Neuro-Controller with Simultaneous Perturbation

for Robot Arm

–Learning of Kinematics

and Dynamics without Jacobian

Yutaka Maeda

1

, Nobutaka Kitajima

1

, Tsubasa Inagaki

1

and Hidenori Onishi

1

Kansai University, Faculty of Engineering,

Department of Electrical Engineering and Computer Science

Abstract. We report two control schemes for a two-link robot arm system using

a neuro-controller. We adopted the simultaneous perturbation learning rule for

a neuro-controller. Ordinary gradient type of learning rule uses Jacobian of the

objective system in a direct control scheme by a neural network. However, the

learning rule proposed here requires only two values of an error function. Without

Jacobian or related information of the objective robot arm, the neuro-controller

can learn an inverse of robot kinematics and dynamics, simultaneously. Some

results are shown.

1 Introduction

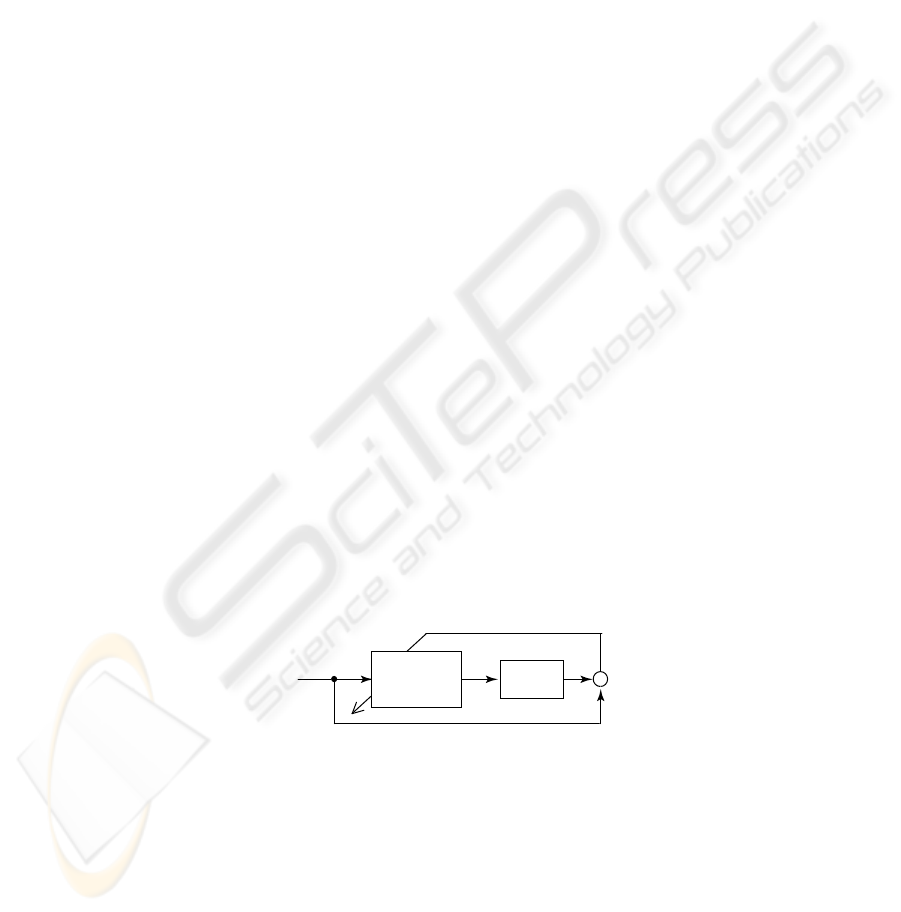

Neuro-Controller (NC) by a direct inverse control scheme (see Fig.1) is a promising

approach for non-linear control problems. When we use a gradient type of learning

rule such as the back-propagation method for the NC, it is essential to know Jacobian

or related information on an objective plant[1]. However, it is generally impossible or

very difficult to know the Jacobian especially for a nonlinear objective.

Neuro-

controller

Plant

+

-

y

u

J(w)

w

f (u)

y

d

Desired

output

Output

Error function

Fig. 1. A basic scheme for a neuro-controller.

In this paper, we propose control schemes by neural networks (NNs) using the si-

multaneous perturbation learning rule for a two link robot arm system. This learning

rule does not directly require a derivative of an error function but only values of the

Maeda Y., Kitajima N., Inagaki T. and Onishi H. (2004).

