DYNAMIC NEGOTIATION FOR REAL-TIME

MANUFACTURING EXECUTION

L.Q. Zhuang, J.B. Zhang, B.T.J. Ng, Y. Tang, Y.Z. Zhao

Singapore Institute of Manufacturing Technology, 71 Nanyang Drive, Singapore

Ke

ywords: Multi-Agent System, Performance and Cost for Manufacturing Execution, Agent Consortium, Dynamic

Negotiation

Abstract: This paper presents a dynamic negotiation framework for real-time execution in self-organised

manufacturing environments. The negotiation strategies in this framework bridge the gap between

distributed negotiation of self-interested agents and cooperative negotiation among agent groups. In

particular, the proposed framework is based on the model of Performance and Cost for Manufacturing

Execution (PCME). By forming the dynamic organisation called agent consortium, individual agents

negotiate over the PCME in order to optimise the resource allocation under time constraints and uncertainty

of job execution, and resolve the conflicts to fulfil the goal of the overall system. The ultimate goal of the

framework is to reduce the negotiation time, make effective use of resources, adapt to the changes in

execution and increase the throughput of the entire system. Experimental work based on PCME has been

carried out to demonstrate the high performance of this approach despite unanticipated and dynamic

changes in the manufacturing execution environments.

1 INTRODUCTION

In modern complex manufacturing execution

environments, autonomous or self-organised systems

are being deployed to deal with increasingly diverse

operations and to control real-time dynamic

situations under uncertainty. These real-time tasks

are further complicated by coalition coordination.

The need for more flexibility, robustness and

scalability and the trend to handle increasing

complexity is driving research into the area of

distributed intelligent computation.

Distributed artificial intelligence (DAI) is the

emerging information technology to meet the new

challenges. Over the past few years, agent-based

computing has been hailed as the next significant

breakthrough in areas of DAI (Sargent, 1992).

Intelligent agents and multi-agent systems (MAS)

are able to conduct independent jobs in open and

unpredictable environments. The properties of an

intelligent agent, such as social ability, mobility,

autonomy, reactivity and pro-activeness have made

MAS a very relevant technology for various

manufacturing domains such as enterprise

integration, manufacturing planning, scheduling and

control, and holonic manufacturing systems (Shen,

1999). The MAS architecture is able to adapt itself

to changes and disturbances in the manufacturing

execution such as dynamic execution changes,

process changes and equipment failures etc. The

MAS architecture is also able to model the

manufacturing execution processes in distributed

ways to reduce the complexity of manufacturing

systems and to increase the interoperability between

the heterogeneous systems at the same time. As

such, more and more researchers are introducing the

agent technologies and MAS architecture to real-

time manufacturing areas, including manufacturing

execution, automated material handling and

autonomous robotic control systems (Deen, 2003).

Odell proposed “The Agile Manufacturing

Information System”, an agent-based model, which

defined cell agent architecture as self-contained unit

that had its own structure and behaviour (Odell,

2002). This model provided a conceptual

architecture and a general approach for agent-based

manufacturing systems. Jennings et al. proposed the

321

Q. Zhuang L., B. Zhang J., T. J. Ng B., Tang Y. and Z. Zhao Y. (2004).

DYNAMIC NEGOTIATION FOR REAL-TIME MANUFACTURING EXECUTION.

In Proceedings of the Sixth International Conference on Enterprise Information Systems, pages 321-326

DOI: 10.5220/0002651003210326

Copyright

c

SciTePress

agent-based control systems for electricity

transportation management and manufacturing line

control (Jennings 2003). The proposed negotiation

protocols between the agents in this distributed

manufacturing system had proven the effectiveness

of the framework. Fatima et al. introduced an

organisational policy known as TRACE (Task and

Resource Allocation in Computational Economy)

(Fatima 2001). The task allocation in the model is

NP-complete; hence the centralised solutions to the

problem are not feasible. TRACE is able to adapt

itself to any changes in the computational load by

reorganising the MAS. Dias et al. used market-based

coordination mechanism for optimisation of task and

resource allocation for multi-robot control systems

(Dias 2002). The optimisation for the activities of

robots can be achieved in an adaptive way. Ng et al.

proposed a framework called Self-Organising Multi-

Equipment Control (SOMEC) for the holonic

manufacturing systems (Ng, 2003). Intelligent units

(IU) in a set of equipment worked together to

achieve a global goal via the cooperative negotiation

approach. The above research work has

demonstrated that MAS is an effective architecture

to handle the adaptive manufacturing execution

processes in dynamic and uncertain environments.

