AN HORIZONTAL APPROACH TO BATCH SCHEDULING

Using the Simultaneous Manufacturing philosophy

Ana Almeida, Carlos Ramos

Knowledge Engineering and Decision Support Group, Institute of Engineering – Polytechnic of Porto, Porto, Portugal

Sílvio do Carmo Silva

Universidade do Minho, Dept. de Produção e Sistema, sGualtar, Braga – Portugal

Keywords: Batch Scheduling, Horizontal Scheduling

and Simultaneous Manufacturing

Abstract: This paper is concerned with Batch Scheduling in job-shop like manufacturing systems. The Horizontal

Scheduling approach is used, assuming that full scheduling of a simple or complex job, based on the job

routing network of operations, from the first operation to the last, is performed before another job is

considered for scheduling, having in consideration existing manufacturing processors and their availability.

We follow this approach because we aim at compressing job flow time to a minimum as a strategy to

meeting job due dates. To further enhance this objective the idea behind Simultaneous Manufacturing

through, the widespread use of batch overlapping with Job Scheduling Patterns, which proved particularly

effective in reducing job throughput time, maintaining operating simplicity and requiring reduced

coordination

1 INTRODUCTION

A job as defined in this work, is typical of reality but

untypical in theoretical scheduling problems

addressed in the literature. Our approach considers a

job to be a manufacturing order for a number of

identical products. These may be simple, i.e. having

a set of operations to be carried out in a given

sequence in a batch of identical parts, called simple

products. The products may also be complex

products, having a set of operations carried out in a

given sequence in a batch of products, each one

made of several different parts. The manufacture of

these complex products is typical of industries of

type A and T as defined in (Chase and Aquilano,

1998). It is mainly, but not only, for these types of

industries that the scheduling approach and methods

presented in this paper are most appropriate. A job is

specified by the quantity of products necessary, i.e.

it’s batch size, the manufacturing operations and

their precedence relationship, processing times of

operations and the manufacturing processors to be

used. Processing times include auxiliary time

elements such as set up time and time for parts

handling at a machine.

We strongly explore the possibility of different

b

atch overlapping and batch splitting schemes for

finding good schedules. Actually, we focus the

quality of scheduling in shortening job throughput

times and meeting job due dates. The reason is that

this has a positive contribution to both profits and

customer service. To further enhance this multi-

objective we adopt a strategy to scheduling known

as horizontal scheduling (Vollman et al., 1996).

Under Horizontal Scheduling, a job is scheduled

first in all the required processors before another job

is considered for scheduling. Therefore, again,

priority to execute a job already started is given and

consequently flow time further reduced. The

scheduling approach combining all or some of these

factors for reducing job throughput time has been

named as Simultaneous Manufacturing (Almeida

et.al., 2003).

2 PROBLEM DEFINITION

The problem under consideration can be included in

the job-shop class with renewable resources.

Because it assumes the existence of alternative

283

Almeida A., Ramos C. and do Carmo Silva S. (2004).

AN HORIZONTAL APPROACH TO BATCH SCHEDULING - Using the Simultaneous Manufacturing philosophy.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 283-287

DOI: 10.5220/0001138302830287

Copyright

c

SciTePress

resources to process the task we can say that is a

flexible job-shop problem (Brucker and

Schlie,1990). Besides that, it is considered a variable

number of operations per task, so it is not restricted

to the pure job-shop problem but it refers to the

general job-shop problem (Conway et al., 1967).

Additionally, it is more general than this because

any task may be processed on more than one

machine at the same time. This happens not only

because several parts, to be fabricated and

assembled, belong to the same task, but also because

batch overlapping strategies may be adopted. This

scheduling problem scenario includes a much

general case than the basic JSSP, typically addresses

in JSSP literature, and is more realistic and in line

with what happens in practice We call the

scheduling problems of the type defined as Extended

Job-Shop Scheduling Problems (EJSSP).

3 BATCH SCHEDULING

In traditional batch production, a job is considered as

a set of identical parts that are always processed as a

whole, i.e. the full batch must be processed in a

processing stage before it can be transferred to

another to carry out further processing. In cases

where the batch size is large, this can become a too

great penalty to the full duration of the job

processing. So the performance of the manufacturing

system, mainly regarding job throughput time and

accomplishment of job due dates can become highly

poor. This operating weakness can be highly

reduced through Horizontal Scheduling, batch

overlapping and batch splitting. We explore these

strategies in our approach to solve the EJSSP.

