INTELLIGENT ELECTRIC DRIVE SYSTEM

A mechatronics approach

Guy Reginald Dunlop

Department of Mechanical Engineering, Universityof Canterbury, PB4800, Christchurch, New Zealand

Keywords: Mechatronics, Robotics, Intelligent drives, Model based control

Abstract: Drive efficiency is an important consideration in most robotic applications. A hybrid controller for

permanent magnet DC motors has been developed to control the current, and hence the output torque of the

motor. An H bridge is used to provide the basic PWM voltage to the motor, and the controller switches the

bridge between bipolar and unipolar modes in order to minimise the switching losses within the bridge and

motor, and also to minimise the electromagnetic interference. The first application presented is for a

walking robot, and the second is for a dexterous robotic hand. In both cases, control is obtained from a

voltage sourced inverter by means of a tight control loop that uses position readings to infer velocity so that

a full DC motor model can be utilised in the control computer. For the dexterous hand, current control is by

model prediction to avoid the need for direct measurement. The controller and communications are

contained within a small programmable system on a chip which together with a dual H bridge driver is

integrated into small circuit board that is used for distributed control within the hand.

1 INTRODUCTION

Most robots being manufactured are using

permanent magnet electric drives, either DC or

brushless DC. The ideas presented in this paper

apply to both types of drive but discussion will be

restricted to the brushed DC motor.

Figure 1: The walking robot Hamlet.

The walking machine Hamlet (Fielding and

Dunlop, 2002) shown in fig. 1 utilises 18 electric

motors. It has 6 legs each of which is operated by 3

DC motors. These can be clearly seen in the

photograph. Each motor contains an integral shaft

position encoder that provides position information

for the kinematic calculations. The position

information from a motor is also used to derive the

velocity of the motor for use in the velocity servo

loop contained inside the position feedback servo

control loop. Hamlet was designed to explore the

omnidirectional walking gaits of insects (Fielding

and Dunlop, 2004) and as such it moves so slowly

that regenerative energy issues need not be

considered. The walker used 6 FPGA (field

programmable array) units to control the 6 legs. The

controllers communicated with off board DSPs via a

single high speed serial bus and the control and

kinematic decisions were computed on the DSPs.

The H bridges were driven in bipolar mode (see

section 2) and were robust enough to withstand brief

current surges during speed reversals or changes.

41

Dunlop G. (2004).

INTELLIGENT ELECTRIC DRIVE SYSTEM - A mechatronics approach.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 41-48

DOI: 10.5220/0001147900410048

Copyright

c

SciTePress

Figure 2: The dexterous Canterbury hand.

The miniature motors within the dexterous hand

shown in fig. 2 are difficult to control as they have

low inertia ironless rotors that have a low “thermal

mass” and are easily overheated. A thermal model

was needed to prevent this, and crucial to its

operation, was precise control of the current in the

motor to reduce resistive heating.

There are a total of 11 DC motors in the hand

and 7 computers so temperature control is of some

importance. As shown in fig.3, each finger contains

2 DC motors with a computer and driver unit. The

heating of the motor armature during the current

pulse needed to break joint stiction is transient, but

the resulting temperature step is superimposed on

top of the temperature within the hand. The need to

minimise the temperature within the enclosed hand

palm space lead to the development a very efficient

drive system using a hybrid switching scheme for

the DC motors. The various motor driving schemes

are discussed in the next section followed by the

application of models for current control which are

presented along with simulation results.

2 BASIC DRIVE STRUCTURE

The purpose of any rotary actuator used in robotics

is to produce torque and speed in a well controlled

manner. This requires four quadrant control of the

torque-speed characteristics of the driver and motor

combination as shown in fig.5(a). No matter which

kind of drive is used, none can handle situation

where the load can drive the motor at a speed where

the back emf is greater than the supply voltage

unless additional overvoltage circuitry is added,

something not required here.

Some commercial constant current IC drivers

provide only two quadrant motor control and can be

destroyed during regenerative operation when

kinetic energy from the motor and robot is absorbed

by the drive. The usual way to avoid this problem is

to use a bipolar drive system that switches at

ultrasonic frequencies so that four quadrant control

is always achieved. However, the cost is more heat

than for a unipolar drive system.