However most of above research work only used the

fixed negotiation strategies for the different

manufacturing execution aspects and did not provide

goal recovery mechanism and time boundary of

negotiation for the autonomous agents.

For real-time manufacturing execution systems,

the response time is one of the important issues in

order to fulfil the manufacturing execution targets.

The normal timeframe for each task is restricted

within a few seconds for most of the execution

activities. Hence MAS architecture to support the

above manufacturing system only allows very

limited time for agents to interact with each other.

On the other hand, the resource utilisations within

the execution domain need to be optimised as well.

So the agent negotiation and coordination in such a

framework must be carried out in an adaptive way.

Traditional global optimisation techniques used in

the planning and scheduling systems are not suitable

for the resource and task allocation in the real-time

execution environment.

Agent negotiation and coordination for real-time

execution requires a unique mechanism. In this

paper we propose a multi-phase dynamic negotiation

framework that is focused on the fast and flexible

decision making aspect of the system so that it is

responsive enough for the time critical tasks and also

adaptive for dynamic environments. In the proposed

framework, a specific virtual organisation concept

called agent consortium is introduced for the MAS

architecture. The PCME is applied as a measurement

for agents to negotiate among the consortia and the

PCME value can be calculated based on the

structure of each consortium.

The remainder of the paper presents details of

the framework that can be used to coordinate the

execution activities of physical equipment units in

the manufacturing environment. Section 2 defines

the mathematical model for the dynamic negotiation.

Section 3 defines the multi-phase negotiation

strategies for real-time manufacturing execution. In

Section 4 we demonstrate the experimental work of

applying the proposed framework for an

autonomous Automated Storage and Retrieval

Systems (ASRS). In Section 5 the benefits of the

proposed framework will be summarised.

2 DYNAMIC NEGOTIATION

MODEL

Through decomposition, abstraction and

organisation, the traditional manufacturing execution

system that is organised in the hierarchical structure

can be transformed into the MAS architecture.

Dynamic integrative negotiation strategies are used

in the proposed framework to reach the contract

agreement in a co-operative way at the interests of

global goals, whereas individual agents are

responsible for allocating resources to ensure their

own interests when they carry out the tasks. The

proposed dynamic negotiation strategies aim to

strike a balance between the distributed negotiation

and the cooperative negotiation so that a more

effective and adaptive mechanism can emerge in the

new framework.

2.1 Agent Consortium

The agent consortium is defined as a group of

relevant agents with some capabilities to fulfil the

specific job in the system. The proposed approach

defines an initiator agent for each job. The initiator

agent issues the job contract with a specific

workflow. According to the workflow requirement,

each agent that is qualified for the job joins a

consortium with other agents involved in the job

processes. So the consortium can be formed by

relevant agents in form of a partially ordered set

(poset) according to the workflow dependencies.