3.1 Batch Overlapping

Batch overlapping means transferring work from a

machine, which is processing an operation of the

job, to another machine, for processing the next

operation, before the entire batch has been finished

on the previous machine. This is very common, in

practice, sometimes done randomly, with different

amounts of overlapping, and other times under a

well defined overlapping procedure. In this case,

transfer batches are clearly defined. These are

batches, normally smaller than the total job batch

size, transferred between two successively required

machines. When a transfer batch is equal to the total

job batch size batch overlapping does not take place.

In the extreme, when trying to fully implement

Simultaneous Manufacturing we should seek

maximum overlapping, i.e. the transfer of work

between processors should be continuous, which

means transfer batches of size one.

Batch overlapping does not necessarily changes

the processing batch size at a processing stage. A

processing batch size is the amount of units of a job

processed in a machine continuously before it takes

another job.

3.2 Horizontal Approach

Horizontal Scheduling (Vollman et al., 1996), have

in consideration that jobs are manufacturing orders

of products, resulting from fabrication of parts and

their assembly. The scheduling process is focused on

the job, in such a way that all the operations are

scheduled in all the required re-sources or processors

before the next job is considered for scheduling.

Using this approach it is possible to have a good

perception of the state of each job during the

scheduling time horizon and easily establish the

scheduled job completion date, which permits

verifying if job due date is likely to be

accomplished.

Horizontal Scheduling implements the concept

of Simultaneous Manufacturing in batch production

of complex product manufacturing orders. In this

work this is achieved, through the widespread use of

batch overlapping. The main purpose is to reduce

job throughput time as a strategy to meet due dates.

3.3 Simultaneous Manufacturing

The Simultaneous Manufacturing (SM) philosophy

aims at the complete manufacturing of each single

product of a product order in the minimum possible

time. The intention is to take the minimum time to

manufacture the whole job, i.e. the product order. To

achieve this, each set of parts belonging to each

product of the order must flow in a coordinated way

through the sys-tem, i.e. in a way such that they are

processed before any other parts, and arrive

simultaneously to where they are needed for

assembly. This assembly must be performed

immediately, according to available processors. In

this way, the throughput time for the complete

manufactured and assembly of each product of the

product order is minimum, and therefore the full job

throughput time is minimum too. Additionally, the

work-in-process is likely to be low (Almeida et al.,

2003). In our scheduling approach, mechanisms

were developed for implementing SM in a user-

controlled manner.

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

284

4 JOB SCHEDULING PATTERNS

One of the main mechanisms, which allow

implementing Horizontal Scheduling and SM in our

work, is what we call Job Scheduling Patterns (JSP).

A JSP is a virtual schedule of a given job, based

flexible batch transfer sizing, batch overlapping

and/or batch splitting (Almeida, 2002). A JSP is one

of several possible alternative schedules, for a given

job, under an empty manufacturing system, i.e. with

all processors considered available, in an unspecified

time horizon. A job can have several JSP, which can

be generated for better exploring the utilization of

manufacturing processors or machines.

A requirement for establishing a JSP is the job

operation plan. This specifies all operations and their

precedence interrelationships of each single product,

simple or complex, of a job order. It may be

expressed as graph as the one shown in figure 1.

Figure 1: Precedence graph representation of a Job

operation plan.

The computation procedure determines the starting

and finishing time instants for all the operations of a

job on each processor or machine depending on

transfer batch size, on the job operation plan adopted

and on machines to be used. This establishes a JSP.

Overall computing procedure

Compute the duration of each graph path and store the

sequence of operations for each one

For the critical paths

From the operation of level one until the last level operation

If prec(op

i

) = {} and op

i

is the first operation (level one)

Then

compute t

start(opi)

and t

fin(opi)

store the obtained values at the list of processed operations

Else

make a = op

i

and b = succ(op

i

)

compute the displacement

∆

ts

(a

b)

;;

compute t

start(b) e

t

fin(b)

store the obtained values at the list of processed

operations

For the non-critical paths

From the last level operation until the operation of level one

If op

i

∉to the highest duration graph path

make a = op

i

and b = succ(op

i

)

compute t

fin(a) e

t

start(a)

compute the displacement

∆

ts

(a

b)

;;

store the obtained values at the list of processed operations

Where:

prec( ) precedence operator

succ( ) succession operator

a

b represents a precedence relationship,

meaning that a directly precedes b

;;

lt

(a

b)

transfer batch between a and b

;;

∆

ts

(a

b)

displacement or overlapping time between

the starting time instants of two operations

a and b

;;

t

start(op

i

)

instant of processing start for operation a

t

fin(op

i

)

instant of processing end for operation a

4.1 Illustrative Example

op

1

Op

2

Op

4

op

3

Supposing that we intend to manufacture a batch

with 8 product units within a deadline, td, of 70 tu,

being the release date, rk, the instant 0, we have: n =

8, td = 70 and rk = 0. The precedence graph is

represented in figure 1.

