DEVELOPMENT OF AN EXPERT SYSTEM FOR DETECTING

INCIPIENT FAULT IN TRANSFORMER BY DISSOLVED GAS

ANALYSIS

Prof. N. K. Dhote

G.H.Raisoni College of Engg.,CRPF Gate No-3 , Digdoh Hills, Nagpur-16

Prof. D.M.Holey

G.H.Raisoni College of Engg.,CRPF Gate No-3 , Digdoh Hills, Nagpur-16

Prof. M.R.Ram

teke

V.N.I.T., Nagpur

Keywords: Incipient Faults, Dissolved Gas Analysis and Expert system

Abstract

Power transformer is a vital component of power system, which has no substitute for its major role. They are

quite expensive also. It is therefore, very important to closely monitor it’s in – service behavior to avoid

costly outages and loss of production. Many devices have evolved to monitor the serviceability of power

transformers. These devices such as Buchholz relay or differential relay respond only to a severe power

failure requiring immediate removal of transformer from service, in which case, outages are inevitable. Thus,

preventive techniques for early detection of faults to avoid outages would be valuable. A prototype of an

expert system based on Dissolved Gas Analysis (DGA) technique for diagnosis of suspected transformers

faults and their maintenance action are developed. The synthetic method is proposed to assist the popular gas

ratio methods. This expert system is implemented into PC by using “Turbo Prolog” with rule based

knowledge representations. The designed expert system has been tested for N.T.P.C., Talcher (India)

transformer’s gas ratio records to show its effectiveness in transformer diagnosis.

1 INTRODUCTION

Like any diagnosis problems, diagnosis of an oil-

immersed transformer is a skilled task. A transformer

may function well externally with monitors, while

some incipient deterioration may occur internally to

cause fatal problem in later development. Nearly 80

% of faults result from incipient deteriorations.

Therefore, faults should be identified and avoided at

earliest possible stage by some predictive

maintenance technique.

DGA is very efficient tool for this purpose. Like a

blood test or a scanner examination of the human

body, it can warn about an impendent problem, give

an early diagnosis and increase the chances of finding

the appropriate cure. The operating principle is based

on slight harmless deterioration of the insulation that

accompanies incipient faults, in the form of arcs or

sparks resulting from dielectric breakdown of weak

or overstressed parts of the insulation, or hot spot due

to abnormally high current densities in conductors,

whatever the cause, these stresses

will result in

chemical breakdown of some of the oil or cellulose

molecules consisting the dielectric insulation. The

main degradation

products are gases, which entirely

or partially

dissolve in the oil where they are easily

detected at the ppm level by DGA analysis

2 DEVELOPMENT OF

DIAGNOSIS AND

INTERPRETATION

Oil degradation and other insulating materials e.g.,

cellulose and paper generally produce fault gases in

transformers. Theoretically, if an incipient fault is

present, the individual gas concentration, generating

210

K. Dhote N., M.Holey D. and R.Ramteke M. (2004).

DEVELOPMENT OF AN EXPERT SYSTEM FOR DETECTING INCIPIENT FAULT IN TRANSFORMER BY DISSOLVED GAS ANALYSIS.

In Proceedings of the Sixth International Conference on Enterprise Information Systems, pages 210-215

DOI: 10.5220/0002630302100215

Copyright

c

SciTePress

rate and total combustible gas (TCG) are all

significantly increased.

By using gas chromatography [4,6] to analyze the gas

dissolved in transformer’s insulating oil, it becomes

feasible to judge the incipient fault types. The main

gases formed as a result of electrical and thermal

faults in transformers and evaluated by DGA are H

2,

C H

4,

C

2

H

2,

C

2

H

4,

C

2

H

6,

CO, C O

2.

Their relative

proportions have been co related through empirical

observations and laboratory simulations, with various

types of transformer encountered in transformer in

service

Many interpretative methods based on DGA to

diagnose the nature of incipient deteriorations have

been reported. Even under normal transformer

operational conditions, some of these gases may be

formed inside. Thus, it is necessary to build

concentration norms from a sufficiently large

sampling to asses the statistics.

