GENETIC ALGORITHMS APPLIED TO THE OPTIMIZATION

OF GASIFICATION FOR A GIVEN FUEL

Miguel Caldas

Mechanical Engineering Department, IST, Technical University of Lisbon, Portugal

Luisa G. Caldas

Civil Engineering and Architecture Department, IST, Technical University of Lisbon, Portugal

Viriato Semião

Mechanical Engineering Department, IST, Technical University of Lisbon, Portugal

Keywords: Gasification, Genetic Algorithms, Optimisation

Abstract: Gasification is a well-known technolog

y that allows for a combustible gas to be obtained from a

carbonaceous fuel by a partial oxidation process (POX). The resulting gas (synthesis gas or syngas) can be

used either as a fuel or as feedstock for chemical production. Recently, gasification has also received a great

deal of attention concerning power production possibilities through IGCC process (Integrated Gasification

Combined Cycle), which is currently the most environmentally friendly and efficient method for the

production of electricity. Gasification allows for low grade fuels, or dirty fuels, to be used in an

environmental acceptable way. Amongst these fuels are wastes from the petrochemical and other industries,

which may vary in composition from shipment to shipment, and from lot to lot. If operating conditions are

kept constant, this could result in lost of efficiency. This paper presents an application of Genetic

Algorithms to optimise the operating parameters of a gasifier processing a given fuel. Two different

objective functions are used: one to be used if hydrogen production is the main goal of gasification; other to

be used when power/heat production is the aim of the process. Results show that the optimisation method

developed is fast and simple enough to be used for on-line adjustment of the gasification operating

parameters, for each fuel composition and gasification aim, thus improving the overall performance of the

industrial process.

1 INTRODUCTION

This paper presents an application of Genetic

Algorithms to optimize the operating parameters of a

gasifier processing a given fuel.

Gasification is a well-known technology that

al

lows for a combustible gas to be obtained from a

carbonaceous fuel by a partial oxidation process

(POX). The resulting gas (synthesis gas or syngas)

can be used either as a fuel or as feedstock for

chemical production. The major constituents of

syngas are CO, H

2

, CO

2

and H

2

O. From these, only

H

2

and CO are combustible and only H

2

is

interesting as chemical feedstock.

Formally defined, gasification is the conversion

o

f solid and liquid materials into a gas through

reaction with oxygen, steam and carbon dioxide, or a

mixture of these gases, at a temperature exceeding

700 ºC. In industrial applications, a solid or liquid

fuel is conveyed to a vessel (the gasifier) and mixed

with oxygen and steam. The CO

2

and H

2

O resulting

from the combustion of a fraction of the fuel will

also become an agent of gasification for the

remaining fuel. There will exist some N

2

present in

the gasifier, because the oxygen stream is not 100%

pure and also, possibly, because N

2

can be used as a

conveying gas for the pneumatic transportation of

the fuel. Some heat can be recovered from the

gasification chamber (gasification is an overall

58

Caldas M., Caldas L. and Semião V. (2004).

GENETIC ALGORITHMS APPLIED TO THE OPTIMIZATION OF GASIFICATION FOR A GIVEN FUEL.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 58-63

DOI: 10.5220/0001140400580063

Copyright

c

SciTePress

exothermic reaction, which will generate heat) to

produce steam.

Traditionally, gasification has been used as a

means of producing heating gas for domestic and

industrial needs (town gas) and as a source of

hydrogen for the heavy chemical industry. Recently,

gasification has received a great deal of attention

concerning power production possibilities, since it is

the core of the IGCC process (Integrated

Gasification Combined Cycle). IGCC is the most

environmentally friendly method for the production

of electricity since it allows for all the pollutants to

be removed in a pre-combustion stage, at the gas

cleanup (Haupt et al., 2000). It also permits any fuel

to be used in a combined cycle, thus greatly

increasing electricity production efficiency.

One of the major advantages of gasification is

that it allows for less noble fuels, or dirty fuels, to be

used for the above-mentioned purposes. Amongst

these are wastes from the petrochemical and other

industries. In the latter case, each shipment of wastes

supplied to be gasified usually presents a different

composition. This is quite understandable since the

waste supplier industry will deal with different

feedstocks of prime matter, or will produce different

products in a given time span. So, naturally, the

waste produced will present a different composition

from case to case.

