IMPLEMENTATION OF A DEVICE COMPATIBLE WITH

DIFFERENT FIELDBUSES USING RECONFIGURABLE

CIRCUITS

Miguel Ángel Domínguez, Mª Dolores Valdés, Mª José Moure

Department of Electronic Technology, University of Vigo, Vigo, Galicia, Spain

Keywords: Industrial networks, Fieldbuses, WorldFIP, Profibus, FPGA

Abstract: Fieldbuses are serial communication networks very used in industrial control applications. They constitute

the lower level of the communication networks in a flexible manufacturing system. Nowadays there are a

lack of standardization in the area of fieldbuses and it supposes the existence of a lot of proprietary

protocols. Thus, the interconnection of equipment from different manufacturers has become very

problematic. It implies that a change in equipment supposes a change in the fieldbus too with the

consequent economic losses. This paper proposes the implementation of a device using reconfigurable

circuits such as FPGAs (Field Programmable Gate Arrays) that can be used as a communication processor,

compatible with different fieldbuses making only little changes in the programming code and in the level

and impedance matching circuit (depending on the electrical features of the corresponding fieldbus). Thus,

the same hardware can be connected to different fieldbuses. The implementation of fieldbus communication

processors using FPGAs implies that the interface can be easily adapted to different protocols (improvement

in the interconnection between products of different manufacturers) and that the programming code can be

easily modified, adding new functionality when it is necessary.

1 INTRODUCTION

According to the definition of the IEC (International

Electrotechnical Commision) and the ISA

(Instrument Society of America), fieldbuses are

digital serial, multidrop data buses for low-level

communication of industrial control process and

instrumentation devices like actuators, sensors and

local controllers. The aim of fieldbuses is the serial

communication between primary elements of

automation (sensors and actuators with control and

measurement functions) and control devices of a

higher level (PLCs, numeric control machines,

processors, etc.).

Before the appearance of fieldbuses, the

connections between process units (PLCs,

controllers, etc.) and field devices (sensors and

actuators) were point-to-point links. It meant

complex (a lot of wires) and expensive (in time and

money) installations. Also the maintenance and

modification tasks were harder. These problems are

solved with fieldbuses because all devices are

connected through a single physical medium

(twisted pair, coaxial, two wires, optical fiber, etc.)

extended over the whole area of the distributed

control process system (cost reduction). Thus, new

devices can be added, connecting to the fieldbus,

without additional wiring (easy maintenance and

modification).

It can be said that fieldbuses emerged as a

response to the following needs: wiring reduction in

installations, easily reconfigurable systems, reduced

transmission times, data transmission reliability,

intrinsic security in hazardous areas, improvement of

transmitted signal, increase of information flow,

integration of manufacturing data in the information

system of the enterprise, increase of processing

capacity (intelligence) of sensors and actuators,

decentralization of the processing resources to make

distributed process systems, control equipment with

standard connections to guarantee the interworking

of different products and the compatibility of

equipment and designed software.

A fieldbus implements only three layers of the

OSI model (physical, data link and application).

Fieldbuses support short messages, real-time

variable exchanges (response times between 5 and

100 ms), great reliability (security in

communications), data rates usually lower than 1

46

Domínguez M., Valdés M. and Moure M. (2004).

IMPLEMENTATION OF A DEVICE COMPATIBLE WITH DIFFERENT FIELDBUSES USING RECONFIGURABLE CIRCUITS.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 46-53

DOI: 10.5220/0001132400460053

Copyright

c

SciTePress

Mbps (over copper cable) and distances from 200

meters up to 2 kilometers. Usually the physical

medium is a pair of wires with EIA RS-485

interface, although there are applications over

optical fiber, coaxial cable, infrared, radiofrequency

and electrical power lines.

The lack of standardization is a problem in the

area of industrial communication networks. It

implies that there are a lot of different commercial

solutions and protocols, making difficult the

compatibility between equipment of different

manufacturers. Thus, in this paper the authors

propose the implementation of fieldbus

communication processors using reconfigurable

circuits. In this way a communication protocol can

be modified without changes in the hardware

support that implies an economic saving. In this line

the authors have implemented a communication

processor based on a FPGA (Field Programmable

Gate Array) supporting two important fieldbus

standards in the area of industrial control such as

WorldFIP and Profibus. The chosen FPGA for this

project was the FLEX 10K20RC240-4 from the

ALTERA company [Lías, 2000].

2 PROFIBUS AND WORLDFIP

Profibus (Process field bus) is a fieldbus protocol

proposed by the German manufacturers (ABB,

AEG, Siemens, Bauer, etc.) in 1987. It was

standardized as DIN 19245 in 1991 [PROFIBUS,

1991] and the CENELEC (Comité Européen de

Normalisation ELECtrotechnique) included this

protocol in the standard EN 50170 (Volume 2) in

1996 [CENELEC, 1996].

The French manufacturers (Cegelec,

Telemecanique, Efisystem, Gespac, etc.) have driven

the WorldFIP protocol. First, it was standardized

with the denomination FIP (Factory Instrumentation

Protocol) in the French standard NFC 46 601 to 605

[AFNOR, 1990]. Afterwards this protocol was

described by CENELEC into its standard EN 50170

(Volume 3) with the name WorldFIP (World Factory

Instrumentation Protocol) [CENELEC, 1996], being

the same than the former French standard but with

little difference such as the adoption of the

international standard IEC 1158-2 (now renamed as

61158-2) for the physical level [IEC, 1993].

