AN AUTOMATION SYSTEM BASED ON LABVIEW TO

CONTROL THE TEST OF MECHANICAL FLOW METERS

Mechanism to characterize flow measurers

Javier Martínez (1), Ricardo Alvarez (3), Petronilo Cortez (4), Víctor Mejia (5)

Mexican Institute of Water Technology (IMTA) Paseo Cuauhnahuac No. 8532,Cuernavaca, Morelos,

México:

Victor Hugo Zárate Silva(2)

Institute Tecnologico and of Superior Studies of Monterrey - Campus Morelos,

Mexico: victor hugo zarate silva.

Abstract: A mechanical flow meter is a device used mainly to measure and calculates velocity of weater´s

flow on rivers and open channels. These devices, as the time of use pass trough, suffer

mechanical imperfections, that are why it is important to calibrate them twice a year, depending

of its time of use. At the Mexican Institute of Water Technology (IMTA in Spanish) was

designed and developed a circular water tank for propose of test of these meters. The present

paper shows the automation systems designed to control the tests to calibrate these mechanical

meters. The system is based on LabVIEW. LabVIEW is a general purpose programming tool

with extensive libraries for data acquisition instrument control, data analysis, and data

presentation. With this tool and a special hardware interface, it was possible to automate the

process to test these meters. The system is called SCM (System of characterization of

mechanical meters). SCM control the test of two mechanical meters simultaneously, and has

some user's control features that permit the Operator a easy to use human machine interface.

1 INTRODUCTION

Before that disappear the installation where

himself towards the Calibration of the mechanical

meter flow the Mexican institute Technology water

builds a circular water tank for purpose apart the

test calibration those meters.

This circular water tank have 12m of diameter,

80cm

. Cross section and 1.40m of depth with a

motor is of 15 kV. for move the arm of 12m the

mechanical flow meter are device use for

Measurement the speed in river and open channel,

the which testing needs depending on your use.

This measurements it are carry with the help of

a hea

dphone and a battery, himself submerge the

device in the water flow and himself count the turn

that get your cops a the open or close a circuit each

revolution in a period of time give and with this

date and know the area is possible calculate the

expense.

In the channel in the beginning himself

produce

r the characterizations in form manual:

before the apocopated demand, himself use the

tool the computation for produces the

characterizations of the measurement of flow.

2 PERIPHERY AT CONSIDERS.

For carry at handle the development of software

was necessary take in count the information that

drive each a of the mechanics, list the parts that

will be in the system and in consequence define the

software.

CONCEPT

a) The measurement flow are system mechanics

of m

easurement of flow of water, consist of a

system of six cones or cup, the as are impulse

for the flow of water.

In of mechanism have platinum that himself close

for each t

our complete that gives the disc o cups.

530

Martínez J., Hugo Zárate Silva V., Alvarez R., Cortez P. and Mejia V. (2004).

AN AUTOMATION SYSTEM BASED ON LABVIEW TO CONTROL THE TEST OF MECHANICAL FLOW METERS - Mechanism to characterize flow

measurers.

In Proceedings of the Sixth International Conference on Enterprise Information Systems, pages 530-535

DOI: 10.5220/0002607705300535

Copyright

c

SciTePress

Given himself mechanics character, each flow

meter has himself proper characterization of

answer.

b) The signal of the flow meter is transmitter

since the arms towards the smallhouse of

control for means of brush location in the axis

central.