In the present work we determine the optimum

operational parameters for the gasification of a given

fuel, as characterized by its elementary composition

and Lower Heating Value (LHV). The parameters to

be optimized are the Operating Pressure, Oxygen to

Fuel ratio, Steam to Fuel ratio, and Heat Recovered.

Two different objective functions are used, since

the goals to be reached are different if the

gasification process is intended to produce an

hydrogen rich gas for chemical feedstock, or a

combustible gas for power/heat production. In the

former case, the syngas’ hydrogen percentage will

be maximized, while in the latter the gasification

Cold Gas Efficiency is the parameter to be

maximized (Cold Gas Efficiency is the quotient

between the heating capacity of the syngas and the

original fuel heating capacity. The heating capacity

is the product of the lower heating value and the

mass flow). Thermal efficiency (defined as the

quotient between: 1) the sum of the heat recovered

in the process and the heating capacity of the syngas;

and 2) the fuel heating capacity), which is a

parameter closely related to Cold Gas Efficiency, is

also analyzed.

The optimization method developed could be

used for on-line adjustment of the gasification

operating parameters for different fuel compositions

and gas’ final purpose, thus improving overall

performance of the industrial process.

Genetic Algorithms (GAs) have been used to

determine optimal operational parameters for several

industrial processes and other practical applications

(for example, Dickinson and Bradshaw, 1995;

Wright, 1996; Huang and Lam, 1997). They are

particularly suitable for problems that are either

multimodal (i.e., present several local extremes), or

discontinuous, since in these cases conventional

optimization methods based on calculus, like

gradient methods, tend to fail. GAs are also effective

in smother problems that could be solved using more

traditional methods, what makes them very flexible

and adaptable to a variety of solution spaces. In the

present work, it is suspected that the objective

functions are in fact multimodal, what lead to the

choice of GAs as the search procedure.

The structure of the paper is the following: in

section 2 the gasification modeling is briefly

described, section 3 verses on the search and

optimization process using GAs, section 4 presents

the main results of this work, and section 5 draws

conclusions.

2 GASIFICATION MODELLING

Gasification is a complex chemical process that

involves a multitude of phenomena, like

devolatization, pyrolysis, heterogeneous gas-solid

reactions and homogeneous gas-gas reactions

(Govind and Shah, 1984; Liu et al., 2000; Benyon,

2002). Each phenomenon has its one rate of reaction

and a full CFD, heat transfer and chemical kinetic

simulation is required to perform a detailed

simulation of the process. See Benyon (2002) for an

excellent dissertation on the subject. A brief

description of the process follows.

The first part of the gasification process is the

pyrolysis of the fuel. When solid fuels are concerned

the term devolatilization is usually utilized. During

pyrolysis some gaseous constituents are released

from the fuel. These include CO, CO

2

, H

2

, H

2

O,

H

2

S, COS, HCN, NH

3

, CH

4

, C

2

H

2

and some other

heavier hydrocarbons in lesser quantities.

After pyrolysis a char residue containing fixed

carbon and ash will remain and will undergo further

oxidation. The volatiles released will react in the

gaseous phase.

The main char heterogeneous reactions are

reactions between the char’s fixed carbon and O

2

,

H

2

, H

2

O and CO

2

producing CO, H

2

, CO

2

and CH

4

.

Reactions with O

2

and H

2

are exothermic and those

with H

2

O and CO

2

are endothermic. See Benyon

(2002) for details.

In the gaseous phase there will be combustion

reactions that will tend to convert all of the

GENETIC ALGORITHMS APPLIED TO THE OPTIMIZATION OF GASIFICATION FOR A GIVEN FUEL

59

hydrocarbons into CO

2

and H

2

O and some

equilibrium reactions, noticeably the water-gas shift

and the methanation reactions, to be described below

– Eqs. (1) and (3).

