A NEW PARADIGM FOR SHIP HULL INSPECTION USING A

HOLONOMIC HOVER-CAPABLE AUV

Robert Damus, Samuel Desset, James Morash, Victor Polidoro, Franz Hover, Chrys Chryssostomidis

Sea Grant Autonomous Underwater Vehicles Lab, Massachusetts Institute of Technology, Cambridge, MA, USA

Jerome Vaganay, Scott Willcox

Bluefin Robotics Corporation, Cambridge, MA, USA

Keywords: Autonomous Underwater Vehicle, hovering, feature-relative navigation, inspection

Abstract: The MIT Sea Grant AUV Lab, in association with Bluefin Robotics Corporation, has undertaken the task of

designing a new autonomous underwater vehicle, a holonomic hover-capable robot capable of performing

missions where an inspection capability similar to that of a remotely operated vehicle is the primary goal.

One of the primary issues in this mode of operating AUVs is how the robot perceives its environment and

thus navigates. The predominant methods for navigating in close proximity to large iron structures, which

precludes accurate compass measurements, require the AUV to receive position information updates from

an outside source, typically an acoustic LBL or USBL system. The new paradigm we present in this paper

divorces the navigation routine from any absolute reference frame; motions are referenced directly to the

hull. We argue that this technique offers some substantial benefits over the conventional approaches, and

will present the current status of our project.

1 INTRODUCTION AND

EXISTING CAPABILITIES

The majority of existing autonomous underwater

vehicles (AUVs) are of a simple, torpedo-like

design. Easy to build and control, the torpedo-

shaped AUV has proven useful in many applications

where a vehicle needs to efficiently and accurately

survey a wide area at low cost. As the field of

underwater robotics continues to grow, however,

new applications for AUVs are demanding higher

performance: in maneuvering, precision, and sensor

coverage. In particular, the ability to hover in place

and execute precise maneuvers in close quarters is

now desirable for a variety of AUV missions.

Military applications include hull inspection and

mine countermeasures, while the scientific

community might use a hovering platform for

monitoring coral reefs, exploring the crevices under

Antarctic ice sheets, or close-up inspection in deep-

sea archaeology. An autonomous hovering platform

has great potential for industrial applications in areas

currently dominated by work-class remotely

operated vehicles (i.e., tethered, ROVs): subsea

rescue, intervention, and construction, including

salvage and wellhead operations.

Frequent hull inspection is a critical maintenance

task that is becoming increasingly important in these

security-conscious times. Most ships (whether

civilian or military) are only inspected by hand, in

dry-dock, and thus rarely - certainly not while they

are in active service. Standards do exist for UWILD

(Underwater Inspection in Lieu of Drydock), but

divers have typically performed underwater

inspections, a time-consuming, hazardous job.

Additionally, there is a high probability of divers

missing something important, because it is so

difficult for a human being to navigate accurately

over the hull of a ship, with their hands, and often in

poor visibility. With a loaded draft on the order of

30m and a beam of 70m for a large vessel,

debilitating mines can be as small as 20cm in size,

and in this scale discrepancy lies the primary

challenge of routine hull inspection.

127

Damus R., Desset S., Morash J., Polidoro V., Hover F., Chryssostomidis C., Vaganay J. and Willcox S. (2004).

A NEW PARADIGM FOR SHIP HULL INSPECTION USING A HOLONOMIC HOVER-CAPABLE AUV.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 127-132

DOI: 10.5220/0001145701270132

Copyright

c

SciTePress

The simplest inspection is a visual examination

of the hull surface. Underwater however,

(particularly in harbors and at anchor in coastal

waters) a visual inspection must be performed very

close to the ship. The health of a ship’s skin may

also be judged by measuring plating thickness, or

checking for chemical evidence of corrosion. For

security purposes, a sonar image may be adequate

because of larger target size. For instance, the US

Customs Service currently uses a towfish sidescan

sonar to check hulls (Wilcox, 2003).

Some military vessels are now using small, free-

swimming ROVs for in-situ inspection (Harris &

Slate, 1999). This method eliminates the safety

hazard of diver work, but retains the disadvantage of

uncertain navigation and human load. The only

commercial hull inspection robot, at the time of this

writing, is the Imetrix Lamp Ray. Lamp Ray is a

small ROV designed to crawl over the hull surface.

