AN AGENT ARCHITECTURE FOR STEEL PRODUCT BUSINESS

NETWORKS

Heli Helaakoski

VTT Electronics, Rantakatu 5 A, FIN-92101 Raahe, Finland

Janne Kipinä

Oulu Polytechnic, Raahe Institute of Technology and Business, Rantakatu 5 A, FIN-92101 Raahe, Finland

Harri Haapasalo

Department of Industrial Engineering, University of Oulu, P.O. Box 4610, FIN-90014 University of Oulu, Finland

Keywords: Software agents, B2B application, distributed manufacturing systems, supply chain management

Abstract: Networked manufacturing enter

prises are now moving towards more open information exchange for

integrating their activities with those of their suppliers, customers and partners within wide supply chain

networks. Therefore there has been increasing need for software systems to support business networks. This

paper introduces SteelNet agent architecture, which facilitates a real collaboration of companies by enabling

a seamless information and material flow in a business network. Different operations of order-delivery

process in the network have been modelled as agents that are able to collaborate with each other. The

SteeNet agent architecture is a basis for a prototype that handles the operations of manufacturing steel

products in a supply chain.

1 INTRODUCTION

The development of business and industry has led to

a situation where companies cannot compete alone

anymore and this has created a need for the

companies to network with each other. These

business networks are rather complex coalitions of

business relationships where different counterparts

of individual relationships and networks actively

communicate with each other (Gummesson, 2000).

Traditional Electronic Data Interchange (EDI)

an

d legacy systems no longer respond to today’s

needs, because they are very inflexible and

expensive to use and maintain, especially for small

and medium-size companies. Current Internet

technologies are expected to ease these restrictions

by being more efficient and economical. With the

development of Internet technologies, the traditional

B2B systems have extended to business networks

where several companies are collaborating via

electronic messages.

Recently, agent technology has been considered

an

important approach for developing industrial

distributed systems (Jennings et al., 1995, Jennings

and Woolridge, 1998). Agents can be used to

encapsulate existing software systems to solve

legacy problems and integrate the activities of

manufacturing enterprises, such as design, planning,

scheduling, simulation execution and product

distribution, with those of their suppliers, customers

and partners into an open, distributed intelligent

environment via networks (Fox et al., 1993,

Barbuceanu and Fox, 1997).

The SteelNet project presents an agent

archi

tecture for networked medium and small size

manufacturing companies. The SteelNet architecture

takes into account the fact that the networked

companies use different types of information

technology and various data security solutions,

467

Helaakoski H., Kipinä J. and Haapasalo H. (2004).

AN AGENT ARCHITECTURE FOR STEEL PRODUCT BUSINESS NETWORKS.

In Proceedings of the Sixth International Conference on Enterprise Information Systems, pages 467-470

DOI: 10.5220/0002605904670470

Copyright

c

SciTePress

which must be able to collaborate with the SteelNet

system. The purpose of this paper is to present how a

community of agents can make decisions and carry

out tasks within a manufacturing network. By

digitising the information flow between the

collaborative companies they have a possibility to

increase their competitive position and profitability.

This paper is organised as follows: section 2

describes the business case of the SteelNet project.

Section 3 describes a technical architecture for

network manufacturing enterprises. Section 4

describes a prototype application for distributed

manufacturing. Section 5 concludes and outlines our

future plans and work.

2 STEELNET BUSINESS CASE

Business-to-business transactions consist of several

typically repeated chains of events like the

requisition of resources, a request for quotes from

candidate business entities, vendor selection, order

enactment and delivery, relationship management

among businesses, and product life cycle

management. These events are relevant to the

functions of several business networks, such as a

strategic sourcing network, an electronic

procurement network, a network for virtual

enterprise, a network for product design,

manufacturing, inventory, and delivery management,

a network of electronic marketplaces, a network for

workflow/supply-chain management, and a network

for supplier relationship management (Blake and

Gini, 2002). Autonomous and intelligent software

agents are capable of easing this complex

environment of business networks in electronic

commerce.

The SteelNet business network consists of

several collaborating companies in the steel product

industry. Within the business network, companies

work together as a supply chain, while each of the

companies has their own field of expertise like

bending, flame cutting and welding. Besides this

business network each company has its own

customers and partners, therefore each company

must have equal rights in the SteelNet system

(Haapasalo et al., 2002, Iskanius and Haapasalo,

2003).