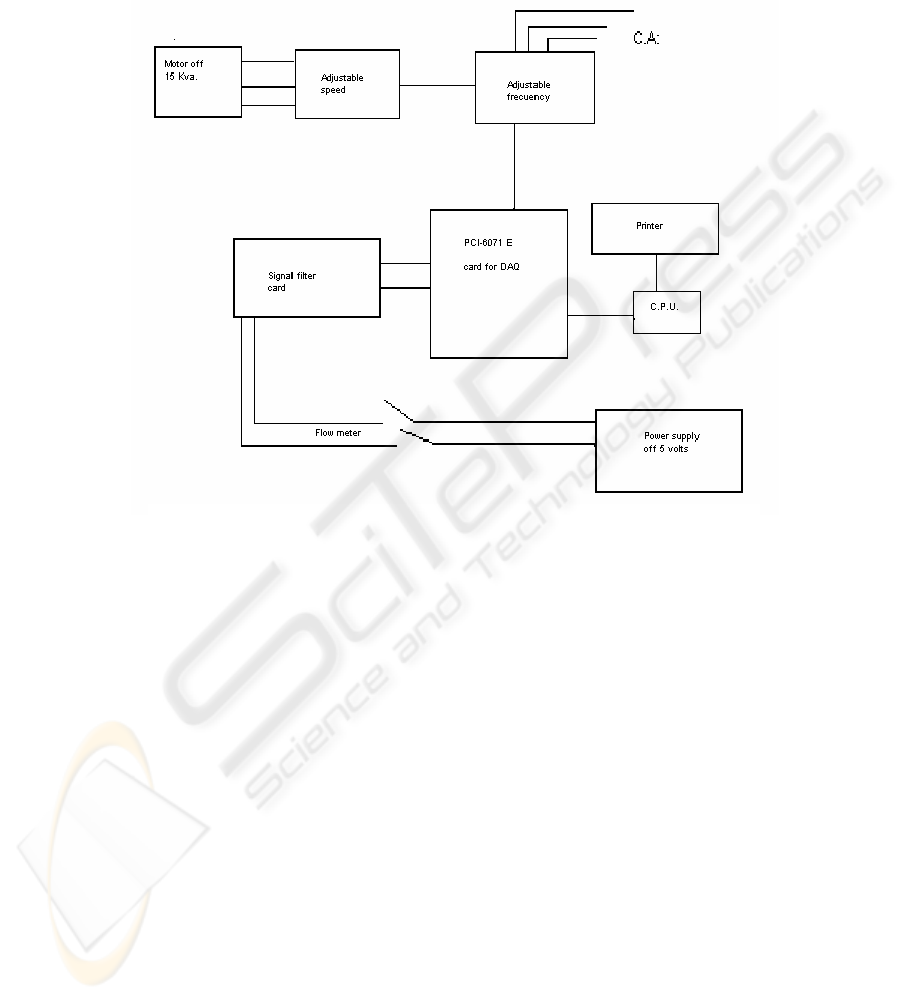

In the fig.1 himself see the complete system.

Fi

g

ure 1: Draw of com

p

lot of circular water tank s

y

ste

m

COMPONENT IN THE SYSTEM

1. PCI-6071 E card for DAQ

2. - Adjustable frequency ABB

3. -Pentium II 400mhz computer

4, -Signal filter card

5. -Power supply

6. -Flow meter

7. -Engine of 15 kV.

8. -Adjustable speed

9.-Software LabView

Himself make a description for each

component.

1. - PCI-6071 E card for DAQ

This is E Series multifunction DAQ I/O, it can

solve DAQ and control system applications,

automatization, programmable input ranges and

gains where determinism in your software is

critical.

The E series not only do you have the

flexibility to easily port your applications between

different computer platforms and operating

systems.

This is install in of the PC and it is possible

configure for software and the connection of

jumper according this conditions that the person

want.

This hardware has libraries for facilitate the

communications with the instrument that are

necessary for measurement the signals.

2. - Adjustable frequency ABB.

The controlador of C.A. of 1 to 75 HP count

with a display and at keys for control the panel,

also with a menu where is optional the drive, in

form manual and automatic.

A bridge of diodes converts line power almost

entirely to active power. The displacement power

factor approaches unity (>0.98) regardless of speed

or load of the connected motors.

A Motor control Card controls the Inverter the

Stage and monitors the operation of the ACS 501.

A Control Interface Card is the link between

the operator and the ACS 501. It features a Control

Panel with an alphanumeric display and keypad. A

terminal block for external control connections is

also located on the Control Interface Card.

AN AUTOMATION SYSTEM BASED ON LABVIEW TO CONTROL THE TEST OF MECHANICAL FLOW

METERS: Mechanism to characterize flow measurers

531

The Control Interface Card is optically isolated

from the line potential. The Control Interface Card

common is connected to the chassis ground

through 10-megohm resistor.

2.3. - Pentium IV 400mhz computer.