Neuro-Controller with Simultaneous Perturbation for Robot Arm Learning of Kinematics and Dynamics without Jacobian.

In Proceedings of the First International Workshop on Artificial Neural Networks: Data Preparation Techniques and Application Development, pages

16-22

DOI: 10.5220/0001149200160022

Copyright

c

SciTePress

2

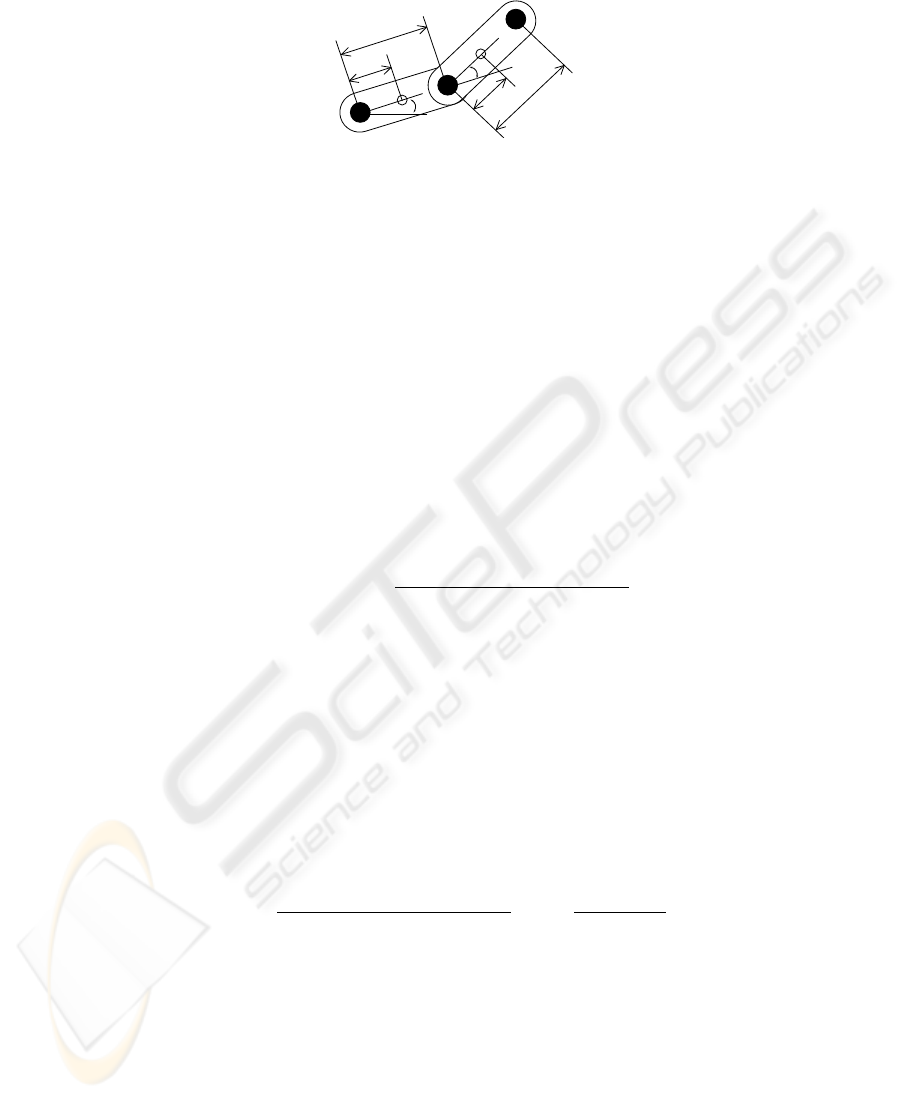

l

link-1

link-2

1

l

2

r

1

r

1

ǰ

2

ǰ

Top

Fig. 2. Two link robot arm system.

error function itself. Therefore, without knowing Jacobian of the objective system, we

can design a direct neuro-controller and then the neuro-controller can learn a robot

kinematics and a dynamics simultaneously. Moreover, the NC is able to adapt changing

environment through learning.

2 Simultaneous Perturbation for Neuro-Controller

The simultaneous perturbation(SP) and its applications are widely reported[1–4]. We

explain the SP learning rule with a sign vector for NCs. Now let w, J(·) and u be a

weight vector of the NC including thresholds, an error function and an input for the

robot arm, respectively. The learning rule via the SP is as follows;

w

t+1

= w

t

− α

J(u(w

t

+ cs

t

)) − J(u(w

t

))

c

s

t

(1)

Where, α and c are a positive learning coefficient to adjust a magnitude of a modifying

quantity and a magnitude of a perturbation, respectively. s denotes a sign vector whose

components are +1 or -1. Moreover, t is iteration.

