LINEAR MODELLING AND IDENTIFICATION OF A MOBILE

ROBOT WITH DIFFERENTIAL DRIVE

Patr

´

ıcia N. Guerra

∗

Pablo J. Alsina

∗

Adelardo A. D. Medeiros

∗

Ant

ˆ

onio P. Ara

´

ujo

∗

Federal University of Rio Grande do Norte – Departament of Computer Engineering and Automation

UFRN-CT-DCA – Campus Universit

´

ario – 59072-970 Natal RN Brazil

Keywords:

Nonholonomic robots, robot control, stabilization control, linear modeling of robots.

Abstract:

This paper presents a modelling and identification method for a wheeled mobile robot, including the actuator

dynamics. Instead of the classic modelling approach, where the robot position coordinates (x, y) are utilized as

state variables (resulting in a non linear model), the proposed discrete model is based on the travelled distance

increment ∆l. Thus, the resulting model is linear and time invariant and it can be identified through classical

methods such as Recursive Least Mean Squares. This approach has a problem: ∆l can not directly measured.

In this paper, this problem is solved using an estimate

f

∆l based on a second order curve approximation.

Experimental data were colected and the proposed method was used to identify the model of a real robot.

1 INTRODUCTION

Usually, realistic mathematical models of mobile

robots are obtained through the physics laws that gov-

ern their behavior. Approaches applying artificial in-

telligence techniques to the input and output measure-

ments are also utilized. Several model types were de-

veloped for non holonomic mobile robots. LTI (linear

time invariant) models are usually obtained through

Taylor series linearization on only one point of opera-

tion of the system. A QLPV (quasi-linear parameter-

varying) model for a car-like robot is presented in the

literature (Economou et al., 2002).

The classic mathematical model of a mobile robot

has a structure similar to the mathematical model of

robot manipulators, so that techniques of parametric

identification developed for the latter can be adapted

for the former. However, most of these techniques as-

sume that robot speed and acceleration measurements

are available, which is not generally true.

Differently of the identification techniques for ma-

nipulators, enough discussed in the literature (Poignet

and Gautier, 2000; Efe et al., 1999), the mobile

robot identification techniques have been less stud-

ied. An identification of the dynamic model of a

micro-robot using the recursive least mean square

1

The authors received partial financial support of the

Brazilian agencies CAPES and CNPq.

method (RLMS) is presented by Pereira (Pereira,

2000; Pereira et al., 2000). As the model to be iden-

tified through RLMS is non linear, a simplification is

used: the orientation θ(t), which is time-variant, is

considered constant during each sampling period.

In this work a linear (not a linearized one) dynamic

model for mobile robots is presented. The proposed

model is equivalent to the non linear dynamic model,

commonly adopted for non-holonomic mobile robots

(Yamamoto et al., 2003). The proposed model uses

the variable ∆l, distance traveled by the robot during

a sampling interval, instead of the traditional mod-

elling, where its absolute position is used (x, y). The

problem due to the impossibility of measuring the

traveled distance ∆l during a sampling period is over-

come through the use of an estimate,

f

∆l, of this value.

The identification of this discrete dynamic model is

attained using a classic method of identification of lin-

ear systems, the recursive least mean squares.

The rest of this paper is organized as follows. Sec-

tion 2 describes the robot and its modelling by the

equivalent linear and non-linear models. Section 3

presents the proposed calculation method for a nu-

meric value of the immeasurable variable ∆l. In sec-

tion 4, experimental results validating the proposed

approach are shown. Finally, in section 5, the ob-

tained results are discussed and the conclusions and

future perspectives are presented.

263

Guerra P., Alsina P., Medeiros A. and Araújo A. (2004).

LINEAR MODELLING AND IDENTIFICATION OF A MOBILE ROBOT WITH DIFFERENTIAL DRIVE.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 263-269