The agent consortium can be represented by a

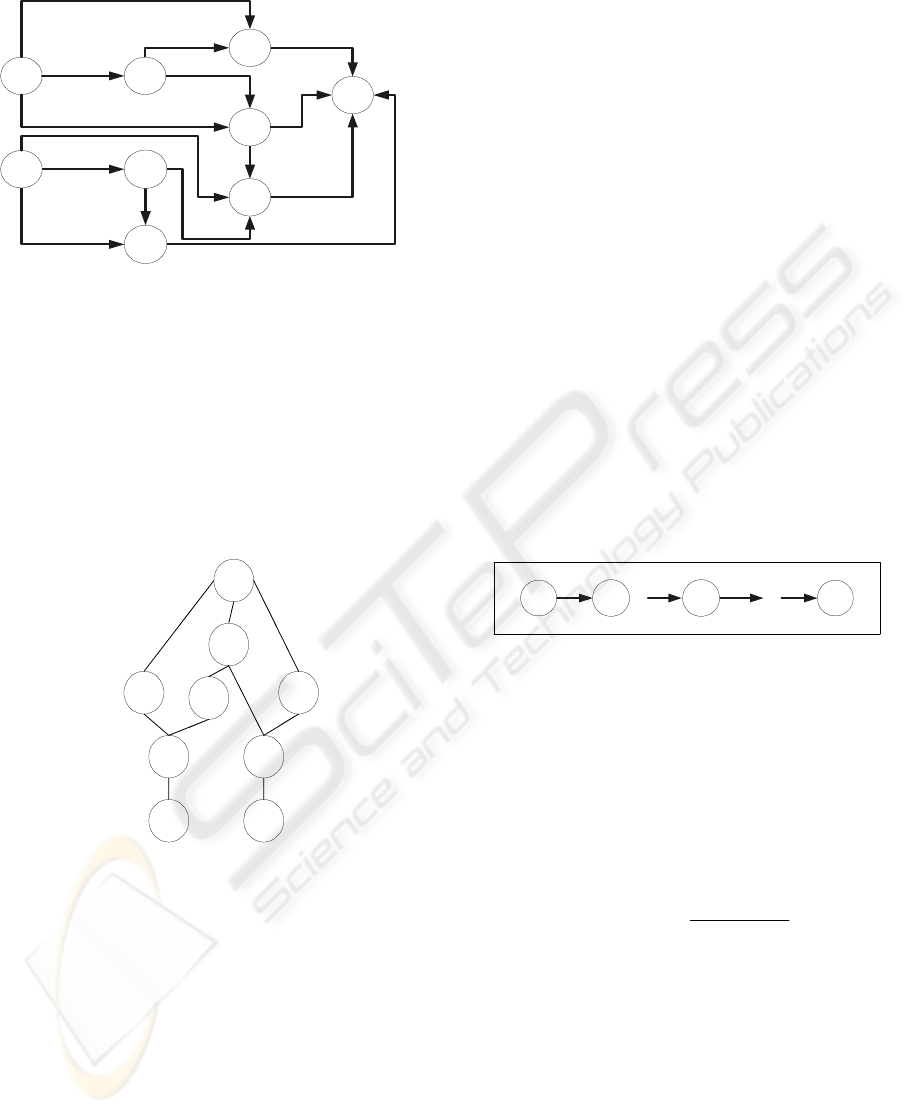

directed graph (digraph, see an example in Figure 1).

More than one consortium could be formed for each

job. In Figure 1, a node from P1 to P9 represents the

agent for the different cell controller or equipment.

ICEIS 2004 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

322

Figure 1: Digraph for an agent consortium.