Note that only two values of the error function J(u(w)) and J(u(w + cs)) are

used to update the weights in the neural network. Any information about the objective

plant such as Jacobian does not have to be required in this learning rule. Therefore,

this learning rule is easily applicable to the direct control scheme by NCs for a plant

including unknown and/or unmodeled factors.

It is known that the learning rule has the following property[1]. That is, the learning

rule is a kind of stochastic gradient learning rule.

E

µ

J(u(w

t

+ cs

t

)) − J(u(w

t

))

c

s

t

¶

=

∂J (u(w

t

))

∂w

(2)

Note that the SP learning rule is not a merely expansion of the ordinary finite dif-

ference approximation. In our case, we have to adjust plural parameters, that is, weight

values in the NC. The number of the weights is relatively large. If we simply use the

finite difference, we have to know many values of the error J for all weights to update.

On the other hand, the SP method requires only two values of the error, even if the

number of the weights of the NC is large.

17

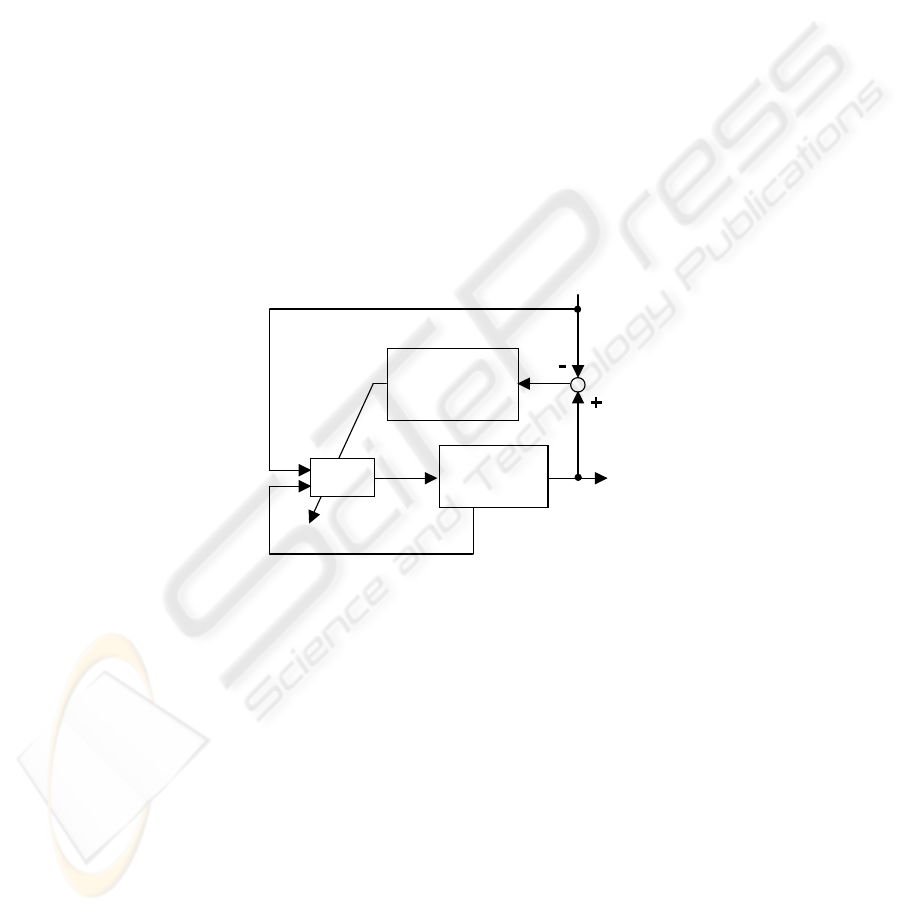

3 Control Scheme 1

3.1 Configuration

We consider the two-link robot arm (see Fig.2) as an objective nonlinear plant. Now our

problem is to control the end of the link-2 of the robot arm in Fig.2. Then purpose of

the NC is to generate proper torque values for the two links.