DOI: 10.5220/0001140602630269

Copyright

c

SciTePress

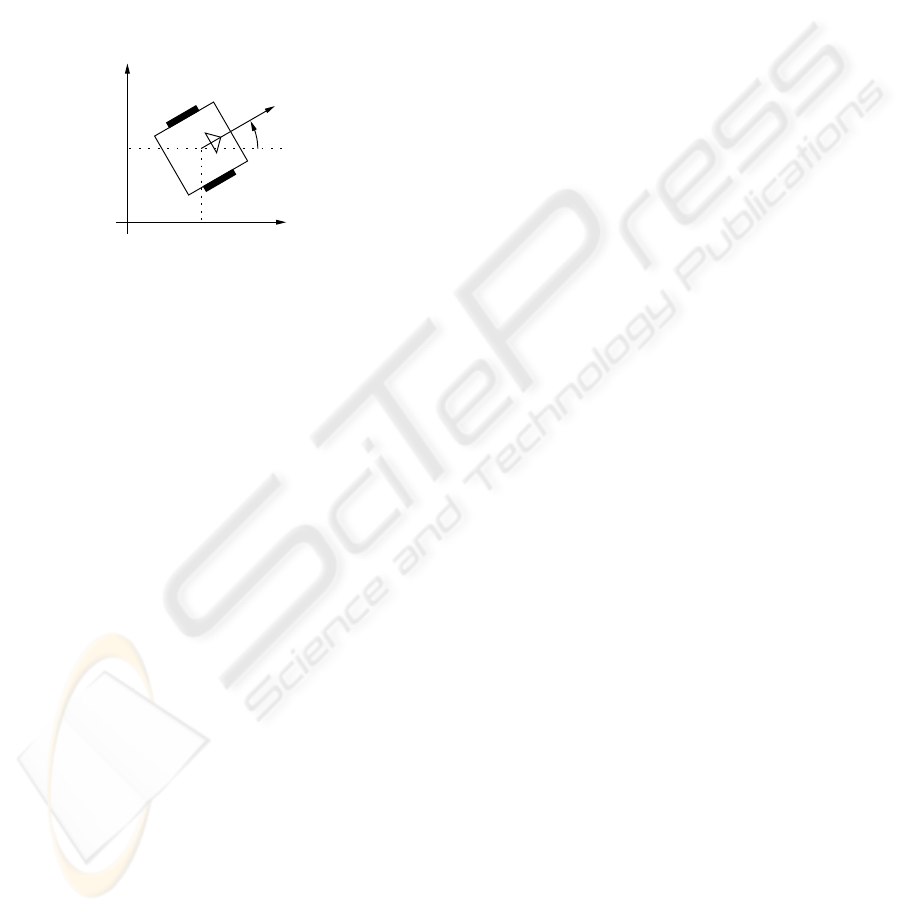

2 ROBOT MODELLING

Figure 1 presents a diagram of the kind of robot we

consider in this work. The robot has two wheels,

driven by two independent electric motors. The

wheels are placed at each side of the robot, in such

a position that their rotation axis are coincident. The

robot configuration is represented by the position of

the center of the axis between the two wheels in the

Cartesian space (x and y) and by its orientation θ (an-

gle between the vector of the robot orientation and the

abscissas axis).

v

x

y

θ,ω

Figure 1: Robot modelling

2.1 Cinematic Model

The cinematic model describes the relations between

the derivatives of robot position and orientation and

the robot linear and angular speeds, v and w, without

taking into account the causes of its movement:

˙x

˙y

˙

θ

=

"

cos θ 0

sin θ 0

0 1

#

·

·

v

w

¸

(1)

This equation models the non-holonomic restrictions

of the robot, due to the fact of its wheels not allowing

lateral movements.

2.2 Dynamic Model

The dynamic model is derived from the physics laws

that govern the several robot subsystems, including

the actuator dynamics (electric and mechanical char-

acteristics of the motors), friction and robot dynamics

(movement equations). The derivation of this model

for a small mobile robot (Vieira et al., 2001) was pre-

sented by Yamamoto (Yamamoto et al., 2003).

For most robots, the modelling process generates a

second-order model expressed by equation 2:

Ku = M

˙

v + Bv (2)

where v = [

v w

]

T

represents the robot linear and

angular speeds, u = [

e

r

e

l

]

T

contains the input

signals (usually armature tensions) applied to the right

and left motors, K is the matrix which transforms the

electrical signals u into forces to be generated by the

robot wheels, M is the generalized inertia matrix and

B is the generalized damping matrix, which includes

terms of viscous friction and electric resistance.

2.3 Equivalent Linear Model

The complete robot model, obtained from the union of

equations 1 and 2, can be represented by the following

state equation:

˙v

˙ω

˙x

˙y

˙

θ

=

−M

−1

B

.

.

. 0

. . . . . . . . . . . . . . .

cos(θ) 0

sin(θ) 0

0 1

.

.

. 0

v

ω

x

y

θ

+

M

−1

K

. . . . . . .

0

·

e

r

e

l

¸

y =

"

0 0 1 0 0

0 0 0 1 0

0 0 0 0 1

#

v

ω

x

y

θ

(3)

where the system output y = [

x y θ

]

T

corre-

sponds to the robot configuration.

To allow the application of linear discretization

techniques, we will rewrite the system equations into

a linear representation of the robot dynamic behav-

ior. To attain this objective, we need to change the set

of state variables: the robot’s configuration, given by

its position x and y and its orientation θ, will be de-

scribed in terms of the robot linear displacement l and

the robot orientation θ.

˙v

˙ω

˙

l

˙

θ

=

−M

−1

B

.

.

. 0

. . . . . . . . . . . . .

1 0

0 1

.

.

. 0

v

ω

l

θ

+

M

−1

K

. . . . . . .

0

·

e

r

e

l

¸

z =

·

0 0 1 0

0 0 0 1

¸

v

ω

l

θ

(4)

The new state equation 4 has the same dynamic

parameters than the original state equation 3 but a

new system output z = [

l θ

]

T

. We observe

that the linear equivalent model was obtained with-

out any simplification assumption. In this way, the

linear model is an exact equivalent representation of

the original non-linear representation in equation 3.

ICINCO 2004 - ROBOTICS AND AUTOMATION

264

2.4 Model Discretization

To allow the application of the classical estimation

techniques, it is necessary to derive a discrete transfer

function equivalent to the model in equation 4. The

first step is the transformation of the state space form

into a continuous transfer matrix:

·

L(s)

θ(s)

¸

=

·

G

11

(s) G

12

(s)

G

21

(s) G

22

(s)

¸

·

·

E

r

(s)

E

l

(s)

¸

(5)

where each term G

ij

(s) has the following structure:

G

ij

(s) =

N

ij

(s)

D(s)

=

α

ij

s + β

ij

s(s

2

+ k

1

s + k

2

)

In the second step, we calculate the four discrete

transfer functions G

ij

(z):

·

L(z)

θ(z)

¸

=

·

G

11

(z) G

12

(z)

G

21

(z) G

22

(z)

¸

·

·

E

r

(z)

E

l

(z)

¸

(6)

where each term G

ij

(z) has the following structure:

G

ij

(z) =

N

ij

(z)

D(z)

