DIMSART: A REAL TIME - DEVICE INDEPENDENT MODULAR

SOFTWARE ARCHITECTURE FOR ROBOTIC AND TELEROBOTIC

APPLICATIONS

Jordi Artigas, Detlef Reintsema, Carsten Preusche, Gerhard Hirzinger

Institute of Robotics and Mechatronics, DLR (German Aerospace Center)

Oberpfaffenhofen, Germany

Keywords:

Telepresence, Distributed Control, Indpendency, Robotic, Telerobotic, DIMSART, RTLinux, VxWorks

Abstract:

In this paper a software architecture for robotic and telerobotic applications will be described. The software

is device and platform independent, and is distributed control orientated. Thus, the package is suitable for

any real time system configuration. The architecture allows designers to easily build complex control schemes

for any hardware device, easily control and manage them, and communicate with other devices with a plug-

in/plug-out modular concept. The need to create a platform where control engineers/designers could freely

implement their algorithms, without needing to worry about the device driver and programming related issues,

further motivated this project. Implementing a new control algorithm with the software architecture described

here, requires that the designer simply follow a template where the necessary code is reduced to only those

functions having to do with the controller. We conducted several teleoperation schemes, one of which will be

presented here as a configuration example.

1 INTRODUCTION

Control methods are nowadays totally related to soft

computing techniques. From this relationship a new

area in software engineering is emerging, which ex-

plores the interplay between the control theory and

software engineering worlds. It is in this research di-

rection that the authors found the need of building a

robotic control software architecture. Among other

things, the architecture should facilitate the develop-

ment of robotic and telerobotic control schemes by

defining beneficial constraints on the design and im-

plementation of the specific application, without be-

ing too restrictive. Keeping this goal in mind, the

DIMSART has been developed by the Telepresence

group of the Institute of Robotics and Mechatronics

to provide a practical, convenient and original solu-

tion.

1.1 Telepresence Environment

The focus of the DIMSART is the development of

Telepresence systems. Telepresence is an extension

of the telerobotics concept in which a human operator

is coupled with as much sensory information as possi-

ble to a remote environment through a robot, in order

to produce an intuitive and realistic interaction with

that environment. The range of senses can encom-

pass vision, tactile, auditory, and even smell and taste

senses. Our interest is focused on the haptic chan-

nel, therefore the type of information which is sent

is motion and force data. From the control point of

view, such systems are often referred to as bilateral

control schemes (see fig.1), because two controls are

simultaneously performed in the telepresence global

closed loop, one on the master side (controlling the

master device), and one on the slave side (controlling

the slave device).

Figure 1: Telepresence Scheme

A telepresence system developed by the Telepres-

ence research group from DLR Oberpfaffenhofen will

be used in this article to show the needs and require-

ments of the architecture, and thus, motivate the de-

velopment of the DIMSART to the reader. Its extrap-

olation to ”mono-lateral” robotics applications will be

straightforward.

102

Artigas J., Reintsema D., Preusche C. and Hirzinger G. (2004).

DIMSART: A REAL TIME - DEVICE INDEPENDENT MODULAR SOFTWARE ARCHITECTURE FOR ROBOTIC AND TELEROBOTIC APPLICATIONS.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 102-109

DOI: 10.5220/0001147301020109

Copyright

c

SciTePress

1.2 Control and Software

engineering Interplay

A not less significant goal is the creation of an har-

mony between the computer science world and the

control engineering world. Not rarely, control engi-

neers are faced with obstacles arising from the pro-

gramming work required for controlling and driv-

ing hardware devices. The software architecture de-

scribed here allows a control engineer to forget about

issues related to device drivers, real time program-

ming, concurrencies or thread programming. Thus,

he/she only needs to concentrate on the specific con-

trol algorithm. As it will be seen, by using this

software platform, the designer is only faced with

the creation a ”module”, for which a template-based

methodology is used. This goal will result in a pro-

gramming time saving for the control designer and

thus the consequence of investing the whole energy

in the control design itself.

1.3 Existing Architectures

The generalized needs of facilitating efficient robotic

system designs and implementations resulted in

the development of several software architectures.

In (

`

Eve Coste-Mani

`

ere and Redi Simmons, 2000)

these general needs are formalized. Furthermore, the

importance of making the right architecture choice

is noted, and some architectures are compared and

contrasted.

Some architectures for robotic systems are very

complete packages which consider the overall struc-

ture for controlling a robot, including all possible

levels of competence in a robotic system (sensing,

mapping, modeling, planning, AI, task execution,

motor control, etc...) either in a hierarchical layered

style (Albu et al., 1988), in a behavioral one (Brooks,

1986), or in an hybrid one (Borrelly et al., 1998),

(Schneider et al., 1998), (RTI, 2004), (Volpe et al.,

2001). However these kind of architectures are more

appropriate for autonomous robot vehicles where

a control at high level or, alternatively, a Decision

Layer, as mentioned in (Volpe et al., 2001), is of high

importance.

Other architectures are not so concerned with

layered structures and emphasize instead the real

time operation as a sequence of control components

executed at a lower level. These architectures tend to

be simpler but more flexible (Scholl, 2001), (Stasse

and Kuniyoshi, 2000).

