BIOPRODUCTS DRYING OPTIMAL CONTROL IN

OSCILLATING REGIMES

Renat Sadykov

Kazan State Architecture Building University, Zelenaya 1, Kazan, Russia

Dmitry Antropov

JSC “Etalon MCS”, Adoratskogo 2, Kazan, Russia

Rauf Kafiatullin

JSC “Kazanenergo” Tukaya162 ,Kazan, Russia

Keywords:

Drying, mathematical model, optimal control, automation.

Abstract: On the basis of the developed approaches and mathematical model (MM) of the bioactive products drying

block is carried out the optimization problem of the equipment choice and its operation modes in view of

deleted binary mixture an ethanol - water composition changes. The analysis of the problem with engaging

of the Pontryagin’s maximum principle has revealed optimal control structure. There is developed the

automated control system of drying installation with firmware, based on modern microprocessor technique.

The guidelines on an drying processes intensification, worked out on the basis of the internal and external

interconnected heatmasstransfer research, and the process optimal control considerably raise productivity of

drying aggregates, reduce fuel and power expenditures.

1 INTRODUCTION

Biotechnology is an effective production method of

bioactive products. Drying as a final stage of the

technological process plays an important role in the

production, since the thermal and mechanical effects

in the drying process affect the quality of the

products.

Let’s consider the drying process of irreplaceable

aminoacids (α –forms) originated in the

microbiology synthesis.

The experiments in (Yenikeev E.S., Ivanova

E.N.) have discovered that vacuum-conductive and

pseudo-liquefied drying methods don’t enable in all

cases to obtain the products of high quality as α-

aminoacids (especially treonin) have high inclination

to an agglomeration. There is the following

explanation of the agglomeration of particles in the

drying process. Binary liquid (ethanol-water 50 vol.

%) is moving out of the material being dried.

Ethanol as being more volatile component is moving

out more quickly and, therefore, an abundance of

water in the material is growing up.

As it is known from the technology of aminoacids

(Gracheva I.M., 1980) they are crystallized in

ethanol-water blend and are well dissolved in water.

Therefore crystal’s partial dilution and their

adhesion take place in the drying process.

It has been shown in (Sadykov R.A., 1988) that

the production problem of homogeneous dispersible

or powdery product might be solved by vacuum-

oscillating drying mode (Sadykov R.A., 1986,

Sadykov R.A., 1988). This process is frequentative

alternation of heating of the material in pseudo-

liquefied layer, pressure impulse drop with

subsequent vacuumization (material cooling by

pressure dumping in drying chamber) and layer

impulse jog by air supply. Material layer at jogging

strikes on special destroying elements is divided

finely and mixed up. Typical curves of the kinetic

and the termogram of the drying process based on

combined pressure drop and vacuum (CPDV) are

shown in fig.1. (U - liquid specific mole contention).

176

Sadykov R., Antropov D. and Kafiatullin R. (2005).

BIOPRODUCTS DRYING OPTIMAL CONTROL IN OSCILLATING REGIMES.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics, pages 176-181

DOI: 10.5220/0001183401760181

Copyright

c

SciTePress

τ, min

Figure 1: Kinetic 1 and termogram 2 of L-treonin

(G=0,007 m3/s, Т

h

=86ºС, h=0,07 m, τ

h

=8 min, τ

v

=5

min)

To find out the dependence of τ

k

- CPDV drying

time aminoacids on some regime parameters it has

been carried out the complete four-factor experiment

(Ivanova E.N.). The following regressive formula

has been derived:

τ

k

= - 2007 + 8,616τ

h

+ 4,5τ

v

+ 88056G + 174,6h

+ 33,28τ

h

h – 0,0075τ

h

τ

v

– 782,76τ

h

G,

where τ

k

- kinetic time, s; τ

v

- vacuumization

time, s; G – heat carrier volume flow m

3

/s ; h – layer

thick, m; τ

h

- heating time, s. It is worth to note that

this formulation is reliable for some given regimes

of the process only. It can not be used for

formalization of the drying process in general and

for its optimization.

The full theory of the drying process for moving

off multicomponent (intersoluble partlysoluble and

interinsoluble) liquid systems (Sadykov R.A., 1989,

Sadykov R.A., 2004) is absent now and the

development of adequate mathematical models

(MM) of the process is quite actual. MM describes

moving kinetic of every component in binary liquid

blend (Sadykov R.A., 1985). The report is devoted

to an optimization of such MM.