=

γ

ij

z

2

+ δ

ij

z + ²

ij

(z − 1)(z

2

+ α

1

z + α

2

)

To obtain a parametrisation appropriated to the pa-

rameter estimation, the transfer functions are con-

verted to equivalent difference equations:

∆l

k

= − α

1

∆l

k−1

− α

2

∆l

k−2

+ (7)

+ γ

11

e

r,k−1

+ δ

11

e

r,k−2

+ ²

11

e

r,k−3

+

+ γ

12

e

l,k−1

+ δ

12

e

l,k−2

+ ²

12

e

l,k−3

∆θ

k

= − α

1

∆θ

k−1

− α

2

∆θ

k−2

+ (8)

+ γ

21

e

r,k−1

+ δ

21

e

r,k−2

+ ²

21

e

r,k−3

+

+ γ

22

e

l,k−1

+ δ

22

e

l,k−2

+ ²

22

e

l,k−3

where ∆l

k

= l

k

− l

k−1

is the linear distance traveled

in a sampling period, ∆θ

k

= θ

k

− θ

k−1

is the an-

gular increment in the robot’s orientation in the same

period, and e

r,k

and e

l,k

are the plant input signals.

3 TRAVELED DISTANCE

COMPUTATION

The variable ∆l is not measurable. In spite of this,

we can use heuristics to calculate a plausible value

for this variable,

f

∆l. The methodology developed to

calculate

f

∆l consists of the following steps:

1. calculation of the path length |

f

∆l|

2. calculation of the direction of the movement, i.e.

the sign of

f

∆l

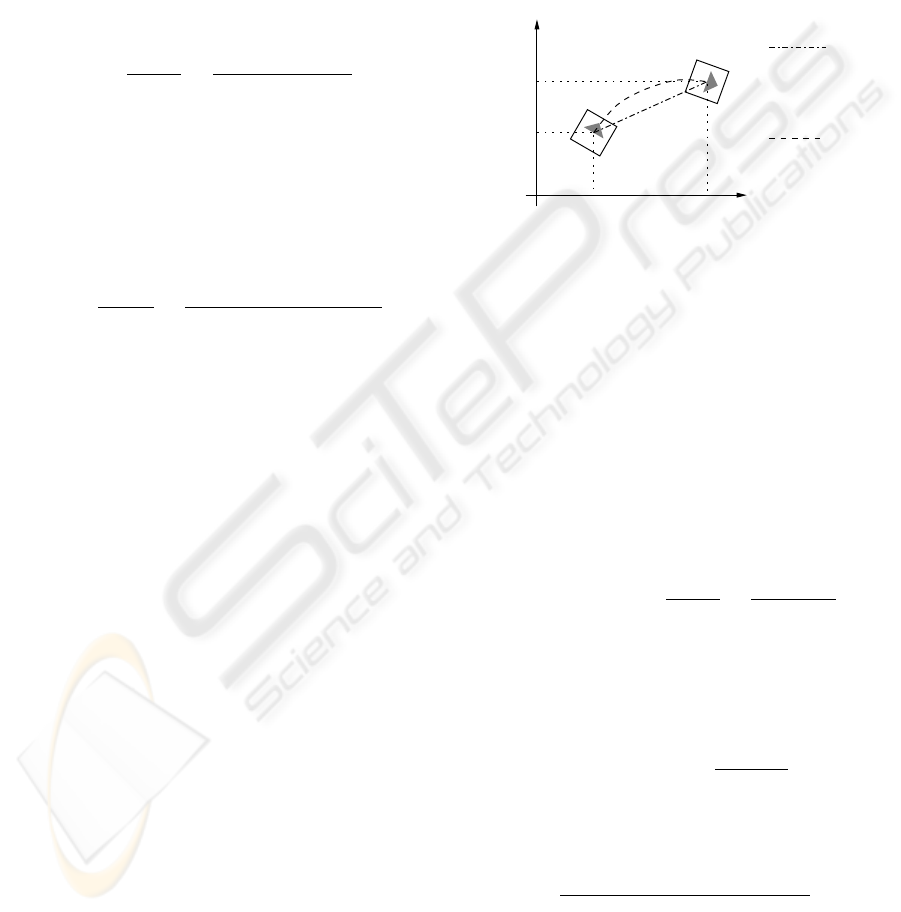

3.1 Path Length Computation

It is possible to obtain with reasonable precision the

robot configuration (x, y, θ) in two consecutive sam-

pling instants, but we cannot be sure about the path

traveled by the robot between the first configuration

and the second configuration. However, a parametric

curve (x(λ), y(λ)), 0 ≤ λ ≤ 1 can be interpolated

between these points and the length of this curve can

be used as an estimated value of |

f

∆l| (see figure 2).

y

0

y

1

x

0

x

1

λ = 0

λ = 1

1

st

degree

polynomial

2

nd

degree

polynomial

Figure 2: Diagram for |

f

∆l| computation

Adopting a 1

st

order polynomial to interpolate, we

are using the Euclidean distance as a measure of the

length of the traveled distance. However, this solution

violates the non-holonomic constraints of the system

when the traveled path is not a straight line.