A comparison between these two protocols and

with other important fieldbuses used in different

areas (industrial control, automotive industry,

microcontrollers, aircrafts, electronic wheelchairs,

ships, home automation) is shown in Table 1

[Domínguez, 2000].

Profibus and WorldFIP are two of the most

important fieldbuses used in industrial control

automation in Europe. They have a lot of

differences. The most significant ones are:

- Data rates: WorldFIP achieves higher data

rates than Profibus (among the standardized

ones because there are Profibus devices from

Siemens that can achieved up to 12 Mbps).

- Types of stations: A Profibus network can

have several master stations (make up a

logical ring and can transfer messages

without remote request) and also slave

stations (only transmit data after the reception

of a request from a master station). WorldFIP

networks have a single active bus arbitrator

(manages the access to the transmission

medium) and the other nodes have

consumer/producer functionality.

- Medium access method: Profibus has a

hybrid method (token passing for the master

stations and master-slave polling for the slave

stations) but WorldFIP uses a centralized

method (access managed by a bus arbitrator

station).

- Timers: Profibus is a protocol with a lot of

timers and then the management of timing

information and the implementation of timers

are more complicated than in WorldFIP.

- Frame format: In the data link level the

protocols are completely different and also

the frame format is not the same.

- Signal level and coding: Profibus uses a RS-

485 communication in the physical level and

WorldFIP uses a Manchester coding. Thus, it

is necessary different circuits to adapt the

signals between the bus and the device.

It can be observed that although Profibus and

WorldFIP have a same philosophy (to provide a

real-time communication oriented to the

transmission of variables with a predictable polling

time), the differences between both protocols are

important and then it forces to implement different

software and hardware for each communication

interface. Thus, all this features must be borne in

mind in the implementation of a compatible device

for these protocols using a FPGA that is proposed

and reported in this paper.

IMPLEMENTATION OF A DEVICE COMPATIBLE WITH DIFFERENT FIELDBUSES USING RECONFIGURABLE

CIRCUITS

47

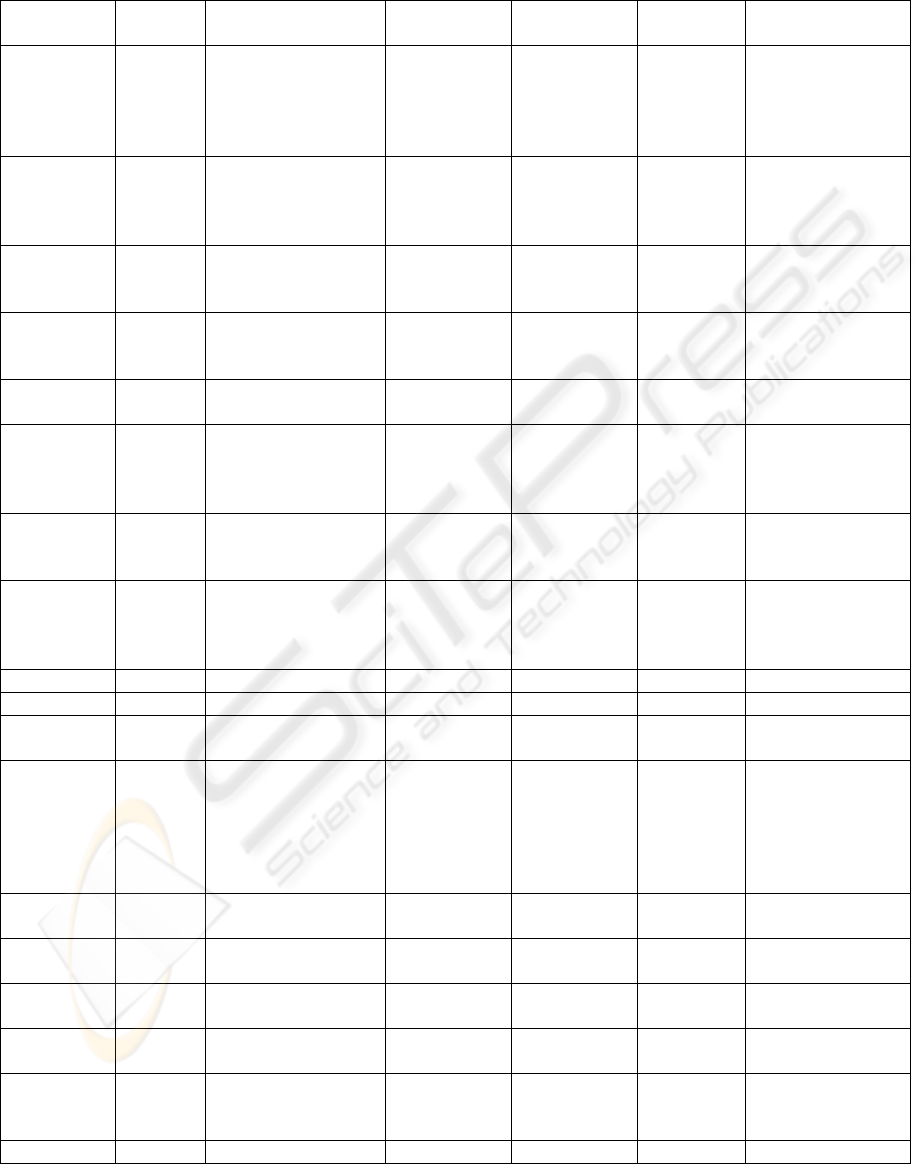

Table 1: Comparison of Profibus and WorldFIP with other important fieldbus protocols.