In the SteelNet system, agents represent major

functionalities of a company. Figure 1 shows the

usual operations in manufacturing companies, which

are substituted by agents in the SteelNet system.

They are able to communicate and collaborate

within the company and likewise with other

companies’ agents via the Internet. This enables a

seamless information flow though all the operations

in a company and also through the whole business

network. Practical operations in a business network

have been analysed through some business cases, in

order to reflect the reality. Delivery processes for

products in project deliveries (modules of oil drilling

rigs) and in volume production (hardened plate

products) have been modelled in the SteelNet

project.

3 TECHNICAL ARCHITECTURE

FOR NETWORKING

MANUFACTURING

ENTERPRISES

The SteelNet environment consists of several

manufacturing companies that have different

network structures. However some generalisations

can be made, in particular that companies have a

private LAN (Local Area Network) which is

connected to the Internet through a firewall. Legacy

systems and workstations are located in the LAN.

The selected architecture must enable workstations

and legacy systems to interact with the SteelNet

system as well as enable the companies to share

information with each other without any

modifications to the company firewall (Helaakoski

et al., 2003).

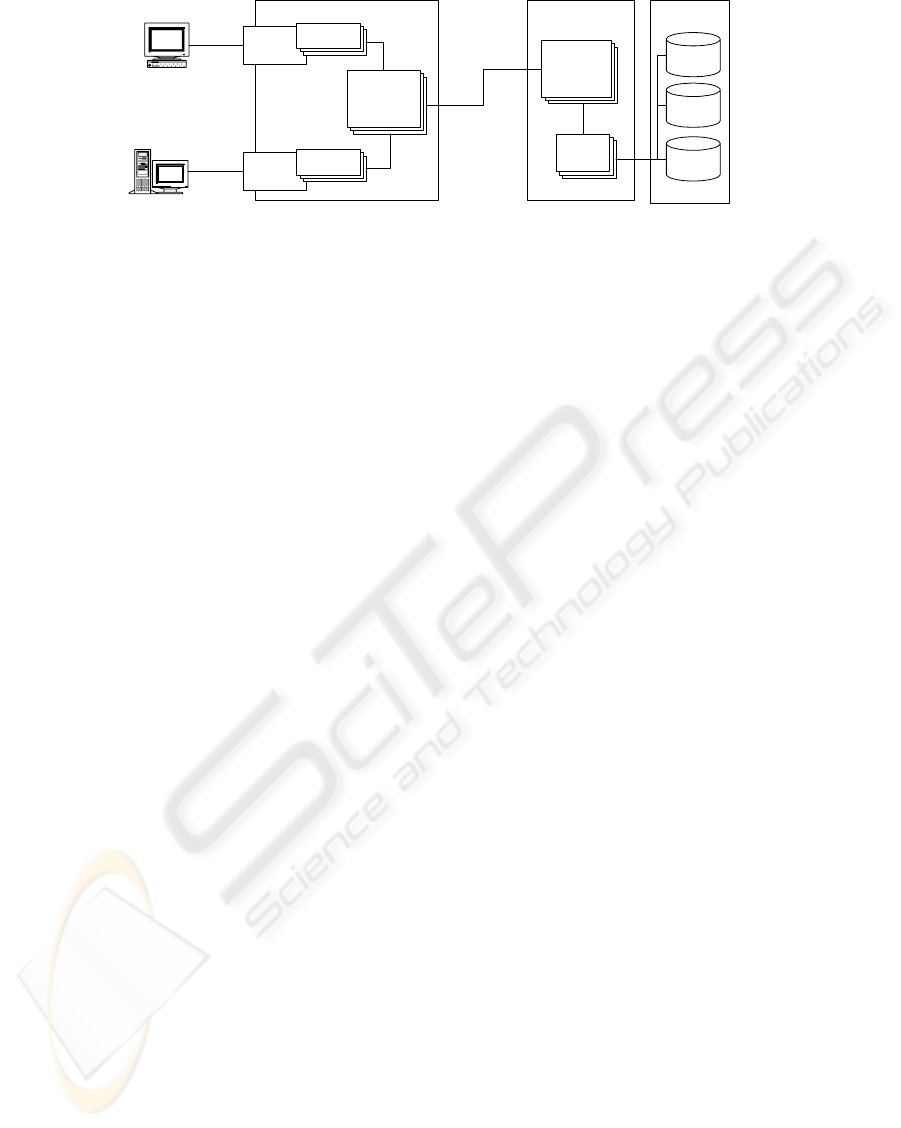

Figure 2 shows the SteelNet architecture. The

Manufacturing

Planning of

work

Administration

Supervision of work

Invoicing

Marketing

Transportation

SteelNet

Figure 1: Usual operations in a manufacturing company.

