STABLE REPETITIVE CONTROL BY FREQUENCY ALIASING

James D. Ratcliffe, Paul L. Lewin and Eric Rogers

University of Southampton

School of Electronics and Computer Science, University Road, Southampton, SO17 1BJ, United Kingdom

Jari J. Hätönen, Thomas J. Harte and David H. Owens

University of Sheffield

Department of Automatic Control and Systems Engineering, Mappin Street, Sheffield, S1 3JD, United Kingdom

Keywords:

Repetitive control, signal processing.

Abstract:

A filtering technique based on frequency aliasing which was initially developed for Iterative Learning Control

is modified so that it can be implemented in real-time and is suitable for Repetitive Control. The aliasing

technique is experimentally verified on a gantry robot facility, which manipulates payloads from a dispenser

onto a constant velocity conveyor. A parallel arrangement consisting of a three-term feedback controller

and a simple structure repetitive controller is used to control the robot. Without the aliasing technique, the

combined control system becomes unstable very rapidly. In contrast, when the aliasing technique is applied,

1000 repetitions are successfully completed and no indications of impending instability can be seen.

1 INTRODUCTION

Repetitive Control (RC) is concerned with improv-

ing the performance of trajectory tracking and set-

point control problems in the cases where the refer-

ence trajectory is repeated ad infinitum or the distur-

bances are repeated and occur in a regularly timed

manner. Examples of this type of application include

food production facilities, printing presses and bulk

product transfer systems such as conveyors. Appli-

cations such as these, tend to be controlled by stan-

dard feedback techniques such as the three-term or

PID controller. This is because they are cheap, ro-

bust methods which are relatively simple to install and

tune, and the production facility can be made opera-

tional rapidly.

The disadvantage of using a simple structure feed-

back controller is that for a repetitive process, the

same level of error will be obtained for each rep-

etition. It is also likely that as the plant dynam-

ics change, due to wear for example, the feedback

controller will gradually become de-tuned and con-

trol performance will reduce, necessitating regular re-

tuning to counteract this.

Repetitive control utilises the error data from pre-

vious executions of the task, to modify the input pro-

file, which is supplied to the plant at the next trial, in

a way which seeks to reduce the tracking error. Theo-

retically, this technique will converge asymptotically

to zero tracking error, if non-repeating disturbances

are not present. This is a property which should make

RC very attractive to industrial applications. How-

ever, RC also has some disadvantages particularly

concerned with algorithm stability. Generally, an al-

gorithm is found to reduce the tracking error for a

number of iterations, but then gradually becomes un-

stable and the tracking error increases exponentially.

Evidently, this type of behaviour is unacceptable in an

industrial context.

It has generally been recognised that this unsta-

ble behaviour is caused by certain signals, which can

build up within the cyclic learning loop. In particu-

lar, these signals include high frequency noise, or low

frequency signals which have an input/output phase

shift larger than 180

◦

. Simple structure learning tech-

niques are unable to compensate for these signals

(Chen and Longman, 2002). Therefore at each rep-

etition, more are added to the learnt signal until this

becomes corrupted to the point where the plant can-

not operate. Standard practice to prevent instability

from occurring is to filter these signals from the error

data. Unfortunately, conventional filtering techniques

induce additional phase lag into the control system,

which results in reduced controller performance and

non-zero residual tracking error. It is therefore nec-

essary to filter the data without introducing additional

phase shift, by using zero-phase methods.