Fieldbus Topology Physical medium Data rate Distances Nodes per

segment

Network access

Profibus Bus Shielded Twisted Pair 9.6 Kbps

19.2 Kbps

93.75 Kbps

187.5 Kbps

500 Kbps

1200 m

1200 m

1200 m

600 m

200 m

32 - Token

- Master-slave

polling

WorldFIP Bus Shielded Twisted Pair

Optical fiber

31.25 Kbps

1 Mbps

2.5 Mbps

5 Mbps

1900 m

750 m

500 m

32 Centralized

(bus arbitrator)

AS-I Bus

Tree

Star

Two wires 167 Kbps 100 m 32 Master-slave polling

Bitbus Bus Twisted Pair

Optical fiber

62.5 Kbps

375 Kbps

1.5 Mbps

1200 m

300 m

29 Master-slave polling

CAN Bus Twisted Pair 50 Kbps up to

1 Mbps

1000 m up to

40 m

127

64

CSMA/CD with

arbitration

ControlNet Bus

Ring

Star

Coaxial

Optical fiber

5 Mbps

5 Mbps

1000 m

3000 m

48 CTDMA

(Concurrent Time

Domain Múltiple

Access)

DeviceNet Bus Twisted Pair 125 Kbps

250 Kbps

500 Kbps

500 m

250 m

100 m

64 CSMA/CD

Firewire

(IEEE 1394)