In this work, we used a parametric curve of 2

nd

degree to calculate the absolute value of

f

∆l because

this is the simplest polynomial allowing interpolating

between the two configurations without violating the

non-holonomics constrains at the contour conditions:

x(λ) = a

2

λ

2

+ a

1

λ + a

0

y(λ) = b

2

λ

2

+ b

1

λ + b

0

tan[θ(λ)] = d(λ) =

dy/dλ

dx/dλ

=

2b

2

λ + b

1

2a

2

λ + a

1

(9)

x(0) = x

0

= a

0

y(0) = y

0

= b

0

x(1) = x

1

= a

2

+ a

1

+ a

0

y(1) = y

1

= b

2

+ b

1

+ b

0

d(0) = tan(θ

0

) = b

1

/a

1

d(1) = tan(θ

1

) =

2b

2

+ b

1

2a

2

+ a

1

(10)

Solving the system 10 results in the following gen-

eral solution:

a

0

= x

0

a

1

=

2[tan(θ

1

)(x

1

− x

0

) − y

1

+ y

0

]

tan(θ

1

) − tan(θ

0

)

a

2

= x

1

− x

0

− a

1

b

0

= y

0

b

1

= a

1

tan(θ

0

)

b

2

= y

1

− y

0

− b

1

(11)

LINEAR MODELLING AND IDENTIFICATION OF A MOBILE ROBOT WITH DIFFERENTIAL DRIVE

265

-0.003

-0.0025

-0.002

-0.0015

-0.001

-0.0005

0

0.0005

0.001

0.0015

0.002

0 50 100 150 200 250 300 350 400

delta_L(m)

number of iterations

calculated from non-linear simulation

linear simulation

Figure 3: Comparison between

f

∆l and ∆l

Similar solutions can be found for the singular

cases where θ

0

or θ

1

have values close to ±

π

2

.

To calculate the length of this curve, we used:

g

|∆l| =

Z

1

0

r

(

dx

dλ

)

2

+ (

dy

dλ

)

2

dλ (12)

Substituting

dx

dλ

and

dy

dλ

in equation 12 we obtain:

g

|∆l| =

Z

1

0

p

Aλ

2

+ Bλ + C dλ (13)

where

A = 4a

2

2

+ 4b

2

2

B = 4a

1

a

2

+ 4b

1

b

2

C = a

2

1

+ b

2

1

(14)

The closed solution for the integral in equation 13

can be found in integral tables.

3.2 Computation of the Movement

Direction

To obtain the sign of the traveled distance, i.e. know-

ing if the robot moved forward or backward, we cal-

culate the value of

0

x

1

, the x coordinate of the cur-

rent configuration point (x

1

, y

1

) calculated with re-

spect to the reference frame attached to the previous

robot position (x

0

, y

0

), as indicated in the figure 4.

If

0

x

1

is positive, the robot will have moved forward

and

f

∆l > 0. Otherwise, the robot will have moved

backward and

f

∆l < 0.

A simple coordinate transformation allows the cal-

culation of

0

x

1

:

0

x

1

= x

1

cos θ

0

− x

0

cos θ

0

+

+ y

1

sin θ

0

− y

0

sin θ

0

(15)