This paper investigates the development of stable,

323

D. Ratcliffe J., L. Lewin P., Rogers E., J. Hätönen J., J. Harte T. and H. Owens D. (2005).

STABLE REPETITIVE CONTROL BY FREQUENCY ALIASING.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics, pages 323-326

Copyright

c

SciTePress

simple structure, repetitive control techniques by us-

ing a frequency aliasing method, as a means of filter-

ing unwanted information from the learning loop and

hence maintaining stability, in an inherently unstable

control system. The aliasing technique was originally

developed by the authors in the ILC context (Ratcliffe

et al., 2005a), but can be ported to the RC context, to

provide a simple, real-time zero-phase filtering tech-

nique. In contrast, many stabilisation techniques in

RC rely upon the use of batch zero-phase filtering,

which is not easily implemented in real-time, as it is

inherently a non-causal technique. Achieving batch

zero-phase filtering in RC systems, involves operat-

ing the plant and simultaneously batch filtering data

over a period of several repetitions, see for example

(Chen and Longman, 1999; Songchon and Longman,

2001).

2 REAL-TIME ALIASING

Shannon’s sampling theorem states that to record a

signal of a given frequency in a discrete-time sys-

tem, the sample frequency must be at least twice the

frequency of the signal. If this requirement is not

met, then frequency aliasing occurs and the higher

frequency components of the original signal are lost.

In most applications, aliasing is a drawback, usu-

ally redressed by means of anti-aliasing filters. In this

application, aliasing is beneficially used to remove the

effects of the undesired frequencies from the learning

controller. The controller configuration uses a simple

structure P-type repetitive controller in parallel with

a PID feedback controller. The feedback controller is

required to smooth the output produced by the alias-

ing technique, but is also useful for producing good

tracking performance during the first few repetitions.

The feedback controller also provides additional ro-

bustness to non-repeating disturbances and can re-

spond to sudden disturbances much more rapidly than

the learning controller. In addition to the feedback

and feed-forward controllers, an additional aliasing

module is implemented on the output generated by

the learning controller. The aliasing module samples

the output generated by the learning controller at a

frequency less than twice the lowest frequency which

needs to be removed from the learning process. In this

way, undesired frequencies are aliased to a lower fre-

quency, while the aliasing filter still allows the RC to

learn frequencies below the alias cut-off. As long as

the cut off frequency is greater than the frequencies

which need to be learnt to satisfy the reference de-

mand, the loss of data caused by aliasing does not pre-

vent the learning controller from improving the per-

formance of the overall system.

In the following analysis, ‘alias frequency’ is used

to describe the sample frequency of the aliasing fil-

ter. ‘Feedback frequency’ is used to describe the sam-

ple frequency of the remaining control system(1kHz).

‘Alias gap’ (ag) is used to relate the alias frequency to

the feedback frequency. The alias gap is the number

of feedback frequency sample instants between each

alias frequency sample instant.

Using a zero-order-hold approach for the aliasing

module is not suitable, as the aliasing filter gener-

ates a signal, which relates poorly to the original non-

aliased signal, due to large step changes in the con-

trol voltage. In a non-causal approach which can

be used for ILC, instead of holding the signal value

constant between aliasing samples, it is possible to

calculate the gradient between adjacent samples and

join them by linear interpolation, a technique which

is commonly used in practical signal processing. Fol-

lowing the successful completion of an iteration, the

ILC algorithm computes the next ILC component of

the plant input vector at feedback frequency. This in-

put vector is likely to contain unwanted frequencies.

The aliasing module then re-samples the input vec-

tor at the aliasing frequency, removing all frequencies

above the aliasing cut-off. The input vector now con-

sists of far fewer sample instants than are required for

real-time operation. Linear interpolation is used to

connect the aliasing frequency sample instants, so that

a smooth signal is produced when the interpolated

signal is re-sampled at feedback frequency. During

the next iteration, each sample instant of the aliased

ILC vector is summed with the input produced by the

feedback controller.

The same principle can be implemented in repeti-

tive control in a causal manner, by delaying the learn-

ing update by a number of samples equal to the alias

gap. The linear interpolation method can then be per-

formed one sample at a time, rather than in a batch.