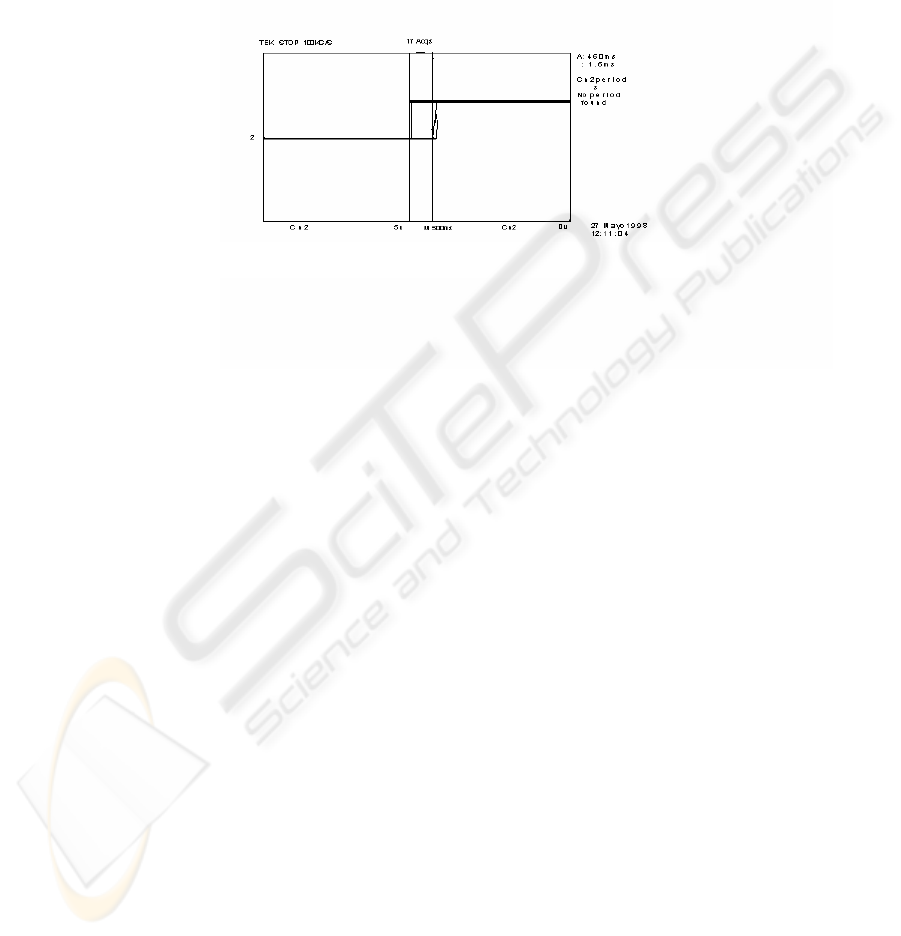

2.4. - Signal filter card.

The signal of the flow meter is very noise how

you look in the fig. 2. For this problem was

necessary place a filter card and a protection at the

circuit by means of an optoisolator circuit.

Fi

g

ure 2: Noise si

g

nal of the flow mete

r

2.5. -Power supplies of 5 volts to 0.5 amperes

for supply the signal to the flow meter.

2.6. -Adjustable speed is manufacture by means

of gears that receive the move of motor of 15 kV.