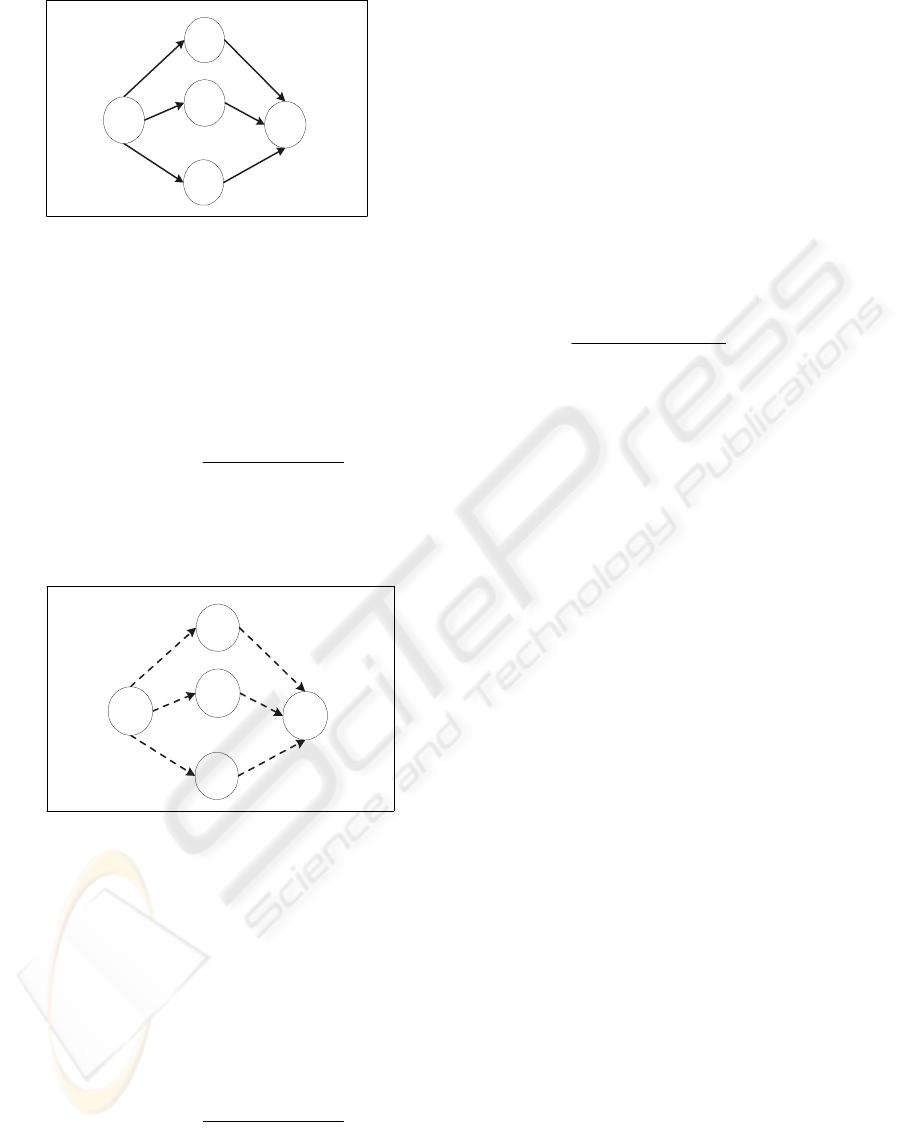

The digraph representing the agent consortium

can be further transformed to an upward drawing,

which is called the Hasse diagram in order to show

the workflow dependencies. Figure 2 shows the

Hasse diagram that is converted from digraph in

Figure 1.

Based on the Hasse diagram constructed for the

agent consortium digraph, the topological sorting of

the agent members can be generated for the above

case: {P1, P3, P2, P4, P6, P7, P5, P8, P9}.

Figure 2: A Hasse diagram for the agent consortium.

In the above case, the poset can be further

divided into five logical groups: G

1

: {P1, P3}, G

2

:

{P2, P4}, G

3

: {P5, P6, P7}, G

4

: {P8} and G

5

{P9}.

Hence, the sequential relationship can be set up

among the logical groups. The concurrent and

redundant relationship can be set up among the

agents in each group.

The following procedure shows the algorithm to

form the logical groups for a consortium.

; Logical Grouping for Hasse Diagram

proc LG(S:finite poset)

k:=1;

while S<>Ф

begin

G

k

:= set of minimal element of S

S: = S – G

k

k:= k +1

end

endproc

Definition for minimal element: Let <A,

≤ > be

a poset, where

≤ represents an arbitrary partial

order. Then an element b ∈ A is a minimal element

of A if there is no element a ∈ A that satisfies a

≤

b.

2.2 Performance and Cost for

Manufacturing Execution

In the proposed framework, four performance

indicators are defined for the PCME model: time for

process, resource cost, system reliability and process

throughput. Three fundamental structures are

defined as the foundation for the PCME model: the

sequential structure, the concurrent structure and the

redundant structure.