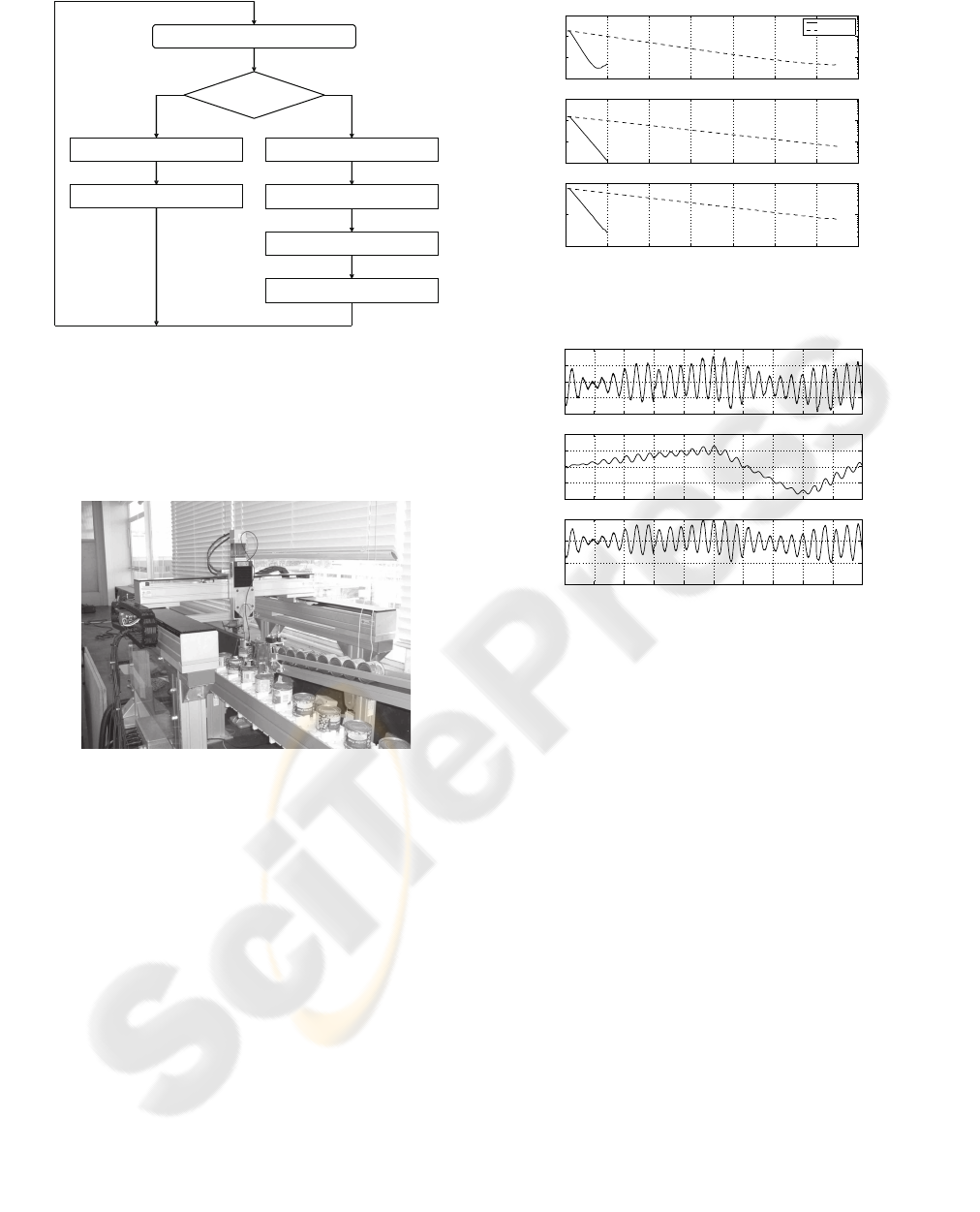

The flowchart in Figure 1 describes the sequence of

events.

