete-event signals can be

acquired in prescribed time intervals and sampling

rates. Configurations for routine periodic data

logging can also be selected for day-to-day

monitoring. All configurations to the data

acquisition components are done through the Web

ICINCO 2004 - ROBOTICS AND AUTOMATION

152

methods provided by the XML Web services using

the user interface functions provided by Scenario

Manager (see Section 3.4). Implicitly, the term

“Internet/Intranet” in the system architecture implies

that a single solution can be applied readily into both

on-site and off-site machine service scenarios. This

also facilitates a common user interface for local and

remote monitoring, day-to-day and “on-demand”

specialist maintenance. Currently, the web services

are being developed using the Microsoft ASP.NET

(Active Server Page) technology. The ASP.NET

security and Windows authentication scheme have

been enforced to disallow unauthorized access to the

web services.

3.2 Monitoring and Fault Detection

For continuous visual monitoring or in the case of a

machine failure (breakdown), MSSS users can use

the historical data saved in the database to carry out

“playbacks” to investigate the recent history of the

machine system and current status using the

corresponding simulation models. In these cases,

animations are driven by the historical data acquired,

but simultaneously, the reference dynamics models

are used to generate the nominal response of the

system with the input data from the historical data.

The output data generated by the simulator and from

the collected historical data can be visualised and

compared using various data analysis and residual

analysis techniques. The data visualisation features

accomplish the 3-D animation for presenting useful

“non-animated” data like electric current and voltage

produced both from the simulator and the collected

data as an additional means for assisting any

monitoring and diagnostic tasks. A fault alarm is

generated, for instance, if a residual signal is

evaluated to exceed a certain threshold; but more

advanced fault detection algorithms can be easily

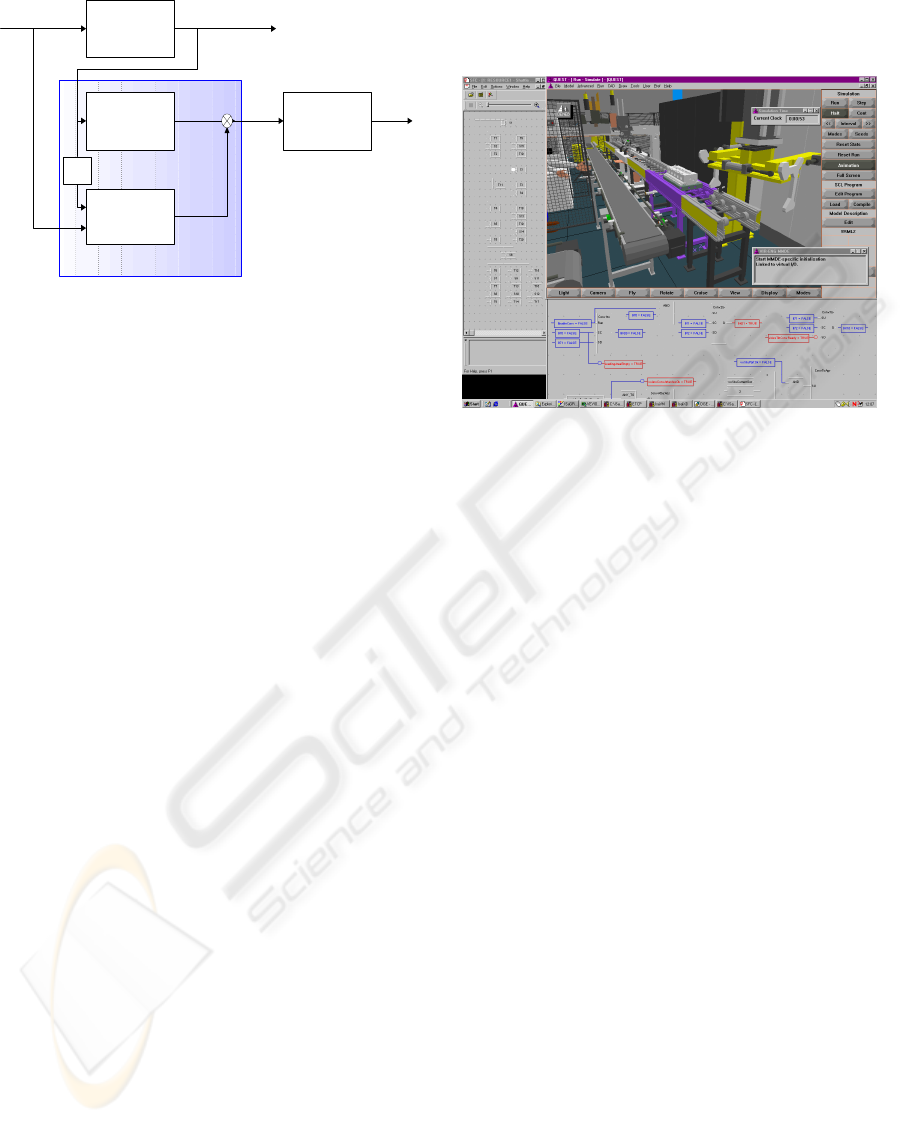

incorporated into MSSS. Figure 4 illustrates

schematically the block diagram of the monitoring

and fault detection scheme for the actuators and

mechanics of a robot manipulator.

3.3 Control System Verification

Control system verification is a desirable feature that

the simulation models can be used to verify the

control programs for testing and verification during

Figure 3: The MSSS environment.

AN INTEGRATED ENVIRONMENT FOR MACHINE SYSTEM SIMULATION, REMOTE MONITORING AND

FAULT DETECTION