The ROV is deployed from the vessel under

inspection; the vehicle swims in and closes with the

hull under human control, then holds itself in place

using front-mounted thrusters for suction. The

operator then drives the ROV over the hull surface

on wheels. This limits the survey to flat areas of the

hull; more complex geometry around e.g. sonar

domes, propeller shafts, etc. must still be visually

inspected with a free-swimming ROV. The Cetus II

AUV is an example of a free-swimming autonomous

system that has also conducted ship hull surveys

(Trimble & Belcher 2002). Using altimeters to

maintain a constant relative distance from the hull,

and the AquaMap long baseline navigation system

(DesertStar, Inc.), Cetus II records globally-

referenced position information, and this (with depth

and bearing to the hull) is the primary navigation

sensor used to ensure and assess full coverage. The

AquaMap system uses a transponder net deployed in

the vicinity of the ship being inspected (see URL in

References); clearly, a long baseline acoustic system

could be used for any vehicle.

Our vehicle program has three unique aspects to

address the needs of ship hull inspection:

development of a small autonomous vehicle

optimized for hovering, and of a hull-relative

navigation procedure, wherein dependence on a

deployed acoustic navigation system is avoided.

The data product this vehicle will produce is a high-

resolution sonar mosaic of a ship hull, using the

DIDSON imaging sonar (University of

Washington’s Applied Physics Laboratory) as a

nominal payload (Belcher et al., 2003).