3 TEST FACILITY

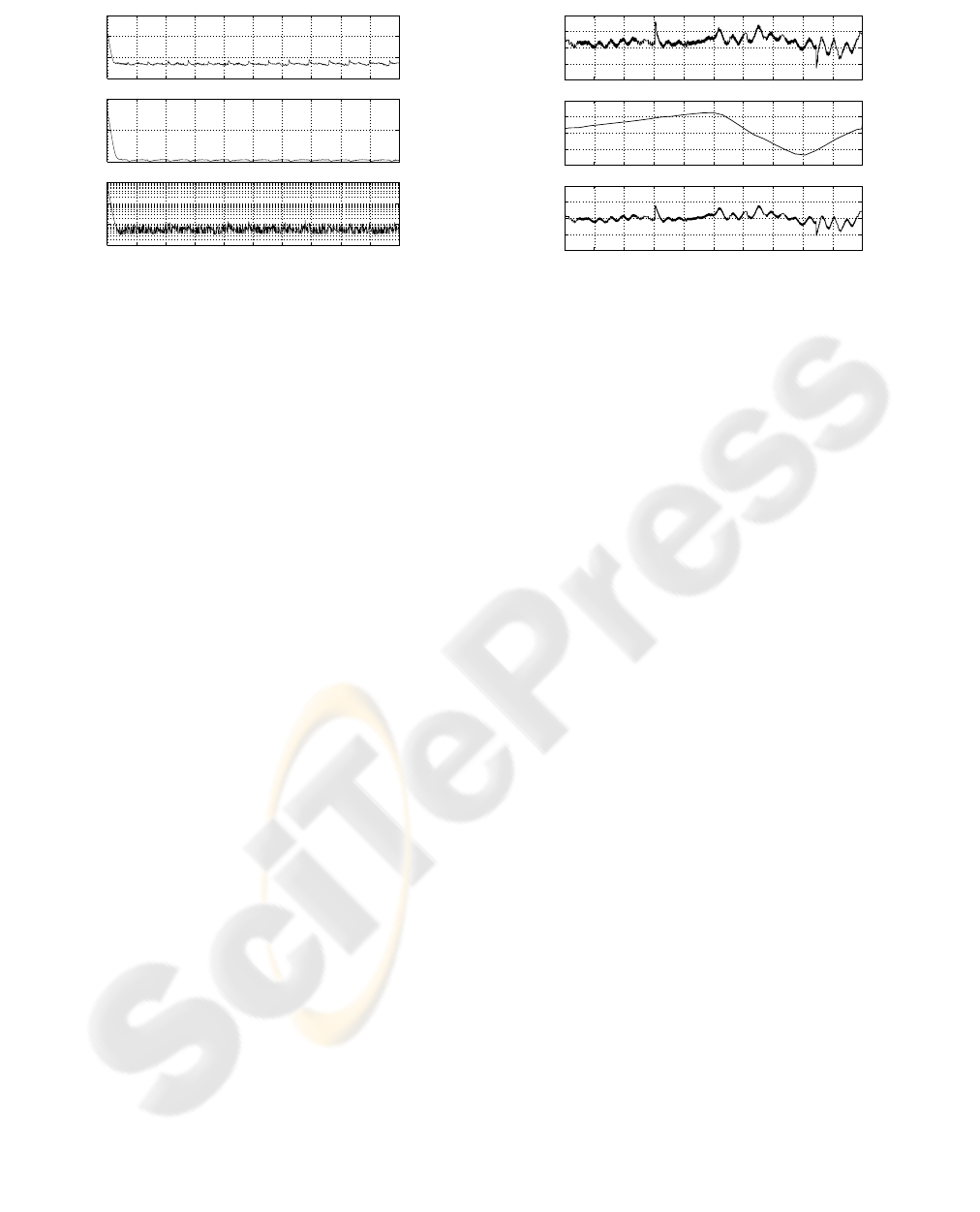

The experimental results presented in Sections 4 and

5 were obtained by implementing the parallel config-

uration controller on the test facility depicted in Fig-

ure 2. It consists of a 3-axis gantry robot mounted

above one end of a plastic chain conveyor. The robot

is required to collect payloads from an asynchronous

dispenser, then transfer them to the conveyor which

is travelling at constant velocity. Once the payloads

reach the opposite end of the conveyor, they are fed

into a return mechanism which cycles the payloads

back to the dispenser. This allows many repetitions

to be performed, with a minimal number of payloads.