y

0

y

1

x

0

x

1

0

x

1

θ

0

Figure 4: Diagram for calculating the sign of

f

∆l

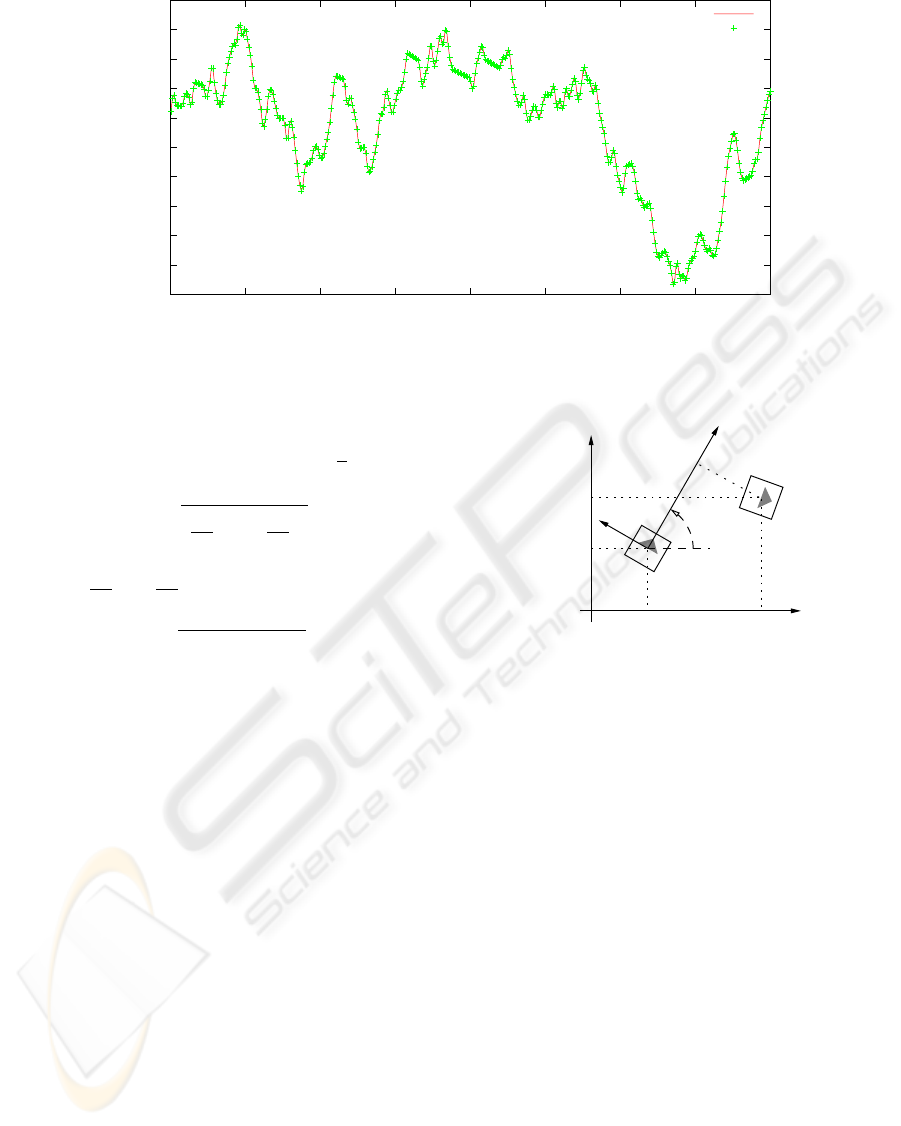

3.3 Validation of Traveled Distance

Computation

Several tests were performed to validate the approxi-

mation of ∆l by

f

∆l. We simulated the linear system

described by equation 4 and the non-linear system de-

scribed by equation 3 with the same input values (e

r

and e

l

), obtaining as outputs, respectively:

z =

·

l

θ

¸

and y =

"

x

y

θ

#

After this, we plotted the values of ∆l = l

k

− l

k−1

,

generated by the linear system, and

f

∆l, which was

calculated using the x and y outputs generated by

the non-linear system and the proposed approxima-

tion. From figure 3, we can observe that

f

∆l (esti-

mated value) is very close to the actual distance trav-

eled by the robot (∆l). The mean error was 0,058%,

with a standard deviation of 0,274%.

ICINCO 2004 - ROBOTICS AND AUTOMATION

266

4 EXPERIMENTAL RESULTS

The results presented in this section were obtained us-

ing a small (7.5 × 7.5 × 7.5cm) mobile robot, with

two wheels driven by two independent DC motors,

very used in robot soccer competitions. A detailed

description of the robot can be found in precedent ar-

ticles (Vieira et al., 2001).

The inputs signals e

r

and e

l

are the armature volt-

ages of the right and left DC motors. The system out-

put y = [

x y θ

]

T

is measured by processing

the image from a fixed camera placed over the robot

workspace (Aires et al., 2001). We use a sampling

rate of 30 samples per second, fixed by the image ac-

quisition card.

The classical method of Recursive Least Mean

Squares (

˚

Astr

¨

om and Wittenmark, 1997) was utilized

for the estimation of the parameters of the model

(equations 7 and 8). The system was excited with

pseudo-random input signals, assuming values be-

tween 1.0 (100% of the motor supply voltage, 9V)

and -1.0 (-9V). As the robot has some high time con-

stants, the input values only changed at each 8 sam-

pling periods. To reduce the chance of high velocities,

the tensions near 0.0 were more probable than the ten-

sions near ±1.0.