The DIMSART architecture shines for its simplic-

ity, flexibility and portability. It can be included to the

second group of architectures, but it is more focused

in the automatic control level. Furthermore, it can

be easily embedded in other architectures or systems

with almost any Linux/Unix operating system type:

Linux, Solaris, RTLinux, VxWorks.

The outline of this paper is as follows. We first

present, in section 2, a chapter dedicated to general

robotic control concepts with a particular scheme ex-

ample which will be used in the subsequent sections

to introduce the DIMSART architecture. We then de-

scribe the software platform and its main parts in sec-

tion 3. Section 4 introduces a complete experimen-

tal setup as a DIMSART configuration example. Fi-

nally, in section 5, some concluding remarks and fu-

ture lines are given.

2 ROBOT CONTROL

We will make use of a telepresence control scheme

example to focus our interest in three aspects: dis-

tributed control, the data flow and the definition of the

acting regions of our framework. Also in this chap-

ter, a more abstract view of a general robotic control

scheme will be introduced, and later it will be speci-

fied within the mentioned example.

2.1 Wave Variables Scheme as

Bilateral Control Example

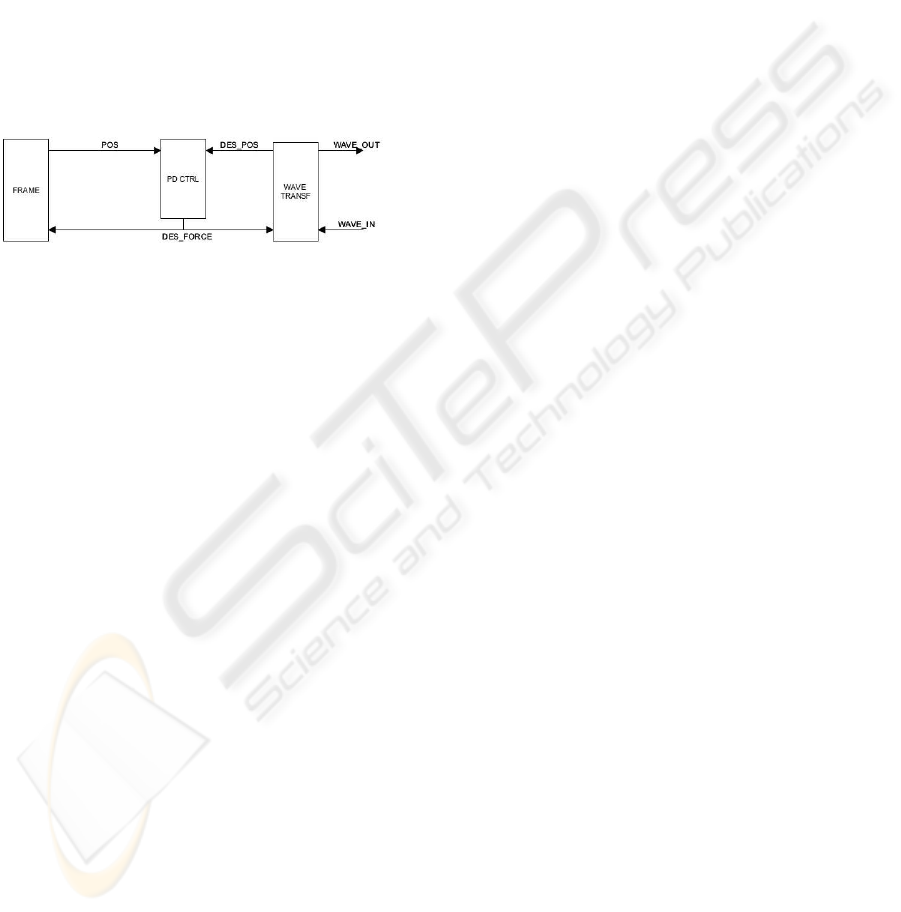

In fig.2 a block diagram of a Wave Variable control

scheme can be seen. The Wave Variables Theory

is a common approach to minimize the degradative

effects of time-delayed communication channels

in telepresence systems. For detailed information

about this theory refer to (Niemeyer, 1996) and

(Artigas, 2003) . It is not the aim of this paper to

detail the control theory behind the scheme. Rather,

it is intended to be used as a reference point for the

DIMSART approach. We will refer to this example

in some of the following sections to give support to

the theoretical explanations of the architecture.

Figure 2: Global control software is decoupled from hard-

ware device, driver and communication

DIMSART: A REAL TIME - DEVICE INDEPENDENT MODULAR SOFTWARE ARCHITECTURE FOR ROBOTIC

AND TELEROBOTIC APPLICATIONS

103

Distributed Control

In telepresence scenarios the concept of distributed

control becomes an important issue. Although from

the hardware point of view both master and slave de-

vices can be quite different, from the control point of

view they are not so dissimilar. The main idea of dis-

tributed control is to divide the global control task of

the system in n identical or quasi identical local con-

trol components. The nature of a bilateral control is

to distribute the control task between both sides, mas-

ter and slave. The control component, -henceforth re-

ferred to as module-, will have to be sufficiently pow-

erful to support

1. The existing differences between master and slave

robots/environments characteristics (for instance,

controller constants, input/output variables, algo-

rithm differences, etc...)

2. Possible different OS platforms. For example, the

master could be controlled by a RTLinux machine,

and the slave by a VxWorks one.