2 DRYING PROCESS

OPTIMIZATION OF

IRREPLACEABLE

AMINOACIDS

During optimization of production process variants

of technical performance are compared among

themselves by reduced costs after CPDV

optimization regime in every variant (Golubev L.G.,

1978). The comparison was performed by criterion

minimization of the drying stage contribution to cost

price of product unit. It means profits maximization

in view of fixed productivity.

The problem of optimization CPDV regime is to

select M value and G(τ), Т

hc

(τ), z(τ) functions when

τ

∈

[0, τ

k

] and z=0 in vacuumization stage, z=1 in

heating.

00

0

1

({[ ()](1)()},

) athc Т VaIzGGTTzd

M

κ

τ

κ

τ

ββ β ββτ

++ − +− +

∫

=

(1)

М – dry aminoacid mole number; Т

hc

– heat carrier

temperature at a layer input;

Т

at

– ambient air

temperature;

0

β

- characterizes expenses

independent on regime;

a

β

- sterile air 1

3

m

cost

T

β

- cost of heating 1

3

m

air up to 1 K; V

β

- cost of

vacuumization pump work in unit time. It is

necessary to keep conditions which ensure product

none overheating, sufficiently low finite humidity,

pseudoliquified regime in heating and none

asportation aminoacids with heat carrier.

Т

at

≤ Т

h

≤ Т

h max

, Т≤Т

max

, U(τ

k

)≤U

k

,

M

min

≤M≤M

max,

G≤G

max

The detailed consideration (1) with taking into

account equations system of CPDV drying MM

(Sadykov et al., 1985) clarifies that

М=М

max

, G=

G

max

in optimal regime; to select Т

гр

(τ) and z(τ)

Pontryagin’s maximum principle is used (Pontryagin

et al., 1983).

The are set: state variables vector

),,,,(

43210

χχχχχχ

=

=(I(τ), U(τ), T(τ),

x(τ), р

c

(τ)), dual variables vector

),,,,(

43210

ξξξξξξ

=

,Pontryagin’s function

4

0

ii

i

H

ξχ

=

=

∑

&

&

and problem’s Hamiltonian

0;1

() { ()},

max

z

H

η

ττ

=

=

Th

∈

[T

at

,Т

m

],

BIOPRODUCTS DRYING OPTIMAL CONTROL IN OSCILLATING REGIMES

177

Т

h max,

T<T

max

T

m

= T≥T

max

where

Т

m

- heat carrier maximum temperature

providing accomplishment of condition :

Т<Т

max

+

2К (index h – means heating , v - vacuumization)

c

р

– specific mass heat of a heat carrier at a constant

pressure

hc

ρ

– heat carrier density at a heater input

State and dual variables must satisfy the equations:

(1 ) ,

hv

zz

χ

χχ

=+−

&& &

4

0

,

i

ii

i

i

χ

ξ

ξ

χ

=

∂

=−

∂

∑

&

&

0,4i =

(2)

and edge conditions:

τ

=0: χ

0

=0, χ

1

= U(0), χ

2

= T(0),

χ

3

= x(0), χ

4

= p

at

;

τ= τ

к

: χ

1

=U

к,

|ξ

0

| + |ξ

1

|=1, ξ

2

= ξ

3

= ξ

4

=η=0.

(3)

State variable р

с

is inserted with a view of obvious

separation of heat carrier’s pump-down stages and

vapour’s pump-down stage: during the

first stage

0xTU ===

&

&&

and during the second

stage are correct of MM equations (Sadykov et al.,

1985):

,U)xy(xU y

&

&

−=

where

y

y

– ethanol mole fraction in eliminated

vapour phase,

x – alcohol mole fraction

Dots mean time differentiation.

,

Mc)rc(V

)]T,x(p[Qc

U

µ+β−α

ρ

−=

&

;U

c

r

T

&&

=

where,

],)1(74,41)][()([

2

222111

xxTpTp

RTU

xy

−−−

−

=

µγµγα

,

T

]

dT

)T(plnd

)y1(

dT

)T(plnd

y[

RT

)T,x(p

2

2

1

1

ρ

−µ−+µ=β

.