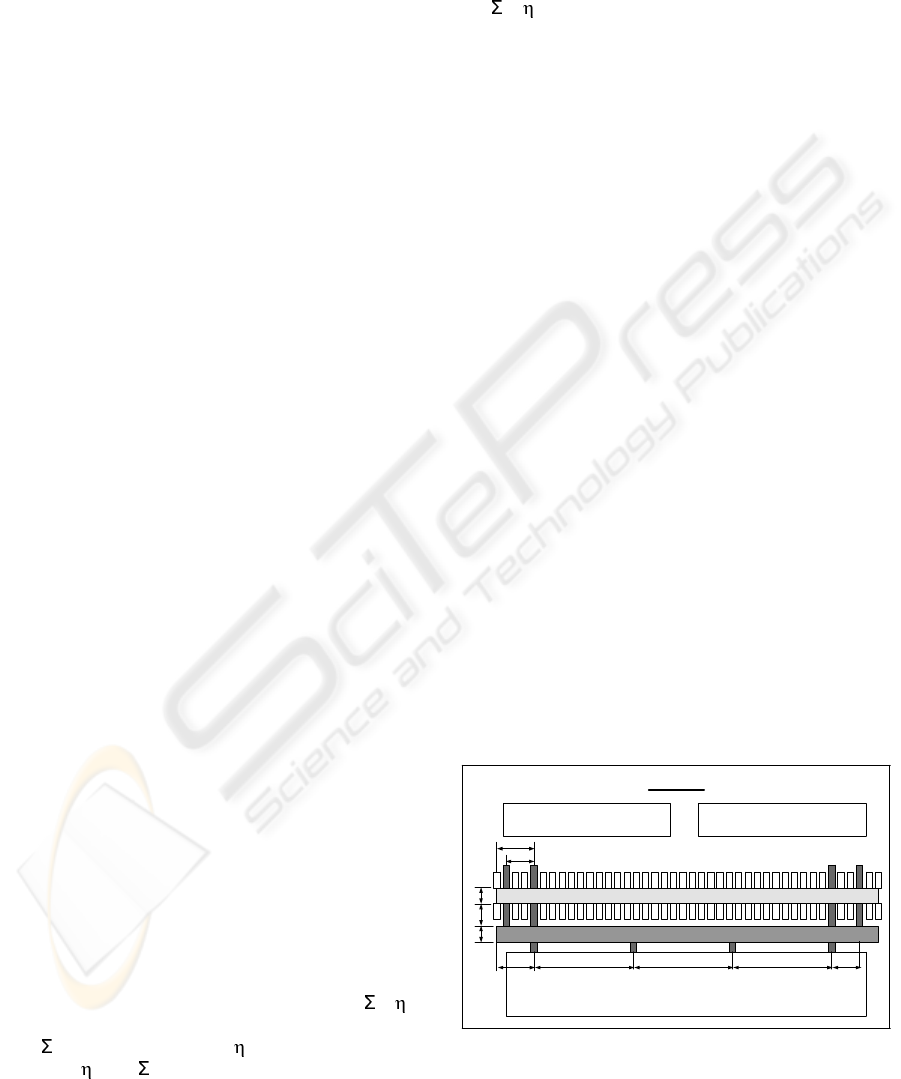

Figure 3 shows the sequential structure in the

PCME model. PCME calculation formulas are

shown in (1) – (4).

Figure 3: PCME for sequential structure.

Time for Process = (1)

Resource Cost = (2)

System Reliability = (3)

Process Throughput = (4)

In (4),

u

is the maximum number of units that

can be processed within the timeframe T.

Where 1 <

u

< n and T =

Figure 4 shows the concurrent structure in the

PCME model. PCME calculation formulas are

shown in (5) – (8).

P1 P2

P3 P4

P6

P7

P8

P9

P5

P1

P2

P3

P5

P9

P7

P8

P6

P4

G1 G2 GnGi

...... ......

∑

=

n

i

GT

1

i

)(

∑

=

n

i

i

GC

1

)(

∏

=

n

i

i

GR

1

)(

∑

=

n

i

i

GT

u

1

)(

∑

=

n

i

i

GT

1

)(

DYNAMIC NEGOTIATION FOR REAL-TIME MANUFACTURING EXECUTION

323

Figure 4: PCME for concurrent structure.

Time for Process=Max{T(A

i

)}(i∈{1,2,…m})(5)

Resource Cost = (6)

System Reliability = (7)

Process Throughput = (8)

Figure 5 shows the redundant structure in the

PCME model. PCME calculation formulas are

shown in (9) – (13).

Figure 5: PCME for redundant structure.

Time for Process=Min{T(A

i

)}(i∈{1,2,…p}) (9)

Resource Cost = Max{C(A

i

)} i∈{1,2,…p}) (10)

System Reliability = 1 – (11)

Where F(A

i

) = 1 – R(A

i

) (12)

Process Throughput = (13)

2.3 Performance Level for Equipment

Execution

For individual equipment, the performance level for

equipment execution can be measured by the

extended and enhanced quality of service (QoS)

concept for the manufacturing execution, which was

introduced by Wong et al. (Wong, 2003). The

performance levels will be taken as negotiation

objects in the agent negotiation for the low-level

equipment execution. The formula to calculate the

performance level is shown in (14).

PL(t) = (14)

Where

PL(t) = the performance level at time t

)(tpi = points for the award or the penalty for i

th

factor at time t

ω

i

= coefficients for i

th

factor

N = number of the award and the penalty factors

3 NEGOTIATION PROCESSES

The proposed dynamic negotiation can be viewed as

distributed search in the space of PCME as well as

performance levels of manufacturing execution

(Jennings, 2001). The negotiation objects are the

performance indicators defined in the PCME model

as well as capabilities of the equipment. A decision-

making model of agents is designed in two levels: at

the consortium level, it will follow the cooperative

negotiation approach, and at logical group level, it

will follow the self-interested negotiation approach.

3.1 Cooperative Negotiation

Approach

Every job generated in the autonomous

manufacturing system is associated with a contract.

