INTEGRATING DESIGN DOCUMENT MANAGEMENT

SYSTEMS USING THE ROSETTANET E-BUSINESS

FRAMEWORK

Paavo Kotinurmi, Hannu Laesvuori, Katrine Jokinen, Timo Soininen

Software Business and Engineering Institute, Helsinki University of Technology, POB 9210, FIN-02015 HUT, FINLAND

Keywords: B2B Applications, Document Management Systems Integration, RosettaNet

Abstract: E-business frameworks providin

g standards and specifications that aim at enabling integrating the enterprise

applications of business partners with relative ease have been recently proposed. This paper reports on

experiences gained from developing a prototype system for integrating design document management

systems based on the RosettaNet e-business framework. We present the requirements for the prototype,

extracted from a case study of a product development network, and the design and implementation of the

system. We then discuss the experiences gained in the light of the feasibility of applying such frameworks

and their supporting technologies as foundations for e-business. The RosettaNet e-business framework was

found to be relatively easy to implement and use. However, the RosettaNet specifications for product

development processes and the related business document definitions, e.g. for design document delivery, are

not sufficient in all respects. As a consequence, two implementations of the same RosettaNet standard

process may be incompatible, and thus the aim of providing easy integration may fail. Furthermore, the

effort required to build the system and fill in the missing parts in RosettaNet to integrate the product design

activities may risk the goal of easy integration.

1 INTRODUCTION

It is expected that the volume and scope of e-

business grows fast and the needed systems

integration among the e-business partners extended

to new areas (Lee and Whang, 2001). One way of

facilitating inter-company application integration,

offering potential cost and extensibility benefits, is

to develop and apply e-business frameworks that

provide standards and specifications enabling

businesses to communicate efficiently over the

Internet (Shim et al., 2000). The aim of such

frameworks is to facilitate integration with less

implementation effort for each e-business partner.

One potential area where such frameworks could

be be

neficial is product development (PD) projects

conducted in company networks in a concurrent and

collaborative manner (Borgman and Sulonen, 2003).

Supporting design information sharing is an

important issue for successful PD (Clark, 1991).

This information is usually stored in different kinds

of documents, such as CAD models within each

company’s Document Management System (DMS),

which is typically a part of a Product Data

Management (PDM) system. Such systems facilitate

the PD process in one company by providing up-to-

date information to all the product designers who

need it (Liu and Xu, 2001). The same type of

support needs to be extended to cover the whole PD

network (Kotinurmi et al., 2003). Thus, there is a

need to integrate DMS systems. With DMS

integration using an e-business framework,

information delivery could become faster, less error-

prone and more transparent than in manual processes

of using e.g. e-mail. End-users in companies could

use their own systems, which they know, and still be

able to collaborate with other companies.

As the research results on implementations

appl

ying e-business frameworks, particularly to PD,

are few (Sayal et al., 2002) (Nurmilaakso, 2003),

this paper contributes by presenting an actual case of

building a prototype implementation and critically

discussing the lessons learned.

This paper is structured as follows: Section 2

d

efines the requirements for DMS integration

extracted from a case study and introduces the

RosettaNet e-business framework. In Section 3, we

describe an architecture and design of a prototype

system for DMS integration supporting RosettaNet.

Section 4 discusses the experiences and lessons

502

Kotinurmi P., Laesvuori H., Jokinen K. and Soininen T. (2004).

INTEGRATING DESIGN DOCUMENT MANAGEMENT SYSTEMS USING THE ROSETTANET E-BUSINESS FRAMEWORK.

In Proceedings of the Sixth International Conference on Enterprise Information Systems, pages 502-509

DOI: 10.5220/0002622405020509

Copyright

c

SciTePress

learned from building the prototype system and

presents related work. Finally, in Section 5 we

present conclusions and topics for future work.

2 REQUIREMENTS AND

MOTIVATION

This section presents the requirements and

motivation for DMS integration and introduces the

RosettaNet e-business framework.

2.1 Requirements

The requirements for a system supporting design

document management in networked PD are based

on a case study of a PD network, which consists of a

customer and its suppliers (Borgman & Sulonen,

2003). The customer designs, manufactures, and

sells consumer electronics products and the suppliers

supply plastic parts to these products.