Bus

Tree

Six wires

Optical fiber

100 Mbps

200 Mbps

400 Mbps

800 Mbps

700 m 63 Time slots

HART Bus Two wires 1200 bps 3000 m 30 Master-slave polling

Interbus-S Ring Twisted Pair 500 Kbps 400 m 256 Token

J1939 Bus Shielded Twisted Pair 250 Kbps CSMA/CD with

arbitration

LonWorks Bus

Ring

Free

Twisted Pair

Optical fiber

Power line

Coaxial

Radio

Infrared

78 Kbps up to

1.25 Mbps

2700 m up to

130 m

64 CSMA/CA

M-Bus Bus Two wires 300 bps up to

9600 bps

1000 m 250 Centralized

Measurement

Bus

Bus Four wires 110 bps up to

1 Mbps

500 m 31 Master-slave polling

Modbus Bus Twisted Pair 300 bps up to

19.2 Kbps

1 Km 248 Master-slave polling

M3S Bus Six wires CSMA/CD with

arbitration

P-Net Ring Shielded Twisted Pair 76.8 Kbps 1200 m 125 - Token

- Master-slave

polling

Seriplex Bus Four shielded wires 98 Kbps 1500 m 300 Master-slave polling

ICINCO 2004 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

48

Emulator PLC

bus arbitrator

TSX

FPC 10

PC

Tap

box

Connection

cable

Terminator

Protocol

Analyzer

TSX

FPC 10

PC

Connection

cable

TBX

8Inputs/8Outputs

Test

point

Equipment

under test

Trunk cable

Terminator

Tap

box

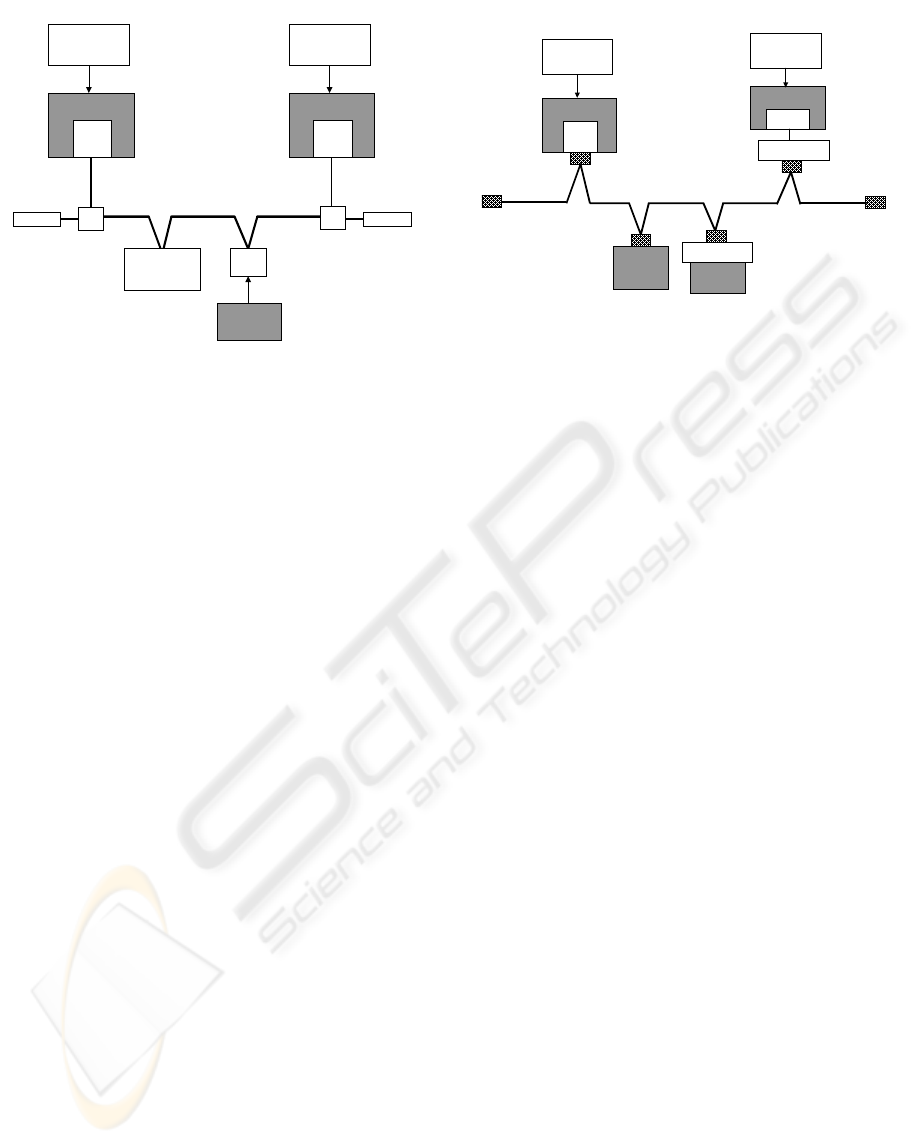

Figure 1: Block diagram of the WorldFIP network used to

check the designed device.

3 DESIGN OF A FIELDBUS

INTERFACE USING FPGA

The implementation of fieldbus communication

processors using SRAM FPGAs has a lot of

advantages derived from its reconfiguration

capability. The most important are:

- The FPGA programming code can be easily

improved adding new functions.

- Little changes in bus definitions (frame

format, transmission headers, etc.) can be

easily solved changing the software

description of the interface, avoiding the

economic cost associated to the equipment

renewal.

- It is possible to design devices for different

fieldbuses with similar physical layers

making little changes in the programming .

Taking into account these advantages, the

development of reconfigurable fieldbus interfaces

results in a very interesting project. Thus, the

authors have worked in the implementation of the

basic communication functions for two very well

known protocols (Profibus and WorldFIP) using a

SRAM FPGA. A Profibus slave station and the basic

services (writing buffer, reading buffer and transfer

buffer) of a WorldFIP consumer/producer station

have been implemented over the same hardware

(FPGA). Thus, this compatible device is able to

transmit and receive any frame in right way over any

WorldFIP and Profibus network.

There are several factors to be considered in the

selection of the FPGA for this application. The most

important are the cost, the operation frequency and

the available logic resources. The fieldbuses operate

Master station

Profibus

boiard

PC

Terminal

connector

Protocol

Analyzer

(Bus spy)

Serial port

PC

FPGA

(Profibus

Slave station)

Profibus network

Level and impedance

matching circuit

Terminal

connector

PLC

(Master

station)

Test

point

Level and impedance

matching circuit

Figure 2: Block diagram of the Profibus network used to

check the designed device.

at low data rates (in this work 9.6 Kbps for Profibus

and 1 Mbps for WorldFIP) and then a high speed

FPGA is not required. By other side, fieldbus

protocols manage many variables that must be

stored. So, in order to simplify the design, it is

suitable the use of a FPGA with embedded memory

blocks. Taking into account these two aspects and

the cost, the FPGA FLEX 10K20RC240-4 from the

ALTERA manufacturer was chosen for

implementing the communication processor of this

project [ALTERA, 1998].

The design was developed using the

MAX+PLUS II CAD tools from ALTERA

[ALTERA, 1994] and the system was specified in

VHDL (Very high speed IC Hardware Description

Language) [IEEE, 1994] to allow the portability of

the design to other FPGA devices.

4 IMPLEMENTED DEVICE

To check the good working of the implemented

device, two networks was used with the structures

represented in Figures 1 and 2.

In the WorldFIP network there are two PCs

connected to the bus through a TSX FPC 10 board

from the Telemecanique manufacturer. One of this

PCs runs a software that emulates the behavior of a

PLC with the functionality of bus arbitrator. The

other one is a protocol analyzer used to capture all

the frames transmitted on the bus and so to verify

the good working of the implemented device

(connected to the test point). Also a TBX module

from Telemecanique with 8 inputs and 8 outputs is

used to generate traffic on the network and so to

study the working of this protocol.

IMPLEMENTATION OF A DEVICE COMPATIBLE WITH DIFFERENT FIELDBUSES USING RECONFIGURABLE

CIRCUITS

49

Vcc

TPC

A

AH

AL

BL

BH

C

RTS

TXD

CONSEM

/ERPHY

CK2FR

CDO

RXD

Gnd2Gnd1INAINB

CREOL

18

3

B

Bus WorldFIP

4

10 KΩ

10 KΩ

22.6 KΩ

22.6 KΩ

2

1

19

17

14

2.2 MΩ

5

16

615

FPGA

13

12

11

10

9

8

4.02 Ω

7 20

n1

n2

n3

n1 = n2

n3 = 1.5 (n1 + n2)

150 nF

47 nF

LL 4448

LL 4448

47 nF

100 pF

100 pF

3.3 pF

3.3 pF

220 µF

47 µF

47 nF

Vcc (5 V)