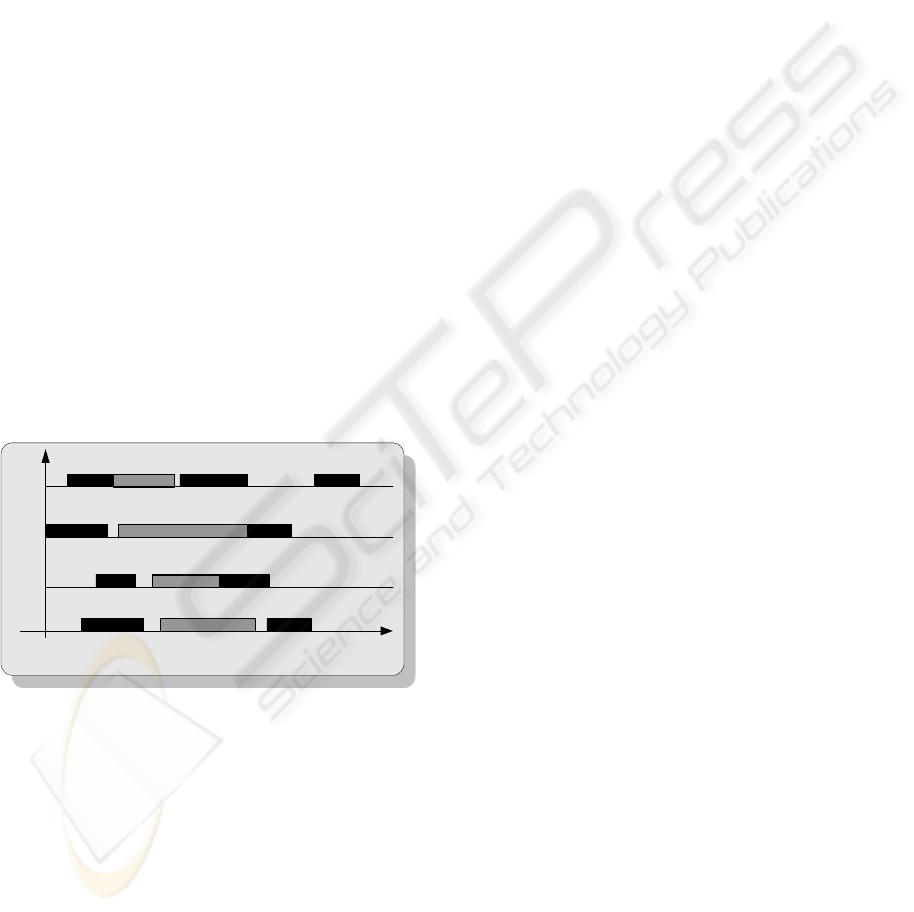

Considering the data of the example and a

unitary transfer batch, the result obtained by the job

scheduling pattern generator mechanism, is

illustrated in figure 2 where the batch displacement

between op1 and op2, and between op2 and op4 is

shown.

We point out that operation op3 could start

anytime between instants 0 and 10. By starting at

instant 10 a late start JSP is used. If had started at

instant 0 we were adopting the earliest start JSP.

121 *)( opopop tplt ;;

8

11 25 27

1

10

18

op

1

; mp

1

221

*

)( opopop

tplt

;;

≥

121

*

)( opopop

tpltn

;;

−

442

*

)( opopop

tplt

;;

242 *)( opopop tplt ;;>

op

2

; mp

2

op

3

; mp

3

op

4

; mp

4

Figure 2: Job Scheduling Pattern with batch

displacement representation.

JPk ={(mp1,(op1, 0, 8)), (mp2,(op2, 1, 25)), (mp3,(op3,

10, 18)), (mp4,(op4, 11, 27))}

AN HORIZONTAL APPROACH TO BATCH SCHEDULING - Using the Simultaneous Manufacturing philosophy

285

5 BATCH SCHEDULING

THROUGH JSP

With basis on the JSP and processor agendas the

Scheduling Plan Generator (SPG), which

implements the horizontal approach generates a

scheduling solution. The SGP draws upon a

scheduling algorithm developed in previous work by

the authors (Almeida et al., 2002). Such algorithm

involves two scheduling phases: the forward

influence phase and the backward influence phase.