3 REQUEST OF THE PROGRAM

3.1 Ask identification.

3.2 Menu with options

Characterizations

Consulting base of dates

Get of low or high dates

Recorder each characterizations

3.3 Made the process of characterizations and filter

signal

3.4 Made the calculate necessary.

3.5 Proportion the equation of characterizations.

3.6 Result

- Date of the user

- Graphic of the result

- Table for calculates for in form normal and

with cable

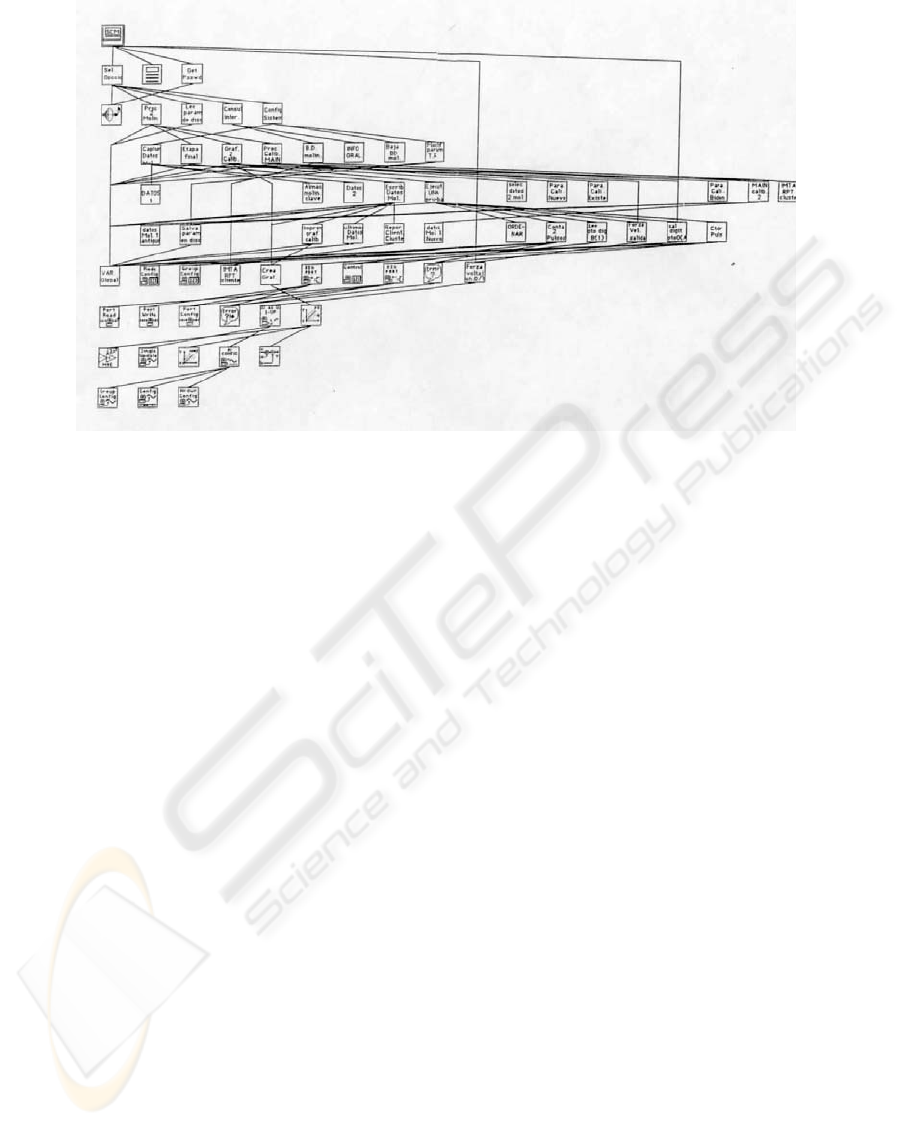

The program himself fulfill in the software

LabView consist in approximately 64 routine, he

model the draw of the program in the fig.3.

A of the screen that us present is the following:

ICEIS 2004 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

532

Fi

g

ure 3: Menu Princi

p

al

MENU PRINCIPAL

1. - Process Characterizations.

2. - Consulting base of dates.

3. - Configuration of the system.

4. - Exit of the system.

1. - Process Characterizations in where himself

the assign clef and register number.

a). - Himself into to base of dates, where himself

can select the file of a flow meter with

Characterizations or himself can give of high

or down.

b). - Himself write the dates of the new flow meter

and dates of maintenance date ingress.

c). The system give a screen for actuality the dates

of the equation of adjustment whit the 12

ranges of speed number of test and how many

time last the process.

d). The system question if have other flow meter if

is “no” following to the screen where sample

the information.

e). The process begins actuality of dates of number

of pulse in the ranges of speed in m/sec. That

is 0.148, 0.402, 0.530, 0.657, 0.912, 1.167,

1.422, 1,676, 1.931, 2.186, 2.441 and 2.996.