In the present paper a simplified gasification

model was used. It is an equilibrium model that

assumes a homogenous temperature throughout the

reaction zone and neglects chemical kinetics effects

and detailed heat transfer modeling. Therefore, all

the reactions are assumed to attain their equilibrium

concentrations at the reaction temperature. This

assumption is very justifiable, since industrial

gasifiers are designed in such a way that irreversible

gasification reactions proceed to their completion

and reversible ones attain equilibrium within the

reaction chamber and within the reactants residence

time. Therefore, in industrial gasifiers that are

commercially available, we can expect to have a

homogeneous temperature and equilibrium

conditions at the gasifier’s exit. Of course, this

model will not allow for an in depth analysis of the

intermediate stages of the gasification complex

phenomena, but that is not the purpose of the present

research, which focus on the overall exit conditions

only.

This model is based on mass balances for each

atomic species (C, H, O, N and S), an energy

balance in order to compute the gasification’s final

temperature and on the equilibrium between the

species using reactions (1) to (5).

222

HCOOHCO +⎯→⎯+ (1)

OHCOSCOSH +⎯→⎯+

OHCHHCO 3 +⎯→⎯+

23 NHNH ⎯→⎯+

222

(2)

242

(3)

322

(4)

(5)

432

3 CHNHHHCN +⎯→⎯+

Each element mass balance provides one

equation. The enthalpy equation offers another one.

Each of the equilibrium reactions (1) to (5) provides

an equation for the species concentration. See any

standard text book, e.g., Levine (1988), for details

on chemical equilibrium.

Therefore, we have eleven equations (five for

elements mass balance, one for enthalpy and five for

equilibrium reactions) and eleven unknowns: the

temperature, T, and the mass flow of the syngas

constituents (H

2

, CO, H

2

O, CO

2

, N

2

, H

2

S, COS,

CH

4

, HCN and NH

3

). The result is a determined

system of non-linear equations that can be solved

through any of the standard numerical techniques

available in the literature.

Having the mass flow of all the elements in the

resulting syngas, it is straight forward to compute

their respective percentage in the syngas

composition, both in terms of mass and in terms of

volume.

The Cold Gas Efficiency is defined, as said

before, as the quotient between the heating capacity

of the syngas and the original fuel heating capacity.

This quotient is expressed in Eq.(6) where the index

i ranges over all syngas constituents, LHV means

Lower Heating Value, and m with an over dot means

mass flow.

FuelFuel

i

ii

LHVm

LHVm

CGE

&

&

∑

=

(6)

Of course that, besides the parameters that will

be manipulated (oxygen to fuel ratio, steam to fuel

ratio, etc…), the fuel elementary composition, fuel

mass flow and fuel LHV must be supplied as inputs

to the model.

Again, notice that, although this model is much

simpler than the full numerical approach presented

in, e.g., Govind and Shah (1984), Liu et al. (2000) or

Benyon (2002), it retains the major effects of the

influence of the parameters that are being

manipulated in the objective functions under

analysis, being therefore well suited for the purpose

at hand. Also, being much simpler, this model is

more manageable, has reduced computational times,

and is thus better suited for linking with Genetic

Algorithms.

3 SEARCH AND OPTIMISATION

PROCESS

The search and optimization method used is a

Genetic Algorithm. The use of a GA was suitable for

the problem under study due to its non-linearity, and

to the possible existence of local minima, where a

conventional optimization procedure might become

trapped. Since a GA searches from a population of

points, not a single point, the probability of the

search getting trapped in a local extreme is limited.

GAs start searching by randomly sampling within

the solution space, and then use stochastic operators

to direct a hill-climbing process based on objective

function values. Genetic Algorithms were first

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

60

presented by Holland (1975), and made familiar to a

broader audience by Goldberg (1989).

A standard Genetic Algorithm was used, with a

total population of 30 individuals per generation,

evolution being carried out through 100 generations.

This means that for each run, 3000 possible

solutions are evaluated, even though there will be

some degree of repetition among them. One of the

sources of solution overlapping among generations

is elitism, a strategy used in this study, in which the

best individual of a generation is always copied to

the following population. A simple kind of memory

can thus be implemented to reduce computational

time, so that when the GA is confronted with a

previously evaluated solution, it automatically

retrieves its objective function values. Uniform

crossover, which works allele by allele, was used

throughout the experiments. The probability of

crossover was 0.5, and the probability of mutation

was kept as 0.04.