Fig.3 shows overall configuration of the robot system using a NC. For one trial, the

NC with certain weights outputs a series of torque signals to the robot arm. Then we

have a locus. Thus we can obtain a value of the error function as follows;

J(u(w)) =

X

i

¡

(x

i

− x

di

)

2

+ (y

i

− y

di

)

2

¢

(3)

Where, x

i

, y

i

and x

di

, y

di

denote actual position of the top and its desired position,

respectively. With the perturbation, we make a trial again and obtain a value of the error.

Using these two values and Eq.(1), we update the weights. We repeat this procedure.

d d

x , y

x, y

Simultaneous

perturbation

RNN

Robot arm

Modify weights

desired

position

torque

τ1, τ2

position

of the top

+

-

θ , θ , θ

& &&

state of the arm:

Fig. 3. Overall configuration of control scheme 1.

The objective plant has a dynamics. Therefore, a simple multi-layered neural net-

work cannot control the plant, since the network does not have any dynamics. Basically,

the NC consists of two multi-layered neural networks shown in Fig.4. However, the

neural networks have time-delayed feedback inputs from outputs of the networks. This

feedback gives dynamics to the networks.

Both networks have 14 neurons in input layer, 20 neurons in middle layer, 1 neuron

in output layer. The NC uses desired position, angles θ

1

and θ

2

, velocities of the angles

˙

θ

1

and

˙

θ

2

, accelerations of the angles

¨

θ

1

and

¨

θ

2

, time-delayed outputs of the network as

inputs. Outputs correspond to torque of the link-1 and the link-2.

18

1ðt

x

y

1

q

2

q

z

-1

z

-1

z

-1

z

-1

z

-1

z

-1

z

-1

z

-1

z

-1

z

-1

z

-1

z

-1

2

q

1

q

2

q

1

q

x

y

1

q

2

q

2

q

1

q

2

q

1

q

t

1

t

2

d

d

d

d

Fig. 4. Neuro-controller used here.

3.2 Result

We consider some practical tasks for the system. Using a proper model of the robot arm,

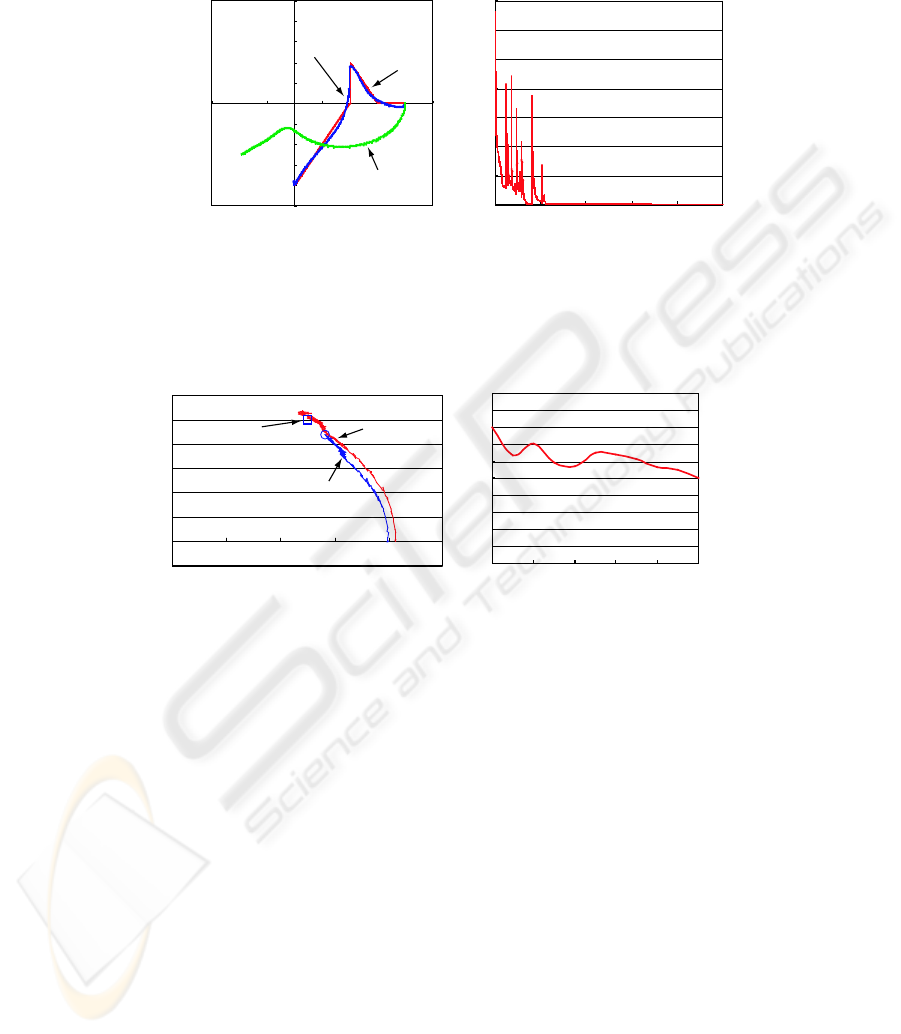

we have a simulation result(see Fig.5) for locus control. Then the learning coefficient

α = 0.0005 and the perturbation c = 0.00008. After 10000 times learning, locus of the

top is close to a desired one. The error value decreases as iteration proceeds.