153

the machine system design, development,

commissioning or re-configuration stage. While this

functionality has been explored in-depth during the

VIR-ENG project, the focus of MASSIVE is to

extend the research outcomes from VIR-ENG to

support verification of control programs that are

developed/modified to cope with maintenance

service tasks. Remote download of control code that

has been verified in a virtual environment is

particularly helpful for the following situations:

• Develop, test and upload temporary control

code in the case of temporary reconfiguration

due to machine service activities (either

preventive or corrective maintenance).

• Remote download of new/modified control

code to include additional functions requested

by the machine users during the operational

phase, e.g. to enhance the performance of the

machine or to cope with slight changes in

production.

MSSS provides control system verification with

two different types of configuration:

• Verification of logic control models and then

the logic control code is generated, compiled

and subsequently downloaded to the target

controller hardware. Verification, testing and

simulation are therefore carried out in a pure

software environment.

• Verification of the actual control logic

hardware and software.

The first configuration type has been developed

and demonstrated successfully using languages

defined in IEC 61131-3 (1993), in particular

Sequential Function Chart (SFC) as the logic control

modelling language (see Figure 5). An important

research area that has recently been identified is to

extend the concept and implementation to

incorporate the function block standard defined in

IEC 61499.

Figure 5: Testing and verification of logic control

models using machine simulations.

The integration of real and simulated machine

controllers with a simulated model of the machine

system in order to test the system’s behaviour, has

been identified to be one of the “hot topics” and

technology trends of virtual manufacturing (Dépincé

et al. 2003). With today’s industrial automation

equipment, this integration can be achieved by

connecting the simulated machine/environment logic

model directly to the machine controller via the OPC

client/server-based data access technology. This

integration technique has been successfully

demonstrated by embedding OPC client functions

into a simulation system (Sundberg et al. 2003)

using the interfacing technique described in Section

4. The current challenge is to incorporate the OPC

communication capability into the unified

communication framework selected for integrating

all MSSS components (see Section 4).