2 PHYSICAL VEHICLE

OVERVIEW

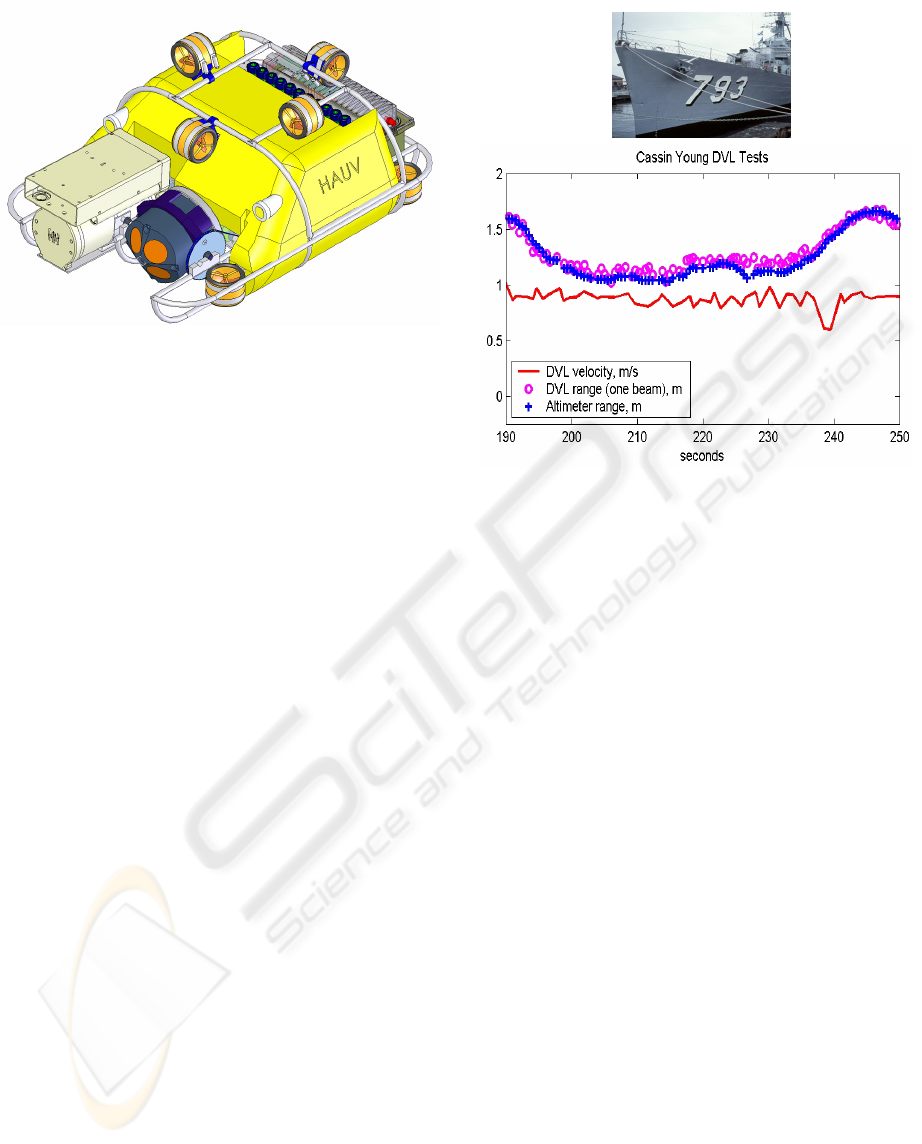

The hovering AUV (HAUV, Figure 1) has eight

hubless, bi-directional DC brushless thrusters, one

main electronics housing, and one payload module.

The symmetrical placement of the large number of

thrusters makes the vehicle agile in responding to

wave disturbances, and capable of precise flight

maneuvers, such as orbiting targets for inspection or

hovering steadily in place. The vehicle is intended

to operate in water depths ranging from the Surf

Zone (SZ) through Very Shallow Water (VSW) and

beyond, up to depths of 100 meters; and to perform

in waves up to Sea State Three.

Onboard non-payload instruments include a

Doppler velocity log (DVL), inertial measurement

unit (IMU), depth sensor, and acoustic modem for

supervisory control. While we do carry a magnetic

compass, this cannot be expected to work well in

close proximity to a metal hull. As noted above, the

nominal payload at this writing is the DIDSON

imaging sonar. Both the DIDSON and the DVL are

mounted on independent pitching servos at the front

of the vehicle, because the DIDSON produces good

imagery at an incidence angle greater than 45

degrees, while the DVL needs to maintain a normal

orientation to the hull. The DVL can also be pointed

down for a bottom-locked velocity measurement.

The vehicle is strongly passively stable, with a

gravity-buoyancy separation of about 3cm. It has

approximate dimensions of 100cm long, 80cm wide,

and 30cm tall; it displaces about 45kg. Of this

weight, about 12kg are for a 1.5kWh battery.

3 OUR APPROACH TO HULL

NAVIGATION

We have chosen to attack this problem from a

feature-relative navigation standpoint, as this has

some advantages compared to current approaches.

Our basic strategy is to measure tangential velocity

relative to the hull being inspected using a Doppler

velocity log (DVL), and to servo a desired distance

from the hull, and orientation, using the individual

ranges from acoustic beams.

The immediate impact of this functionality is the

elimination of support gear for the robot itself; no

localized network setup like LBL is needed. This

reduces complexity and provides a simple, quick

deployment where the robot can operate unattended;

our long-term goal is that the mission focus could

shift towards analyzing the data collected. The lack

of a shipboard system presence also means the craft

ICINCO 2004 - ROBOTICS AND AUTOMATION

128

can be deployed quickly to respond to developing

situations below the waterline.

As a second benefit, the proposed feature-

relative control schemes should work when the ship

being inspected is fixed within a close berth (where

LBL navigation could be poor), anchored and

moving slowly about its mooring, or moving freely

at very low speed, e.g., adrift.

The key technical point to note about navigating

relative to a fixed hull surface is that the vehicle is

constrained absolutely in the DOF normal to the

hull, but not tangentially. A featureless hull is a

poor candidate for visual or sonar image serving,

and the use of DVL velocity measurements for

positioning invokes an obvious drift error over time.

3.1 Suitability of the DVL for this

Task

The DVL (RD Instruments; see URL in References)

comprises four narrow beam transducers, arranged

uniformly at a spread angle of 30 degrees, and

operating broadband in the frequency range of

1200kHz. The Doppler shift is measured for each

beam, and an average sensor-relative tangential

velocity vector is computed. We also have available

the four ranges from the individual transducers: the

device provides range by using the return times from

each sensor and the speed of sound in water.

Complete (four-transducer) measurements are

available at a bandwidth of 3-8Hz, depending on

signal quality and range.