The H bridge driver shown in fig. 4 (4 FETs or

field effect transistors form the left and right

uprights and the motor the cross bar) requires only a

single voltage supply. This is the most commonly

used type of DC motor driver as it uses switching

which is much more efficient than analog amplifier

control. In operation, if FET 1 is on, then FET 3 is

off, and vice versa. Similarly for FETs 2 and 4. The

difference between unipolar and bipolar drive

schemes has been discussed in detail by Tal, and

Persson (1978) so only a brief outline is given here.

Figure 3: A finger from the hand showing the 2 DC motors and the control computer and driver PCB.

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

42

t

V

18

-18

6

(b) Bipolar PWM

t

V

18

-18

6

(b) Bipolar PWM

t

V

18

0

12

(c) Unipolar PWM +ve

t

V

18

0

12

(c) Unipolar PWM +ve

ω

τ

Bipolar

Unipolar

Unipolar

(a)

τ

= - (k

2

/R)

ω

Bipolar

ω

τ

Bipolar

Unipolar

Unipolar

(a)

τ

= - (k

2

/R)

ω

Bipolar

t

V

-

6

-

18

0

(d) Unipolar PWM -ve

t

V

-

6

-

18

0

(d) Unipolar PWM -ve

Figure 5: Four quadrant torque-speed plot. Motoring is

in quadrants 1 and 3 of (a), and regenerative braking in

quadrants 2 and 4. Efficient operation is obtained by using

the unipolar PWM mode and switching to bipolar mode

for the cross hatched regions in quadrants 2 and 4.

2.1 Bipolar Drives

When operated as a bipolar drive, both sides of the

H bridge are switched on and off in antiphase with

each other so that each end of the motor is connected

alternately between zero volts and the supply

voltage. The FETs act as switches for the current

through the DC motor. FETs 1 and 2 are switched on

for a time

τ

s every T s, and then FETs 3 and 4 are

on for the remaining (T -

τ

)

s as shown in fig.5(b).

The PWM (pulse width modulation) ratio is defined

as

τ

/T and it is usual to chose T < 50 µs so that the

switching is not audible. Neglecting the small

voltage drops across the FETs and diodes (they are

intrinsic to the FET), the governing equation for the

average voltage across the motor is:

V

av

= [

τ

/T – 0.5] V

supply

(1)

2.2 Unipolar Drives

CY8C26643

L6024D (½)

8 bit

PWM

18V

Quadrature Encoder

DC

motor

1

0

FET 4

FET 1

FET 3

FET 2

Figure 4: The control computer, the DC motor and

encoder

,

and the H brid

g

e

(

half an L6024D IC

)

.

The unipolar drive switches only one side of the H

bridge. Referring to fig.4, the PWM signal is applied

to FETs 1 and 3, while the sign of the average

voltage applied to (and steady state current through)

the motor is set by FET2. This halves the switching

losses and heating is reduced. When operating at

steady state with positive speed and torque (c.f.

fig.5a), FET 2 is switched on (by setting logic 1 out)

for a positive voltage applied to the motor. The

voltage waveform is shown in fig.5(c).

The PWM signal is applied to FETs 1 and 3 so

that the current through the motor increases

whenever FET 1 is switched on, and decreases when

ever FET 3 is on. The decaying current is able to

circulate around the loop that includes the motor,

and FETs 2 and 3. Only the back emf of the motor

opposes the current and causes it to decay. The

governing equation is:

V

av

= [τ/T] V

supply

(2)

To obtain a negative speed and torque, FET 4

is switched on by selecting logic 0. Switching FET 3

on then causes the magnitude of the negative current

to increase with the negative voltage as shown in

fig.5(d). Switching FET 1 on provides a path for

INTELLIGENT ELECTRIC DRIVE SYSTEM - A mechatronics approach

43

Table 1: Drive switching scheme comparisons.