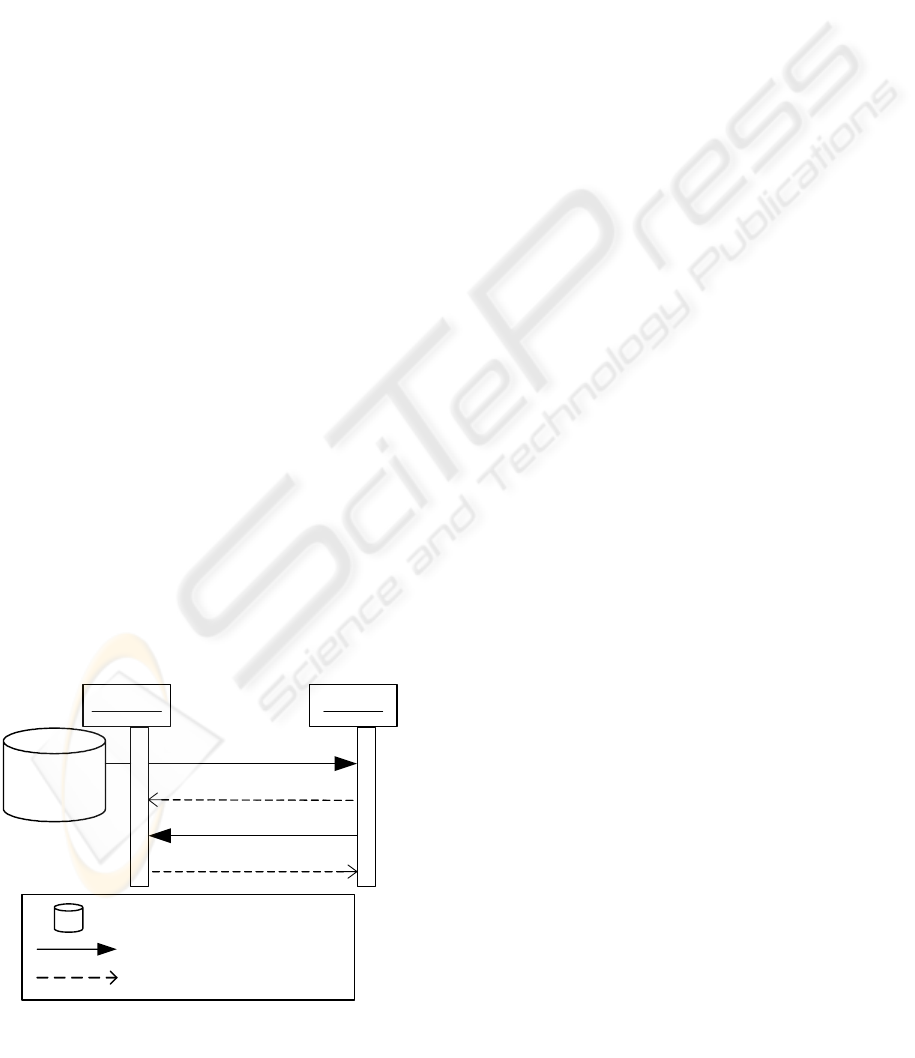

According to the case study, document

management should be a planned, communicated

and documented process between companies in

networked PD. The design documents drive the

supplier’s process in a very straightforward way

(Figure 1): When the supplier receives a new version

of e.g. a CAD-model from the customer, it

immediately triggers some design and

manufacturing work for the supplier. Equally, when

the supplier sends a document (e.g. a measurement

log sheet) to the customer, it triggers e.g. a new

component approval process. Documents

synchronise the processes within the companies of

the network. Thus, document exchange in a network

should itself be considered and treated as a

systematic process. This process can be triggered by

a predefined schedule or an event within one

company (e.g. a new version of a document becomes

available). If any changes to the schedule should

occur, these changes should be communicated to all

relevant companies automatically. These repetitive

information delivery processes can be automated

with the help of e-business frameworks.

It is important to ensure that changed documents

are distributed inside the companies to the engineers

whose work depends on them. Therefore, the

delivered document files must be accompanied with

metadata, i.e. information about the document, such

as its author, version, and relationship to product

components and projects. This should be carried in

the business documents exchanged in the process

steps.

Design documents are typically highly

confidential. There must be a means to distribute the

documents securely to the intended recipients only

and to be certain that the delivery is successful. The

documents should be encrypted if the distribution

takes place over non-secure communication

channels, such as the Internet.

A proper solution supporting design document

exchange should be extendable to new collaboration

partners and processes without requiring major

modifications. The solution should be extendable to

many partner companies using different DMSs, and

therefore based on standards. There are numerous

seemingly applicable e-business frameworks such as

ebXML, RosettaNet and Standard for the Exchange

of Product Model Data (STEP) to support definitions

for processes, business documents, and secure and

reliable messaging over the Internet. Based on our

analyses and comparison of five e-business

frameworks, we chose RosettaNet as the basis for

our system (Kotinurmi et al., 2003).

2.2 RosettaNet

RosettaNet is an industry-driven consortium aiming

at creating, implementing, and promoting open

e-business process standards. The most important

components standardised in RosettaNet are Partner

Interface Processes (PIPs), dictionaries and

RosettaNet Implementation Framework (RNIF).