AN AUTOMATION SYSTEM BASED ON LABVIEW TO CONTROL THE TEST OF MECHANICAL FLOW

METERS: Mechanism to characterize flow measurers

533

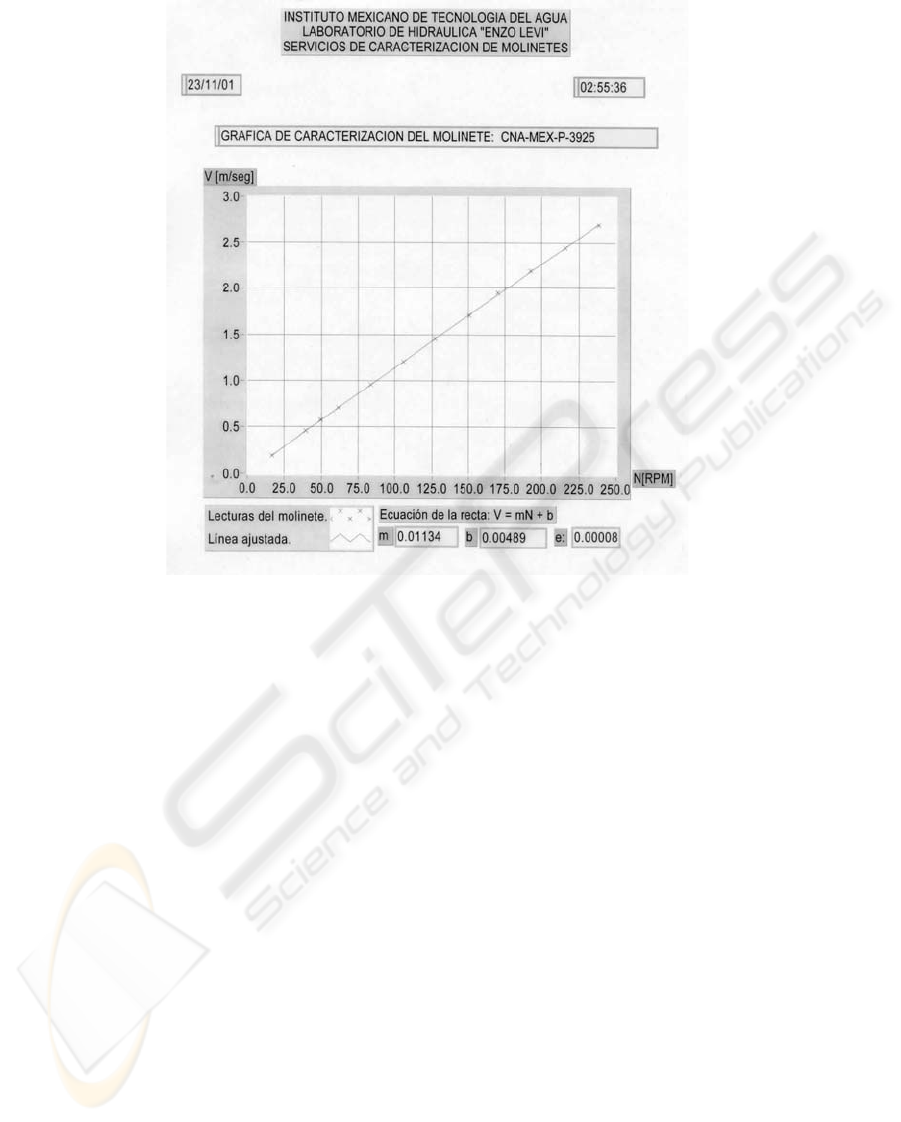

Figure 4: Graphic of characterization of the meter flow

f). When the process finishes himself the can

printer the result in four pages.

1ª. Dates of the user, maintenance and responsible

name.

2ª. Dates of the parameter of equation (m) and (b)

and the graphic that is simple in fig. 4.

3ª Table for gauging in forms normal.

4ª, Table for gauging with cable

2. - Consulting base of dates.

Himself can possible see dates of the flow

meter characterization and edit or print the

information.

3. - Configuration of the system.

Himself can change dates of operation for

example ranges speed, time of advice of error (*).

4. - Exit of the system is when finish all the

process.

* When the flow meter have a problem the

system give signal say “The flow meter doesn’t

ask”

4 CONCLUSION

The development of this software is an innovation

of the technology for characterizes flow meter in

short time and with exact and certain.

With this him comply the objet of achievement

characterizations meter in short time and with

exact and certain.

This mean for fulfill the characterizations for

mean of the characterizations

For mean of the circular water isn’t common,

without embargo the result

Himself compared with characterizations of a

laboratory certify internationally who

Himself is the Laboratory of Canada Center for

Inland Waters obtaining similar results.

By him that can say that this software is

working in of the conditions acceptable.

For him that himself handled of achieve the

certify of all the system.

The operation and maintenance of the software

is easy and rapids.

With the base of dates is possible make

analysis and statistical and with this,

Obtain conclusions for make better the

constructions of the flow meter.

ICEIS 2004 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

534

Fi

g

ure 3: Schematic of the software develo

p

ed for make characterizations in the Circular water tan

k

BIBLIOGRAPHY

PIC Usar manual of national instruments

ABB Adjustable frequency. Installation & start-up

Manual

Congreso instrumentación SOMI XII OCT-1998

AN AUTOMATION SYSTEM BASED ON LABVIEW TO CONTROL THE TEST OF MECHANICAL FLOW

METERS: Mechanism to characterize flow measurers

535