The robot and conveyor emulate many synchronous

Iscurrentsample

amultipleof ag?

ComputeandoutputthePIDandRC setpoints

forthecurrentsample,storeintemporarymemory

Addvalueof‘increment’

to‘storedvalue’

SaveinRCmemorylocation

‘currentsample’ - ag

SavetheRCcomponentdirectlyto

RCmemoryat‘currentsample’ location

ComputedifferencebetweenRCmemoryat

‘currentsample’ and‘currentsample’ - ag

Dividedifferenceby ag

toobtain‘increment’

Set‘storedvalue’ totheRCmemory

valueat‘currentsample’ - ag

YesNo

Figure 1: Program operation flowchart (ag = alias gap)

placement operations which can be found in indus-

try. A detailed description of the robot and models

for each axis can be found in (Ratcliffe et al., 2005b).

Figure 2: Gantry robot, conveyor and payload dispenser

4 INITIAL IMPLEMENTATION

Before implementing the aliasing technique, the plant

is operated without any form of filtering. The feed-

back controller and the learning controller both oper-

ate with a sample frequency of 1kHz. Figure 3 dis-

plays the mse results for each axis on a logarithmic

vertical scale. The learning gain β was set to 10 and

100. The values of mse for iteration 1 represent the

tracking performance, which is achieved by the feed-

back controller alone, because at this stage the repet-

itive controller has had no opportunity to learn any-

thing from previous trials. Clearly, the simple struc-

ture repetitive controller can significantly improve the

tracking performance, as the mse for each axis is

reduced by approximately two orders of magnitude.

0 20 40 60 80 100 120 140

10

−2

10

−1

10

0

10

1

x−axis mse

mse (mm

2

)

0 20 40 60 80 100 120 140

10

−1

10

0

10

1

10

2

y−axis mse

mse (mm

2

)

0 20 40 60 80 100 120 140

10

−2

10

−1

10

0

z−axis mse

Iteration

mse (mm

2

)

gain = 100

gain = 10

Figure 3: mse for 1000 repetitions with alias gap = 70

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

−0.4

−0.2

0

0.2

0.4

Input (V)

X−axis, PID component

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

−2

−1

0

1

2

Input (V)

RC component

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

−1

−0.5

0

0.5

Error (mm)

Time (s)

Figure 4: X-axis inputs and tracking error (repetition 20)

Higher learning gain also results in faster convergence

to minimum error as expected. However, with β equal

to 100, the X-axis mse begins to increase after 17 iter-

ations, which is a clear indication of instability. This

is less noticeable for β equal to 10, but for both val-

ues of gain, the robot visibly began to shake as the

algorithm became unstable.

Figure 4 shows the X-axis feedback controller in-

put, repetitive controller input and measured track-

ing error for iteration 20 with β equal to 100. All

three signals are heavily corrupted by a sinusoid of

frequency 13-14 Hz (81-87 rad/s). Referring to fre-

quency response plots for the robot axes, this fre-

quency corresponds well to a pair of complex con-

jugate poles in the dynamic response of the X-axis.

Effectively, a resonant frequency is allowed to build

up within the learning loop.

5 WITH ALIASING

To restore stability, it is necessary to prevent this reso-

nant frequency from building up in the learning loop.