Control

Scheme

Avantages Disadvantages

Bipolar Good current

control

Faster switching

More heat

More EMI

Unipolar Slower switching

Less heat

Reduced EMI

No current

control

during

regeneration

Hybrid Good current

control

Slower switching

Less heat

Reduced EMI

More complex

circuitry

0 0.001 0.002 0.003 0.004 0.005

-20

0

20

40

60

80

100

120

140

seconds

Current demand, motor current and speed

i

ω

i

d

Figure 6: Over current during speed reversal with a

unipolar drive and a large motor as id steps from -

10A to +10A and ω chan

g

es slowl

y

from -10 to +10

recirculation of the motor current through FETs 1

and 4. The governing equation is then:

V

av

= [τ/T-1] V

supply

(3)

The problems with unipolar drives arise when

the motor speed needs to be reversed and the

reversed current is established by a voltage reversal

before the rotation direction has time to change. This

happens (in quadrants 2 and 4) as the current

magnitude increases when the supply is placed

across the motor, but current still increases (at a

slower rate) when recirculating as the back emf is

now assisting the current. The result is a continual

increase in the current until the motor slows and

reverses. Currents of 40A have been measured

(immediately before destruction) in a commercial IC

rated for 3A in quadrants 1 and 3. The effect has

been simulated for a large motor and the results

presented in fig.6. The mechanism for this is found

from the DC motor equations:

V

a

= Ri + L di/dt + k

ω

(4)

Γ

= ki (5)

where

ω

is the motor speed in rads/s, k

ω

the back

emf of the motor, and

Γ

the torque output by the

motor. When connected to the supply, the armature

voltage V

a

= +V

supply

, and when recirculating the

current, V

a

= 0. Consider a change from negative

speed to positive speed: In quadrant 3 the speed is

still negative while the current has become positive,

so when V

a

= 0, the equation 4 becomes:

di/dt = -[kω + Ri]/L (6)

Since ω is large and negative, the current magnitude

will increase during the recirculate period until the

back emf falls to the voltage drop across the

resistance in the current recirculation loop. Equality

occurs when k

ω

= -Ri or

Γ

= -k

2

ω

(7)

This is shown as the dashed line in the 4 quadrant

torque speed plot in fig.5(a).