3.4 Scenario Manager

Scenarios Manager is the configuration environment

for users to define/create different scenarios, e.g.

monitoring scenario, tentative failure or “what if”

scenario for diagnosis. It acts as the main user

interface for MSSS users to interact with all local

system components as well as remote components

through the Web service client. The concept of

scenarios is specifically introduced to allow users to

combine various components and sub-models in a

very flexible and rapid manner. A scenario is an

Robot

Manipulator

⎥

⎦

⎤

⎢

⎣

⎡

)(

)(

ky

ky

&

⎥

⎦

⎤

⎢

⎣

⎡

)(

ˆ

)(

ˆ

ky

ky

&

⎥

⎦

⎤

⎢

⎣

⎡

)(

)(

ke

ke

&

Robot simulation

Motion

Playback

⎥

⎦

⎤

⎢

⎣

⎡

)(

)(

ky

ky

&

Fault Detection

Al g o r i t h m

Res id ua l

Faul t

Al a r m

1−

z

Ad a pt i v e

Dynamics Model

+

-

Position &

Velocity

Torque command

T

Figure 4: Monitoring and fault detection scheme for

the actuators and mechanics of a robot manipulator.

ICINCO 2004 - ROBOTICS AND AUTOMATION

154

abstract “container” that holds any combinations of

the following types of software objects:

• A simulation model that is comprised of

various sub-models.

• Historical data stream.

• VIO variables to real/simulated control

devices/programs.

• Fault detection algorithms that can be applied

with the simulation model.

• Data processing and visualisation functions.

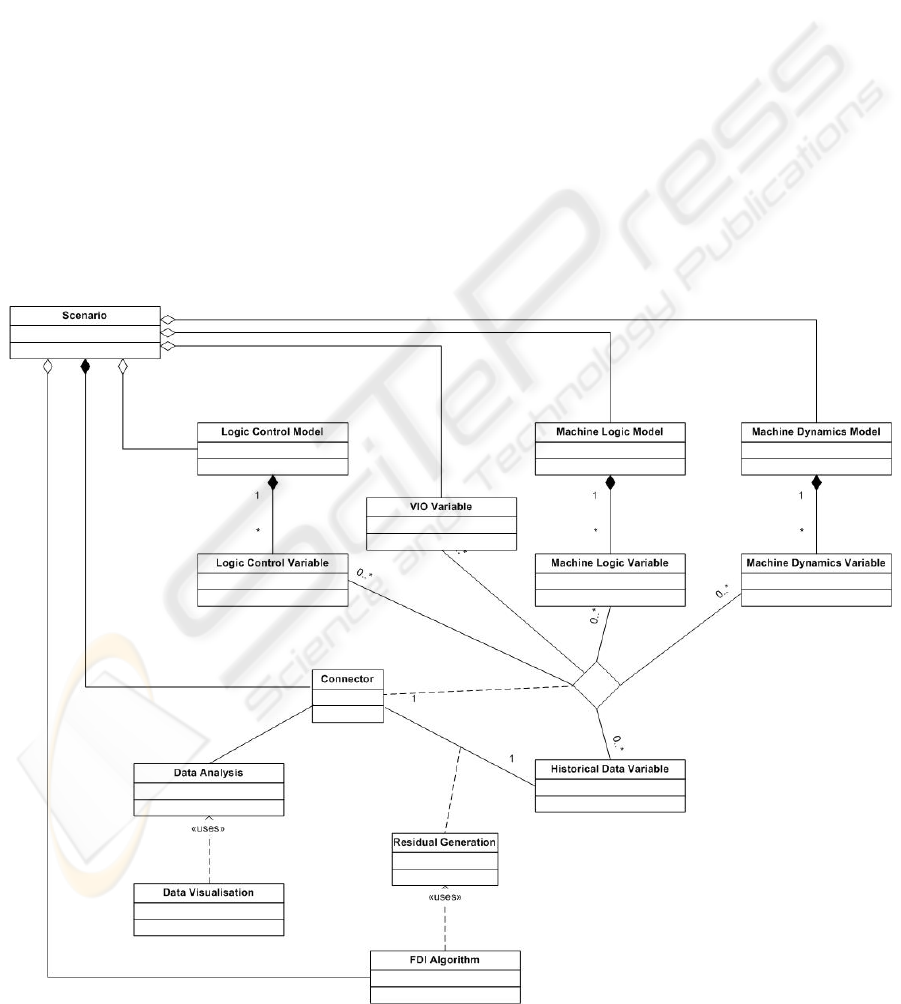

The UML (Unified Modelling Languages) class

diagram shown in Figure 6 represents the

aggregation of a scenario. A connector is a software

communication mediator that defines the interface

for related software objects to communicate with

each other, for instance, different types of sub-

models, different algorithmic modules for residual

analysis and fault detection, possibly developed

using a variety of tools and running on a distributed

platform. The purpose of having the concept of

connectors is twofold. Firstly, it reduces the

dependencies among MSSS components; a single

component or sub-model can be used and reused in

multiple scenarios without any modifications.