Figure 2: DVL performance when towed along the hull of

the USS Cassin Young

We performed a series of tests with the DVL,

with the specific goal of determining suitability for

the hull-relative inspection task. Specifically, we

have considered: a) what is the drift rate of the

integrated velocities? b) What is the noise

characteristic of the independent range

measurements? c) What is the effect of a metal hull,

with biofouling? d) Does the DIDSON acoustic

imaging system interfere with the DVL?

• On a cement and glass wall at the MIT

Ocean Engineering Testing Tank, the

position error in integrating velocity was

confirmed to be about 0.5 percent of

distance traveled. The error goes up

substantially when the sensor is oriented

more than 30 degrees from normal to the

hull.

• We performed field tests along the hull of

the USS Cassin Young, at the Navy

Shipyard in Charlestown, Massachusetts.

As shown in Figure 2, the range and

velocity measurements are well behaved.

• We performed controlled tests at the

Testing Tank, with simultaneous operation

of the DIDSON and the DVL. DIDSON

images (at 5fps) show the DVL pings as a

Figure 1: The HAUV, showing DIDSON (light

brown) and DVL (dark blue) on the front, yellow

flotation in the mid-body, and a large battery at the

stern. Thruster locations are reconfigurable; the main

electronics housing is underneath the foam

A NEW PARADIGM FOR SHIP HULL INSPECTION USING A HOLONOMIC HOVER-CAPABLE AUV

129

faint flash, but the image is by no means

unusable. Conversely, there is a slight

degradation of the DVL’s velocity

performance. The drift rate approximately

doubles, but remains below 1cm per meter

of distance traveled, which is sufficiently

low enough to satisfy our concept of

operations.