RTS: Request To Send

TXD: Transmit Data

CONSEM: Transmiter Consumption

/ERPHY: Physical Error

CK2FR: Clock 2 FR

CDO: Carrier Detect Output

RXD: Received Data

TPC: Transmitted Power Control

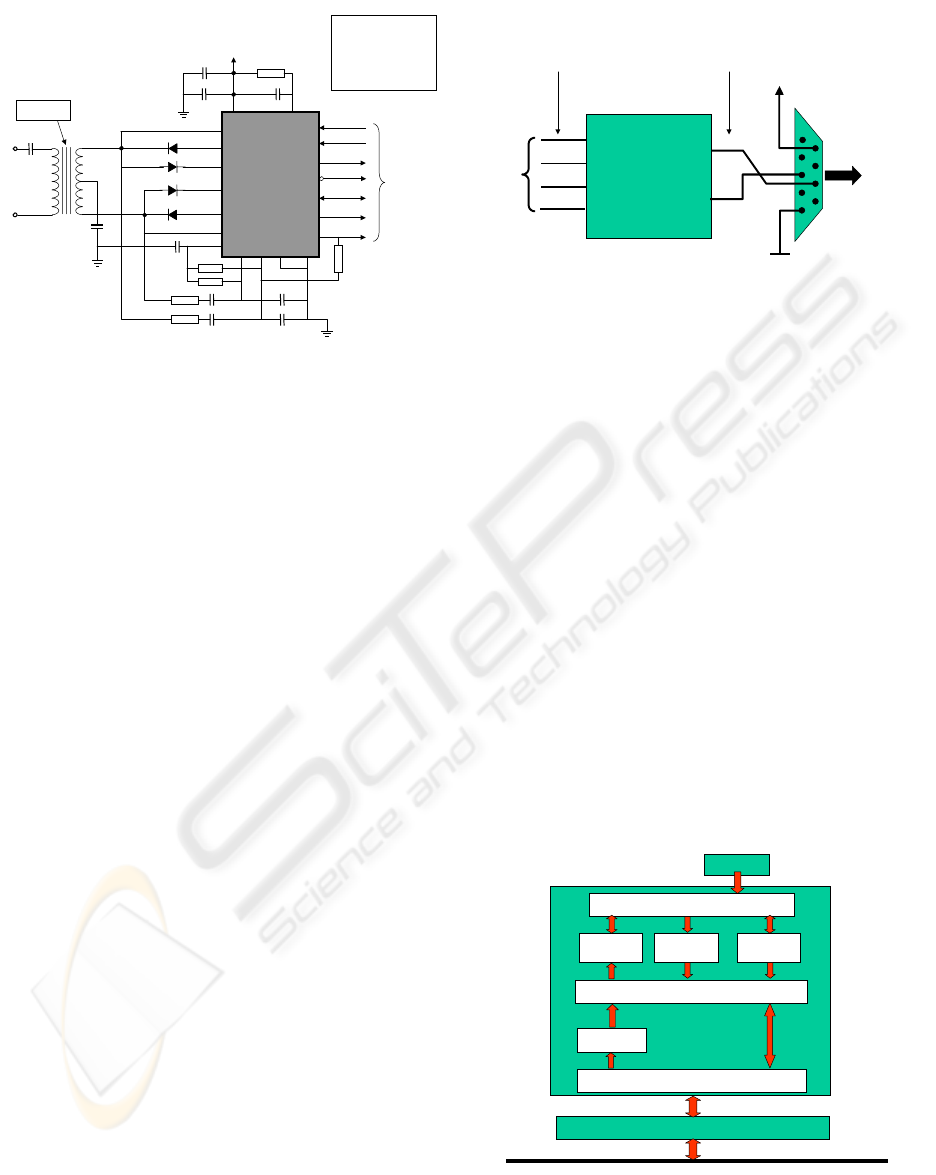

Figure 3: Level and impedance matching circuit for the

WorldFIP fieldbus.

The Profibus network is made up of two PCs,

one PLC and the test point where the implemented

device based on the FPGA is connected for its

verification. One PC has a Profibus board from

Siemens that is programmed for polling the data

produced for the sensor connected to the designed

communication interface (FPGA). The other PC runs

an application, designed by the authors, that allows

the capture (using the serial port with a data rate

limited to 9.6 Kbps) and analysis of all the frames

circulating on the bus (protocol analyzer). The PLC

is used as a master station that generates traffic in

the network and allows the study of the working of

this protocol.

4.1 Level and Impedance Matching

Circuits

Due to the electrical characteristics of Profibus,

WorldFIP and FPGA are not the same, it is

necessary to design different level and impedance

matching circuits (Figure 3 and 4) that convert the

signals present in the bus to TTL/CMOS signals

suitable for the FPGA and vice versa. This is the

unique change in the hardware required for

connecting the designed compatible device based on

FPGA to these two fieldbuses.

The WorldFIP matching circuit is based on an

integrated circuit from Telemecanique known as

CREOL and a transformer connected to the bus line.

In the case of Profibus networks a MAX485CPA

integrated circuit is used to make the conversion of

TTL/CMOS signals to Profibus signals (RS-485).

MAX485CPA

RO

/RE

DE

DI

B

A

VCC

GND

1

2

3

4

8

5

VCC

GND

7

6

6

3

8

5

PROFIBUS

FPGA

Connector

DB9 female

Profibus

signals

TTL/CMOS

signals

Figure 4: Level and impedance matching circuit for the

Profibus fieldbus.