The study also compares results using a micro-

GA and the conventional GA. The main difference

between the two methods relies on the population

size used. Typical population sizes for GAs range

from 30 to 200, based on earlier studies such as

those of Grefenstette (1986), where suggestions for

optimal population choices based on parametric

studies are presented. In this study we use a strategy

named micro-GA (Krishnakumar 1989), which starts

with a small population (in this case, of only 5

individuals) and quickly makes it converge to a

solution. Convergence is measured by comparing the

chromosomes of the individual solutions. If they

differ by less that 5%, it is considered the population

has converged. When that happens, the micro-GA

restarts a new random population while carrying

over the individual with the best fitness in the

previous generation (elitism). This way, new

individuals are often brought into the search, without

loosing track of the ones that did better until that

point. An advantage of using the micro-GA

procedure is that the algorithm tends to perform a

local search around the best solutions during the

generations prior to convergence, since at that stage

solutions only differ by a few alleles. This local

search is important in finding local minima around

good solutions, and is usually hard to implement in

conventional GAs. Another advantage is that the

search procedure is faster, since the micro-GA does

not have the inertia of the large populations

associated with conventional GAs.

4 RESULTS AND DISCUSSION

Two different fuels for gasification were studied:

Visbreaker Tar and Petcoke. These are refinery

residues and a common fuel for gasification. Their

elementary analysis and Lower Heating Value can

be seen in Table 1.

Table 1: Properties of the fuels under study.

Visbreaker Tar Petcoke

C (% wt) 86.1 88.6

H (% wt) 10.4 2.8

O (% wt) 0.5 0

N (% wt) 0.6 1.3

S (% wt) 2.4 7.3

LHV (kJ/kg) 40,938 33,680

Lower and upper bounds for each variable used in

this study are shown in table 2. Please note that the

fuel load considered was 3.6 ton/h, or 1 kg/s, which

mean that the total fuel heat capacity is about 40,000

kW for Visbreaker Tar and around 33,500 kW for

Petcoke. Therefore, the upper bound of the heat

recovered is around 25% of the total fuel heat

capacity.

Table 2: Lower and upper bounds for each variable.

Press.

(bar)

Oxigen/

Fuel

Steam

/ Fuel

Heat Recov.

(kW)