In our bilateral control scheme, the control task is

distributed between master and slave sides through

the Wave Transformer and PD Controller blocks.

Main operation and Data Flow

The two blocks on each side of the system in

fig.2, PD Controller and Wave Transformer, can be

viewed, from the software point of view, as a chain of

algorithms with similar characteristics sequentially

called. This reasoning leads to an object-oriented

direction, in which a Module Template class can be

constructed and from which different objects (the

control elements) can be defined. Modularity will

facilitate a Top-down design methodology, as well as

code reuse.

Defining operating boundaries

By defining the operating boundaries shown in

fig.2, the independence from the hardware driver and

the communication channel will be preserved, or, in

other words, the control task will be uncoupled (from

the software point of view) from the rest of the sys-

tem. Portability and independence are direct conse-

quences. That is, portability to other robotic systems

can be achieved, independently of the robot and com-

munication channel.

2.2 General Robot Control setup

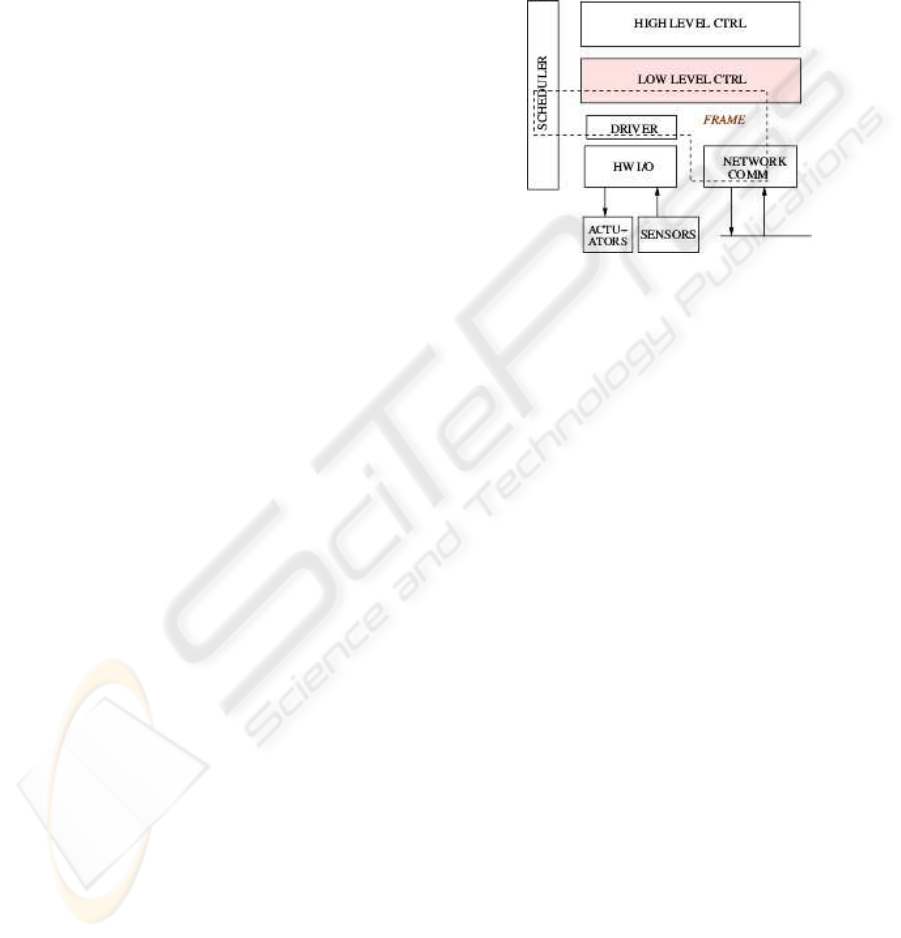

Fig.3 skews the components of a general robotic sys-

tem. On the lowest level, we find the sensors and ac-

tuators of the haptic/robot device. The driver, which

is in charge of initializing and closing the device, and

reading and writing data from/to it, is part of what

we call the frame. The frame encompasses elements

located between the low level control layer, the hard-

ware I/O layer and the network communication layer.

The high level control layer deals with non-real time

control such as task planning or behavioral control.

Our framework will be focused on the low level con-

trol layer and its relationship with the frame.

Figure 3: Components of a general robot control setup

Some of the tasks of the frame include the commu-

nication between the software architecture, the hard-

ware device and the network, and the real time read-

ing, processing and writing scheduling. The fol-

lowing code exemplifies the master’s main operation

of the example depicted in fig.2 for a mono-thread

frame:

dev_open(&Phantom);

dev_init(&Phantom);

main_interrupt_thread(arg){ /*called every 1 ms*/

/* Some inis*/

Read_Comm(in_waves);

Robot_read(local_pos);

/*---------- Control ---------*/

exec_PDctrl(local_pos,

prev_des_pos,

out_force);

exec_WaveTrans(in_waves,

out_waves,

des_pos);

/* context save:*/

prev_des_pos=des_pos;

/*----------------------------*/

Write_Comm(out_data);

Robot_Command(force);

}

dev_close(&Phantom);

Often, the low level controlling task is performed

by the same frame in the real time main interrupt.

However, defining the boundaries indicated in fig.2,

and thus isolating the control task from the rest of the

system, would bring significant benefits. The DIM-

ICINCO 2004 - ROBOTICS AND AUTOMATION

104

SART architecture provides the needed mechanisms

for this job.