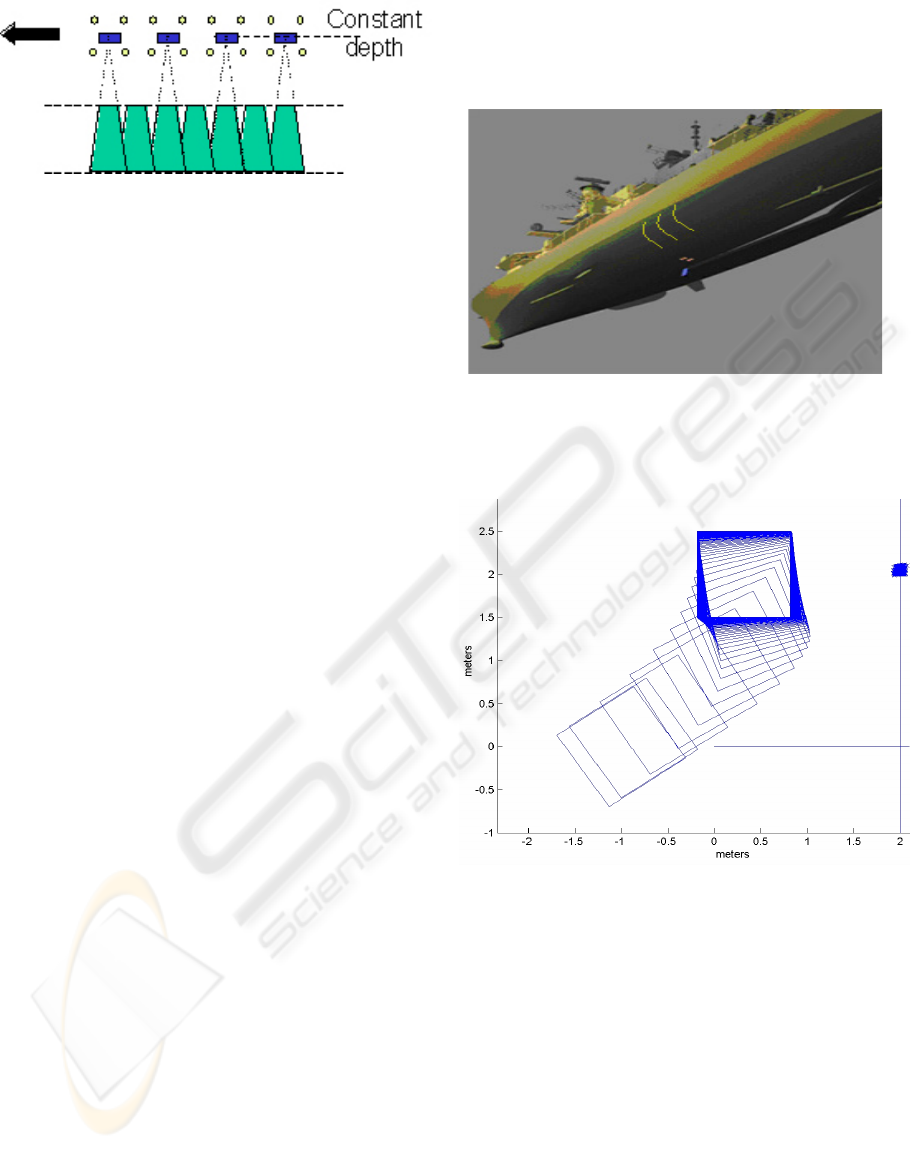

Figure 3: The horizontal slice method; the vehicle makes

passes at constant depth

3.2 Two Approaches Using “Slicing”

The DVL can be used to servo both orientation and

distance to the hull (through the four independent

range measurements) and to estimate the distance

traveled, with reasonable accuracy. When coupled

with an absolute depth measurement, two plausible

inspection scenarios emerge for the majority of a

large ship’s surface: vertical and horizontal

“slicing.” For the purposes of this paper, we

confine our discussion to the large, relatively smooth

surface of the hull sides, bottom, and bow. As with

other existing automated inspection methods, the

stern area with propellers, rudders, shafting and

bosses cannot be easily encompassed within our

scheme.

In the case of horizontal slicing (Figures 3 and

4), paths in the horizontal plane are performed. The

absolute depth provides bounded cross-track error

measurement, while the integrated velocity provides

the along-track estimate of position. This along-

track position, with depth, is recorded for each

image.

Defining the end of a track at a given depth is a

sensing challenge to which we see several possible

approaches. First, there may be landmarks, such as

weld lines, protuberances, or sharp edges as found

near the bow or stern areas. These landmarks,

especially if they occur at many depths, can be used

to put limits on the search area, and to re-zero the

integrated velocity error. Certainly prior knowledge

of the ship’s lines and these features can be

incorporated into the mapping strategy at some

level.

On the other hand, the complete absence of

features is workable also: operate at a given depth

until the integrated velocity safely exceeds the

circumference of the vessel, then move to another

depth. When an object of interest is detected,

immediate surfacing must occur in this scenario

since location along the hull would be poorly

known.

The horizontal slice method is very good for the

sides and bow of a vessel. Many vessels, for

example, large crude carriers (LCC’s) have flat

bottoms, which must also be inspected. Here, aside

from the fact that the vehicle or the imaging sensor

and DVL must be reoriented to look up, there is no

cross-track error available, since the depth is roughly

constant. Long tracks parallel to the hull centerline

would be subject to accrued errors on the order of

several meters. The vertical slice approach (Figure

5) addresses this problem, by making paths down the

sides of the hull and then underneath, in a plane

normal to the hull centerline. Once at the

centerline, options are to turn around and come back

up on the same side, or to continue all the way under

the hull to surface on the other side, after a 180-

degree turn in place (which must be constructed

based on rate gyro information only). In either case,

the important property here is that the path length is

limited, so that the cross-track errors are limited, and

overlap can be applied as necessary. For instance,

using a vertical path length of 130m implies a cross-

track error on the order of 65cm, which is easily

covered by overlapping images with field of view

several meters, assuming no systematic bias.

Convex or concave, two-axis curvature of the

hull also requires some overlap. For instance, in the

extreme case of a spherical hull and the vertical

survey, like ribbons around a ball, the imaged path

lines converge at the bottom. These cases will

require further study and mission design at a high

level.

3.3 Role of Low- and Mid-Level

Control

Dynamically, the vehicle is equipped with high-

performance thrusters so as to operate in shallow

waters, waves, and in proximity to hulls. The

primary sensor we have available, the DVL,

however, is a comparatively low bandwidth device,

which cannot provide robust measurements for

direct control – the noise properties may be

unpredictable, timing may vary, and missed data are

not uncommon. Furthermore, loss of contact with

the hull can occur in regular operation, and even be

exploited as a landmark.