A Key Gas Method [2] based on thermodynamic

considerations. The degree of chemical instauration

of the gases formed is related to the energy density of

the fault. Acetylene is thus mainly associated with

arcing, where temperature reach several thousands

degrees, Ethylene with the hot spot between 150

0

C

and 1000

0

C and Hydrogen with the “cold” gas

plasma of corona discharges.

Dornerburg [1] developed a

method to judge different faults by rating pairs of

concentrations of gases, e.g., C H

4

/ H

2,

C

2

H

2

/

C

2

H

4

with approximately equal solubilities and diffusion

coefficients.

Rogers [2] established more competitive

ratio codes to interpret the thermal fault types with

theoretical thermodynamic assessments. This gas

ratio method was promising because it eliminated the

effect of oil volume and simplified the choice of

units. Moreover it systematically classified the

diagnosis expertise.

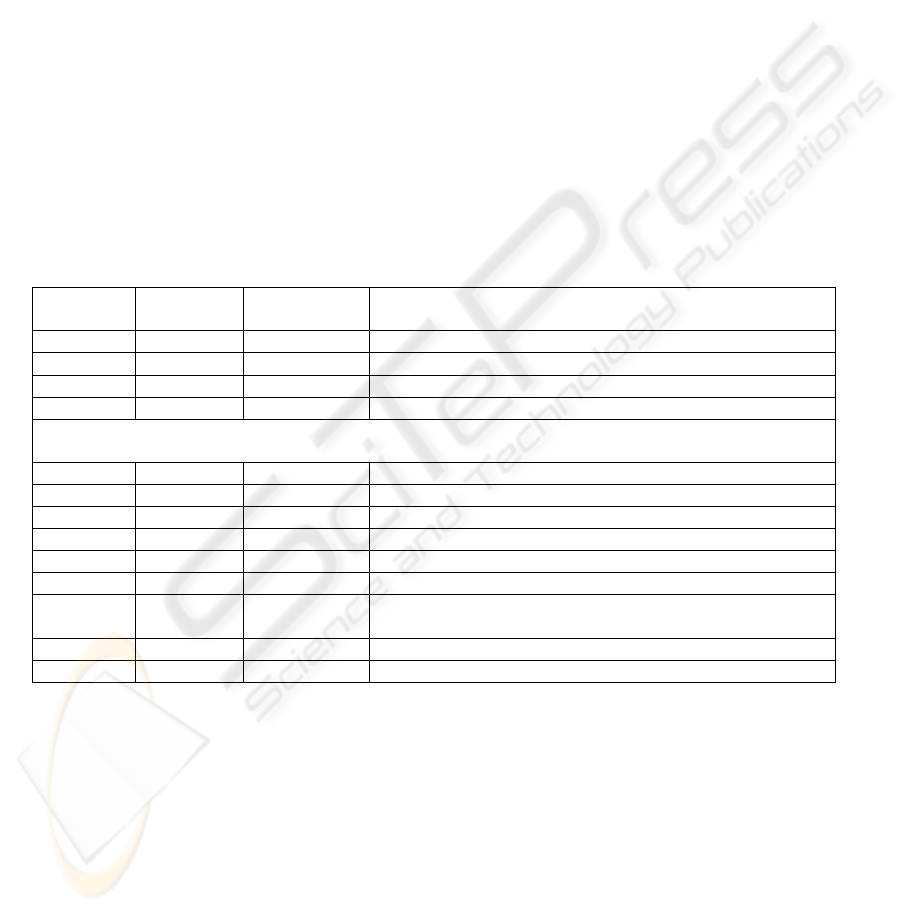

Table 1: IEC/IEEE codes for the interpretation of DGA results

A very recent method, which gives more correct

result about the interpretation of fault, is

Evolutionary Fuzzy Diagnosis System, EFDS [7].

This method also uses three gas ratios. The ratios are

scaled into symbolic codes. The advantage of this

method is that if there is more than one fault

developing at same time, this system finds out the all

the faults with their possibility values.

The most widely used tool for this purpose is the

IEC-IEEE [2] ratio method depicted in Table1. One

drawback of this method in its present form is that a

significant number of DGA results in service fall

outside the proposed codes and cannot be diagnosed.

Other methods that overcome this limitation have

therefore been developed.