Secondly and more importantly, it hides the

underlying communication mechanism from the

software packages adopted in MASSIVE. In other

words, the communication mechanism is

encapsulated by the framework that supplies all the

communication functions in form of a set of

standard libraries.

4 THE COMMUNICATION

FRAMEWORK

The following issues have been considered as vital

when it comes to the development of the

communication framework:

• The suitable communication model for the

data flows within a scenario.

• How machine simulation systems are

integrated with other applications in order to

produce smooth animation effects.

Figure 6: UML class diagram showing the aggregation of a scenario.

AN INTEGRATED ENVIRONMENT FOR MACHINE SYSTEM SIMULATION, REMOTE MONITORING AND

FAULT DETECTION

155

• How data integrity and synchronisation is

maintained if multiple parties are sharing the

data concurrently.

The concept of connectors has suggested the

possibility of having some distributed, many-to-

many complex data flow patterns when running a

scenario. Loose coupling and real-time

(deterministic) performance have been identified to

be the essential requirements when selecting the

communication architecture that supports the

implementation of the connectors: it should facilitate

the dynamic configuration of data producers from

data consumers so that each can act independently of

each other; data exchange among applications

should also happen anonymously in a distributed

platform, without knowing the network locations.

After an extensive investigation into various

communication middleware architectures, such as

the well-known Microsoft’s Distributed Component

Object Model (DCOM) and Common Object

Request Broker Architecture (CORBA), the

Network Data Delivery Services (NDDS)

middleware (Pardo-Castellote et al. 1999) supplied

by Real-Time Innovations (RTI) commercially has

been selected as the most suitable one for

developing the communication framework for

MSSS. NDDS is developed based on the publish-

subscribe model that simplifies peer-to-peer and

many-to-many communications. Applications use

named topics rather than network addresses to

distribute data; a publisher simply creates a

publication and gives it a topic name. Each

subscriber then creates a subscription for the topic

name and instructs NDDS what to do when a new

issue arrives. A publisher can then update the shared

data and notify all subscribers by sending an issue

using only a single NDDS function call. Every time

the publication has a new issue, NDDS handles the

network I/O and transparently sending each issue

from the publisher to all subscribers with a declared

interest in that topic. Subscribers can therefore be

notified when data has been changed and avoid the

need for continuous polling. The publish-subscribe

model is therefore described as notification-based.

The NDDS publish-subscribe model features an

open protocol that adjusts automatically as

applications join and leave the network.

Communications happen anonymously and an

application can join and leave the network without

the need to notify others; this makes the

communications highly fault-tolerant. On the other

hand, NDDS provides fast and deterministic data

distribution over standard IP networks, whereof the

underlying UDP layer handles the data transmission

and multicast efficiently. All these features make

NDDS a very suitable middleware that satisfies the

requirements for the implementation of the

framework.