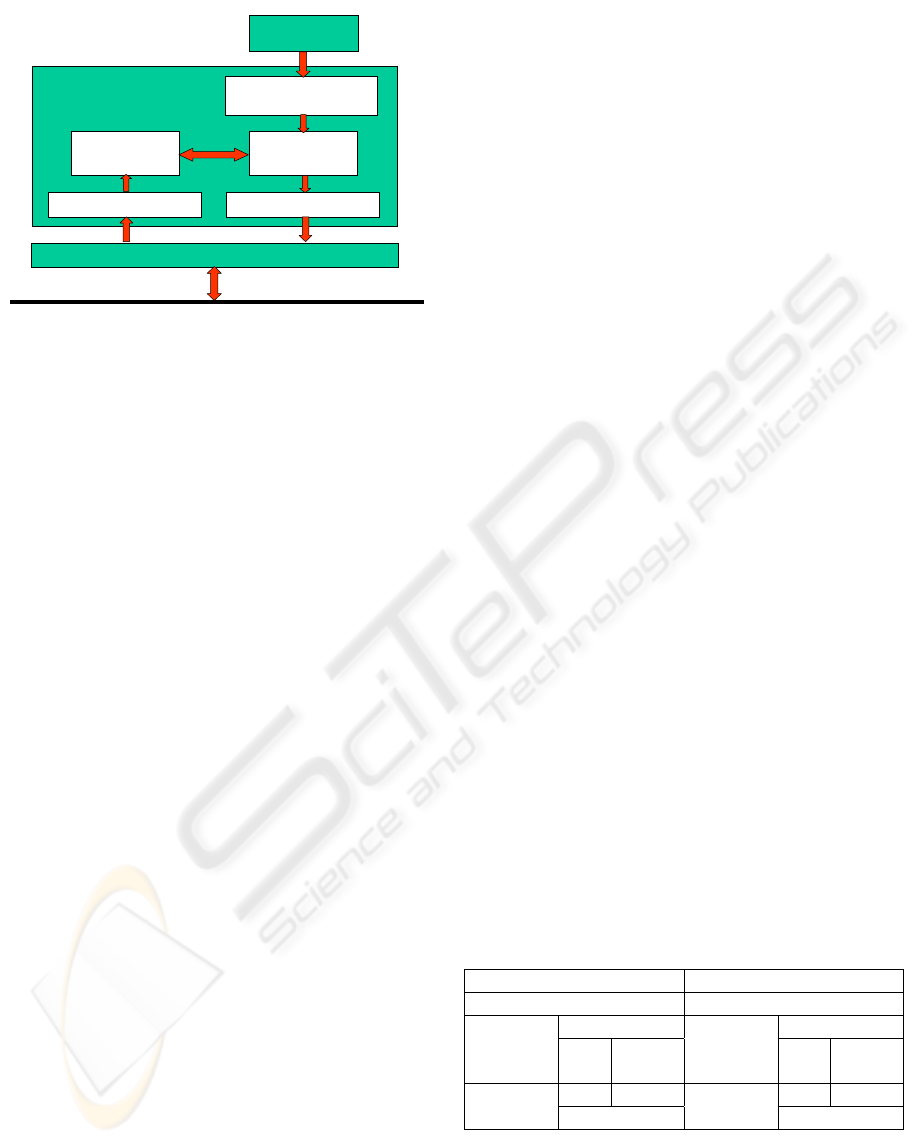

4.2 The Fieldbus Communication

Processor

To get a compatible device between WorldFIP and

Profibus networks two designs were specified using

VHDL. The block diagrams of these two designs are

shown in Figures 5 and 6.

The WorldFIP design consists of a

transmitter/receiver circuit, a receiving buffer, a

WorldFIP control system, the consumed and

produced data bases, an identifier index and a

variable access protocol. The transmitter sends data

adding the Frame Starting Sequence (FES) and the

Frame End Sequence (FES) established in the

WorldFIP protocol. The receiver detects the frames

circulating by the bus and delivers them to the

receiving buffer checking the corresponding Frame

Check Sequence (FCS).

RECEIVING

BUFFER

TRANSMITTER/RECEIVER CIRCUIT

CONSUMED

DATABASE

USER

FPGA

LEVEL AND IMPEDANCE MATCHING CIRCUIT

BUS

WorldFIP CONTROL SYSTEM

IDENTIFIER

INDEX

PRODUCED

DATABASE

VARIABLE ACCESS PROTOCOL

Figure 5: Scheme of the implemented WorldFIP interface.

ICINCO 2004 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

50

RECEIVER CIRCUIT TRANSMITTER CIRCUIT

RECEPTION

APPLICATION

TRANSMISSION

APPLICATION

SENSOR BUFFER

SENSOR

FPGA

LEVEL AND IMPEDANCE MATCHING CIRCUIT

BUS

Figure 6: Scheme of the implemented Profibus interface.

The receiving buffer is used to temporarily store

the last frame received that will be processed by the

WorldFIP control system. To implement this circuit

a cycle shared double port RAM is used to allow a

simultaneous access to this buffer. The WorldFIP

control system processes the frames stored in the

receiving buffer and runs the required actions

according to the protocol. The values of the

consumed and produced variables (set in the

configuration of the device) are stored in the

consumed and produced databases that are also

implemented with a cycle shared double port RAM.