Contract negotiation (Mathieu, 2002) is carried out

by a group of agents that perform specific tasks at

different stages of the whole contract in a dynamic

environment with common resources. Depending on

its position in the consortium, each agent may

assume the dual roles of being an initiator and a

consortium member. The agent members in the

consortium collectively issue a bid using the PCME-

based reasoning and the contract will be granted to

one of the consortia with the best PCME results.

A1

A2

Am

......

X

Y

∑

=

m

i

i

AC

1

)(

∏

=

m

i

i

AR

1

)(

)}({ iATMax

m

N

tp i

N

i

i

) )((

1

ω

∑

=

×

∏

=

p

i

i

AF

1

)(

)}({

1

iATMin

A1

A2

Ap

......

X

Y

ICEIS 2004 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

324

A 6-tuple M = (J, I

0

, G, f, C, A) is defined for the

modelling of the consortium, where J is a set of job

contracts, G is goal of contract, I

0

∈A is initial agent,

A is set of all agents, C⊆A is consortium and f: J ×

I

0

× G Æ C. This model is the basis to dynamically

generate feasible consortia.

The maximum four-round negotiation strategies

are defined for the framework at the consortium

level. The negotiation search space in the next round

will be smaller if the negotiation is not resolved in

the current round.

Strategies for the 1

st

round negotiation: To

negotiate over the time for process in PCME model

and form a set of consortia in terms of Hasse

diagrams. Go to the 2

nd

round negotiation if more

than one consortium is formed, or reach contract

agreement and go to the group level negotiation.

Strategies for the 2

nd

round negotiation: To

negotiate over the cost in PCME model among the

set of consortia in the 1

st

round negotiation and form

a subset of consortia in terms of Hasse diagrams.

Go to the 3

rd

round negotiation if more than one

consortium is formed, or reach contract agreement

and go to the group level negotiation.

Strategies for the 3

rd

round negotiation: To

negotiate over the reliability in PCME model among

the set of consortia in the 2

nd

round negotiation and

form a subset of consortia in terms of Hasse

diagrams. Go to the 4

th

round negotiation if more

than one consortium is formed, or reach contract

agreement and go to the group level negotiation.

Strategies for the 4

th

round negotiation: To

negotiate over process the throughput in PCME

model among the set of consortia in the 3

rd

round

negotiation and form a subset of consortia in terms

of Hasse diagrams. Reach contract agreement and

go to the group level negotiation.

3.2 Self-Interested Negotiation

Once contract agreement is reached and the job is

granted, agents in the consortium will negotiate

internally by their own interests for tasks of the job.

The negotiation objects are based on the

performance level each agent can provide.

Individual agent negotiates over performance level

to reach agreement for task execution. As the result,

one agent may join multiple consortia and hold more

than one job at certain point of time.

The finite state automaton (FSA) can represent

the operation model of the agent. Let A = (Y,

, ,

y

0,

Y

m

) be a 5-tuple, where Y is the set of equipment

states,

is the set of actions, is the set of process

transitions (

: Y × * Æ Y), q

0

is the initial state of

the equipment and Y

m

⊆ Y is the set of final

equipment status.

3.3 Enforcement and Re-negotiation

In practice, the actions of the agents always have a

temporal extent. The FSA can be extended to a 7-

tuple timed automaton (Alur & Dill, 1994): TA =

(Y,

, , y

0

, Y

m,

X, D) where X is a finite set of

clocks and D is set of other data structures.

Timed action should have some checkpoints and

intermediate effects could be incorporated with the

agent state at these checkpoints. The temporal logic

is used to describe the time constraint of the actions

(Subrahmanian, 2000; Collins, 2002; Dix, 2001).

The goal of job is verified upon state changes of

the timed automaton. If the goal is not met after

certain stage, the agent will try for the goal recovery

by re-negotiation within the same cluster, which is

represented by a redundant structure. Another agent

in the same cluster will take the enforcement action.