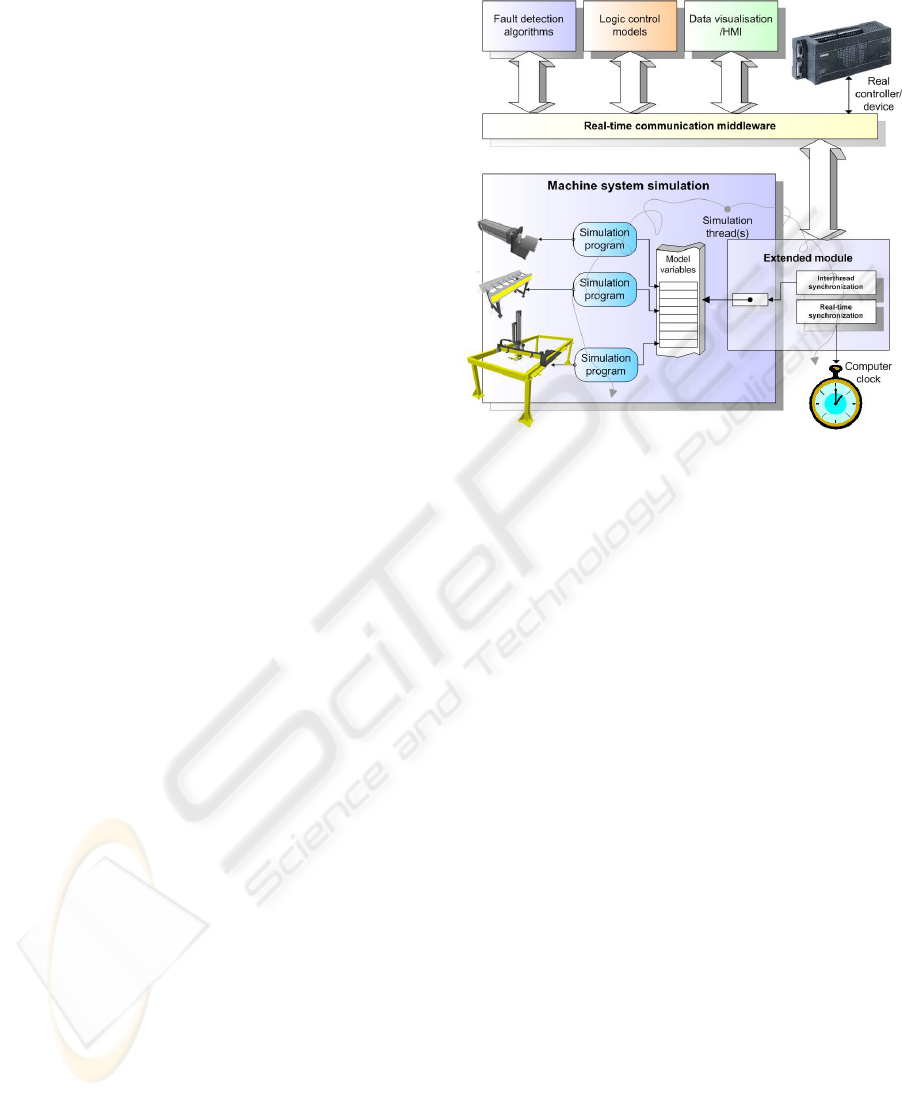

Figure 7: The interfacing method used for integrating

simulation programs with other applications.

Initial implementation of a set of standard

libraries that supports the simulation systems and

different MSSS prototype components to invoke the

NDDS services has been completed using the

simulation system interfacing technique described in

Figure 7. This interfacing technique is characterised

by the use of multithreads to detect and handle data

updates of model variables that are logically

connected to connectors. This relieves the simulation

engine from running a polling loop to detect data

changes. Together with the real-time capability of

NDDS, this results a highly smooth animation effect.

A set of experiments has been carried out to

quantitatively compare the performance of NDDS

with other architectures; NDDS outperforms DCOM

noticeably in terms of both update latency and

throughput.

5 CONCLUSIONS & OUTLOOK

This paper has introduced an innovative virtual

engineering framework for supporting the remote

monitoring, fault detection and maintenance services

of discrete manufacturing machine systems. The

core concept behind this framework is the separation

of a virtual machine (simulation model) into a

number of sub-models including logic control

models, machine/environment logic models and

machine dynamics models. This separation

ICINCO 2004 - ROBOTICS AND AUTOMATION

156

facilitates many useful advanced functions to be

developed, including control system verification,

HIL testing, monitoring by “playback” and model-

based fault detection, etc.