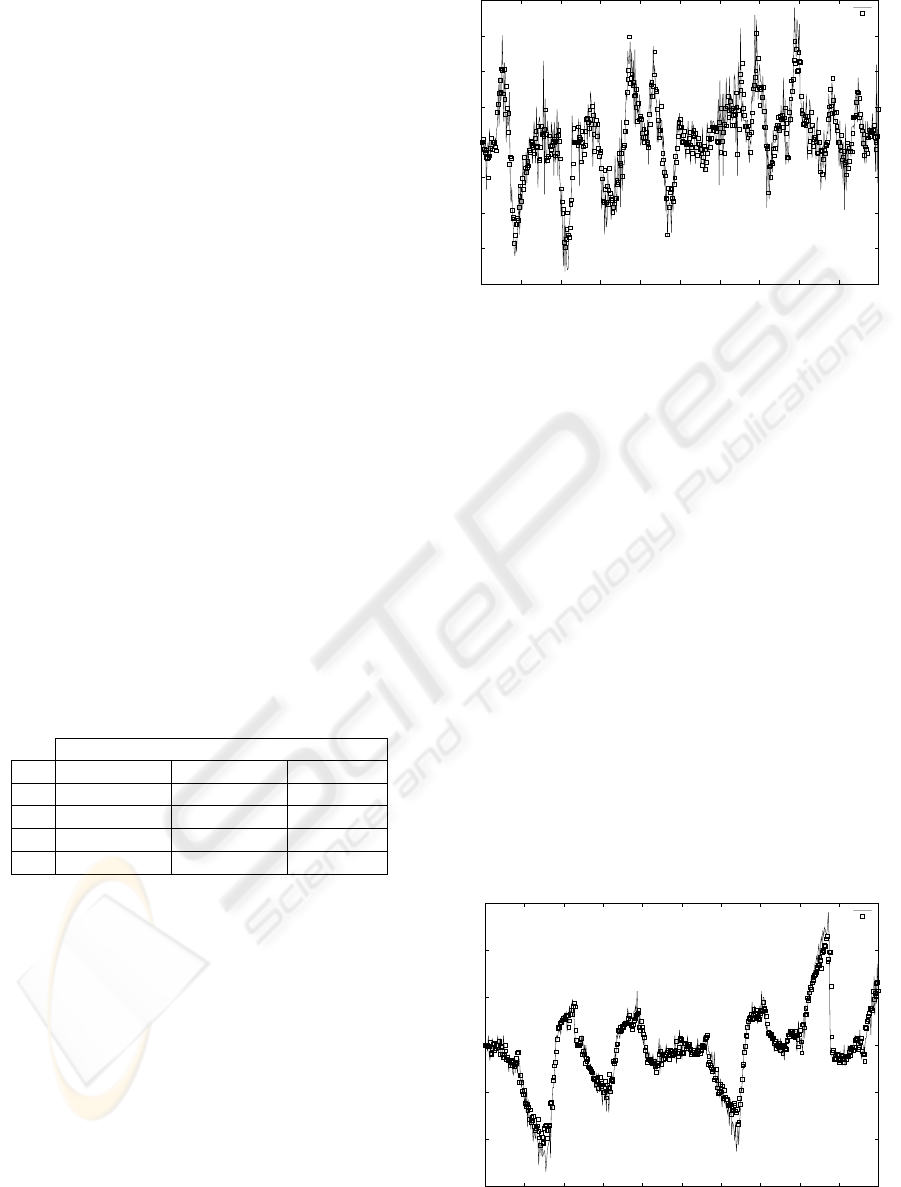

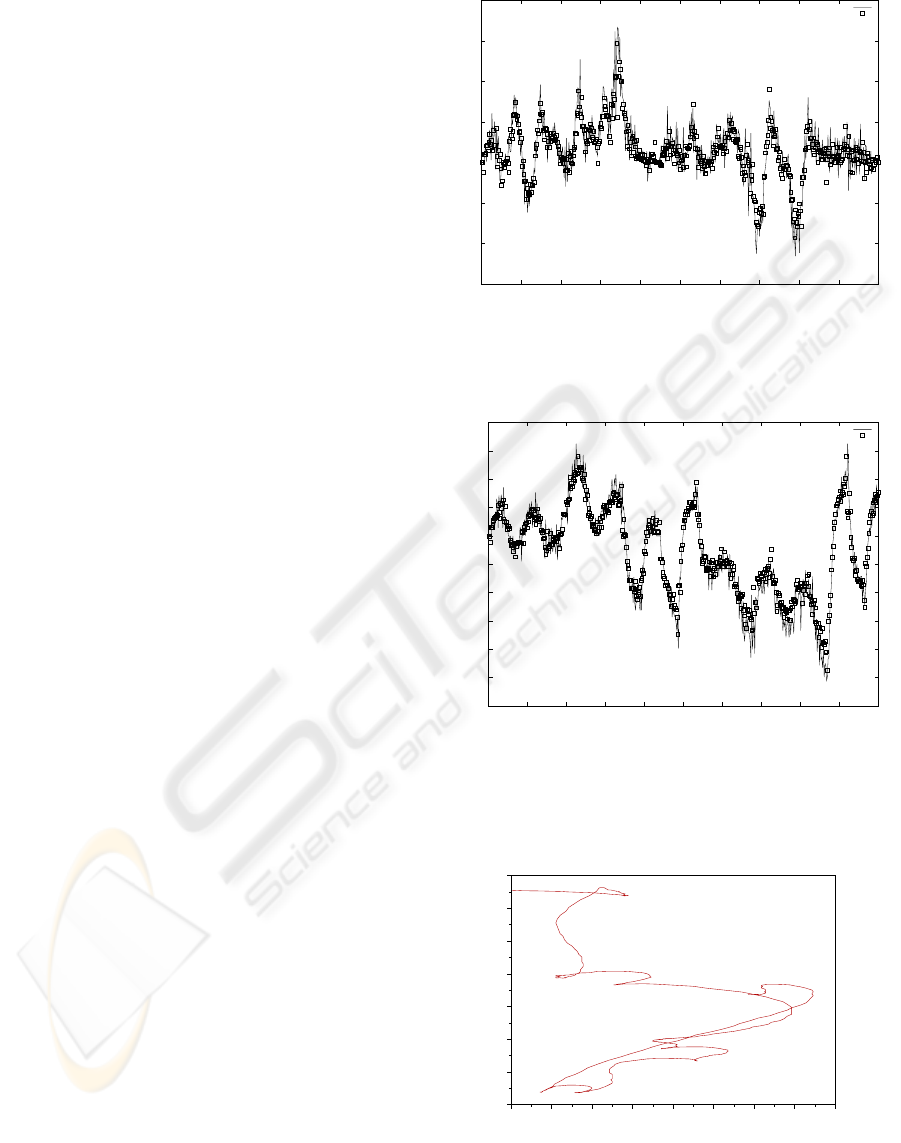

Figure 9 shows the trajectory followed by the robot

during an experiment with 500 samples. The resulting

estimated parameters are presented in table 1.

Table 1: Estimated parameters

α

1

=-0.2125 α

2

=-0.5362

ij γ

ij

δ

ij

²

ij

11 -0.0005195 -0.0005098 0.003019

12 -0.0001753 -0.001158 0.003347

21 0.01099 -0.02627 -0.03326

22 0.001818 -0.06038 0.1074

Figure 5 shows the measured and estimated val-

ues for ∆θ. The error in the estimation of ∆θ has

mean value of 0.000426rad and standard deviation of

0.0685rad. Figure 6 shows the calculated values of

f

∆l and the estimated values for ∆l. The error in the

estimation of ∆l has mean value of -0.000297m and

standard deviation of 0.00261m.