3 HYBRID SWITCH CONTROL

The novel approach adopted Dunlop and Cree

(1997) is to switch between bipolar and unipolar

control modes as required. The current through the

motor is measured and used to switch from unipolar

mode (cross hatched area in fig.5a) to bipolar mode

when operation moves into the diagonally hatched

area shown in quadrants 2 and 4 of fig.5(a). The

detailed switching operation is illustrated in fig. 7

for a step change in demand current from -10A to

+10A for the same large motor used for fig.6. Notice

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

44

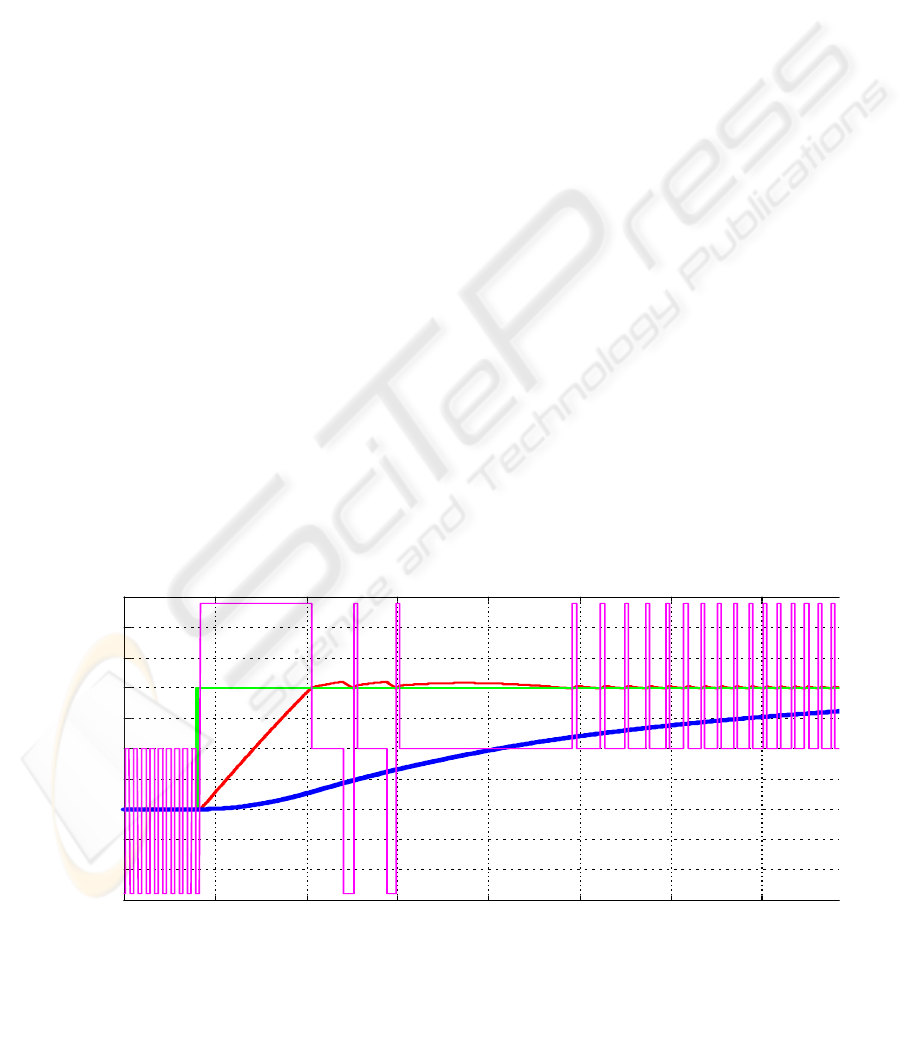

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0

-25

-20

-15

-10

-5

0

5

10

15

20

25

Figure 7: The rapidly switching line represents the motor drive voltage in response to the step reversal in

current demand, the sloping line from -10A to +10A is the motor current, and the wide line from -10 to

+10rads/s is the motor speed.

that the current is fully controlled and that not much

extra bipolar switching is required. The advantages

and disadvantages of the 3 switching modes are

listed in table 1.

The hardware used did not switch both sides at

the same time so the negative voltage step changes

were limited to V

supply

at any one time rather than

2V

supply

for the bipolar drive. Software control can

apply this to all bipolar drives and reduce

electromagnetic interference from the drive.

The application of this hybrid switching

technique to the hand precluded fast measurements

of the motor current which changed very rapidly in

the small motors that have low values of motor

inductance L and relatively high resistance R. Such

rapid current changes would require specialized

hardware to track and control the current as was

done by Dunlop and Cree. It would also need to

operate an order of magnitude faster than for the

larger motors tested with the hardware.

In order to reduce the hardware and heating

requirements in the walker and hand, a model of the

DC motor was used to calculate the motor voltage

required for a given speed state and for the

maximum torque available to change that speed. The

maximum allowable current through the motor is

used to achieve the speed change and that value

must not be exceeded or excessive heating can

destroy the motor. Software is then used to switch

from unipolar driving to bipolar operation as the

motor starts regenerating i.e. operating within

diagonal hatched area in quadrants 2 and 4 in

fig.5(a). As shown in fig.4, the output of the PWM is

applied to FETs 1 and 3, while FETs 2 and 4 can be

driven high or low to set the current direction for a

unipolar drive depending on whether the signal is

connected to logic 1 or 0 by software inside the

CY8C6643 PSoC processor (programmable system

on a chip c.f. Cypress Microsystems). When a

bipolar drive is needed, the PWM is inverted and

applied to FETs 2 and 4. Revision to a unipolar drive

is simply a matter of by passing the inverted PWM

signal and setting the processor output to 0 or 1 for

FETs 2 and 4.

4 MODEL CONTROL

It is desirable to avoid using extra hardware for the

direct measurement of the current in the motors.