Next, we consider a movement of the top to a certain point. Fig.6 shows a result

of the actual robot arm. After pre-training by simulation, the NC is used for the actual

system. Then the learning process and operations themselves are carried out simultane-

ously. α = 0.01 and c = 0.05. After 10 times learning by the actual system, the top

moves to a target point. Before the learning, the top stopped at a point that is different

from the target. As is shown in Fig.6(b), the error decreases.

The learning coefficient α and the perturbation c are determined empirically. How-

ever, the learning rule is not so sensitive to these values.

19

㪄㪇 㪅㪌

㪄㪇 㪅㪋

㪄㪇 㪅㪊

㪄㪇 㪅㪉

㪄㪇 㪅㪈

㪇

㪇㪅㪈

㪇㪅㪉

㪇㪅㪊

㪇㪅㪋

㪇㪅㪌

㪄㪇 㪅㪊 㪄㪇 㪅㪈 㪇㪅㪈 㪇㪅㪊 㪇㪅㪌

x-axis[m]

y-axis[m]

㪇

㪌

㪈㪇

㪈㪌

㪉㪇

㪉㪌

㪊㪇

㪊㪌

㪇 㪉㪇㪇㪇 㪋㪇㪇㪇 㪍㪇㪇㪇 㪏㪇㪇㪇 㪈㪇㪇㪇㪇

Desired locus

Before learning

After learning

Iteration

Squared error

(a) Loci before and after learning. (b) Change of squared error.

Fig. 5. Simulation result for a locus.

㪄㪇㪅㪇㪌

㪇

㪇㪅㪇㪌

㪇㪅㪈

㪇㪅㪈㪌

㪇㪅㪉

㪇㪅㪉㪌

㪇㪅㪊

㪇 㪇㪅㪈 㪇㪅㪉 㪇㪅㪊 㪇㪅㪋 㪇㪅㪌

x-axis[m]

y-axis[m]

㪇㪅㪇

㪇㪅㪉

㪇㪅㪋

㪇㪅㪍

㪇㪅㪏

㪈㪅㪇

㪈㪅㪉

㪈㪅㪋

㪈㪅㪍

㪈㪅㪏

㪉㪅㪇

㪇 㪉 㪋 㪍 㪏 㪈㪇

Iteration

squarred error

Target

After learning

Before learning

(a) Loci before and after learning to target point . (b) Change of squared error.

Fig. 6. Experimental result for a target point.