With the system operating at a sample frequency of 1

0 100 200 300 400 500 600 700 800 900 1000

10

−4

10

−2

10

0

10

2

mse (mm

2

)

x−axis mse

0 100 200 300 400 500 600 700 800 900 1000

10

−2

10

0

10

2

mse (mm

2

)

y−axis mse

0 100 200 300 400 500 600 700 800 900 1000

10

−3

10

−2

10

−1

10

0

mse (mm

2

)

z−axis mse

Figure 5: mse for 1000 repetitions (alias gap = 70, β = 100)

kHz, an alias gap of 70 produces an aliasing frequency

of 14.28 Hz. Shannon’s sampling theorem then stip-

ulates that only signals of half this frequency can be

recorded. Therefore, the aliasing module removes all

signals of frequency larger that 7.14 Hz, including the

resonant frequency between 13 and 14 Hz. Figure 5

displays the mse results for 1000 repetitions, when the

aliasing module is implemented with a alias gap of 70

and the learning gain is equal to 100. The mse is re-

duced by over two orders of magnitude for each axis

and although it oscillates about a mean value, there

is no indication that it increases. The 1000 repetition

test does not guarantee that the control system will be

stable for an infinite number of repetitions. However,

compared to the original controller without aliasing

which achieved 20 repetitions, there is a significant

improvement.

Figure 6 shows the X-axis controller inputs and

recorded tracking error for iteration 1000 with the

alias gap equal to 70. Although the tracking error still

contains sinusoidal oscillations in the frequency range

13-14 Hz, these are clearly being stimulated by the

feedback controller and not the learning controller.

As the feedback controller has no learning or mem-

ory capabilities, the resonant frequency cannot grow

at each repetition.

Referring back to Figure 5, the underlying cause

behind the cyclic variation in mse is not yet under-

stood and requires further investigation. One possible

reason which can be suggested immediately is that the

variation is related to the alias gap number. To investi-

gate this hypothesis, the 1000 repetition test was per-

formed with an alias gap of 100. The increase in alias

gap value has a direct influence on the error reduction,

because the frequency range which can pass through

the aliasing module has been reduced. Therefore the

error reduction is now less than two orders of magni-

tude. However, the amplitude of the cyclic variation

in mse has been greatly reduced and the cycles now

occur every 50 repetitions. Evidently there is a link

between the alias gap and the variation which requires

further investigation.

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

−0.5

−0.4

−0.3

−0.2

−0.1

Input (V)

X−axis, PID component

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

−2

−1

0

1

2

Input (V)

RC component

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

−0.4

−0.2

0

0.2

0.4

Error (mm)

Time (s)

Figure 6: X-axis inputs and tracking error (repetition 1000,

ag = 70, β = 100)

6 CONCLUSIONS

The aliasing technique which was initially developed

for iterative learning control has been successfully

converted to a simple, causal operation which can be

calculated at each sampling instant in a repetitive con-

trol context. Experimental validation demonstrates

that the stability of a simple structure repetitive con-

troller can be greatly improved by using the aliasing

technique.

REFERENCES

Chen, H.-J. and Longman, R. (1999). The importance

of smooth updates in producing good error levels in

repetitive control. In Proceedings of the 38th IEEE

Conference on Decision and Control, Phoenix, Ari-

zona, pages 258–263.

Chen, K. and Longman, R. (2002). Stability issues using fir

filtering in repetitive control. Advances in the Astro-

nautical Sciences, 112(2):1321–1340.

Ratcliffe, J., Hätönen, J., Lewin, P., Rogers, E., Harte, T.,

and Owens, D. (2005a). P-type iterative learning con-

trol for systems that contain resonance. Accepted by

International Journal of Adaptive Control and Signal

Processing.

Ratcliffe, J., van Duinkerken, L., Lewin, P., Rogers, E.,

Hätönen, J., Harte, T., and Owens, D. (2005b). Fast

norm-optimal iterative learning control for industrial

applications. In Proceedings of the 24th American

Control Conference, Portland, pages 1951-1956.

Songchon, T. and Longman, R. (2001). On the waterbed

effect in repetitive control using zero-phase filtering.

Advances in the Astronautical Sciences, 108:1321–

1340.