ICINCO 2004 - ROBOTICS AND AUTOMATION

130

Figure 4: Operation during horizontal survey, looking at

the side of the vessel. The vehicle is shown in blue, with

the four DVL footprints in yellow on the hull. The

DIDSON images (green) are taken looking downward as

the vehicle moves

In waves, the depth sensor also fails as a high-

bandwidth navigation sensor. As a consequence of

these facts, the vehicle has to be capable of short-

term autonomous navigation, through a high-end

inertial measurement unit, and an integrated low-

level control system. The division of control can be

stated as follows: The low-level controller depends

only on the core sensors of the IMU, while a mid-

level layer incorporates the DVL and depth sensor,

and a high-level controller manages the mission and

desired pathlines. This multi-level control system is

to be of the inner-outer loop type, with the DVL and

depth sensor providing setpoints for higher-

bandwidth inner loops. As in most cases of inner-

outer design, the outer loop bandwidth should be at

least 3-5 times slower than the inner loop.

Consider for example the case of yaw control

relative to the hull. At the innermost level, a yaw

rate servo runs at maximum update frequency and

closed-loop bandwidth, employing a model-based

estimator, i.e., a Kalman Filter for handling vehicle

dynamics and sensor channels that are coupled due

to gravity. The mid-level control has coupling, due

to the fact that the DVL is like a velocity sensor on a

moment arm, so that yaw and sway at the wall are

kinematically coupled. This is one of many

concepts from visual servoing that are appropriate

here (e.g., Hutchison et al., 1996). Figure 6 gives

an illustration of hull servoing using nested low- and

mid-level control, and DVL data.

4 SUMMARY

Doppler velocimetry with ranging facilitates a new

feature-relative approach for autonomous ship hull

inspection, one which allows several intuitive

strategies that can account for the majority of the

hull surface. The use of landmarks and ship’s lines,

as well as survey techniques for complex stern

arrangements are still open questions.

Support is acknowledged from the Office of Naval

Research (Dr. T.F. Swean) under Grant N00014-02-

1-0946, and from NOAA and the Sea Grant College

Program, Grant NA 16RG2255.

Figure 5: Vertical slice survey; the vehicle makes depth

passes with zero sway velocity

Figure 6: Example of low- (PID) and mid-level (LQG)

coupled control in the yaw-sway hull positioning problem.

Vehicle initially is at a 42 degree bearing, 3m range; final

position is zero degrees bearing, 1.7m range. The

controller keeps the tangential velocity small while

reorienting, so that the excursion of the DVL “pointer” on

the wall (line on right hand side) is 12cm

REFERENCES

Belcher, E., B. Matsuyama, and G. Trimble, 2003. Object

Identification with Acoustic Lenses.

http://www.apl.washington.edu/programs/DIDSON/M

edia/object_ident.pdf

A NEW PARADIGM FOR SHIP HULL INSPECTION USING A HOLONOMIC HOVER-CAPABLE AUV

131

Harris, S.E. and E.V. Slate, 1999. Lamp Ray: Ship Hull

Assessment for Value, Safety and Readiness. Proc.

IEEE/MTS Oceans.

Hutchinson, S., G.D. Hager, and P.I. Corke, 1996. A

tutorial on visual servo control. IEEE Trans. Robotics

and Automation, 12:651-670.

RD Instruments DVL, http://www.dvlnav.com.

Ship Hull Inspections with AquaMap

http://www.desertstar.com/newsite/positioning/shiphul

l/manuals/Ship%20Hull%20Inspections.pdf.

Trimble, G. and E. Belcher, 2002. Ship Berthing and Hull

Inspection Using the CetusII AUV and MIRIS High-

Resolution Sonar, Proc. IEEE/MTS Oceans.

http://www.perrymare.com/presentations/Oceans%202

002%20Homeland%20Defense.pdf. See also:

http://web.nps.navy.mil/~brutzman/Savage/Submersib

les/UnmannedUnderwaterVehicles/CetusFlyerMarch2

001.pdf.

Wilcox, T., 2003. Marine Sonic Technologies Ltd.,

Personal communication.

ICINCO 2004 - ROBOTICS AND AUTOMATION

132