This paper has pointed out the importance of a

real-time communication framework that provides a

highly flexible communication mechanisms among

different sub-models and other system components,

possibly developed using a variety of tools running

on a distributed platform. RTI’s NDDS has been

selected as the suitable real-time networking

middleware for the development of the underlying

communication framework. Based on the publish-

subscribe model, NDDS provides many-to-many

communications to happen anonymously with

network location transparency, which are essential to

the implementation of connectors – the concept

introduced for maintenance specialists to define

multiple monitoring and fault detection scenarios by

flexibly connecting multiple sub-models,

algorithmic modules and data analysis tools. Future

publications will focus on the dynamics modelling

techniques and fault-detection algorithms for the

real-world industrial test cases within MASSIVE.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the Knowledge

Foundation (KK Stiftelsen), Sweden, and other

industrial participants, including AP&T, DELFOi,

Euromation, Volvo Cars and Volvo Powertrain, for

the provision of the research funding and their

collaborative input to the MASSIVE project. We

would also like to acknowledge Real-Time

Innovations for the grant of NDDS through our

participation in their University Program.

REFERENCES

Adolfsson, J., Ng, A. H. C. and Moore, P. R. (2000)

Modular machine system design using graphical

simulation. In Proceedings of the 33rd CIRP

International Seminar on Manufacturing Systems, 5-7

June, Stockholm, Sweden, pp 335-340.

Chen, J. and Patton, R. J. (1999), Robust model-based

fault diagnosis for dynamic systems, Kluwer

Academic Publishers, Dordrecht.

DELMIA (2003) IGRIP/Envision & QUEST D5 Release

12, Dassault Systemes, http://www.delmia.com.

Dépincé, P., Peer-Oliver, W. and Michael, Z. (2003)

Virtual Manufacturing, MANTYS - Thematic

Technology Trend Report.

Groll, F. (2002) Process visualization and optimization

with modern software tools. In Proceedings of the

International Symposium on Robotics, 7-11 October,

Stockholm, Sweden, pp. 193-197.

IEC 61131-3 (1993) Programmable controllers - Part 3:

programming languages, International

Electrotechnical Commission.

Isermann, R. and Ballé, P. (1997) Trends in the

application of model-based fault detection and

diagnosis of technical process, Control Engineering

Practice, 5 (5), pp. 709-719.

Lewis, R. (2001) Modelling control systems using IEC

61499, The Institution of Electrical Engineers,

London, United Kingdom.

Ljung, L. (1999). System identification: Theory for the

user, Prentice-Hall, Englewood, Cliffs, New Jersey.

Moore, P. R., Pu, J., Ng, A. H. C., Wong, C. B., Chong, S.

K., Adolfsson, J., Olofsgård, P. and Lundgren, J.-O.

(2003) Virtual Engineering: An integrated approach to

agile manufacturing machinery design and control,

Journal of Mechatronics, 13, pp. 1105-1121.

Nelles, O. (2001) Nonlinear system identification,

Springer-Verlag, Berlin, Heidelberg.

OPC Foundation (2003) http://www.opcfoundation.org.

Pardo-Castellote, G., Schneider, S. and Hamilton, M.

(1999) NDDS: The real-time publish-subscribe

middleware, Real-Time Innovations whitepaper,

http://www.rti.com.

Sundberg, M., Ng, A. H. C. and de Vin, L. J. (2003)

Distributed modular logic controllers for modular

conveyor systems. In Proceedings of the 20th

International Manufacturing Conference, Cork,

Ireland, pp. 493-500.

VIR-ENG (2001) Integrated design, simulation and

distributed control of agile modular manufacturing

machinery (VIR-ENG) ESPRIT Framework IV 25444,

final report, Final report, June.

Wolfram, A. and Isermann, R. (2002) Component based

tele-diagnosis approach to a textile machine, Control

Engineering Practice, 10, pp. 1251-1257.

AN INTEGRATED ENVIRONMENT FOR MACHINE SYSTEM SIMULATION, REMOTE MONITORING AND

FAULT DETECTION

157