Lower bound 20 0 0 0

Upper bound 57.5 2 2 9000

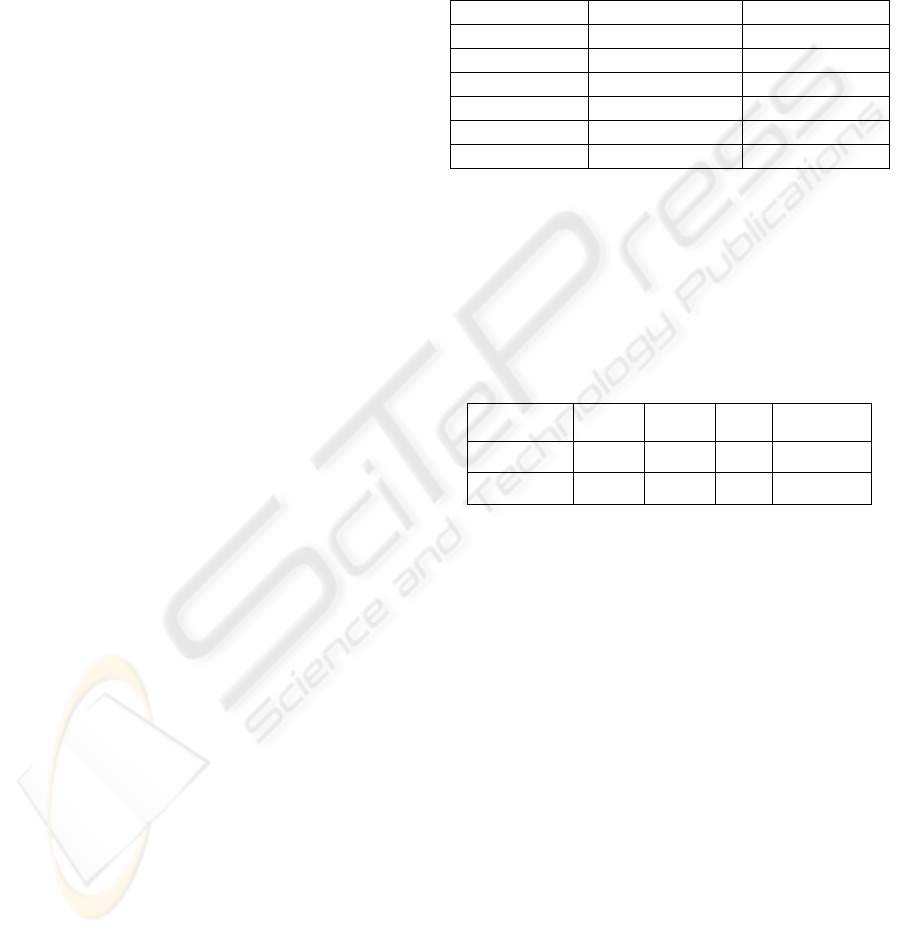

Results converge independently of the starting

population, which is random. This can be seen in

Fig.1, which depicts the Cold Gas Efficiency (CGE)

of the population’s best individual solution plotted

against the number of elapsed generations for 3

different initial populations. Fig.2 shows the search

evolution for the best individual Cold Gas

Efficiency, for 500 generations. It can be seen that

the quality of the solutions improved sharply during

the first generations, a tendency which continued

steadily, though in a less prominent fashion, until

approximately generation 100, after which

improvements were only marginal.

As can be seen from Table 1, the best Cold Gas

Efficiency the GA was able to attain when gasifying

Visbraker Tar was 89%. This value of CGE is

reached when the Pressure, Oxygen/Fuel ratio,

Steam/Fuel ratio and Heat Recovered have the

following values (22.5 bar, 0.89, 0.41, 0 kW). For

this solution the Dry Hydrogen Percentage (DHP) in

the gas is 44%.

If, conversely, we maximize the DHP, a value of

52% is reached for this parameter. The operating

conditions are (20 bar, 1.02, 1.94, 0 kW) and the

GENETIC ALGORITHMS APPLIED TO THE OPTIMIZATION OF GASIFICATION FOR A GIVEN FUEL

61

CGE is 83%. As can be seen, the largest change in

the operating parameters between these two cases

occurs in the Steam/Fuel ratio.

It was interesting to find out that thermal

efficiency, although being a relevant parameter to

measure the overall efficiency of the process, should

not be used as an objective function. The reason for

this is that an excessive weight will be placed in the

heat recovered, hurting both the CGE and the DHP

in the syngas. The gasification process would then

be shaped almost as a heat generating process, and

this is not the intention. As an example, if thermal

efficiency was to be maximized in the above case,

the operating parameters would be (20 bar, 1.43, 0,

9575 kW), resulting in a thermal efficiency of 92%.

However, the CGE would only be 68% and the DHP

would equal 29%. As it can be seen, these

parameters are worse than either of the previous

cases, thus confirming that this solution should be

avoided.

0.6

0.65

0.7

0.75

0.8

0.85

0.9

0 20406080100

Generation

CGE

Run 1

Run 2

Run 3

Figure 1: Evolution of the best individual Cold Gas

Efficiency for three random initial populations.

Figure 2: Evolution of the best individual Cold Gas

Efficiency (CGE) throughout 500 generations.

If the two previous operating conditions - (22.5 bar, 0.89,

0.41, 0 kW) and (20 bar, 1.02, 1.94, 0 kW) - were to be

used for a different fuel (in the present case Petcoke), the

resulting CGE and DHP would be 88%, 29% for the first

case and 79%, 41% for the second. In case the operating

conditions were maximized for Petcoke, the solutions

obtained would be (20 bar, 0.83, 0.51, 0 kW), CGE=89%,

DHP=30% if CGE is maximized and (20 bar, 1.02, 2.0,

540 kW), CGE=79%, DHP=42% if DHP is maximized.

These operating condition do not differ significantly from

those obtained when Visbreaker Tar was being considered,

so, at least for these two petrochemical products, optimum

operating conditions are rather independent of fuel

composition. Table 3 summarizes the results obtained

using a standard GA. Note that the 540 kW present in the

last line of Table 3 are under 1.5% of the total fuel heat

capacity of this case, being therefore almost negligible.

Table 3: Results obtained using a standard GA. Values in

bold indicate the objective function being maximized.

Variables Objective

Functions

Fuel Press.