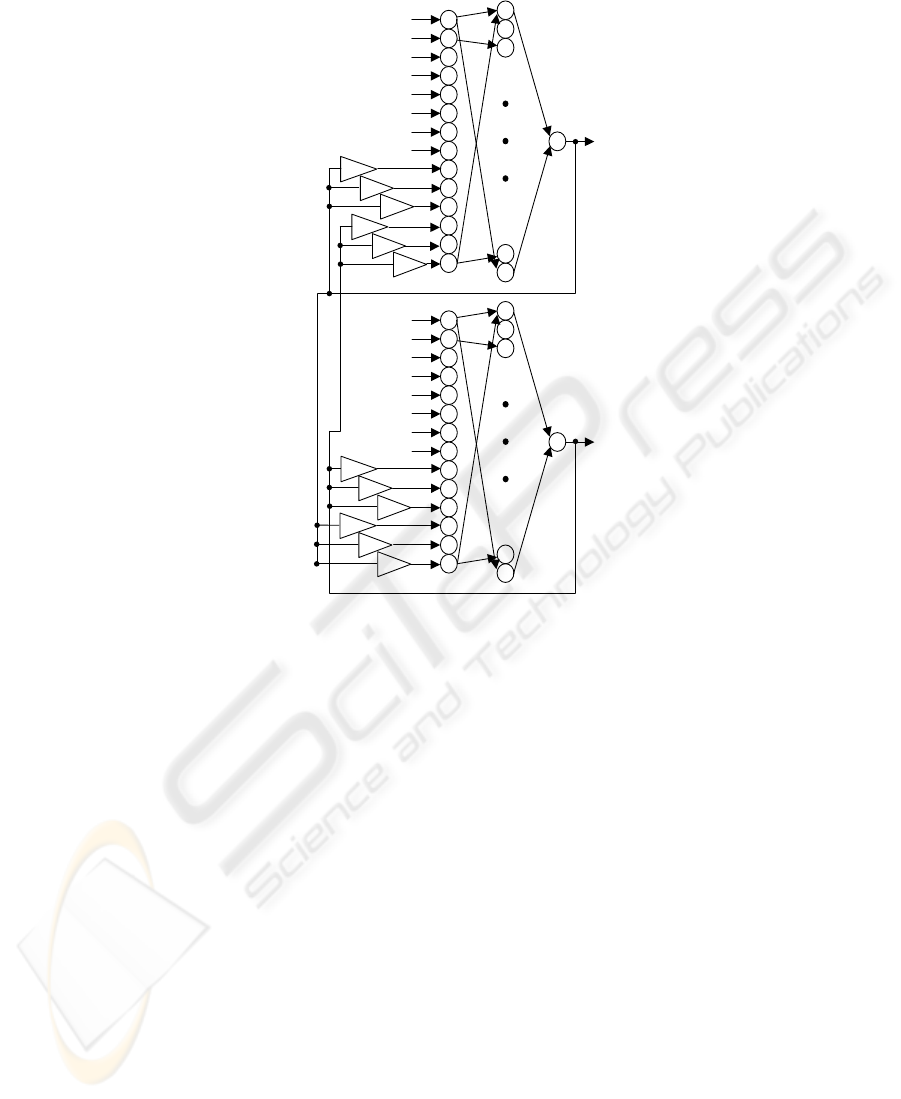

4 Control Scheme 2

4.1 Configuration

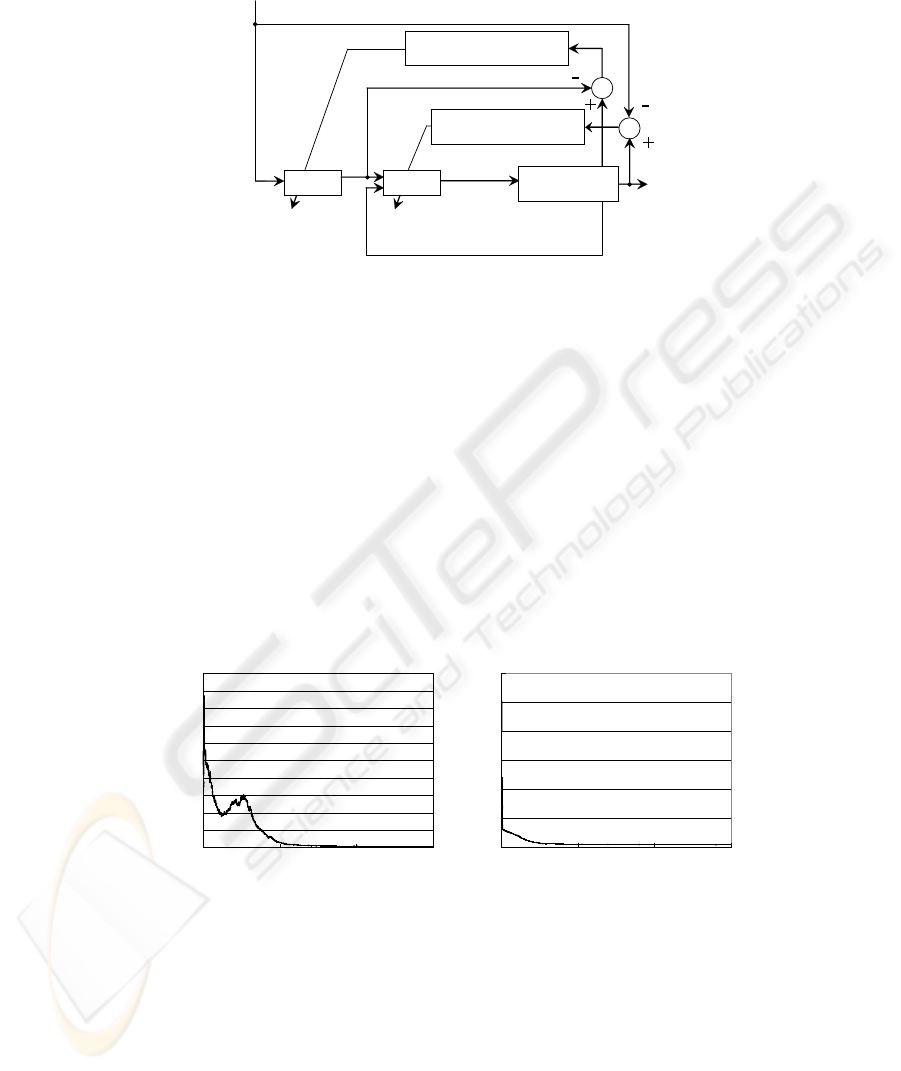

Next, we consider more complicated configuration to handle the problem. We prepare

two NNs. One neural network is for kinematics. Inputs of the network are desired po-

sition of the top of the arm in xy coordinate. Outputs are angles for the two arms. The

neural network must learn an inverse kinematics of the robot arm system. The second

neural network is a recurrent neural network (RNN). Inputs of the network are the an-

gles of the arm, that is, the outputs of the first network and state of the objective robot

arm. Outputs are torque values for the two links. The second network must learn an

inverse dynamics of the plant. The configuration is depicted in Fig.7.

In this case, it is difficult to carry out the learning of these two NNs, simultaneously.

As same as the previous configuration, if we use an ordinary gradient method to update

20

+

-

θ

1

, θ

2

θ , θ , θ

& &&

RNNNN