New document (version)

Acknowledge: received

Document

Management

system

Measurement log sheet

Acknowledge: received

Internal

processes

SupplierCustomer

Information system

Business document delivery

Acknowledgement of delivery

PIPs define common inter-company public

processes such as “PIP 2A10 Distribute Design

Engineering Information” and the associated

business documents. Trading partners’ internal

processes interact with PIPs to initiate or receive

business documents. RosettaNet PIPs are divided to

eight clusters noted by numbers, and the clusters are

further divided to segments noted by letters. Cluster

2 deals with Product information. It is divided to

four segments, e.g. 2C “Product Design

Information”. Segment 2D “Collaborative Design &

Figure 1: Information delivery in networked PD

INTEGRATING DESIGN DOCUMENT MANAGEMENT SYSTEMS USING THE ROSETTANET E-BUSINESS

FRAMEWORK

503

Engineering” PIPs have not been released and

cannot be utilised yet.

Each PIP contains a specification document,

Document Type Definitions (DTD) and Message

Guidelines (MG). A specification document defines

the process with Unified Modeling Language

(UML) activity diagrams and textual descriptions,

the roles of the partners, and necessary conditions to

initiate messaging. Each PIP defines one or more

business documents. The DTD and MG define the

PIP service content of one business document. The

DTD defines the valid Extensible Markup Language

(XML) document structure of a PIP service content.

The MG introduces additional constraints and

guidelines, such as what a modification date means

and how the date value should be represented.

Figure 2 represents a fragment of a service content

XML document.

RosettaNet business dictionary (RNBD) defines

common terms used in all the PIPs. In addition to

dictionaries, RosettaNet uses certain identifiers, such

as Data Universal Numbering System (DUNS)

codes to identify companies uniquely.

<ProductInformationObject>

<GlobalActionCode>Add

</GlobalActionCode>

<Version>1.2</Version>

<ObjectName>Cover345</ObjectName>

<Supplier>DUNS number</Supplier>

<Description GlobalLanguageCode="EN">

Note the red areas on the model are

Work in Progress</Description>

<modificationDate>

<DateStamp>20031015Z</DateStamp>

</modificationDate>

</ProductInformationObject>

Figure 2: PIP 2A10 service content fragment

RosettaNet Implementation Framework (RNIF)

specifies messaging. It defines the RosettaNet

business message that contains the service content

specified by PIP DTD and MG, and the necessary

headers and security features needed to process the

messages. RNIF also defines how attachments are

encoded in the RosettaNet business messages. These

attachments can be of arbitrary file format, such as

AutoCAD. RNIF contains exception-handling

mechanisms and makes sure that the delivery is non-

repudiated, so neither the sender nor the receiver can

later deny having sent/received the RosettaNet

business message. Many vendors, such as BEA and

Microsoft, support RNIF in their products.

To set up RosettaNet messaging using a certain

PIP, the companies involved set up a Trading

Partner Agreement (TPA) to specify both the

business and technical aspects of the collaboration

for each PIP. Example business aspects are

conditions for trading, such as how certain elements

are used, confidentiality, and when and how the PIP

must be answered. Technical aspects include e.g.

security features, such as the use of certificates for

authentication and the addresses where the

RosettaNet business messages are delivered.

3 DESIGN & IMPLEMENTATION

In this section, we will first present the architecture,

functionality, and internal data model of a prototype

system to support DMS integration. Then we will

present the implementation and test setup briefly.