4 IMPLEMENTATION AND

RESULTS

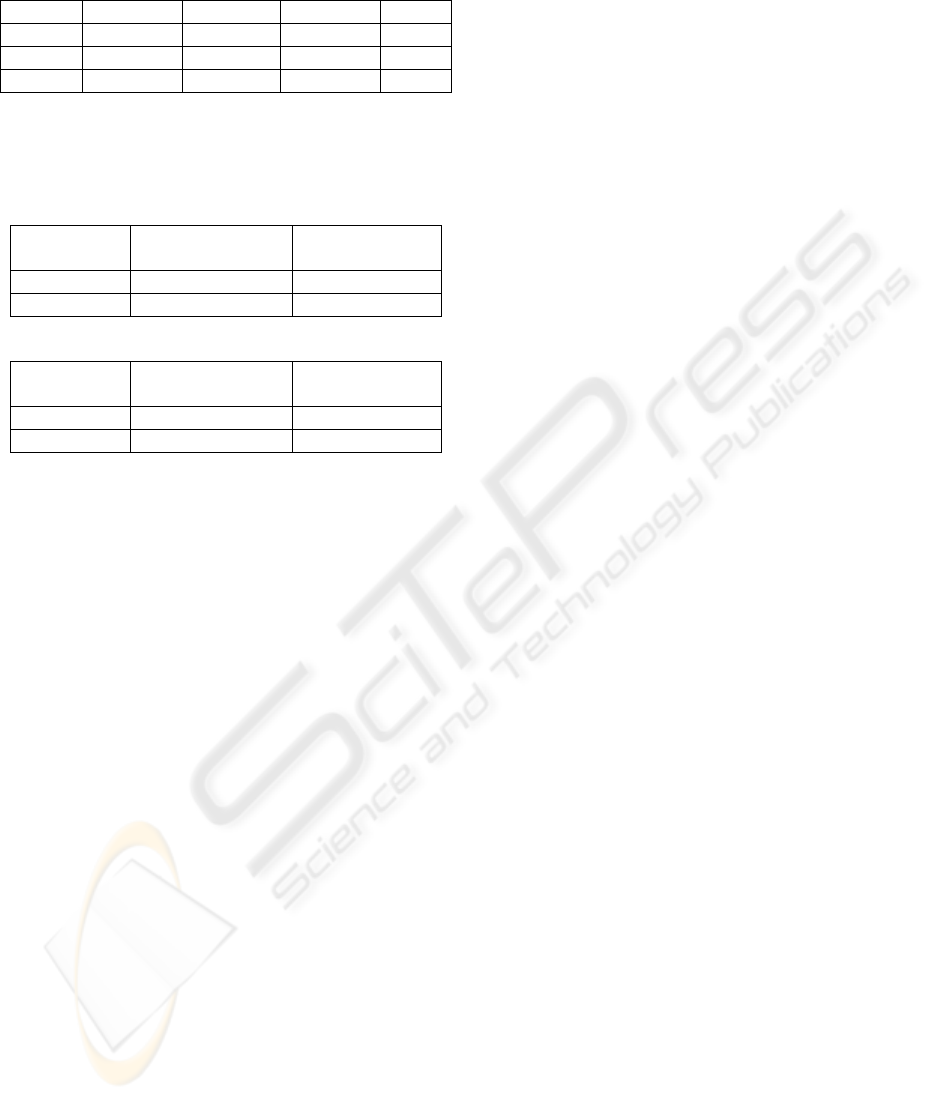

Current research project used an ASRS environment

as the test platform. It integrates with assembly

lines, packing areas, kitting areas and

incoming/outgoing interfaces. Figure 6 shows the

layout of one level of the entire ASRS architecture.

PCME specifications and performance levels are

defined for each category of the automated

equipment such as Rail Guided Vehicle (RGV) and

Stacker Crane (SC). The following performance

level specifications are defined and used as

parameters for the negotiation strategies: job

execution priority, number of jobs on hold, position

on storage, distance and congestion.

The Java agent development framework (JADE)

was used as development toolkit for the test.

Figure 6: Level 1 of ASRS test environment

We used 30, 60 and 90 pallets for different test

loadings. The test results are shown in table 1.

Level 1

0

1

0

2

0

3

Stacker Cranes 1 & 2

0

4

0

5

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

4

0

4

1

4

2

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

4

0

4

1

4

2

RGV 1 & 2

Kitting Area

Incoming Truck Dock Area Outgoing Truck Dock Area

4.5m

6.0 m

6.0 m 16.0 m 16.0 m 16.0 m 4.5m

2.1m2.1m 3.6m

DYNAMIC NEGOTIATION FOR REAL-TIME MANUFACTURING EXECUTION

325

Table 1: Result for number of negotiation rounds.

Pallets 2-round 3-round 4-round >4

30 86.7% 13.3% 0% 0%

60 66.7% 26.7% 6.6% 0%

90 53.3% 28.9% 11.1% 6.7%

The average time spent on negotiation is shown

in table 2. The average time spent on handling is

shown in table 3.