2.3 Bilateral Control Scheme with

DIMSART embedded

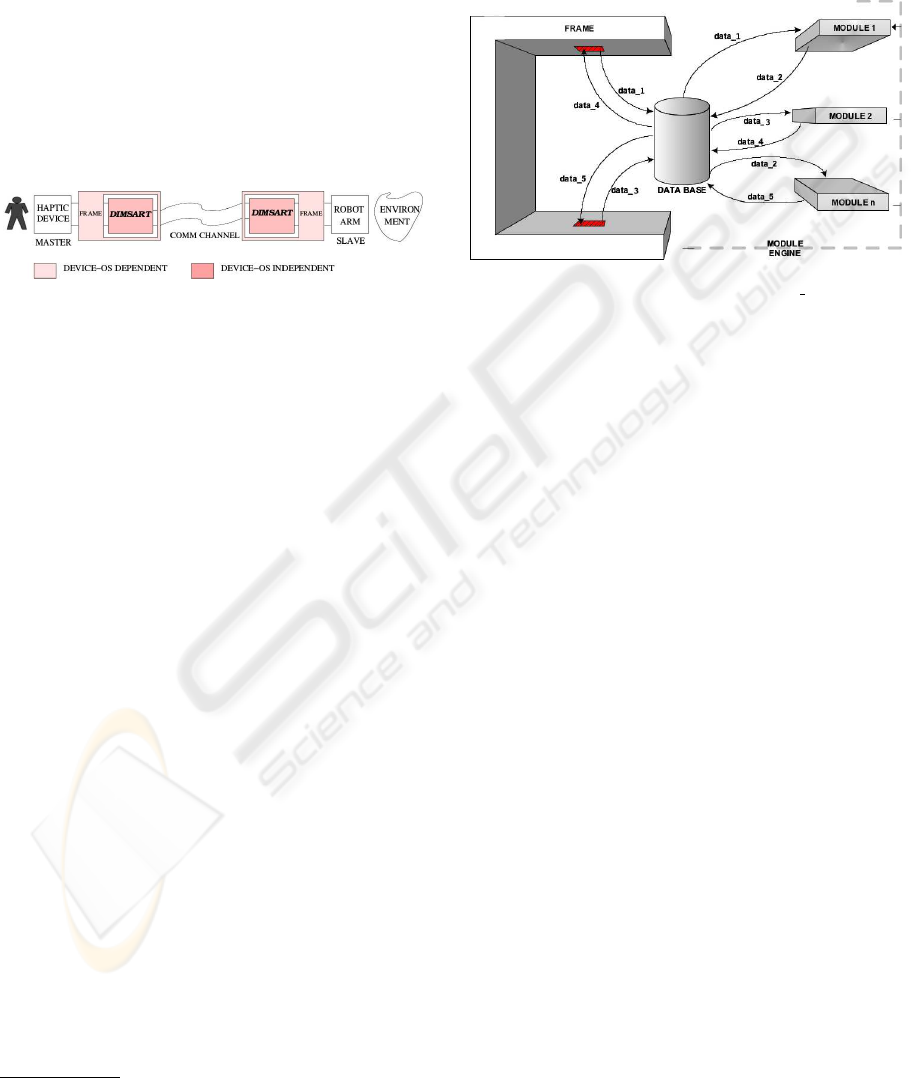

At this point, we are ready to concretely define

specific requirements for the architecture, as well

as its location in a robotic scheme. Fig.4 shows

the introduced bilateral control example with a

DIMSART on each side. Each DIMSART performs

the control for each side and could be running in

different operating systems.

Figure 4: Bilateral control scheme with two DIMSART: one

on the master side, one on the slave side.

Requirements

1. OS independency.

2. Device independency. This implies that the archi-

tecture can be set for any DoF

1

, I/O data types and

sampling rate.

3. Modular. Permits a Top-down control scheme de-

sign methodology. Flexibility upon the design.

4. Dynamic. Only one compilation must be needed

to construct any control scheme configuration.

5. Must allow distributed control.

3 ARCHITECTURE OVERVIEW

The DIMSART can be defined as a real time device

independent software architecture for distributed con-

trol in robotic and telerobotic applications. The cen-

tral point of the DIMSART consist of a dynamic Data

Base. Around the Data Base, there is a frame and

modules. These two kind of elements interact with

the Data Base by writing data to it or reading from

it. A module, which implements a specific control al-

gorithm, gets its input from the Data Base and writes

its output to it. The device driver (frame) also reads

and writes from and to the Data Base in a similar

manner. The modules are sequentially called by a

Module Engine and transform the input data to

produce their output. The following subsections de-

scribe each element mentioned above. Fig.5 is a block

1

DoF: Degrees of Freedom

diagram of the DIMSART overview. Furthermore, in

a higher layer, a GUI has been developed to configure

the robotic control scheme. The user can choose from

a list of read-to-use modules which ones to activate,

and configuration parameters can also be set for each

module.

Figure 5: DIMSART Concept Diagram. ”data x” stands for

data types.