The identifier index contains all information about

the identifiers of the consumed and produced

variables (identifier number, type, length of the

variable and its address in the corresponding

database). Finally, there is an interface between the

external circuits (the corresponding sensors and

actuators) and the designed communication

processor that is implemented in the variable access

protocol block.

A WorldFIP network with a data rate of 1 Mbps

was used for this work. The bus uses Manchester

coding (each half symbol has different logic level).

Thus, the system requires two clocks, the main one

of 10 MHz used by the receiver (take 5 samples per

half symbol) and another of 2 MHz used to control

the data sending.

The Profibus design comprises a receiver circuit,

a transmitter circuit, a reception application module,

a transmission application module and a sensor

buffer. The receiver circuit manages the reception of

the characters conforming the frames transmitted by

the bus. When a byte is received, this circuit

indicates to the reception application module if it is

valid or not. The reception application module takes

the valid data bytes and analyzes them to verify the

destination address and the type of frame. It checks

for possible errors in transmission (uses a check

field of the frame) and if there are not errors the

transmission application receives the information of

the received frame. Then, the transmission

application module generates the corresponding

response frame that is sent to the transmitter circuit

so that it conforms and transmits the frame

characters. This design includes a sensor buffer to

store the last measurement from a specific sensor.

This value is read by the transmission application

module to generate the adequate response frame

when a request frame asking for this data is received

in the device.

The data rate of the Profibus network used in this

work is 9.6 Kbps (limited by the protocol analyzer

station that uses the serial port to capture the frames

circulating by the bus). Then, the clock signal

frequency used by the receiver and transmitter

circuits is 9.6 KHz too. It is resynchronized with the

bus every time a new character is detected.

4.3 Technical Comparison

Table 2 shows a comparative of the FPGA logic

resources required to implement the WorldFIP and

the Profibus communication processors.

It can be observed that the average of the logic

used resources is very similar in both cases. The

WorldFIP interface uses more memory blocks and

interconnection resources because it needs to store

more variables (several consumed and produced

data, identifier index, variables of management to

indicate the presence of a station in the bus, etc.)

than in the case of Profibus (only the data stored in

the sensor buffer).

The occupation of resources in the FPGA used in

this project is very high. Thus, it is adequated for the

implementation of simple communication interfaces

(a Profibus slave station and a WorldFIP

consumer/producer station with the basic services

and producing only one variable). When more

functions must be implemented (for example, the

design of a Profibus master station, a WorldFIP

Table 2: FPGA resources used in this project.

WORLDFIP PROFIBUS

Resources of FPGA Resources of FPGA

Logic Logic Interconn.

Logic

Cells

Memory

Blocks

Interconn.

Logic

Cells

Memory

Blocks

94% 60% 94% 33% 74%

82%

56%

81%

consumer/producer station with all the services

provided by the data link layer or a WorldFIP bus

arbitrator station), it is required the use of a bigger

FPGA with more logic resources.