3.1 Architecture

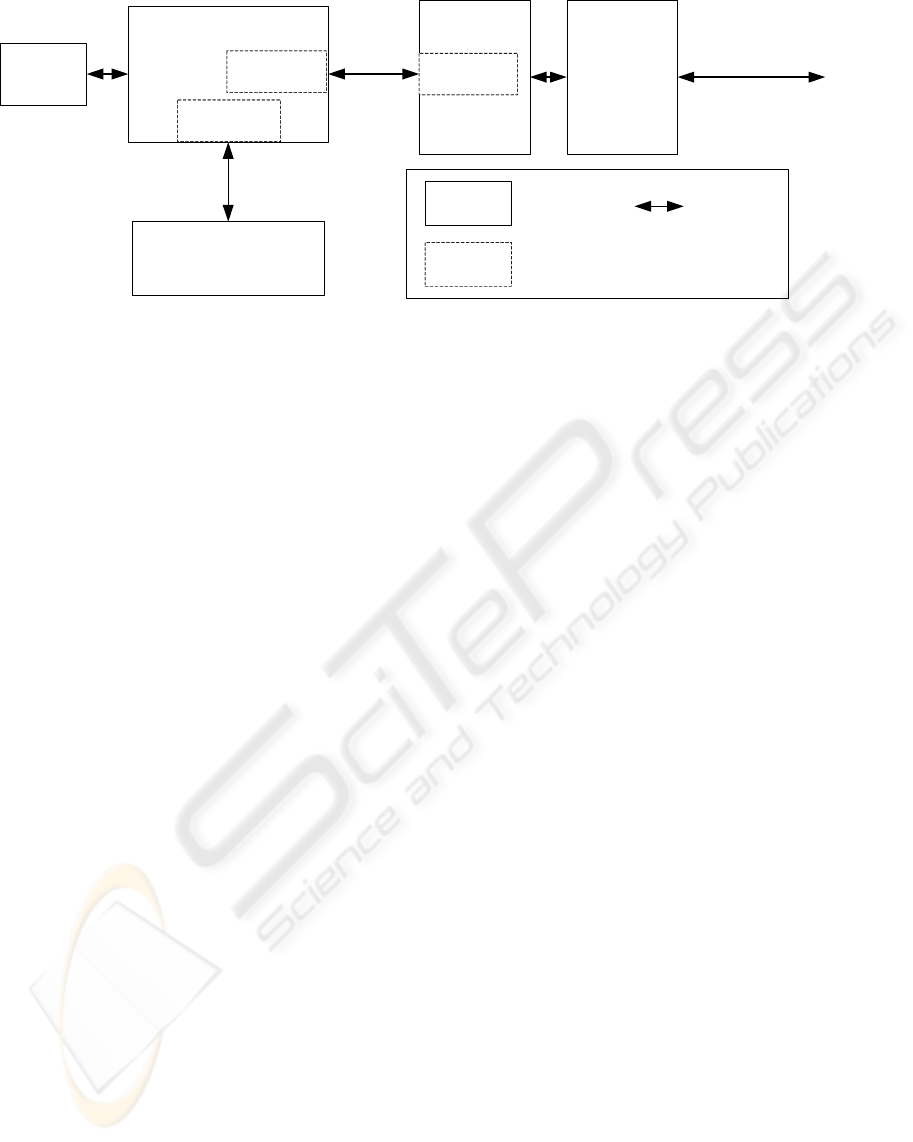

Our prototype system consists of five architectural

components (figure 3).

PDM system is a repository for design

documents and their metadata. It notifies the PDM

adapter of changes in its contents.

PDM adapter is connected to the rule engine and

has interfaces to the PDM system and the RN

adapter. It notifies the rule engine of events in the

PDM system, retrieves design documents and

metadata from the PDM system, and sends them to

the RN adapter.

Rule engine has a user interface for defining

document delivery rules for the design documents,

e.g. a rule saying that updates to a specified design

document must be sent to a specified trading partner.

The rule engine also evaluates these rules each time

there are changes in the PDM system.

RN adapter is connected to the RosettaNet

messaging server and has an interface to the PDM

adapter. Based on the design documents it receives

from the PDM adapter, it adds RosettaNet specific

delivery information to them.

RosettaNet messaging server constructs

RosettaNet business messages from the documents

received by the RN adapter. It controls the exchange

of business messages with trading partners based on

the RNIF specification.

3.2 Functionality

Our prototype system implements the following two

use cases, which illustrate its functionality.

ICEIS 2004 - SOFTWARE AGENTS AND INTERNET COMPUTING

504

PDM

interface

RN Adapter

PDM Adapter

PDM System

messaging

interface

messaging

interface

Internet

Document

attributes

& files

PIP XML

data &

files

HTTP

RosettaNet

business

messages

HTTP,

HTTP/S

Component

Interface

Data flow

Rule

engine

RosettaNet

messaging

server

Figure 3: System Architecture

The first use case is automated delivery of a

design document update in the PDM system to a

trading partner using RosettaNet. This guarantees

that the trading partners always have the latest

version of the design document in their PDM

system. A prerequisite for this is that the prototype

system has been configured with information about

trading partners, design documents in the PDM

system, and document sending rules.

Information about changes in the design

documents in the PDM system is notified through

the PDM adapter to the rule engine, which evaluates

the event against the defined rules. If design

document update must be sent to a trading partner,

the PDM adapter takes control. It retrieves the

design document and its metadata from the PDM

system, constructs the PIP service content from the

metadata, and sends them and the name of the

trading partner to the RN adapter.

The RN adapter instructs the RosettaNet

messaging server to initiate a new PIP with the

trading partner. The design document is added as an

attachment to the business message and the metadata

is added to the PIP service content.

The second use case is receiving design

document updates from trading partners, which is

essentially the reverse of the first use case. Upon

receiving a business message that contains the

design document the prototype system adds this new

document version as such to the PDM system.