3.1 Modules

In this framework, a Module is a piece of software

intended to perform real time operations. As already

mentioned, the module is the data processing unit of

the DIMSART. The range of possible functionalities

of a module is quite wide. Some examples are control

algorithms such as P, PD, PID controllers for robots

or haptic devices; simulation of an environment

such as a virtual wall; a magnitude converter such

as a data normalizer for sending data through a

network; a numerical integrator or derivator such as a

velocity-to-position converter; a wave transformer as

the one shown in fig.2.

There are two types of data with which the Module

interacts: internal local data, which stores config-

uration parameters of the module and is located in

the same module, and the data to process, which

is stored in the Data Base. The real time main op-

erations of a module can be synthesized in three steps:

1) Read: read data from the Data Base.

2) Compute: process the data to perform the control.

3) Write: write the output data to the Data Base.

The type or types of data which the module

extracts from the Data Base, and later the types to be

written, are defined in its activate function. There,

the module tells the Data Base the data type or types

which need to be read, and the type or types which

are to be written.

DIMSART: A REAL TIME - DEVICE INDEPENDENT MODULAR SOFTWARE ARCHITECTURE FOR ROBOTIC

AND TELEROBOTIC APPLICATIONS

105

Moreover, as it will be seen in section 3.3, the

Module Engine provides a mechanism for com-

municating with the active modules. By means of

a Command interface, the user will be able to send

commands from the frame space to a specific mod-

ule. These commands are internally defined in the

module, and they are thought to set the configuration

parameters of the module (in the previous example, a

Command could be used to set the constants of the

PD Controller, or to specify the configuration of the

Wave Transformer).

Once the DIMSART is loaded in a robotic system,

any control engineer can easily implement a module

by simply following a module pattern in a pure ”write

your code here” style. The aim of the DIMSART is to

create a list of modules, from which control engineers

will be able to build complex control schemes by

choosing and combining modules from this list.

Thus, a chain or sequence of modules will be created

to perform the control task of a robotic application.

As it will be seen in the following subsections, after

a module ”library” is created, the user will be able to

activate and deactivate modules in a plug-in/ plug-out

methodology.

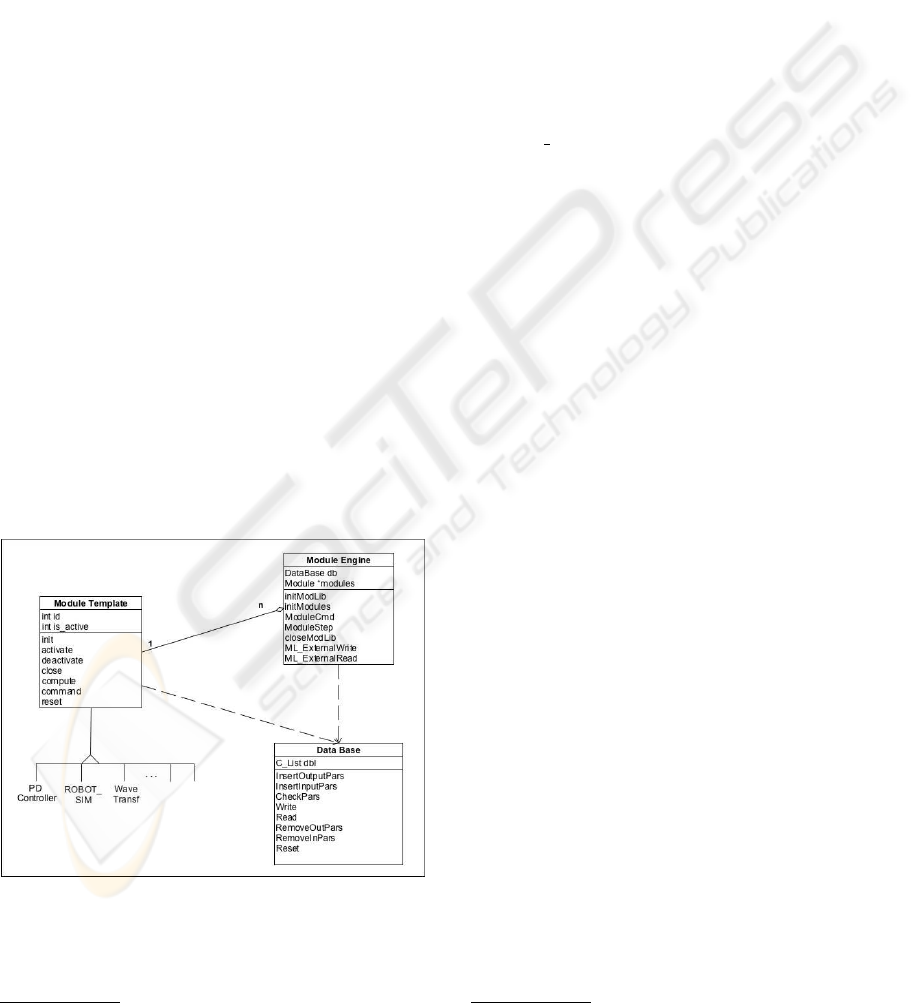

Module Template

As already stated, every control block has simi-

lar characteristics. The Module Template formalizes

the base of every module in an object oriented way.

The class

2

struct Module is declared here with a

group of functions and some attributes (see fig.6).