x, y

state of the arm:

Robot arm

τ1, τ2

xd, yd

desired position

simultaneous perturbation

learning rule

simultaneous perturbation

learning rule

-

+

torque

angle

position

of the top

Modify weights

Modify weights

angle

Fig. 7. Overall configuration of control scheme 2.

the weights in these two networks, it is essential to know the Jacobian of the plant. On

the hand, our approach does not require the information.

The first NN for the kinematics updates their weights based on the error defined by

the output angles and the actual angles of the two links of the robot arm. Moreover, the

second RNN learns the dynamics using the error defined by the actual xy position of

the robot arm and the corresponding desired position.

4.2 Simulation result

㪇

㪌

㪈㪇

㪈㪌

㪉㪇

㪉㪌

㪊㪇

㪊㪌

㪋㪇

㪋㪌

㪌㪇

㪇 㪈㪇㪇㪇 㪉㪇㪇㪇 㪊㪇㪇㪇

(a) Error for inverse kinematics

Iteration

Squared error

㪇

㪈㪇

㪉㪇

㪊㪇

㪋㪇

㪌㪇

㪍㪇

㪇 㪈㪇㪇㪇 㪉㪇㪇㪇 㪊㪇㪇㪇

(b) Error for inverse dynamics

Iteration

Squared error

Fig. 8. Change of errors.