ICEIS 2004 - SOFTWARE AGENTS AND INTERNET COMPUTING

468

Company Agent Container

User with PC and

web browser

Java

Servlet

Container

Legacy

Systems

Proxy

Legacy System

<<LAN>>

<<LAN>>

Task specific

company

agents

Main Agent Container Database Server

Task specific

coordinator

agents

Database

connectors

<<SSL>>

Data

Order

Data

Manufactu-

ring Data

Task specific

servlets

Task specific

modules

Figure 2: The SteelNet architecture.

architecture consists of one service provider and one

or more companies. Each company has their own

agent container server and a set of task specific

agents. Each of these agents handles one of the roles

presented earlier in Figure 1. The service provider

has corresponding co-ordinator agents, that act as

mediators between agents of the same role in

different companies. Furthermore, the co-ordinator

agents provide a data storage for the company

agents. The communication between agents is

secured by using a Secure Sockets Layer (SSL)

connection.

The SteelNet architecture defines a set of basic

services that are available for all agent containers in

the system. The services include a web application

server to provide user interfaces, a user

administration service, a file distribution service and

an alarm service and an information service for

companies’ to register their manufacturing and

transportation services to the network.

The use of co-ordinator agents makes the system

centralised, but it has some very considerable

advantages. All data is easily available and in

obscure situations it is easier to inspect if the data

has been changed and by whom. Furthermore,

security issues can be addressed more easily in a

centralised environment that in a decentralised one.

One drawback in this centralised approach is

scalability. When the number of companies and

active agents grows significantly, co-ordinator

agents won’t be able to handle the vast amounts of

incoming and outgoing data in reasonable time.

Thus, in the future the architecture should be

enhanced in order to make it more affordable and

decentralised.

The architecture enables the physical location of

the company agent container to be in the service

provider’s premises. This arrangement will be

especially useful for small companies that do not

have such legacy systems that need to be connected

to the SteelNet system, or if they don’t have enough

resources to maintain an agent container server.

In the SteelNet project, business models are

being developed to enable the use of information

systems in an open manner between independent

companies. After a suitable business model is found

the technical solution must be further refined to

facilitate the use of the business model.

4 PROTOTYPE APPLICATION

FOR DISTRIBUTED

MANUFACTURING IN THE

STEEL PRODUCT INDUSTRY

The SteelNet architecture forms a base, on top of

which the functionality of an electronic distributed

supply chain is built by implementing agents for

different roles. In the SteelNet project a prototype

application is being developed to demonstrate the

use of the architecture in a real-world supply chain.

The first phase of the prototype implementation has

been completed and it includes the basic services

described earlier, except the file distribution service,

and an application for a real-time tracking of heavy

steel product manufacturing in a business network.

The manufacturing tracking functionality has

been implemented by developing company and co-

ordinator agents to share manufacturing-related data

with each other using well-defined ontology. The

co-ordinator agent provides facilities to store the

data securely. The co-ordinator agent notifies the

company agents about events that they might be

interested in, for example a new manufacturing

order in which the company is involved in or a

change of a schedule. This enables the company

agents to raise alarms when there seems to be delays

in the manufacturing process, so that the companies

can re-arrange their internal schedules, thus helping

to reduce any undesired bull-whip effect, especially

for companies that are at the end of the process

chain.

In the first phase, the company agents provide a

web application that is used to update information in

the system. The user interfaces are delivered by

using standard Java Servlet and JSP technology-

AN AGENT ARCHITECTURE FOR STEEL PRODUCT BUSINESS NETWORK

469

based web applications that can be used with any

modern web browser.