Mechanisms for implementing these phases were re-

ported and explained in (Almeida, 2002).

The SPG picks up information about the work

and processors, related with the scheduling problem

and suggests possible solutions if they exist. It

verifies the time horizon of the processors associated

to each operation and looks for their availability in a

relevant time interval.

An important feature the SPG, when it is not

possible to schedule the whole job batch to meet its

due date, is its ability to suggest a split batch size

that can be manufactured within the due date. This

may be important for time phasing delivery and

negotiation with customers.

Going back to the example, the obtained results

for the scheduling of the referred job using the

algorithm implemented by the SPG, are represented

in figure 3.

Figure 3: Results of application of the Scheduling Plans

Generator.

The only solution obtained stems from some

imposed restrictions on batching. By relaxing batch

size, trough batch splitting, for example, it might be

possible to take advantage of other available time

intervals of manufacturing resources. In this case the

split batches of the order could be taken separately

for scheduling by the same method and, possibly

provide further alternatives to scheduling.

When it is not possible to schedule a job within

the MP agendas, based on a given JSP, then some

strategies can be applied to obtain a solution, within

the available time intervals in the MP agendas.

These strategies can include trying a new JSP,

considering different transfer batches sizes, and

applying a batch splitting process followed by JSP

generation for the split batches. The scheduling

mechanisms in the SPG give suggestions about

where to split a job batch. Thus, we can break one

job batch in two or more smaller job batches whose

sizes can fit within the available time intervals of the

manufacturing processors.

6 CONCLUSIONS

Under today’s highly competitive markets it is

important to provide good service to customers and,

at the same time, reduce costs in manufacturing. One

clear contribution on these lines is to manufacture

job orders within the shortest time that is reasonably

possible, keeping work in process low. This has a

direct effect on profitability, since fast turnover of

short-term investment is achieved, and, of course, on

fast deliveries, which is an important requisite for

customer satisfaction.

We presented in this paper an approach oriented

towards achieving very short manufacturing

throughput times of customer orders. The approach

uses the Job Scheduling Pattern concept, and

implements a Horizontal Scheduling approach in

order to achieve the Simultaneous Manufacturing

philosophy. The main imbedded strategy used is

what we described as Scheduling through JSP.

Based on the described scheduling approach a

Scheduling Plan Generator was developed, which

can be seen as a powerful tool to aid users to

improve detailed shop floor scheduling in complex

manufacturing environments, integrating both

fabrication of parts and their assembly into customer

ordered products.

14 16

11

55

60

70

5

50

45

47 50

30

2623

15

20 38

45 60

8

28

25

mp

1

; op

1

mp

2

; op

2

mp

3

; op

3

mp

4

; op

4

REFERENCES

Chase, R. B., Aquilano, N.J., Jacobs, F.R., 1998.

Production and Operations Management: A Life Cycle

Approach. 8th ed., Irwin, Homewood, Boston.

Vollmann, T. E., William, L. B., Whybpark, D. C., 1996.

Manufacturing planning and control systems. Richard

D. Irwin, Inc..

Almeida, A. Ramos, C. , & Silva, S. C. Silva, 2003.

Simultaneous Manufacturing in Batch Production,

ISATP2003, Proceedings of the IEEE International

Symposium on Assembly and Task Planning,

Besançon, France, 2003.

Brucker, P., Schlie R., 1990. Job-shop scheduling with

multi-purpose machines, Computing 45, 369-375.

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

286

Conway, R. W., Maxwell, W. L., and Miller, L. W., 1967.

Theory of Scheduling, Addison-Wesley Publishing

Company.

Almeida, Ana, Ramos, Carlos, Silva, Sílvio Carmo, 2002.

Toward Dynamic Scheduling of Manufacturing. The

International Journal for Manufacturing Science &

Production, Freund Publishing House, Ltd..

Almeida, Ana, 2002. Analysis and Development of

Mechanisms and Algorithms to Support Product

Oriented Scheduling, Doctoral Thesis on Production

Engeneering, University of Minho, Portugal.

AN HORIZONTAL APPROACH TO BATCH SCHEDULING - Using the Simultaneous Manufacturing philosophy

287