Figure 6: Class-like Diagram of the DIMSART

2

Simulated class in C code

3.1.1 Initialization and Activation

Initialization of a module means that its internal

memory is allocated, and its internal variables and

constants are initialized. This process takes place

for every module belonging to the modules list

(attributed in the Module Engine, see fig.6),

during the initialization process of the DIMSART.

On the other hand, only the desired modules

for the specific control scheme will be activated.

Activate means to insert the input and output data

types needed by the module under consideration into

the Data Base. Thus the Data Base will dynam-

ically grow by means of each module activation.

The Module Engine, or more precisely, the

Module

Step function (which will be called at

every time step), will act by calling the Compute

function of each active module.

It is important to note the differences between the

tasks of the initialization and activation processes. In

order to make the DIMSART compatible with most

operating systems, the conception of these initial pro-

cesses is based on a kernel/modules

3

model of op-

erating systems like Unix or Linux (Corbet, 2001).

A kernel module in RTLinux, for instance, allocates

its memory during its insertion process. Once the

RTLinux module is inserted it should not allocate

more memory.

3.2 The Data Base

The core of the Data Base is a dynamic list which

stores the incoming data from each active module,

and the data coming from the frame (which comes

from the hardware device). Furthermore, the Data

Base incorporates a set of mechanisms for the data

interaction between the active modules and the

dynamic list. Its construction is performed during the

initialization of the Module Engine and at each

module activation processes.

During the initialization the dynamic list is created

according to a Device Descriptor of the hardware

device. In this descriptor, characteristics such as the

DoF and input and output data types are enclosed.

After the initialization process, the Data Base is

created. At this point, each time a module is activated

new data fields are created in accordance with the

data types needed by the module. Modules can

be inserted or removed at any time during system

operation (which in turn will insert or remove input

and output types into the Data Base).

3

Unix/Linux kernel modules

ICINCO 2004 - ROBOTICS AND AUTOMATION

106

Types Matching Check

The matching check function performs a test to val-

idate the coherency of the relationship between the in-

put and output types of a constructed scheme. Fig.7

presents a closer view of the master side of the ex-

ample in section 2.1. It shows the data interactions

between the blocks in the master side. The PD Con-

troller, for instance, requires position and desired po-

sition as data inputs and outputs desired force. After

the scheme is constructed, the Types matching check

ensures that some other module provides the required

data. In our example, the Wave Transformer provides

desired position to the PD Controller, and the frame

position.

Figure 7: Detailed view of the control scheme in the master

side

3.3 The Module Engine

The Module Engine is the software layer between

the driver and the Data Base and modules. Through

it, a set of capabilities are provided to control and

schedule the engine of the DIMSART from the

frame. A description of the main functionalities

and attributes follows. Refer to fig.6 to locate each

function and attribute described here.

Frame Descriptor: The frame provides to the

Module Engine a descriptor of the robot in the

Module Engine initialization function. This

descriptor contains information about the DoF of

the device, number of input and output data types,

and which types are needed by the device. With

this information, the Module Engine initializes

the Data Base.

List of Modules: During the initialization step, a list

of modules is created with all the included mod-

ules in the DIMSART software architecture from

which, the user chooses which ones to activate.

Module Step: This is the beating heart of the

Module Engine. This is the function that the

main loop of the frame calls at every time step. The

Module Step sequentially calls the Compute func-

tion of each activated Module. This is how each

one of the activated modules performs its real time

computation.

Module Command: An interface to send commands

to the DIMSART from the frame space is also pro-

vided in the Module Engine. A command can

be sent to the Module Engine, or to a specific

module as seen in section 3.1. By sending com-

mands to the Module Engine, the user will be

able to set the configuration of the control scheme.

Some of the most representative commands are the

activation and deactivation of a module, the reset

of a module, or the initialization or the close of the

DIMSART.

Frame Communication: The hardware driver or a

user space (the frame) communicates with the Data

Base in a similar way as the modules do. These

communication mechanisms are also provided in

the Module Engine.

3.4 The Frame

The frame, as indicated in section 2.2, is a space

which joins elements belonging to the hardware de-

vice communication, to the network communication,

and to the DIMSART architecture. The main func-

tions of a frame are outlined here.

- Initialization of the hardware device.

- Initialization of the DIMSART.

- Interaction with the Data Base.

- Call of the Module Step (see sec. 3.3) in every

time step.

- Close the DIMSART.

- Close the hardware device.

The initialization of the DIMSART needs to know

the device characteristics. This is done through the

Device Descriptor (defined in the frame), in which

the following data is enclosed: number of degrees of

freedom of the device; input data types needed by

the frame, which is the data to be commanded to the

device; and output data types, which is the data to be

processed by the active modules in the DIMSART.

The interaction with the Data Base is the read and

write mechanisms for the frame. Two ”external” func-

tions are provided for this purpose. To review the

above concepts, the following code corresponding to

the example presented in section 2.1, shows how a de-

vice driver with a DIMSART embedded should look

like.

init_funct(DevDescr){

dev_open(&Phantom);

dev_init(&Phantom);

initModLib(&DevDescr); /*ini DataBase*/

initModules(&initarg); /*ini all mods*/

cmd.ModNr=MOD_ENGINE;

cmd.ParamNr=MOD_ON;

DIMSART: A REAL TIME - DEVICE INDEPENDENT MODULAR SOFTWARE ARCHITECTURE FOR ROBOTIC

AND TELEROBOTIC APPLICATIONS

107

cmd.Value=PDctrl;

ModuleCmd(&cmd); /*Activates PD ctlr*/

/*Other mod activations go here*/.