3.3 Data model of design documents

The prototype system uses an internal data model for

the exchanged design documents. The data model

defines how the design documents should be stored

in the partner’s PDM system. As the current PIPs do

not include sufficient design document metadata to

accomplish this, we had to define our own internal

data model for the integration.

The internal data model describes the structure of

the document, its life cycle status, its relations to

other documents, projects and products, and other

relevant information, such as its creator and creation

time. The data model is based on an analysis of three

companies’ internal data models for design

documents in their PDM systems (Jokinen, 2003).

3.4 Implementation

3.4.1 PDM System

The PDM system manages the design documents

and their metadata within a company. It notifies the

PDM adapter of changes in its contents, e.g. creation

of a new document version.

Our PDM system is called EDMS (Engineering

Data Management System). It was built in our

research group in a project with KONE Elevators,

where it is in production use. (Peltonen, 2000)

EDMS includes commit procedures that are

executed each time an object is modified, e.g. new

documents are created. These procedures have been

configured to send an event notification to the PDM

adapter. The notification includes an identifier of the

object concerned. We have defined partner specific

access rights to EDMS and a way to define the

capabilities to define what PIPs they can receive.

3.4.2 PDM Adapter

The PDM adapter connects three other components:

the rule engine, the PDM system, and the RN

adapter. It forwards event notifications from the

PDM system to the rule engine, retrieves design

document files and metadata from the PDM system,

INTEGRATING DESIGN DOCUMENT MANAGEMENT SYSTEMS USING THE ROSETTANET E-BUSINESS

FRAMEWORK

505

and sends them as PIP service content and

attachment to the RN adapter.

The PIP service content is formed in the PDM

adapter. If the evaluation of the delivery rules results

in sending a document to partners, the PDM adapter

retrieves the document file from the PDM system

and sends it to the RN adapter. It also retrieves the

document metadata defined in the internal data

model and forms an XML representation of it. The

PDM adapter decides which PIP should be used,

depending on the event, the type of document, and

the receiver. The rules for deciding the PIP have

been hardcoded, as there are only four of them in the

prototype. The PDM adapter then transforms the

metadata with Extensible Stylesheet Language

Transformation (XSLT) to the service content of the

corresponding PIP.

The same procedure is conducted in reverse

order when receiving a design document from a

trading partner. The service content is transformed

to the data model format using the XSLT file

corresponding to the PIP used. The information is

then stored in the PDM system.

The PDM adapter is implemented using Java

programming language and it runs under Apache

Tomcat application server on Linux platform.

3.4.3 Rule engine

The rule engine has a user interface for defining

document delivery rules, e.g. a rule saying that

updates to specified design documents must be sent

to a specified trading partner. The rule engine

evaluates the rules each time there are changes in the

PDM system, such as new documents created.

The document delivery rules are defined with a

web user interface. They have inputs, conditions and

consequences. The rules take PDM objects (e.g.

documents, users, projects) as inputs. The conditions

can be related to, e.g., document version state or

document type. The consequence defines the action

to be taken if the rule applies: normally the

consequence is to send the document to one or more

trading partners. The rule engine evaluates the rules

after receiving event notifications from the PDM

adapter.

The user interface also includes functions for

sending documents manually and simulating events

from the PDM system to see which documents

would be sent to trading partners, and according to

which rules. The rules can be project specific and

have time constraints. There is also a delivery

manager, which shows the delivery information of

all the documents sent.

The rule engine is implemented with the same

technologies as the PDM adapter. The user interface

is implemented using Java servlets and HTML

templates. The evaluation is based on an algorithmic

engine, Drools, for implementing custom object-

related business rules.

3.4.4 RN Adapter

The RN adapter facilitates communication between

the PDM adapter and the RosettaNet messaging

server. The design documents and their metadata

that the RN adapter receives from and sends to the

PDM adapter are information used by PDM systems.

The RosettaNet messaging server, however, sees

everything as RosettaNet business messages

belonging to a PIP. The RN adapter has the logic to

do transformations, such as replacing organization

names used as identifiers in the PDM system with

DUNS codes required by RosettaNet.

We have implemented most of the RN adapter

using Microsoft .NET architecture and C#

programming language. The interface to the PDM

adapter is implemented using the Web Service (WS)

technologies Web Services Description Language

(WSDL) and Simple Object Access Protocol

(SOAP). The integration with the RosettaNet

messaging server is implemented using native

methods of the RosettaNet messaging server.

3.4.5 RosettaNet messaging server

The RosettaNet messaging server provides the

means to extend the PDM integration to trading

partners. It implements the functionality specified in

RNIF, e.g. it creates RosettaNet business messages

and provides their secure exchange over the Internet

with trading partners. The RosettaNet messaging

server cannot initiate new PIPs or respond to PIPs on

its own. The RN adapter does this.