IMPLEMENTATION OF A DEVICE COMPATIBLE WITH DIFFERENT FIELDBUSES USING RECONFIGURABLE

CIRCUITS

51

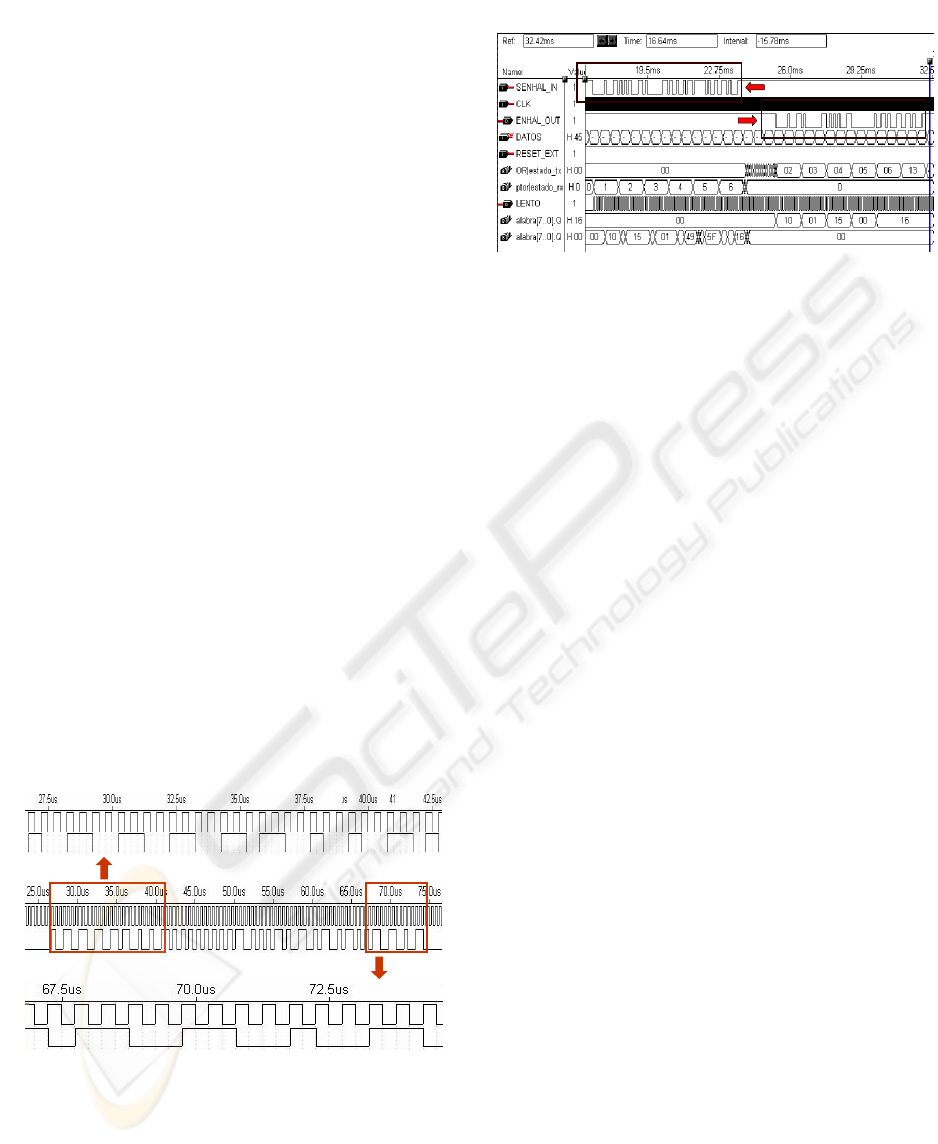

4.4 Simulation

To verify the behavior of the designed

communication interface, many functional/timing

simulations and tests were developed. Figure 7

shows an example of the simulation results of the

transmitter circuit of the WorldFIP communication

processor where the generation of the FSS (Frame

Starting Sequence) and the FES (Frame End

Sequence) can be observed. Figure 8 shows other

example of simulation for the Profibus interface

where a received request frame and the

corresponding response frame generated by the

Profibus communication interface can be observed.

5 CONCLUSIONS

In this paper the authors propose a solution to design

compatible devices for different fieldbuses using

reconfigurable circuits. In this work it is

demonstrated that it is possible to get a device that

can be connected to two of the most important

fieldbuses used in Europe in industrial control

processes like WorldFIP (French standard) and

Profibus (German standard). This device is designed

using a FPGA (Field Programmable Gate Array)

from ALTERA. It is programmed with the necessary

code (in VHDL) to specify the services of a Profibus

slave station and the basic services (writing buffer,

reading buffer and transfer buffer) of a WorldFIP

consumer/producer station.

Figure 7: Simulation results of the WorldFIP transmitter

circuit.

REQUEST FRAME

RESPONSE FRAME

Figure 8: Simulation results for the Profibus interface.

Thus, this device can be used either in a

WorldFIP network or in a Profifus network without

changes in the hardware (it is only necessary to

change the connector that contains the adequate

level and impedance matching circuit). It supposes a

great money saving when a user needs to change the

protocol of its fieldbus system and also an

improvement in the interconnection between the

fieldbus devices that can be supplied in the market.

The FPGA used in this work is a low cost circuit

with limited logic resources. The use of the

resources is very high as it is shown in section 4.3.

Thus, to implement more complex devices like

Profibus master stations, WorldFIP bus arbitrator

stations or WorldFIP consumer/producer stations

with the complete seven services that can be

provided in the protocol, it is necessary to use a

FPGA of higher level with more logic resources and

interconnection elements and also more expensive.

In this line of research, it would be very

interesting for future works to get the

implementation of multiple fieldbus protocols in a

unique FPGA. Also it would be possible to

implement an intelligent reception module able to

identify the type of network from the analysis of the

received frames to automatically use the adequate

protocol. Thus, a total compatibility of the field

devices would be achieved with the advantages that

it supposes. A problem for getting this aim would be

that the used FPGA should have a lot of logic

resources and interconnection elements and its price

would be very high. But it can be solved with a

design of a more complex device with multiple

FPGAs and may be other reconfigurable devices.

REFERENCES

AFNOR, 1990. Standard NFC 46-601 to 605: Bus FIP

pour échange d’information entre transmetteur,

actionneur et automate.

FSS

FES

ICINCO 2004 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

52

CENELEC, 1996 (December). Standard EN 50170:

General purpose field communication system.

Domínguez, M.A., 2000. Contribution to the analysis of

the data link level in communication protocols for

standard fieldbuses (In Spanish), Ph.D. Thesis,

Department of Electronic Technology, University of

Vigo, Spain.

IEC, 1993. Standard IEC 1158: Fieldbus standard for use

in industrial control system.

IEEE, 1994 (June). IEEE 1076-1993: IEEE Standard

VHDL Language Reference Manual, SH16840.

Lías, G., Valdés, M.D., Domínguez, M.A. and Moure,

M.J., 2000. Implementing a fieldbus interface using a

FPGA. In FPL’2000 10th International Conference on

Field Programmable Logic and Applications. Villach,

Austria, August 2000, Lecture Notes in Computer

Science 1896, R.W. Hartenstein, and H. Grünbacher

(Eds.), ISBN 3-540-67899-9, Springer-Verlag, pp.

175-180.

PROFIBUS Nutzeorganisation, 1991 (April). Profibus

standard: Translation of the German standard DIN

19245 (part 1 and part 2), PROFIBUS

Nutzeorganisation e.V. Wesseling Germany.

ALTERA, 1998. ALTERA Data Book, Altera Corporation,

San José (CA).

ALTERA, 1994 (July). MAX+PlusII Getting Started,

Altera Corporation.

IMPLEMENTATION OF A DEVICE COMPATIBLE WITH DIFFERENT FIELDBUSES USING RECONFIGURABLE

CIRCUITS

53