}

main_interrupt_thread(arg){

/* Some inis */

Read_Comm(inwaves);

Robot_read(pos);

DB_ext_write(pos,inwaves);

Module_Step(); /*compute active mods*/

DB_ext_read(force,outwaves);

Write_Comm();

Robot_Command(force);

}

DB

ext write : Writes the device output data to the

Data Base (position in the example).

Module Step : function which schedules all active

modules (in the previous example the compute

function of the modules PD Controller and Wave

Transformer are called).

DB ext read : Reads the device input data from the

Data Base (desired force in the example.)

The data coming from the robot is no longer in the

driver, but instead in a data container, from which

other elements will be able to read. Thus, a software

boundary between the frame and the DIMSART is de-

fined.

4 EXAMPLE

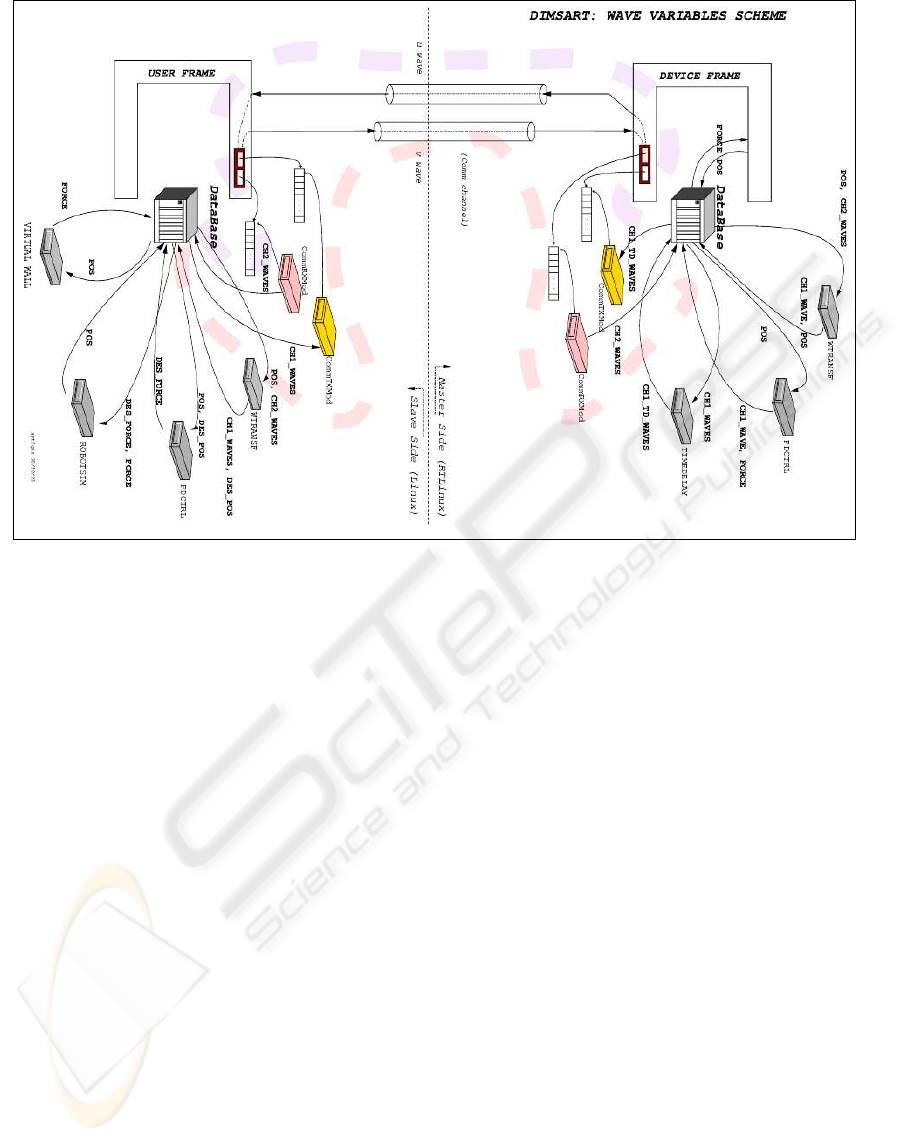

Fig.8 shows the complete scheme for the above pre-

sented Wave Variables scheme example, and table

1 its Commands configuration. The system is dis-

tributed within two computers, each one running a

DIMSART architecture. The computer governing the

master is equipped with a RTLinux OS. The slave

runs under Linux. On the master side there is a frame

driving a PHANToM 3DoF (Massie and Salisbury,

1994) as a master device with a DIMSART configura-

tion. The communication between master and slave is

performed through UDP sockets . On the slave side, a

user frame governing a DIMSART is used to simulate

a slave robot and a virtual environment. This specific

scheme was built for testing the performance of the

Wave Variables control scheme as well as for verify-

ing the modular container approach of the DIMSART.

As it can be seen, the communication between the

two sides is performed through some dedicated mod-

ules. These two modules provide the interface be-

tween the DIMSART and the communication chan-

nel.

Table 1: Master and slave Commands configuration. Dest

is destination. m&s means master and slave. MOD

ON, for

instance, activates the module.