This lead to the development of model control for

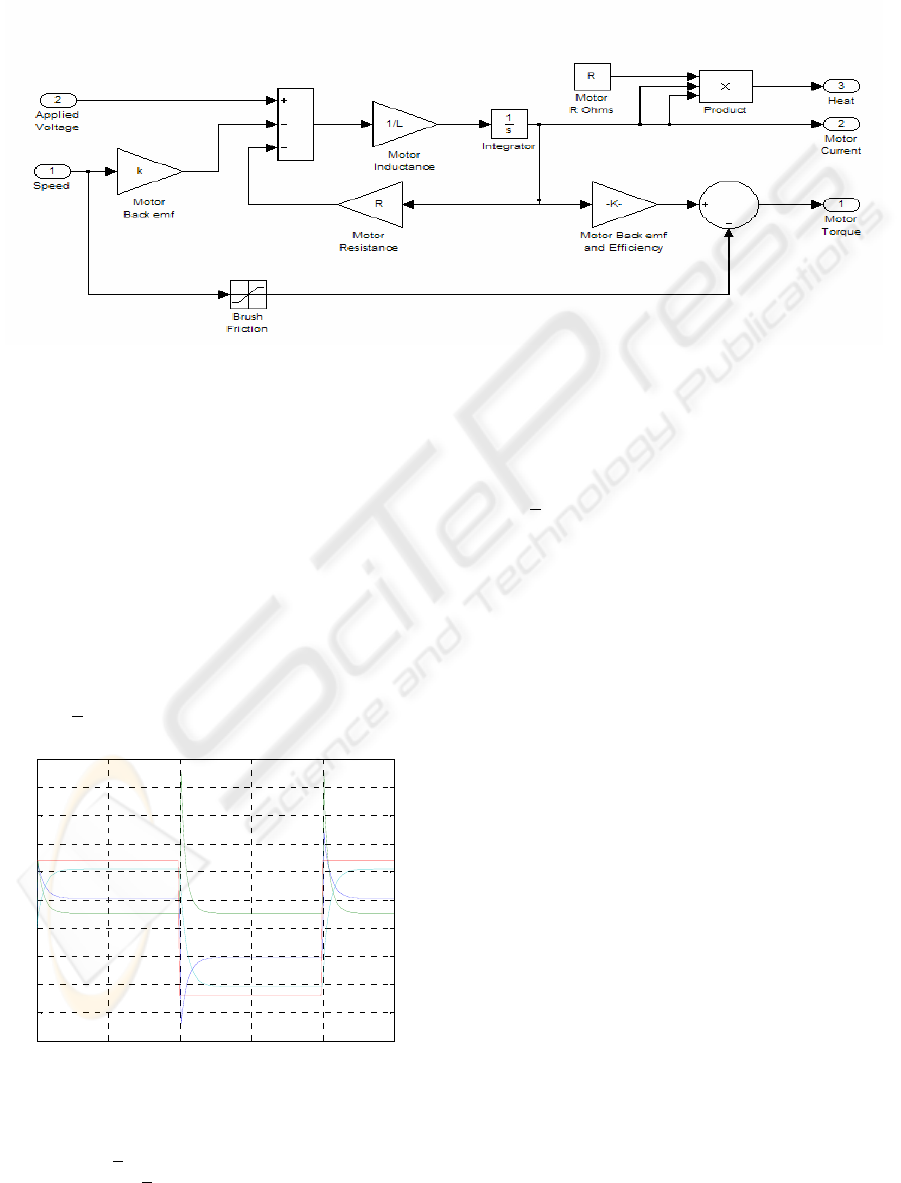

the 11 DC motors in the dexterous hand. A Simulink

model of the DC motor used in the hand (a

Minimotor 1016 012G) is shown in fig.8. The

leadscrew driven linkages in the finger have a slight

effect on the motor and gearbox, and almost none

during regenerative braking as plain lead screws are

not easily back drive. The main effect is the motor

and gearbox inertia. The basic DC model includes

the thermal power output by the armature resistance,

and the effect of brush and bearing friction. This

friction is overcome by the specified “no load”

current but, as seen from equation 5, the no load

current is zero. In fact the friction must be overcome

and the “no load” current is required to do this. The

friction is modeled as Coulomb friction which

opposes the motion and decreases the torque

INTELLIGENT ELECTRIC DRIVE SYSTEM - A mechatronics approach

45

available for motoring in quadrants 1 and 3 of the

torque-speed diagram shown in fig.5(a). The friction

increases the braking during regenerative operation

in quadrants 2 and 4.

Figure 8: Simulink model of the Minimotor includes brush friction to account for no the load torque output.

When the voltage applied to the motor undergoes

changes from +12V to -12V, the motor speed

demand undergoes a step change from 1050 rads/s to

-1050 rads/s as shown in fig.9, and the motor current

peaks at 0.16A. The heating associated with these

peaks during regeneration are a maximum of 2.8W

and the average power is 0.38W for 0.1s reverse

cycling. This is to be compared to the steady state

running value of 0.26W. Thus an increase of 46% of

heat in the motor must be dissipated which equates

to a 46% rise in the temperature above ambient.