3 THE PROPOSED DIAGNOSTIC

EXPERT SYSTEM

This study is aimed as developing a rule-based expert

system to perform transformer diagnosis. The details

of system are described below:

C2H2/

C2H4

CH4/H2

C2H4/

C2H6

Range of gas ratio

0 1 0 < 0.1

1 0 0 0.1-1

1 2 1 1-3

2 2 2 Greater than 3

Characteristic Fault :

0 0 0 Normal ageing

2 1 0 Partial discharge of low energy density

1 1 0 Partial discharge of high energy density

1-2 0 1-2 Continuous sparking

1 0 2 Discharge of high energy

0 0 1 Thermal fault of low temp <150 deg cel

0 2 0

Thermal fault of low temp between

150-300 deg cel

0 2 1 Thermal fault of medium temp between 300-700 deg cel

0 2 2 Thermal fault of high temp >770 deg cel

DEVELOPMENT OF AN EXPERT SYSTEM FOR DETECTING INCIPIENT FAULT IN TRANSFORMER BY

DISSOLVED GAS ANALYSIS

211

3.1 Expert System Structure

Expert system is one of the area of Artificial

Intelligence (AI) which has moved out from research

laboratory to the real word and is shown its potential

in industrial and commercial application .An expert

system is computer system which can act a human

expert within one particular field of knowledge .The

expert system embodies knowledge about one

specific problem domain and possesses the ability to

apply this knowledge to solve

problem domain.

Ideally the expert system can also learn from its

mistakes and gain experience from its successes and

failure. The system should able to explain the

reasoning behind the way in which it has aimed at a

particular conclusion.

An expert system comprises three base components.

1. Knowledge base

2.An inference engine

3.An user interface

The ‘Knowledge Base’ comprises a series of facts

and rules about the particular problem area from

which system draws its expertise. A fact is a clear

concise statement, which expresses something, which

is true within particular problem domain. A rule used

in this system is expressed in If- Then forms. A

successful expert system depends on a high quality

knowledge base. For this transformer diagnosis

system, the knowledge base incorporates some

particular interpretation methods of DGA. In order to

make use of the expertise which is embodied in the

knowledge base. The expert system must also posses

an element, which can scan facts and rules and

provide answers to the queries given to it by the user.

This element is known as ‘Inference Engine’. The

Inference Engine has the ability to look through he

knowledge base and apply the rules to the solution of

a particular problem. It is a component that generates

new knowledge from base knowledge .It is, therefore,

the driving force of the expert system.

The ‘User Interface’ is the means by which the user

communicates with the expert system and vice versa.

Ideally this interface should be as simple as possible

so as to facilitate its use by the experienced users.

That is an ideal expert system would allow the user to

type his questions to the system in English. The

system would then recognize the meaning of the

questions and use its inference engine to apply the

rules in the knowledge base to deduce an answer.

This answer would then be communicated back to

user in English.

3.2 The Proposed Diagnostic Method

Diagnosis is a task that requires experience. It is

unwise to determine an approach from only a few

investigations. Therefore, this study uses synthetic

‘expertise method, with the experienced procedure to

assist the gas ratio method. For the development of

any expert system, there should be proper selection

of a development tool. The different packages i.e.,

Expert system, Shell, Rule master, etc. can also be

used for development, but these packages have their

own limitations, since they use their own rules and

instructions. But a computer language is more

flexible and the user can develop his own

methodology for the program formulation. So instead

of using package, we can choose computer language

for expert system development. The language chosen

should be simple and declarative. ‘Turbo prolog’ has

these facilities. One of the major advantages of

prolog is that it has its own inference engine, which

facilitates easy development of expert system.

Therefore, prolog has been used for the development

of proposed expert system.