Table 2: Result for average negotiation time.

Initiator Negotiation

Time (Old)

Negotiation

Time (New)

RGV 6.36 (seconds) 3.12 (seconds)

Stacker Crane

8.22 (seconds) 3.68 (seconds)

Table 3: Result for average handling time.

Initiator Handling

Time (Old)

Handling

Time (New)

RGV 56.76 (seconds) 43.32 (seconds)

Stacker Crane

68.92 (seconds) 48.90 (seconds)

5 CONCLUSION

This paper presents a PCME-based dynamic

negotiation approach that is particularly applicable

to the distributed manufacturing system, which is

dynamic and time-critical in nature. The research

work uses a real-time multi-equipment material

handling system as a test platform. This system is

time-critical in operation and therefore, requires an

adaptive, fast and efficient decision-making

mechanism.

The approach discussed in this paper adopts the

strategy of balancing of the cooperative negotiation

and the self-interested negotiation. It also effectively

sets the boundary of negotiation and reduces the

rounds of negotiation through the use of PCME as

the assessment criteria.

The dynamic negotiation approach has been

applied in the execution control of an ASRS system.

The results of the experiments show that this

approach is sufficiently efficient and has achieved

higher percentage of goal attaining in terms of

average task execution time.

A test model with more sophisticated

environment is being built for the future research

work.

REFERENCES

Sargent, P., 1992. Back to school for a brand new ABC. In

The Gauardian.

Shen, W.M. and Norrie, D.H., D.H., 1999. Agent-Based

Systems for Intelligent Manufacturing: A State-of-the-

Art Survey. In International Journal of Knowledge

and Information System. Vol. 1(2), pp. 129-156.

Deen, S.M., 2003. Agent-based Manufacturing, Springer

Verlag. Heidelberg, 1

st

edition.

Odell, J.J., 2002. Agent-Based Manufacturing: A Case

Study. In Journal of Object Technology. Vol. 1(5), pp.

51-61.

Jennings, N.R., 2003. Agent-Based Control Systems. In

IEEE Control System Magazine. Vol. 23(3), pp. 61-74

Fatima, S.S. and Wooldridge, M., 2001. Adaptive Task

and Resource Allocation in Multi-Agent Systems. In

the fifth International Conference on Autonomous

Agents.

Dias, M.B., 2002. Opportunistic Optimization for Market-

Based Multirobot Control. In IROS2002, International

Conference on Intelligent Robots and Systems.

Ng, B.T.J., Zhang, J.B., Lin, W.J., Wong, M.M., Luo, M.

and Ma, H., 2003. Fast Self-Organizing Holonic Based

Multi-Equipment Control. In ICCA’03, the Fourth

International Conference on Control and Automation.

Jennings, N.R., Faratin, P., Lomuscio, A.R., Parsons, S.,

Sierra, C., and Wooldridge, M., 2001. Automated

negotiation: prospects, methods and challenges. In

International Journal of Group Decision and

Negotiation. Vol. 10(2), pp. 199-215.

Wong, M.M., Zhang, J.B., Tang, Y., Zhuang, L.Q., 2003.

A QoS-aware Dynamic Transfer Order Optimisation

Methodology for Automated Material-handling

Systems. In ICCA’03, the Fourth International

Conference on Control and Automation.

Mathieu, P., and Verrons, M.H., 2002. A genetic model

for contract negotiation. In AISB2002, Artificial

Intelligence and the Simulation Behaviour.

Alur, R., and Dill, D., 1994. Automata for Modelling

Real-time Systems. In Theoretical Computer Science.

Vol. 126(2), pp. 183-236.

Subrahmanian, V.S., Bonatti, P., Dix, J., Eiter, T., Kraus,

S., and Ozman, F., 2000. Heterogeneous Agent

Systems. MIT Press, Boston 1

st

edition.

Collins, J., Ketter, W., and Gini, M., 2002. A Multi-agent

Negotiation Testbed for Contracting Tasks with

Temporal and Precedence Constraints. In

International Journal of Electronic Commerce. Vol.

7(1), pp. 35-57.

Dix, J., Kraus, S., and Subrahmanian, V.S., 2001.

Temporal Agent Programs. In Artificial Intelligence

Journal. Vol. 127(1), pp. 87-135.

ICEIS 2004 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

326