(bar)

Oxigen

/ Fuel

Steam

/ Fuel

Heat

Recov.

(kW)

CGE

DHP

Visbreaker

Tar

22.5 0.89 0.41 0

89%

44%

Visbreaker

Tar

20

1.02 1.94 0 83%

52%

Petcoke

20 0.83 0.51 0

89%

30%

Petcoke

20 1.02 2 540 79%

42%

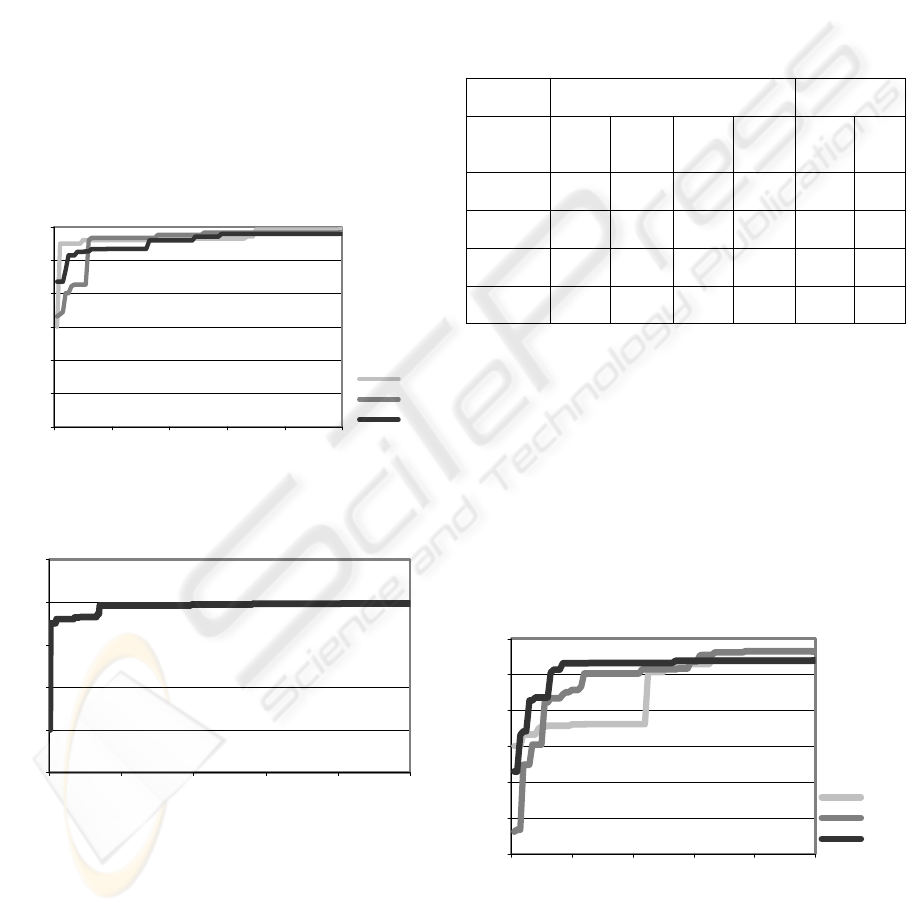

Finally, the Micro-GA technique was tested in the

same cases. Results were equivalent to those

obtained using a conventional GA. Therefore, no

apparent advantage resulted from the local search

features introduced by the Micro GA. In fact,

slightly inferior results were observed when using

the Micro GA. The evolution of the cold gas

efficiency of the population’s best individual

solution for Visbreaker Tar is presented in Fig.3 as

an example, which compares almost exactly with

Fig.1. Again, three random and independent initial

population solutions are presented.

0.7

0.75

0.8

0.85

0.9

0.95

0 100 200 300 400 50

0

Generation

CGE

Figure 3: Evolution of the best individual Cold Gas

Efficiency (CGE) for three random initial populations,

using a Micro GA.

0.6

0.65

0.7

0.75

0.8

0.85

0.9

0 20 40 60 80 100

Generation

CGE

Run 1

Run 2

Run 3

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

62

5 CONCLUSIONS

The optimisation method developed is fast, simple

and robust enough to be used for on-line adjustment

of the gasification operating parameters for each fuel

composition and aim of gasification, thus improving

overall performance of the industrial process.