Our RosettaNet messaging server is Microsoft

BizTalk server 2002 extended with Microsoft

Accelerator for RosettaNet 2.0. For our prototype

system to work, it needs to be configured with

necessary partner information such as the used PIP,

DUNS numbers of the trading partners, IP addresses

etc. The configuration requires manual insertion of

data to a database. Typically, the configuration work

for a new trading partner takes a few minutes.

3.4.6 Test set-up

The end-to-end solution has been tested in an

environment that simulates two partner companies.

We had two instances of EDMS servers with

different database schemas to represent two different

companies. A design document update in one EDMS

server led to the construction of a complete

RosettaNet business messages according to the four

PIPs used. The business message was sent to the

ICEIS 2004 - SOFTWARE AGENTS AND INTERNET COMPUTING

506

other EDMS server, where the design document was

saved correctly.

4 EVALUATION & DISCUSSION

Integrating design document management systems

using the RosettaNet e-business framework seems to

be feasible. However, the integration took a

significant effort although tools specifically

designed for this purpose were used. Furthermore,

RosettaNet did not support all the aspects of the

integration needs adequately, which may lead to

problems in wide-scale e-business use of

RosettaNet. In this section, we motivate these

findings through discussing the system architecture

and implementation and by evaluating the support

RosettaNet offered. We also discuss our solution

with respect to the relatively scarce earlier research

reporting on the practical aspects of integration in

PD and the usage of e-business frameworks.

4.1 Architecture and design

The architecture of the prototype system allowed

successful implementation of the requirements posed

by the case. The goal of our prototype system was a

minimalist yet functional implementation. Our

design choices were to leverage code reuse by using

commercially available applications when possible

and to aim for modularity to accommodate possible

future extensions. The choices for Microsoft

RosettaNet Accelerator and EDMS over competing

products were made primarily because of their

availability to us, but also because of the relative

ease of modifying them.

Based on the requirements and the chosen

applications, we identified three separate units of

logic in our prototype that we needed to implement

ourselves: the PDM adapter, the RN adapter and the

rule engine. The integration of the PDM system with

the RosettaNet messaging server needs functionality

that is specific to both of them. As the PDM adapter

and the RN adapter are implemented in two separate

units, either the PDM system or the RN messaging

server can be replaced with some other product

while still retaining the implementation for the other

adapter. We also needed to implement the rule

engine, as we were unable to find any existing

product suitable for the task. In addition, we had to

define the internal data model to provide flexibility

to adopting new PIPs, while the available PIPs as

such were not adequate.

Overall, we consider our architecture modular.

Changing the PDM system or the RosettaNet

messaging server would only require modifying the

associated adapter, and it is also possible to replace

the rule engine. The use of interoperable

communication protocols and an internal data model

throughout the prototype system should increase the

number of potential candidates for a new PDM

system or RosettaNet messaging server. The internal

data model enables easy transition to new PIPs, as it

can be transformed to a specific PIP with XSLT.

Otherwise, the addition of a new PIP or modifying

an existing one would require a lot more effort.

4.2 Implementation

The resources used for implementation were

significant. The prototype system allows design

documents to be transferred to the partner’s PDM

system without human intervention. However,

transferring large files may introduce a problem.

The prototype implementation took a lot of

resources although existing tools were used. Two

student groups used 700 hours implementing the

PDM adapter and the rule engine. The EDMS

configuration took 100 hours. The RN adapter was

implemented in 80 hours, and the RosettaNet

messaging server configuration took 40 hours.

Integration of the different components, testing, and

other additional work took about 80 hours, so

altogether the implementation of the prototype

system was done in about 1000 hours. This only

includes the actual implementation time, excluding

e.g. getting to know the systems used. An industrial

implementation would naturally require more time,

as our system is only a prototype. As this

implementation is for only design document

delivery, it is a considerable effort.

In order for the system to be flexible, adding new

PIPs or trading partners should be easy. To add

support for a new PIP in the prototype system takes

less than two days. Building a new XSLT takes

about a day. The modification needed for the system

components takes altogether less than one day. To

add a new partner or PIP to the prototype system

requires minor modifications to the PDM system,

the PDM adapter, the RN adapter and the RosettaNet

messaging server.

The test set-up was only a laboratory simulation

using two different PDM database schemas and

system instances of the same PDM systems

representing two companies. It showed that the

system basically works, but further testing in more

realistic settings is obviously needed.

One issue that the tests revealed was that transfer

of large files as attachments is a potential problem,

because RNIF recommends BASE-64 encoding.