RT

)T,x(pµ

=ρ

Q(p) – effective eviction speed

r – specific molar evaporation heat of a thin mixture

с – specific mole heat of a humid material at account

on a mole number of a dry material

µ

1

– alcohol molecular weight

µ

2

– aqua molecular weight

Then

p

c

(τ) must satisfy equations:

γ

1

– activity ratio of an alcohol fumes

γ

2

– activity ratio of an aqua fumes

Р

1

(τ) – alcohol fumes saturation pressure

Р

2

(τ) – aqua fumes saturation pressure

c

p - pressure in the drying chamber

),(

maxmax

max

max

2

h

h

h

Т

cG

UrM

T

K

TT

Т

phc

−−+

⋅

−

ρ

&

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

178

(4)

саtch ррp −=

&

(5)

Formulation (4) is relevant to the physics of process

and is derived from its MM.

Formulation (5) is supplied for substitution of an

intermittent growth (of the

р

с,

to the value of р

аt

) for

uninterrupted process while there is a material

jogging. The above make it possible to use the

theorem of Pontryagin with limits on the differential

features of

χ

&

.

The substitution is relevant because the value of

р

с

has no influence on a heating stage (it assumes that

р

с

is equal to an atmospheric pressure). Fast

approaching of the

р

с

to the р

аt

before

vacuumization is necessary.

Meanwhile due to (5) the

р

с

differs from the р

аt

in

a value less then 0,03% in 8 sec from the beginning

of the process. In (2) the

χ

&

is continuous by control

(Т

h

,z) and is continuously differential by

χ

all

over the entity of real physical limits of alternation

of

χ

except of hyper surface:

р

с

- р(х, Т)=0, (6)

where

χ

&

has ordinary discontinuity (Korn et al.,

1978). Though the left part of (6) is continuously

differential by

χ and this enables the continuity of

ξ

and Н by τ (Korn et al., 1978) on the segment [0,

τ

к

]. From the maximum’s principle it is following

that ξ

0

=const≤0. Thus

04i / =χ∂χ

∂

&

3,0=i

and

44,

c

c

p

p

ξ

ξ

∂

=−

∂

&

&

On account of the limitedness

c/c pp ∂∂

&

and the

stipulation ξ

4

(τ

к

)=0 enables ξ

4

(τ)=const=0.

Invariability of ξ

0

and ξ4 simplifies the problem.

While solving the boundary problem (2)-(3) with

every fixed τ the control is selected which enables

maximum Н from the following : a) z=0; b) z=1 и

Т

h

=Т

at

and c) z=1 и Т

h

=Т

m

.

Such simplicity of the control choice law is a result

of affine dependence

H from Т

h

and from

discontinuity of z value area.

The method of resolving the boundary problem – is

a reduction to the series of Cauchy problems

(Krylov V.I., 1977). Cauchy problems integration is

complicated by discontinuity in right-hand members

(2). The solution has extreme points therefore

special numerical method has been designed.

Its difference from prevalent methods consists in the

combination of different step of integration choice

laws - Rhunge law (problems (Krylov V.I., 1977) for

“flat” sectors and immediate estimation in extreme

points.

The prime cost of product unit minimums

discovered in such a way (for i variant of the

equipment) have been used for the comparison of

reduced costs for each variant.

i

R =

i

P +

E

i

C (7)

R - reduced costs

P – prime cost

E - normative factor recoupment of capital

investments

C – capital costs

To design industrial crystal aminoacid drying

block the best variant has been selected.

Thus the method of the CPDV drying optimal

regimes has been proposed. It is based on the MM of

the process and takes into account componentwise

contents of ethyl alcohol and aqua in aminoacids. It

can be used in design and valuation of oscillating

drying apparatus and their automated control

,)1()]()1(74,41[

2

2

1

12211

2

T

dT

dp

x

dT

dp

xxppxx

&

&

⎥

⎦

⎤

⎢

⎣

⎡

−++−−−

γγγγ

)T,x(ppc >

),( cc pQp

V

x

−

=cvp

&

),( Txppc ≤

BIOPRODUCTS DRYING OPTIMAL CONTROL IN OSCILLATING REGIMES

179

systems. The results of this work can be generalized

in the case of removal of an endless amount of thin

mixture components from drying products. It is

necessary to note that there are probable situations in

such distention when it fails to set optimal G in

advance. So

G(τ) function must be searched as

Т

d

(τ) z(τ), by solving the problem of Pontryagin’s

maximum principle.