The second phase of the prototype

implementation will be completed during the spring

of 2004. The main focus is to integrate company

agents with legacy systems. The integration work

will start with two companies participating in the

SteelNet project. The described prototype addresses

the issues related to information flow and

transparency in a distributed manufacturing process.

By using electronic distribution of information with

the help of agents, the information flow can be

improved significantly, which can be considered

essential for optimising throughput times of

manufacturing processes.

For the implementation, JADE (Java Agent

Development Framework) has been selected as the

used agent platform. JADE's main features are

compliance to FIPA standards for software agents

and the use of the platform-independent Java

programming language (Bellifemine et al., 1999).

5 CONCLUSIONS

This paper describes the information technology

problems in networking companies to form a supply

chain. An agent technology-based technical

architecture is presented to address the problems. A

prototype application using the architecture in the

context of distributed manufacturing in steel product

industry is described.

The presented architecture intends to distinguish

itself from similar ones by being designed and

implemented for real-world use by companies of

various sizes and in different industries. At the

current state the architecture has limitations in

scalability, which need to be addressed in the future.

The described prototype implements an

application for efficient distribution of information

in distributed manufacturing, but later the system

can be easily extended to cover other areas of a

supply chain network. The companies participating

in the SteelNet project have tested the prototype in

laboratory conditions and the results are promising.

The prototype will be field-tested during the spring

of 2004, thus creating more valuable information for

future development of the architecture and

prototype.

The agent technology has proven to be an

applicable and affordable solution for electronic

business networks. However, the technology needs

to be developed further to provide a significant

benefit when compared to traditional methods.

ACKNOWLEDGEMENTS

We gratefully acknowledge the funding and support

by the Technology Development Centre of Finland

(TEKES) and the companies associated with this

project.

REFERENCES

Barbuceanu, M. and Fox, M., 1997. Integrating

Communicative Action, Conversations and Decision

Theory to Coordinate Agents. In Proceedings of

Autonomous Agents'97, Marina del Rey, CA.

Bellifemine, F., Rimassa, G. and Poggi, A., 1999. JADE -

A FIPA-Compliant Agent Framework. In Proceedings

of the 4th International Conference and Exhibition on

the Practical Application of Intelligent Agents and

Multi-Agents, UK, 1999.

Blake, M.B. and Gini, M., 2002. Guest Editors,

Introduction to the Special Section: Agent-Based

Approaches to B2B Electronic Commerce,

International Journal of Electronic Commerce,

Volume 7, Number 1, Fall 2002, pp. 7.

Fox, M.S., Chionglo, J.F., and Barbuceanu, M., 1993. The

Integrated Supply Chain Management System.

Internal Report, Dept. of Industrial Engineering, Univ.

of Toronto.

Gummesson, E., 2000. Suhdemarkkinointi 4P:stä

30R:ään. 2

nd

ed. Yrityksen Tietokirjat & Evert

Gummesson, Jyväskylä. 453 p.

Haapasalo, H., Uutela, P., and Pajari, S., 2002. Developing

co-operation in SME manufacturing network –

fundamental concepts from the steel product industry.

In Proceedings of Conference on Small Business

Research, University of Kuopio, Kuopio, Finland.

Helaakoski H., Feng S.C., Jurrens K.K., Ojala K., and

Kipinä J., 2004. Collaborative Software Agents in

Steel Product Industry, The IASTED International

Conference on Artificial Intelligence and Applications,

Innsbruck, Austria, accepted.

Iskanius, P. and Haapasalo, H., 2003. Developing order-

delivery process in manufacturing network case of

steel product industry. In Proceedings of 20th

International Manufacturing Conference - IMC-20,

Cork, Ireland.

Jennings, N.R. and Wooldridge, M.J., 1998. Applications

of Intelligent Agents. Agent Technology: Foundations,

Applications, and Markets. Jennings, N.R. and

Wooldridge, M.J (Eds.), Springer, pp. 3-28.

Jennings, N.R., Corera, J.M. and Laresgoiti, I., 1995.

Developing Industrial Multi-Agent Systems. In

Proceedings of ICMAS’95, San Francisco, The AAAI

press/The MIT press, pp. 423-430.

ICEIS 2004 - SOFTWARE AGENTS AND INTERNET COMPUTING

470