This increases their size by one third, which is

significant, as design documents can be larger than

100 MB. PIPs allow typically only two hours to

acknowledge the RosettaNet business messages,

INTEGRATING DESIGN DOCUMENT MANAGEMENT SYSTEMS USING THE ROSETTANET E-BUSINESS

FRAMEWORK

507

which is challenging, as the network delivery and

server encodings may take a lot of time.

4.3 The use of RosettaNet

There were several problems with the use of

RosettaNet. The existing PIPs are not defined with

PD in mind. As a result, the definitions available in

current PIPs service contents did not provide

sufficient support for most of the document metadata

we wished to exchange in business documents. To

carry the document metadata identified in the

internal data model, we had to misuse certain PIPs in

order not to lose information. Misusing the standard

obviously affects the interoperability of our

prototype system. The RNIF seems well thought out

although those big attachments can cause problems.

So far, we have used PIP2C5 “Notify of

Engineering Change Order” with change request

documents, initially PIP2A1 “Product Information

Notification”, and later the newer versions of PIP

2A1 “Distribute Product Catalog Information” for

new document delivery. Later the 2A1 PIPs were

replaced by 2A10 “Distribute Design Engineering

Information”, which was released after we had

implemented the solution using PIP 2A1. The first

PIPs enabled meaningful carrying of only roughly

30% of the internal data model information. PIP

2A10 increased this to 85%, but for some of the

attributes of our internal data model this meant only

a close but not precise match to the term. For

example with the PIP service content fragment in

figure 2, we did not follow strictly the MGs for the

contents of “objectName” and “Supplier”. We used

them to carry the name of the exchanged document

and the document creator information. In the

remaining 15%, there were few trivial attributes for

which we did not find a close match in the PIP MG.

In addition, some of the information in the PIP

service contents needs to be better defined to avoid

misinterpretations. An example of needed extensions

to RNBD and from there to MGs is life cycle

statuses for documents. As companies define the life

cycle statuses, e.g. “pending, ready, approved,

obsolete” in different ways, RosettaNet should

provide clear definitions for these kinds of

enumerated lists to avoid misinterpretations, e.g.

whether a document should be ready before it can be

approved or vice versa. In addition, it is currently

not possible to specify that document A has

subdocuments A1 and A2. In the future, these issues

might be rectified by the forthcoming standards for

collaborative design and engineering (PIP 2D).

Technically the use of both the DTDs and MGs

for business document validation is problematic. If

the MGs are ignored and just DTDs used, the trading

partners need to agree each time on how to use

certain elements in the TPA. In future, at least some

of these issues are rectified as RosettaNet plans to

introduce W3C XML Schema for business

document validation, as it can carry the information

currently defined by DTDs and MGs.

We have noted that the more recent PIP

specifications tend to be a lot better than the older

ones, such as PIPs 2C5 and the 2A1 used in the

beginning. The resource usage for implementation

could have been also a lot less with implementation

guidelines, such as the ones available in RosettaNet

for collaborative forecasting.

4.4 Related work

There are few experience papers on e-business

integration implementations (Nurmilaakso, 2003).

We do not know of any other research on applying

e-business frameworks for PD collaboration.

Liu and Xu (2001) state similar requirements for

web-based PDM systems supporting collaboration.

They propose web browser PDM interface as a

solution, instead of the unique interfaces that were

typical at the time. The modern PDM systems have

web interfaces, but they still differ in usage logic.

Domazet et al. (2000) present an infrastructure

for collaboration based on an event-driven software

component framework using the Common Object

Request Broker Architecture (CORBA) and STEP.

The modelling capabilities distributed over the

Internet using CORBA facilitate collaboration

between product designers, and STEP provides the

common terminology. This infrastructure is partially

based on standards that are not used in our case

network and would be hard to introduce into it.

Sundaram and Shim (2001) present an

infrastructure for B2B exchanges with RosettaNet.

They have a three-tier client-server prototype that

allows customers to send RosettaNet PIPs using a

browser. Their prototype constructs RosettaNet PIP

service contents.

Sayal et al. (2002) present a tool, HP Process

Manager, that supports RosettaNet PIPs and allows

generating complete processes from PIPs by taking

also internal integration needs into account. The

functionality of this tool is similar to what our RN

adapter and RosettaNet messaging server does by

providing support for RNIF and the common

elements used in all RosettaNet PIPs.

Both experience articles with RosettaNet contrast

with our solution, as they do not present integration

to any enterprise information systems (IS). To

integrate the IS with the RosettaNet PIPs was the

most time demanding part according to our

experiences as there were the conflicts between the

terms used in IS and the ones specified in the PIP

ICEIS 2004 - SOFTWARE AGENTS AND INTERNET COMPUTING

508

service contents. Similar difficulties may well exist

with also with other e-business processes.