Thermal efficiency should not be chosen as an

objective function to be maximized under the

penalty of placing too much emphasis on the heat

recovered, thus compromising both the CGE and

DHP of the syngas.

The fundamental parameter that will influence

the best operating conditions for heat/power

production or hydrogen production is the Steam/Fuel

ratio, the Oxygen/Fuel ration being correspondently

adjusted.

Heat recovered should be marginal in order to

attain optimal conditions.

Results seem to be rather insensitive of pressure.

However, even if pressure is a less important

parameter for CGE and DHP, it is fundamental in

the operational aspects of the gasification.

Furthermore, and most importantly for industrial

applications, pressure is determinant for determining

the gas production capacity of the gasifier.

Therefore, operating pressure is a parameter that

should not be overlooked.

For the two studied fuels, the best operating

conditions to maximize CGE or DHP seem to be

independent of the fuel. Further work is required to

evaluate if this feature remains in a broader range of

fuels, including biomass and other non-

petrochemical fuels.

The Micro-GA technique was also used with

identical results than those obtained through regular

GA, no benefits resulting from the local search

features of the Micro-GA.

Future work will include the expansion of these

methods to multicriteria optimization, using Pareto-

based techniques.

ACKNOWLEDGEMENTS

This work has been partially performed with the

financial support of: 1) Fundação para a Ciência e a

Tecnologia, Programa PRAXIS XXI, under the PhD

scholarship SFRH/BD/4833/2001; 2) the European

Commission’s 5

th

Framework Programme for RTD,

under the contract NNE5-2001-00670 (Migreyd

project). 3) Fundação para a Ciência e a Tecnologia,

project POCTI/AUR/42147/2001, and the European

Union, FSE/ FEDER.

REFERENCES

Benyon, P.J., 2002, Computational modelling of entrained

flow slagging gasifiers, PhD thesis, University of

Sydney, Australia.

Dickinson, S. and Bradshaw, A., 1995, Genetic Algorithm

Optimization and Scheduling for Building Heating

Systems, Genetic Algorithms in Engineering Systems:

Innovations and Applications, 12-14 September 1995,

(pp. 106-111), University of Sheffield: Conference

Publication No. 414, Institution of Electrical

Engineers.

Goldberg, D., 1989, Genetic Algorithms in Search,

Optimization and Machine Learning, Addison-Wesley

Publishing Company.

Govind, R. and Shah, J., 1984, Modeling and Simulation

of an Entrained Flow Coal Gasifier, AIChE Journal,

30 (1), pp. 79-92.

Grefenstette, J., 1986, Optimization of control parameters

for genetic algorithms, IEEE Transactions on Systems,

Man and Cybernetics, SMC-16 (1), pp. 122-128.

Haupt, G., Zimmermann, G., Hourfar, D., Hirschfelder,

A., Romey, I., Oeljeklaus, G., Folke C., and Semiao,

V., 2000, IGCC - The best choice for producing clean

power, Proceedings of POWER-GEN Europe 2000,

Helsinki, Finland.

Holland, J., 1975, Adaptation in Natural and Artificial

Systems, The University of Michigan.

Huang, W. and Lam, H., 1997, Using genetic algorithms

to optimize controller parameters for HVAC systems,

Energy and Buildings, 26, 277-282.

Levine, I.N., 1988, Physical Chemistry, Third

International Edition, McGraw-Hill, Singapore.

Liu, G., Rezaei, H., Lucas, J., Harris, D. and Wall, T.,

2000, Modelling of a Pressurised Entrained Flow

Gasifier: the Effect of Reaction Kinetics and Char

Structure, Fuel, 79, pp.1767-1779.

Krishnakumar, K., 1989, Micro-genetic algorithms for

stationary and non-stationary function optimization, in

Rodriguez, G. (ed.), Intelligent Control and Adaptive

Systems, 7-8 November (pp. 289-296), Philadelphia,

Pennsylvania: SPIE – The International Society for

Optical Engineering.

Wright, J., 1996, HVAC optimization studies: Sizing by

genetic algorithm, Building Services Engineering

Research and Technology, 17 (1), pp. 1-14.

GENETIC ALGORITHMS APPLIED TO THE OPTIMIZATION OF GASIFICATION FOR A GIVEN FUEL

63