Dest. Module Command Value

m&s COMM RXMOD CRX ADD DATA CH2 WAVES

m&s MOD ENG MOD ON COMM RXMOD

m&s WTRANSF MOD B PARAM 10

master WTRANSF MOD CONF MODE MASTER

slave WTRANSF MOD CONF MODE SLAVE

m&s MOD ENG MOD ON WTRANSF MOD

master PDCTRL MOD K PARAM 3000

slave PDCTRL MOD K PARAM 5000

m&s MOD ENG MOD ON PDCTRL MOD

master TIMEDELAY MOD TD PARAM 10

master MOD ENG MOD ON TIMEDELAY MOD

m&s COMM TXMOD CTX ADD DATA CH1 TD WAVES

m&s MOD ENG MOD ON COMM TXMOD

m&s MOD ENG MATCHING CHECK /

5 CONCLUDING REMARKS AND

REMAINING ASPECTS

The DIMSART has been presented in this pa-

per. It provides a solution to embed a robotic or

telerobotic control scheme in a hardware device-

OS-communication channel configuration. Indepen-

dence, distributed control, dynamics and flexibility

are values provided to the architecture. The system

performance depends on several parameters which

may vary in every particular scheme. The number of

degrees of freedom, the number of active modules

and the length of the active modules influence the

system performance. The system has been tested

in several robotic and telerobotic contexts and has

shown good performance. One of them has been

presented in this paper as an example and as a tool to

describe the DIMSART architecture to the reader. A

very representative application is the ROKVISS

4

, a

Telepresence experiment in which a force feedback

joystick on Earth is to be controlled with the DIM-

SART architecture, and a 2 DoF robot, which will be

mounted on the ISS is also to be controlled with the

same architecture. For detailed information about the

ROKVISS experiment see (Preusche et al., 2003).

Future work for DIMSART will include several as-

pects. ”Online” module compilation and the exten-

sion of the Data Base to multiple data formats and

dimensions are issues which are already being devel-

oped. Future lines could extend the DIMSART to

high level control and multi-thread architectures.

4

Robotic Component Verification on the International

Space Station (ISS)

ICINCO 2004 - ROBOTICS AND AUTOMATION

108

Figure 8: A real bilateral DIMSART setup

REFERENCES

Albu, J., Lumia, R., and McCain, H. (1988). Hierarchical

control of intelligent machines applied to space station

telerobots. Transactions on Aerospace and Electronic

Systems, 24(24):535–541.

Artigas, J. (2003). Development and implementation of

bilateral control using the wave variables therory in

the rokviss experiment. Internal publication, DLR

(German Aerospace Center) - Insitute of Robotics and

Mechatronics.

Borrelly, J.-J.,

´

Eve Coste-Mani

`

ere, Espiau, B., Kapellos, K.,

Pissard-Gibollet, R., Simon, D., and Turro, N. (1998).

The orccad architecture. The International Journal of

Robotics Research, 17(4):338–359.

Brooks, R. A. (1986). A robust layered control system for a

mobile robot. IEEE Journal of Robotics and Automa-

tion, 2(1):14–23.

Corbet, A. R. . J. (2001). Linux Device Drivers, 2nd Edition.

Number 0-59600-008-1.

`

Eve Coste-Mani

`

ere and Redi Simmons (2000). Architec-

ture, the backbone of robotic systems. In Proceed-

ings of the 2000 IEEE International Conference on

Robotics and Automation, San Francisco, CA.

Massie, T. and Salisbury, J. (1994). The phantom haptic in-

terface: A device for probing virtual objects. In Pro-

ceedings of the ASME International Mechanical En-

gineering Congress and Exhibition, pages 295–302,

Chicago.

Niemeyer, G. (1996). Using Wave Variables in Time De-

layed force Reflecting Teleoperation. PhD thesis, Mas-

sachussetts Institute of Technology.

Preusche, C., Reintsema, D., Landzettel, K., and Hirzinger,

G. (2003). Rokviss - towards telepresence control in

advanced space missions. In Humanoids 2003 - The

Third IEEE International Conference on Humanoid

Robots, Munich, Karlsruhe (Germany).

RTI (2004). Constellation. www.rti.com/products/ constel-

lation/index.html.

Schneider, S. A., Chen, V. W., Pardo-Castellote, G.,

and Wang, H. H. (1998). Controlshell: A soft-

ware architecture for complex electromechanical sys-

tems. The International Journal of Robotics Research,

17(4):360–380.

Scholl, K.-U. (2001). MCA2 (Modular Controller Architec-

ture). Software platform. http://mca2.sourceforge.net.

Stasse, O. and Kuniyoshi, Y. (2000). Predn: Achieving effi-

ciency and code re-usability in a programming system

for complex robotic applications. In Proceedings of

the 2000 IEEE International Conference on Robotics

and Automation, San Francisco, CA.

Volpe, R., Nesnas, I., Estlin, T., Mutz, D., Petras, R., and

Das, H. (2001). The claraty architecture for robotic

autonomy. In 2001 Aerospace Conference IEEE Pro-

ceedings, pages 1/121–1/132.

DIMSART: A REAL TIME - DEVICE INDEPENDENT MODULAR SOFTWARE ARCHITECTURE FOR ROBOTIC

AND TELEROBOTIC APPLICATIONS

109