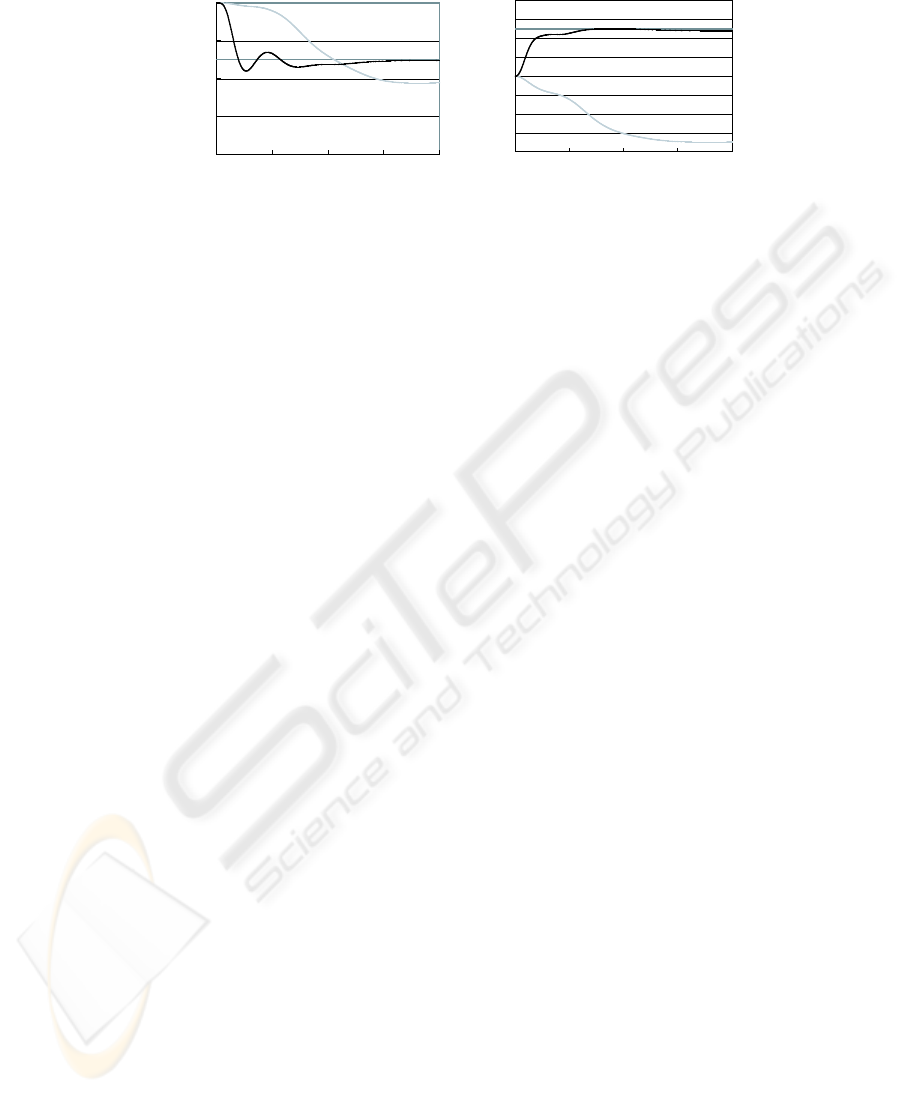

We consider a task to move the top of the arm to a certain point using the control scheme

2.

21

㪇㪅㪇

㪇㪅㪈

㪇㪅㪉

㪇㪅㪊

㪇㪅㪋

㪇㪅㪇 㪌㪅㪇 㪈㪇㪅㪇 㪈㪌㪅㪇 㪉㪇㪅㪇

x position[m]

Time[sec]

desired position

before learning

after learning

㪄㪇㪅㪋

㪄㪇㪅㪊

㪄㪇㪅㪉

㪄㪇㪅㪈

㪇㪅㪇

㪇㪅㪈

㪇㪅㪉

㪇㪅㪊

㪇㪅㪋

㪇㪅㪇 㪌㪅㪇 㪈㪇㪅㪇 㪈㪌㪅㪇 㪉㪇㪅㪇

y position[m]

Time[sec]

desired position

before learning

after learning

Fig. 9. Simulation result.

Fig.8 shows changes of the errors for the kinematics and the dynamics. This simu-

lation result reveals that 1000 learning gives proper accuracy to move the top of the arm

to the desired position. Then, α = 0.0008 and c = 0.0003.

Fig.9 is xy position of the top. After 3000 learning, the top moves to the desired

position. This shows that the first NN and the second NN learn the inverse kinematics

and the inverse dynamics properly.

5 Conclusion

This paper describes two control schemes for the two link robot arm. In these control

schemes, the NNs learn the inverse of the kinematics and the dynamics of the objective

robot system without Jacobian of the plant. The simultaneous perturbation learning rule

makes this possible.

Acknowledgement

This work was financially supported by Grant-in-Aid for Scientific Research(No.16500142)

of the Ministry of Education, Culture, Sports, Science and Technology of Japan.

References

1. Maeda, Y., deFigueiredo, R.J.P.: Learning Rules for Neuro-Controller via Simultaneous Per-

turbation. IEEE trans. on Neural Networks, 8 (1997) 1119–1130

2. Spall, J.C.: Multivariable stochastic approximation using a simultaneous perturbation gradient

approximation. IEEE Trans. Autom. Control, AC-37 (1992) 332–341

3. Cauwenberghs, G.: A fast stochastic error-descent algorithm for supervised learning and op-

timization. in S.J.Hanson, J.D.Cowan and C.Lee(eds.), Advances in neural information pro-

cessing systems 5, Morgan Kaufmann Publisher. (1993) 244–251

4. Maeda, Y., Hirano, H., Kanata, Y.: A learning rule of neural networks via simultaneous per-

turbation and its hardware implementation. Neural Networks, 8 (1995) 251-259

22