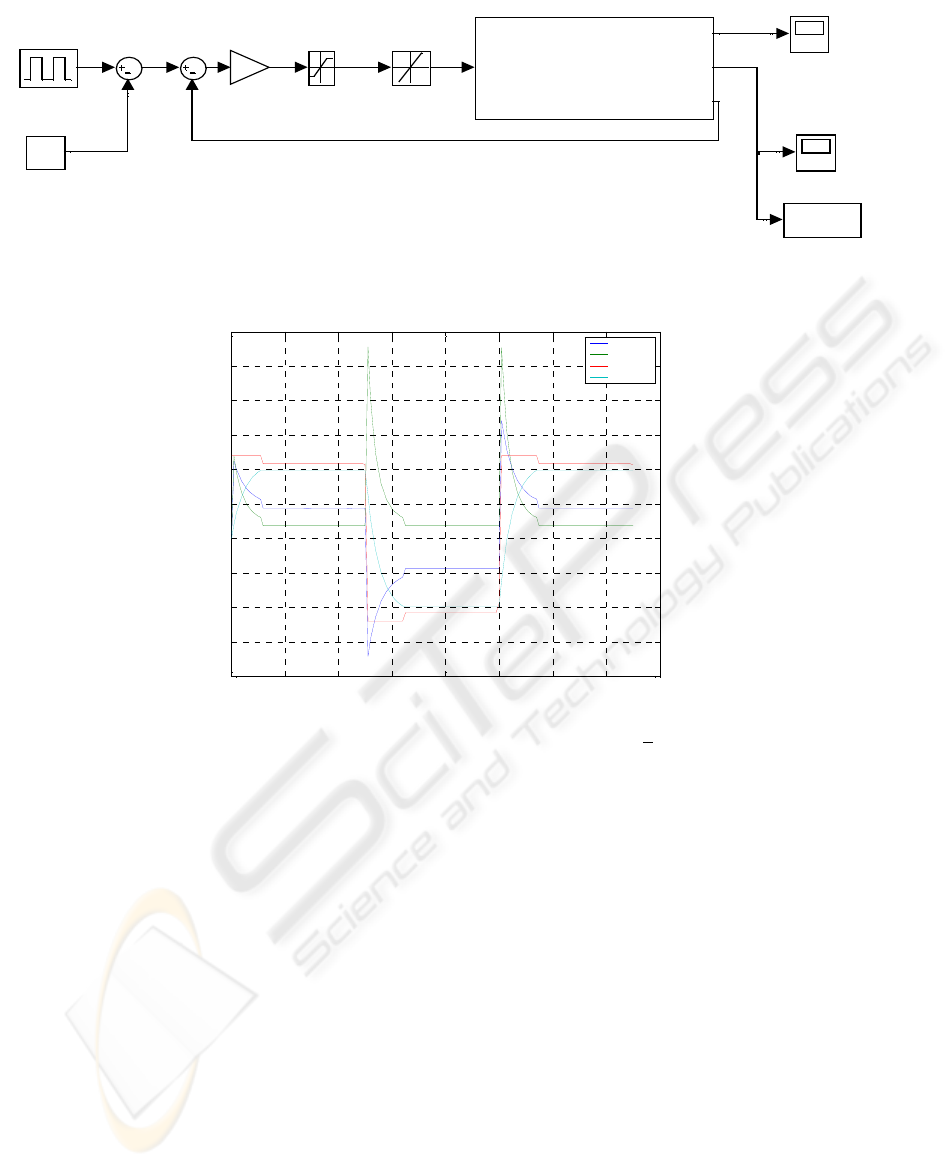

This model is placed inside a simple speed

control loop as shown in fig.10. The voltage is

limited to

+12V which is the supply voltage for the

test motor. The rate of change of the voltage applied

to the DC motor is also limited to eliminate

numerical problems associated with both the

Simulink model, and in the PSoC controller which

converts the model voltage into PWM signals for the

H bridge. The short term average of the H bridge

output matches the voltage computed in the speed

control loop. The performance for motor speed

changes

+1000 rads/s is shown in fig.11(a). There

are still large current peaks and the peak power is

2.8W with an average of 0.35W. Some improvement

is needed.