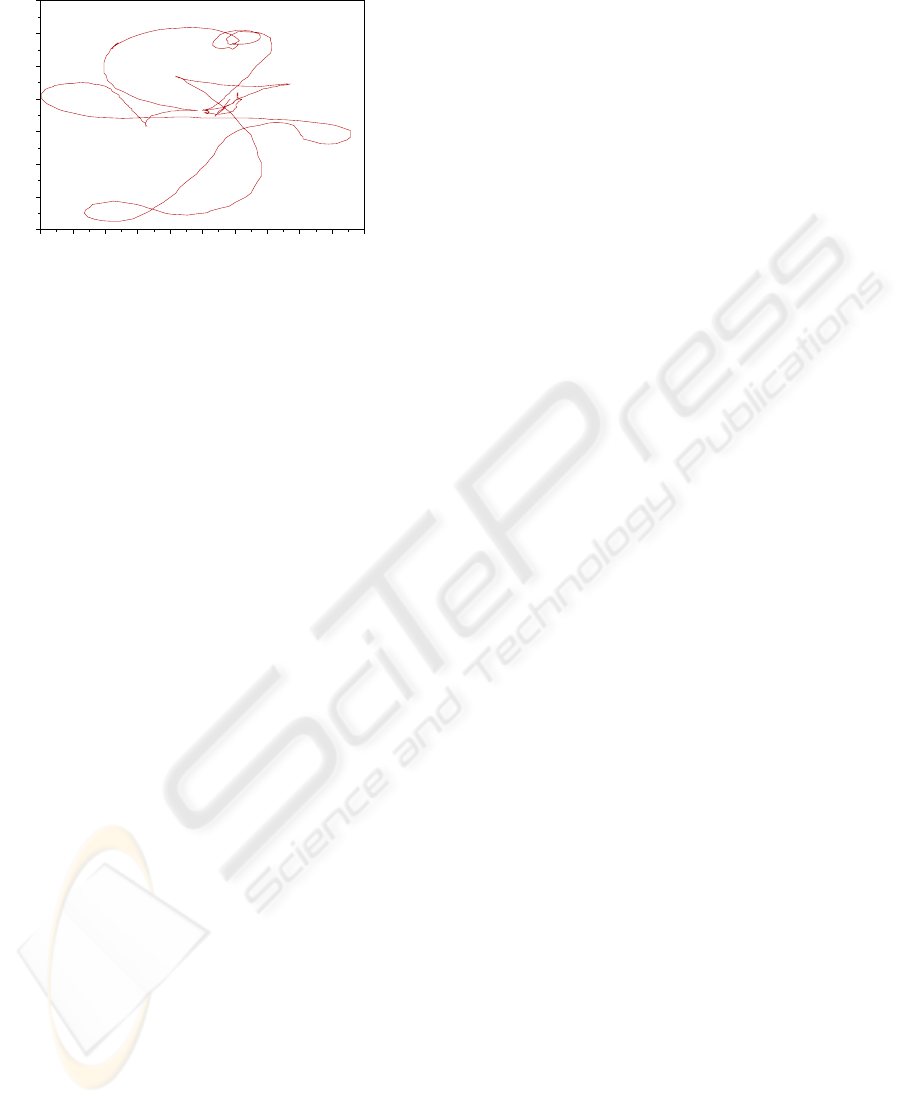

To validate the generality of the obtained model,

we calculate the estimation errors using the same pa-

rameters with a different trajectory (figure 10). Figure

7 shows the measured and estimated values for ∆θ

(mean value of 0.00878rad and standard deviation of

0.0814rad) and figure 8 shows the calculated values

of

f

∆l and the estimated values for ∆l (mean value of

-0.000435m and standard deviation of 0.00267m).

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0 50 100 150 200 250 300 350 400 450 500

measured

estimated

Figure 5: ∆θ measured and ∆θ estimated

5 CONCLUSION

We proposed the substitution of the robot position

variables (x, y) by the distance traveled in a sampling

period ∆l. This substitution resulted in an equivalent

exact linear dynamic model, suitable for identification

through the standard linear systems methods. More-

over, the linearity of the proposed model allows its ap-

plication on the design of dynamic controllers based

on classic linear discrete techniques, as proposed by

Vieira (Vieira et al., 2004).

It can be observed that, in spite of the fact that the

identified model have been defined in the discrete do-

main, there is no impediment of obtaining the contin-

uous model from the same, also allowing its use in the

design of controllers in the continuous domain.

-0.03

-0.02

-0.01

0

0.01

0.02

0.03

0 50 100 150 200 250 300 350 400 450 500

measured(calculated)

estimated

Figure 6:

f

∆l calculated and ∆l estimated

LINEAR MODELLING AND IDENTIFICATION OF A MOBILE ROBOT WITH DIFFERENTIAL DRIVE

267

REFERENCES

Aires, K. R. T., Alsina, P. J., and Medeiros, A. A. D. (2001).

A global vision system for mobile mini-robots. In

SBAI - Simp

´

osio Brasileiro de Automac¸

˜

ao Inteligente,

Canela, RS, Brasil.

˚

Astr

¨

om, K. J. and Wittenmark, B. (1997). Computer Con-

troled Systems. Information and System Sciences.

Prentice-Hall, EUA, 3 edition. ISBN 0-13-314899-8.

Economou, J., Tsourdos, A., and White, B. (2002). Takagi-

sugeno model synthesis of a quasi-linear parameter

varying mobile robot. In IROS - IEEE/RSJ Interna-

tional Conference on Intelligent Robots and Systems,

volume 3, pages 2103–2108.

Efe, M., Kaynak, O., and Rudas, I. (1999). A novel com-

putationally intelligent architecture for identification

and control of nonlinear systems. In ICRA - IEEE In-

ternational Conference on Robotics and Automation,

volume 3, pages 2073–2077, Detroit, MI, USA.

Pereira, G. A. S. (2000). Identificac¸

˜

ao e controle de micro-

rob

ˆ

os m

´

oveis. Master’s thesis, Universidade Federal

de Minas Gerais, Belo Horizonte, MG, Brazil.