3 AUTOMATION DRYING

PROCESS

The algorithm of automatic optimum control mode

is based on optimization model which, in turn, is

formulated on the basis of MM of drying process in

view of the technology requirements raised to an

end-product.

The automated control system model of drying

workshop is designed to allow familiarizing with the

processes proceeding in drying installation at

absence of technological object.

The laboratory-scale plant consisting of several

oscillating drying installations includes the

following technological control objects: dryer;

charging device; unloading mechanism; receiver;

condenser; hotwell.

The system emulator implements the following

functions of the automatic control and supervision:

1 Automatic control: dryer top pressure; dryer

lower part temperature; air temperature to a dryer;

air temperature from a dryer; pressure before a

receiver.

2 Remote supervision: dryer top pressure; product

temperature on an entry; product temperature on an

exit; dryer lower part temperature; air temperature to

a dryer; air consumption in a dryer; pressures before

a receiver.

The automated control system model includes the

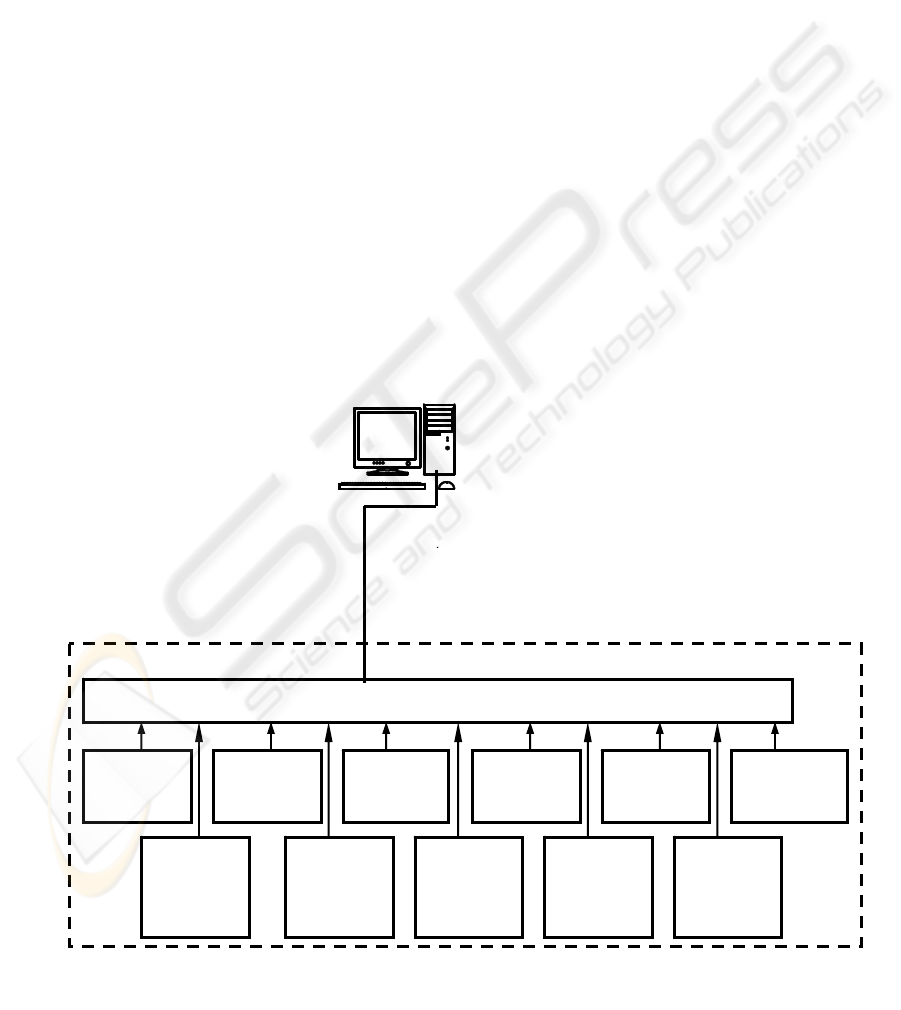

following levels (fig. 2): a level of sensing

transducers and actuating mechanisms; a level of

control unit (PLC); a level of the operators interface

(HMI).