3.3 Experienced Diagnostic Procedure

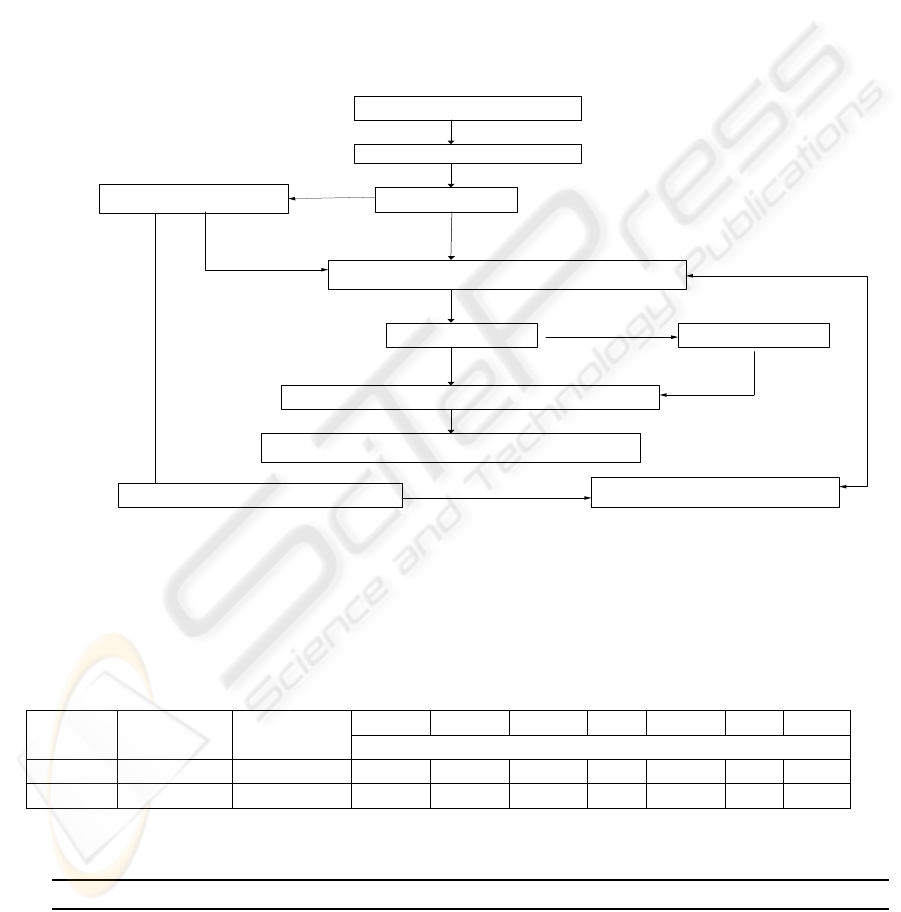

As shown in figure 1, the overall procedure of routine

maintenance for transformer is listed. The core of this

procedure is based on the implementation of DGA

techniques. The gas ratio method is significant

knowledge source. The Key gas method [2],

Dornerburg [1], Rogers [2], IEC [2] and EFDS [7]

approaches have been implemented together. The

single ratio method is unable to cover all possible

cases; other diagnostic expertise should be used to

assist this method. Synthetic expertise method and

database records have been incorporated to complete

these limitations.

The first step of this diagnostic procedure begins by

asking DGA for an sample to be tested, more

important information about transformer’s condition

such as VA rating, Voltage rating, volume of oil in

tank and date of installation of transformer must be

known for further inference. If the transformer is not

degassed after previous diagnosis, then probability of

fault and rate of evolution of total combustible gases

are found. If rate of evolution is normal, further

diagnosis can be bypassed. Permissible limits for

different gases are checked. For the abnormal cases,

the gas ratio method is used to diagnose transformer

fault type. If different diagnosis results are found

from these ratio methods, a system diagnosis is

adopted. After these procedures, different severity

degrees are assigned to allow appropriate

maintenance suggestions.

ICEIS 2004 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

212

4 IMPLEMENTATION OF

PROPOSED EXPERT SYSTEM

An expert system is developed based on the proposed

interpretative rules and diagnostic procedure of an

overall system. To demonstrate the feasibility of this

expert system in diagnosis, the

gases data are

supported by ‘NTPC, Talcher’ have been tested.

After analyzing oil samples, more than Ten years

worthy gas records are collected. In the process of

DGA interpretation, all of these data may be

considered, but only data that have significant effects

on diagnosis are listed in the later demonstration.