Pereira, G. A. S., Campos, M. F. M., and Aguirres, L. A.

(2000). Modelo din

ˆ

amico para predic¸

˜

ao da posic¸

˜

ao

e orientac¸

˜

ao de micro-rob

ˆ

os m

´

oveis observados por

vis

˜

ao computacional. In CBA - Congresso Brasileiro

de Autom

´

atica, Florian

´

opolis, SC, Brazil.

Poignet, P. and Gautier, M. (2000). Comparison of weighted

least squares and extended kalman filtering methods

for dynamic identification of robots. In ICRA - IEEE

International Conference on Robotics and Automa-

tion, volume 4, pages 3622–3627, San Francisco, CA,

USA.

Vieira, F. C., Alsina, P. J., and Medeiros, A. A. D. (2001).

Micro-robot soccer team - mechanical and hardware

implementation. In Congresso Brasileiro de Engen-

haria Mec

ˆ

anica, pages 534–540.

Vieira, F. C., Medeiros, A. A. D., Alsina, P. J., and

Ara

´

ujo Jr., A. P. (2004). Position and orientation con-

trol of a two-wheeled differentially driven nonholo-

nomic mobile robot. In ICINCO – International Con-

ference on Informatics in Control, Automation and

Robotics, Set

´

ubal, Portugal.

Yamamoto, M. M., Pedrosa, D. P. F., and Medeiros, A.

A. D. (2003). Um simulador din

ˆ

amico para mini-

rob

ˆ

os m

´

oveis com modelagem de colises. In SBAI -

Simp

´

osio Brasileiro de Automac¸

˜

ao Inteligente, Bauru,

SP, Brazil.

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

0 50 100 150 200 250 300 350 400 450 500

measured

estimated

Figure 7: ∆θ measured and ∆θ estimated

-0.03

-0.025

-0.02

-0.015

-0.01

-0.005

0

0.005

0.01

0.015

0.02

0 50 100 150 200 250 300 350 400 450 500

measured(calculated)

estimated

Figure 8:

f

∆l calculated and ∆l estimated

−0.25 −0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07

−0.7

−0.5

−0.3

−0.1

0.1

0.3

0.5

0.7

0

−0.25 −0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07

−0.7

−0.5

−0.3

−0.1

0.1

0.3

0.5

0.7

×

−0.25 −0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07

−0.7

−0.5

−0.3

−0.1

0.1

0.3

0.5

0.7

×

50

−0.25 −0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07

−0.7

−0.5

−0.3

−0.1

0.1

0.3

0.5

0.7

×

100

−0.25 −0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07

−0.7

−0.5

−0.3

−0.1

0.1

0.3

0.5

0.7

×

150

−0.25 −0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07

−0.7

−0.5

−0.3

−0.1

0.1

0.3

0.5

0.7

×

200

−0.25 −0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07

−0.7

−0.5

−0.3

−0.1

0.1

0.3

0.5

0.7

×

250

−0.25 −0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07

−0.7

−0.5

−0.3

−0.1

0.1

0.3

0.5

0.7

×

300

−0.25 −0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07

−0.7

−0.5

−0.3

−0.1

0.1

0.3

0.5

0.7

×

350

−0.25 −0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07

−0.7

−0.5

−0.3

−0.1

0.1

0.3

0.5

0.7

×

400

−0.25 −0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07

−0.7

−0.5

−0.3

−0.1

0.1

0.3

0.5

0.7

×

450

−0.25 −0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07

−0.7

−0.5

−0.3

−0.1

0.1

0.3

0.5

0.7

×

500

Figure 9: First example of system trajectory output

ICINCO 2004 - ROBOTICS AND AUTOMATION

268

−0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07 0.11 0.15 0.19

−0.4

−0.3

−0.2

−0.1

0

0.1

0.2

0.3

0

−0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07 0.11 0.15 0.19

−0.4

−0.3

−0.2

−0.1

0

0.1

0.2

0.3

×

−0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07 0.11 0.15 0.19

−0.4

−0.3

−0.2

−0.1

0

0.1

0.2

0.3

×

50

−0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07 0.11 0.15 0.19

−0.4

−0.3

−0.2

−0.1

0

0.1

0.2

0.3

×

100

−0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07 0.11 0.15 0.19

−0.4

−0.3

−0.2

−0.1

0

0.1

0.2

0.3

×

150

−0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07 0.11 0.15 0.19

−0.4

−0.3

−0.2

−0.1

0

0.1

0.2

0.3

×

200

−0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07 0.11 0.15 0.19

−0.4

−0.3

−0.2

−0.1

0

0.1

0.2

0.3

×

250

−0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07 0.11 0.15 0.19

−0.4

−0.3

−0.2

−0.1

0

0.1

0.2

0.3

×

300

−0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07 0.11 0.15 0.19

−0.4

−0.3

−0.2

−0.1

0

0.1

0.2

0.3

×

350

−0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07 0.11 0.15 0.19

−0.4

−0.3

−0.2

−0.1

0

0.1

0.2

0.3

×

400

−0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07 0.11 0.15 0.19

−0.4

−0.3

−0.2

−0.1

0

0.1

0.2

0.3

×

450

−0.21 −0.17 −0.13 −0.09 −0.05 −0.01 0.03 0.07 0.11 0.15 0.19

−0.4

−0.3

−0.2

−0.1

0

0.1

0.2

0.3

×

500

Figure 10: Second example of system trajectory output

LINEAR MODELLING AND IDENTIFICATION OF A MOBILE ROBOT WITH DIFFERENTIAL DRIVE

269