5 CONCLUSIONS AND FUTURE

WORK

We have presented a design and implementation of a

prototype system for supporting design data

management in product development (PD) networks.

The prototype system integrates design document

management systems (DMS) using the RosettaNet e-

business framework. It can automatically deliver and

receive e.g. the latest version of design documents.

Our experiences with the implementation and use

indicate that using RosettaNet e-business framework

for this purpose seems basically feasible. However,

there are also major potential problems regarding the

effort to implement the integration and the level of

support offered by RosettaNet. The resources used

for implementation were significant as this relatively

simple implementation took about 1000 hours,

including only the actual implementation time. The

secure delivery of documents according to

RosettaNet Implementation Framework was easy to

implement, but attachments handling is ineffective.

The RosettaNet specifications for the common

processes and the related business document

definitions should support design document

information exchange better, e.g. by ensuring

common understanding of important terms and

providing better guidelines for the usage. As

business document definitions currently enable

misusing the standard, two implementations of the

same RosettaNet process are not necessarily

compatible. Hence, the aim of industry-wide cost-

effective B2B integration through the use of the e-

business frameworks may be compromised,

particularly in the case of PD. This lack of support

by the e-business framework may also affect other

business processes besides PD.

Future work includes further testing of our

prototype system and integrating it with different

DMS and messaging servers. In addition, the utility

of the prototype system and the effect of this type of

DMS integration on the whole PD process

effectiveness should be evaluated. As the existing

RosettaNet specifications lacked the support for

design document information exchange, the relevant

future specifications should be tried. Furthermore,

more empirical data on integration efforts is needed

to better understand what is the impact of e-business

frameworks in practical systems integration efforts.

ACKNOWLEDGEMENTS

We gratefully acknowledge the financial support

from the National Technology Agency of Finland

(Tekes). We thank Jukka Borgman and Simo Jokela

for their advice on the requirements, Hannu Peltonen

for support in the implementation, and the students

who participated in the implementation.

REFERENCES

Borgman, J. and Sulonen, R. 2003. A Case Study of the

Impacts of Preliminary Design Data Exchange on

Networked Product Development Project

Controllability, in Proc. of 14

th

Int. Conf on

Engineering Design.

Clark, K. and Fujimoto, T. 1991. Product Development

Performance: Strategy, Organisation, and

Management in the World Auto Industry, Harvard

Business School Press.

Domazet, D.R., Miao Chun Yan, Chee Fook Yew, Kong,

H.P.H. and Goh, A. 2000. An Infrastructure for Inter-

Organizational Collaborative Product Development”,

in Proc. of the 33rd Hawaii Int. Conf. on System

Sciences, pp. 2176 –2185.

Jokinen, K. 2003. A Standard Data Model for Product

Development Documents. Master's Thesis. Helsinki

School of Economics.

Kotinurmi, P., Borgman, J. and Soininen T. 2003. Design

Document Management in Networked Product

Development Using Standard Frameworks, in Proc. of

14th Int. Conf. on Engineering Design.

Lee, H and Whang, S. 2001. E-Business and Supply Chain

Integration, Stanford Global Supply Chain

Management Forum SGSCMF- W2-2001.

Liu, D.T., Xu and X. W. P. 2001. A review of web-based

product data management systems, in Computers in

Industry, v.44, n.3, p.251-262.

Nurmilaakso, J.M. 2003. XML-based Supply Chain

Integration: A Review and a Case Study. Licentiate

theses, Helsinki University of Technology.

Peltonen, H. 2000. Concepts and an Implementation for

Product Data Management. In Acta Polytechnica

Scandinavica, Mathematics and Computing Series No.

105. The Finnish Academies of Technology, Espoo.

RosettaNet, 2003, http://www.rosettanet.org/.

Sayal, M., Casati, F., Dayal, U. and Shan, M-C. 2002.

Integrating Workflow Management Systems with

Business-to-Business Interaction Standards, in Proc.

of 18th Int. Conf. on Data Engineering, pp. 287 –296.

Shim S.S.X., Pendyala, V.S., Sundaram, M. and Gao, J.Z.

2000. Business-to-Business E-Commerce

Frameworks, IEEE Computer 33(10): pp. 40-47.

Sundaram, M. and Shim, S. 2001. Infrastructure for B2B

Exchanges with RosettaNet, in Proc. of the 3

rd

Int.

Workshop on Advanced Issues of E-Commerce and

Web-Based Information Systems, pp. 110-119.

INTEGRATING DESIGN DOCUMENT MANAGEMENT SYSTEMS USING THE ROSETTANET E-BUSINESS

FRAMEWORK

509