From the expertise of diagnosis, normal state can be

confirmed only by inspection of the transformer’s

normal level. In practice, most of the transformer oil

samples are normal, and this can be inferred

successfully on the early execution of this expert

system. However, the success of an expert system is

mainly dependent on the capability of diagnosis for

transformers in question. In the implementation,

many gas records that are in abnormal condition are

chosen to test the justification of this diagnostic

system. Amongst those implemented, two are listed

and demonstrated

Ask for sampling DGA

Relevant information

If Degas

Compare gas concentration limit

Ratio method system diagosis

inter severity degree

Preventive maintenance

store data as background

Normal maintenance

Rate of evolution

No

YES

Less

Than

0.1

Cuft/

day

More

than

0.1 cuft/

day

Abnormal

Normal

Different

Result

Analogous

result

Fig 1- Procedure of proposed expert system

DATA:

TSTPS1, Date of installation: 12/03/90

200MVA, 400KV /21KV,

Volume of tank: 500 gallons.

Table 2: Concentration of gases in PPM.

C2 H2

C2 H4

C H4

H2

C2 H6

CO

CO2

Sample

No.

Date of

sampling

Whether

Diagnosed

Concentration of gases in ppm.

1 29/07/96 Yes 0 3 2 2 8 0 25

2 25/12/96 No 35 105 490 383 53 88 589

Sample-1

Results of Sample Implementation:

* All gases are within the safe level.

• Normal ageing of transformer.

Figure 1: Procedure of proposed expert system

DEVELOPMENT OF AN EXPERT SYSTEM FOR DETECTING INCIPIENT FAULT IN TRANSFORMER BY

DISSOLVED GAS ANALYSIS

213

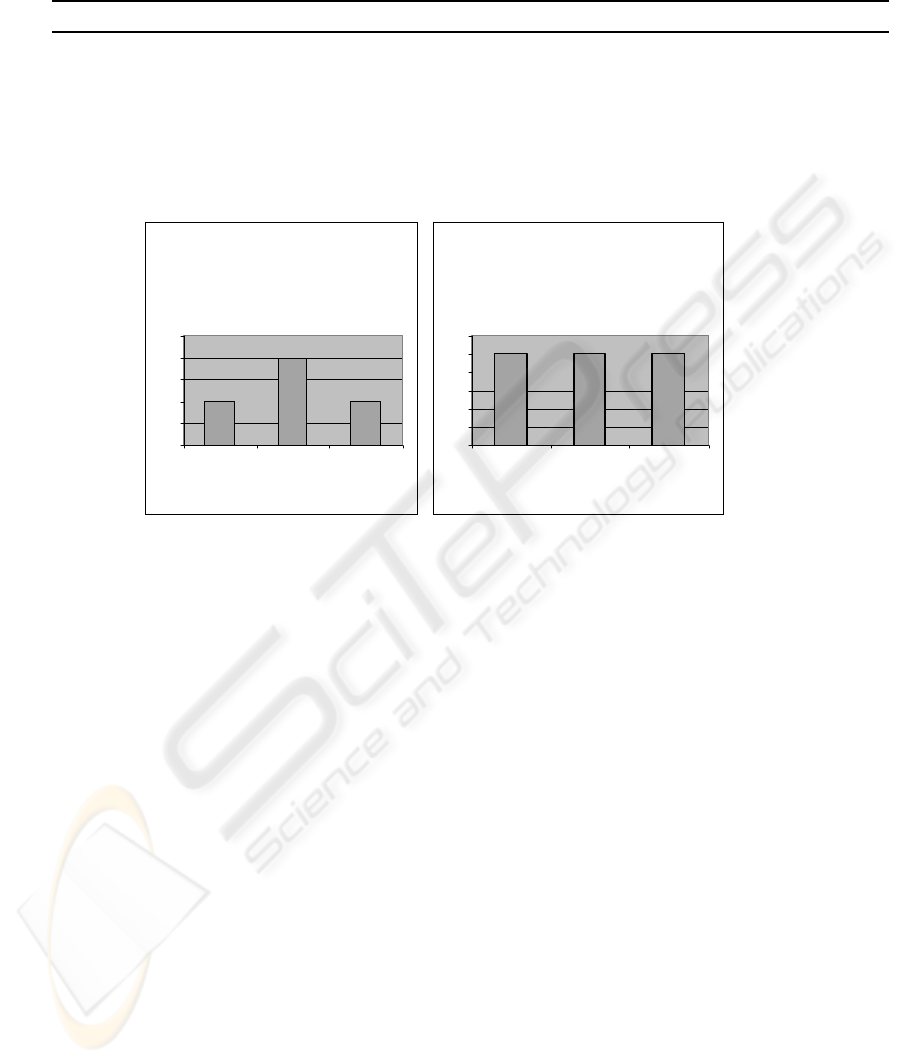

Sample –2

Results of Sample Implementation:

Rate of TCG = 1.29 cu.ft. /day

Key Gas Method: Severe Overheating

Dornerburg Ratio: Thermal Decomposition.