In the laboratory-scale plant of the drying plant

control system the role of sensing transducers is

played by PC with program emulation of drying

installation work. The program simulates work of

field sensing transducers, emulating their current

output signals. Current signals are transferred to the

next level - on an input of the control unit.

Drying installation

actuators heat-carrier

sensor

liquid phase

structure

sensor

gas phase

structure

sensor

level of

loading

(or mass)

sensor

clearing

degree

sensor

material

humidity

sensor

relative air

humidity

sensor

drying

chamber

pressure

sensor

flow

meter

RS-485

HMI

material

temperature

sensor

PLC

Figure 2: Model of control system of the drying plant.

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

180

At this level the control logic of technological

installation is implemented. According to which

incoming data from sensing transducers and actuators

is being processed and analyzed. Generation of

control actions on the specified algorithm takes place.

The control level of the drying plant

automation system is implemented on modern

microprocessor devices. One controller with

necessary input-output modules is used for each

drying plant.

There are following modules included:

The programmed control unit with a

support of InterBus network. Implements drying

installation control algorithms.

The analog input module. Signals from pressure

and consumption sensors.

The module of signals from temperature

transmitters.

The module of discrete output signals. It is used

for management of quick-acting valves, the

ventilating fan and the vacuum pump.

One control unit with modules of input-output

provide implementation of the following functions:

• Data acquisition from sensing transducers;

• Preprocessing and normalizations of analogue

and discrete signals;

• Output of control actions on actuators;

• Management of technological installation:

data from sensing transducers level is being

processed and analyzed. Control actions on the

specified algorithms of regulating are being

generated.

The level of operator interface supplies the

operator with on-line information of a process

passing. Ensure reception of managing instructions

from the operator and transfer instructions to the

control unit. At this level functions of accumulation

and representation of the archival historical

information are implemented by SCADA-system.

In the capacity of workstations of operators are

used PC with the network InterBus interface. An

operating system established at operators stations -

Microsoft Windows. OPC Server provides data

exchange between the managing controllers and the

operators interface.

REFERENCES

Yenikeev E.S., Zolotov A.V., Karaeva G.A., and others.

Deposit copy in ОНТИТЭИ microbioindustry., №167

МБ - Д 83.

Ivanova E.N., Kapitonov N.A., Migunov V.V and others.

Deposit copy in ОНТИТЭИ microbioindustry., №168

МБ - Д 83.

Gracheva I.M., Gavrilova N.N., Ivanova L.A. Technology

of the microbial albuminous medications, aminoacids

and lipoids. - М.: Food industry, 1980. – 448pp.

Sadykov R.A., Karpov A.M., Pobedimski D.G., and

others. Design of the optimal drying technology of the

crystal aminoacids. Biotechnology, 1988, т.4, №3

340-345 pp.

Sadykov R.A., Migunov V.V, Verner Z.S., and others.

Drying method of the dispersed materials. Patent №

3788966 БИ№ 6.1986.

Sadykov R.A., Bakhtiyarov F.R., Pevzner I.L. and others.

Vacuum dryer for drying friable and lumping

materials. Patent № 1460562.БИ №11.1988.

Sadykov R.A., Migunov V.V., Karpov A.M. and another.

Study and Theoretical Modelling of the Drying of the

Aminoacids - The Products of Microbial Synthesis

Acta. Biotechnol. 5 (1985), 4, 363 -373 pp.

Sadykov R.A., Migunov V.V. Heat mass transmission at

vacuum-conductive drying of the dispersed materials.

ТОХТ. - 1989. Т XXIII, № 3, 331- 339 pp.

Sadykov R.A. Transport processes at momentary phases

contact. KSEU 2004, 176 p.

Golubev L.G., Sazhin B.S, Valashek E.R. Drying in

pharmaceutical industry. - М.: Medicine, 1978. - 272

pp.

Pontryagin, L. S., Boltyansky, V. G., Gamkrelidze, R. V.

and Mischenko, E. F., Mathematical theory of optimal

processes, Nauka, Moscow, 1983, 392 pp., (in

Russian).

Korn G., Korn T. Math’s handbook for researchers and

engineers. -М: Science, 1978.-831 pp.

Krylov V.I., Bobkov V.V., Monastyrnuii P.I..

Computational approaches - M.: Science, 1977, т.2.-

400 pp.

BIOPRODUCTS DRYING OPTIMAL CONTROL IN OSCILLATING REGIMES

181