Although this short speed reversing cycle is

somewhat extreme, it does show the various factors

that come into play. The main factor is to limit the

voltage by a known amount relative to the back emf

so that the current can be limited. Rather than

applying a step of voltage to the motor, the voltage

can be changed slowly to match the speed changes.

0 0.05 0.1 0.15 0.2 0.25

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

2.5

3

seconds

Figure 9: Responses of the control system and load to

rectangular demands for speed change. From the top at

50 ms, the traces are: V

a

the average voltage applied to

the motor (

+12V),

ω

the motor speed in krads/s, i the

motor current (

+50mA), and the heat produced in the

armature windings in Watts.

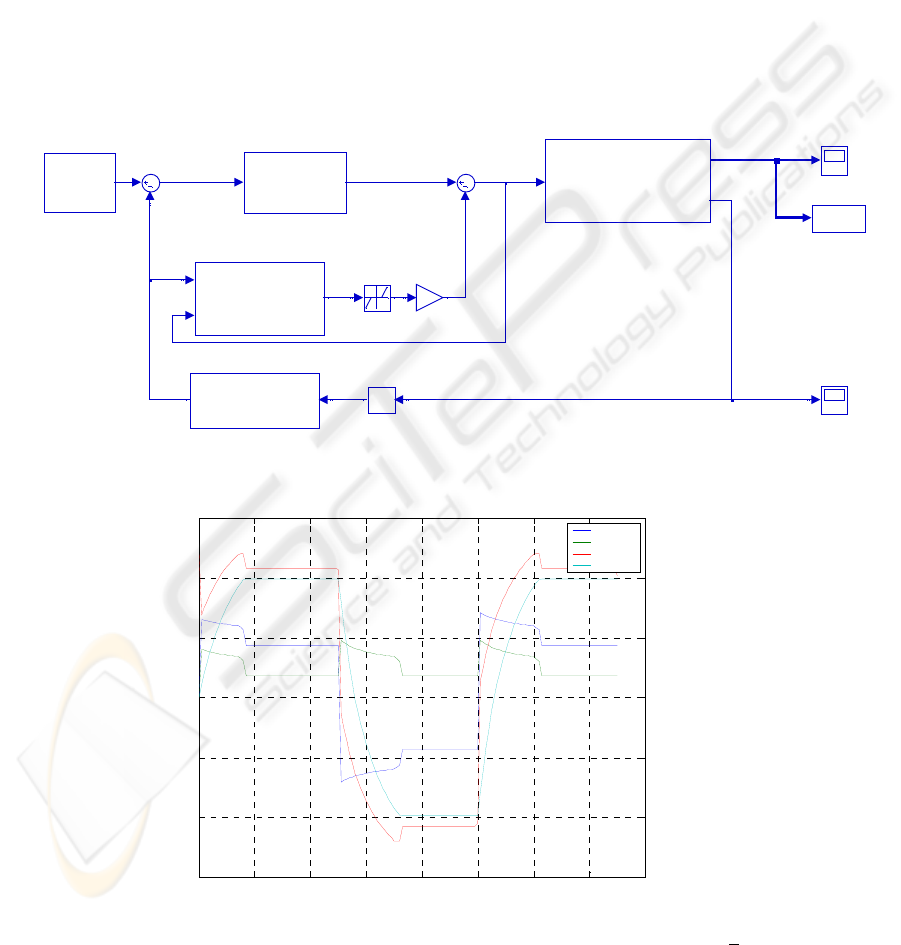

The Simulink model shown in fig.12 contains a

sub loop to control the voltage demand. This is

simply a model of the electrical part of the motor

with no provision for friction. The derivative of the

shaft position output from the gearbox is used to

derive the speed, and after adjustment for the

gearbox ration, this speed estimate is used in the

velocity feedback loop as well as in the DC motor

model that is used to estimate the motor current that

would result from the application of the voltage

output by the speed error to voltage block in fig.12

(shown as gain and limit blocks in fig.10). The

friction does not need to be modeled in the current

estimator; it is effectively taken care of since the

measured position and derived speed are already

reduced by the friction. The dead zone for the

current limit, gain and summation junction that

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

46

1

V

si m out

To Workspace

Saturation Rate Limiter

Pulse

Generator

Load

Position

Motor Voltage

Load Shaft Rotation rads

Amps Watts Volts rads/s

rads/s

DC Motor + Load Model

1000

Constant

Amps

Figure 10: A finger from the hand showing the 2 DC motors and the control computer and driver PCB.