Roger’s Ratio Method: Winding circulating currents

IEC Method: Discharge of high-energy thermal fault (300-700 deg .C)

EFDS Method: Low energy discharge with 45 % probability.

System Diagnosis: Low energy discharge

IEC DIAGNOSIS:DISCHARGE

OF HIGH ENERGY THERMAL

FAULT

0

0.5

1

1.5

2

2.5

123

C2H2/C2H4 CH4/H2 C2H4/C2H6

EFDS METHOD:LOW ENERGY

DISCHARGE WITH 45%

PROBABILITY

0

0.2

0.4

0.6

0.8

1

1.2

123

C2H2/ C2H4 CH4/ H2 C2H4/ C2H6

-----------------------------------------------------------------------------------------------------------------

Recommendation of maintenance:

-----------------------------------------------------------------------------------------------------------------

• Investigate immediately.

• Oil should be degassed.

• Retest oil within half month.

-----------------------------------------------------------------------------------------------------------------

5 CONCLUSION

Prototype expert system is developed on a PC

using ‘Turbo Prolog’. It can diagnose the

incipient faults of the suspected transformers

and suggest proper maintenance actions. System

diagnosis is proposed to assist the situation,

which cannot be handled properly by gas ratio

methods. Results from the implementation of

the expert system shows that the expert system

is a useful tool to assist human experts and

maintenance engineers.

The knowledge of this expert system is

incorporated within the particular interpretative

methods of DGA. The data base supported by

NTPC, Talcher for about 10 years collection of

transformer inspection is also used to improve

the interpretation of diagnosis. The two

examples presented are depicted from records

and symmetry of test results is listed to justify

them. This work can be continued to expand the

knowledge base by adding any new experience,

measurement and analysis techniques

.

REFERENCES

E. Dornerburg, W.Strittmatter, Monitoring Oil Cooling

Transformers by Gas Analysis, Brown Boveri

Review, 61,pp 238-247,May 1974.

R.R.Rogers, IEEE and IEC Codes to Interpret Incipient

Faults in Transformers, Using Gas in Oil

Analysis,

IEEE Trans. E.I., Vol. EI –13, NO.-5,pp 349-354,oct

1978.

M.Duval, Hydro-Qubec, It Can Save Your Transformer,

IEEE Electrical Insulation Magazine, Vol.5, No.6,

Nov/Dec 1989.

ASTM Method D 3612, Analysis of Gases Dissolved in

Electrical Insulating Oil by Gas Chromatography,

1979.

ICEIS 2004 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

214

G.Belanger, M.Duval, Monitor for Hydrogen dissolved in

transformer Oil, ‘Hydran’ Available from Syprotech

Inc., Canada, IEEE Trans. on Electrical Insulation,

Vol E1-12, No.-5,pp 335-340,1977.

H.Tsukioka, K.Sugawara, E. Mori, S.Hukumari,

S.Sakau,New Apparatus for Detecting H2, CO, &

CH4 Dissolved in Transformer Oil, IEEE Trans.

Electrical Insulation, Vol. E1-18, No.4, pp 409-419,

1983.

Yann- Chang Huang, Hong-Tza Yang, Ching-Lien Hnany,

Developing a New Transformer Fault Diagnosis

System Through Evolutionary Fuzzy Logic, IEEE

Trans. on Power Delivery, Vol.12, No2, April 1997.

ANSI / IEEE CS7.104-1978,Guide for the Detection and

Determination of Generated Gases in Oil Immersed

Transformer and Relating to the Serviceability of the

Equipment.

DEVELOPMENT OF AN EXPERT SYSTEM FOR DETECTING INCIPIENT FAULT IN TRANSFORMER BY

DISSOLVED GAS ANALYSIS

215