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

2.5

3

seconds

i 0.1A

P W

Va 10V

w rads/s

Figure 11: Speed demand is 0 Æ+1000Æ-1000Æ+1000 rads/s. The drive saturates at

+12V. The peak and average

power dissipation is 3.5W, average of 0.35W using the controller in fig.10. The peak current is 0.17A

follow the estimator are used to decrease the voltage

if excessive motor current would result from directly

applying the demand voltage.

5 DISCUSSION

The use of a velocity control loop within a position

control loop ensures that good positioning

performance can be attained. Hower, large speed

demands translate into large voltages being applied

to the DC motor, and this can give rise to large

currents, and excessive heating. The use of a current

estimator that has the voltage demand and the actual

motor speed as inputs has been shown to provide

good estimates of the current that would occur

should the demand voltage be placed on the actual

motor and load. A dead zone is used to process the

estimated current so that no output occurs unless the

specified motor current limits are exceeded (note

that the limits used here are for inside the hand, not

those specified by Minimotor for a motor with free

air circulation). When the estimated current exceeds

the limits set, then the excess current value is

converted to a voltage that is subtracted from the

demand voltage to give a modified voltage for

application to the actual motor.

6 CONCLUSION

The novel approach used here has proved adequate

for control of the heat build up within a confined

space when several motors are used. Control of the

motor current was crucial for this and as

demonstrated, good control was obtained by using a

model current estimator implemented on a small

control microprocessor. The processor also allowed

for a hybrid switch control of the H bridge to be

used to further reduced the heating. The PSoC

INTELLIGENT ELECTRIC DRIVE SYSTEM - A mechatronics approach

47

controller converts this modified voltage to a PWM

value. It also takes into account the sign of the

voltage and the direction of rotation so that the

appropriate PWM mode can be selected.

REFERENCES

Tal, J., and Persson, E.K., 1978. Pulsewidth modulated

amplifier for DC servo systems. Proc. 7

th

Symp. on

Incremental Motion Control Systems and Devices: DC

motors and control systems, Eds. B.C.Kuo, and J.Tal,

SRL Publishing Co., ISBN 0-918152-02-X, Vol. 1,

ch.11, pp180-200.

Fielding, M. R., and Dunlop, G. R., 2002. Omni

directional hexapod walking and efficient gaits using

restrictedness, Proc 5

th

Int. Conf. on Clinbing and

Walking Robots. ISBN 1-8600-5838-06, pp 501-508.

Fielding, M. R., and Dunlop, G. R., 2004. Omni

directional hexapod walking and efficient gaits using

restrictedness. Accepted for IJRR.

Dunlop, G. R., and Cree, A., 1997. A four quadrant

current driver for direct digital control of a DC motor.

Proc. 26

th

Symp. on Incremental Motion Control

Systems and Devices, Ed B.C.Kuo, SRL Publishing

Co., ISBN 0-931538-20-3, pp 143-150.

Cypress Microsystems www.cypressmicro.com

si m ou t

To Workspace

Speed rads/s Voltage

Speed to Voltage

Speed Required

Speed

Demand

Load

Position

Output SpeedMotor Speed

Gearbox

-K-

Gain

du/dt

Derivative

Motor Voltage

Amps Watts Volts rads/s

Load Shaft Rotation rads

DC Motor + Load Output Model

Motor Speed

Motor Voltage

Motor Am ps

DC Motor + Load Model

Current Limit

Amps

Figure 12: A finger from the hand showing the 2 DC motors and the control computer and driver PCB.

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16

-1.5

-1

-0.5

0

0.5

1

1.5

seconds

i 0.1A

P W

Va 10V

w rads/s

Figure 13: Speed demand is 0 Æ+1000Æ-1000Æ+1000 rads/s. The voltage drive saturates at

+12V. The peak e

power dissipation is 0.45W with an average of 0.25W for the controller in fig.12. The peak current is around 0.07A so

current control is greatly enhanced.

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

48