APPLICATION OF DE STRATEGY AND NEURAL NETWORK

In position control of a flexible servohydraulic system

Hassan Yousefi, Heikki Handroos

Institute of Mechatronics and virtual Engineering, Mechanical Engineering Department,

Lappeenranta University of Technology, 53851,Lappeenranta, Finland

Keywords: Differential Evolution, Backpropagation, Position Control, Servo-Hydraulic, Flexible load.

Abstract: One of the most promising novel evolutionary algorithms is the Differential Evolution (DE) algorithm for

solving global optimization problems with continuous parameters. In this article the Differential Evolution

algorithm is proposed for handling nonlinear constraint functions to find the best initial weights of neural

networks. The highly non-linear behaviour of servo-hydraulic systems makes them idea subjects for

applying different types of sophisticated controllers. The aim of this paper is position control of a flexible

servo-hydraulic system by using back propagation algorithm. The poor performance of initial training of

back propagation motivated to apply the DE algorithm to find the initial weights with global minimum. This

study is concerned with a second order model reference adaptive position control of a servo-hydraulic

system using two artificial neural networks. One neural network as an acceleration feedback and another

one as a gain scheduling of a proportional controller are proposed. The results suggest that if the numbers of

hidden layers and neurons as well as the initial weights of neural networks are chosen well, they improve all

performance evaluation criteria in hydraulic systems.

1 INTRODUCTION

Problems which involve global optimization over

continuous spaces are ubiquitous throughout the

scientific community. In general, the task is to

optimize certain properties of a system by

pertinently choosing the system parameters. For

convenience, a system’s parameters are usually

represented as a vector. The standard approach to an

optimization problem begins by designing an

objective function that can model the problem’s

objectives while incorporating any constraints.

Consequently, we will only concern ourselves

with optimization methods that use an objective

function. In most cases, the objective function

defines the optimization problem as a minimization

task. To this end, the following investigation is

further restricted to minimization problems. For

such problems, the objective function is more

accurately called a “cost” function.

One of the most promising novel evolutionary

algorithms is the Differential Evolution (DE)

algorithm for solving global optimization problems

with continuous parameters. The DE was first

introduced a few years ago by Storn (Storn, 1995)

and Schwefel (Schwefel, 1995).

When the cost function is nonlinear and non-

differentiable Central to every direct search method

is a strategy that generates variations of the

parameter vectors. Once a variation is generated, a

decision must then be made whether or not to accept

the newly derived parameters. Most stand and direct

search methods use the greedy criterion to make this

decision. Under the greedy criterion, a new

parameter vector is accepted if and only if it reduces

the value of the cost function.

The extensive application areas of DE are

testimony to the simplicity and robustness that have

fostered their widespread acceptance and rapid

growth in the research community. In 1998, DE was

mostly applied to scientific applications involving

curve fitting, for example fitting a non-linear

function to photoemissions data (Cafolla AA.,

1998). DE enthusiasts then hybridized it with

Neural Networks and Fuzzy Logic (Schmitz GPJ,

Aldrich C., 1998) to enhance or extend its

performance. In 1999 DE was applied to problems

involving multiple criteria as a spreadsheet solver

application (Bergey PK., 1999). New areas of

interest also emerged, such as: heat transfer (Babu

BV, Sastry KKN., 1999), and constraint satisfaction

problems (Storn R., 1999) to name only a few. In

133

Yousefi H. and Handroos H. (2005).

APPLICATION OF DE STRATEGY AND NEURAL NETWORK - In position control of a flexible servohydraulic system.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics, pages 133-140

DOI: 10.5220/0001190301330140

Copyright

c

SciTePress

2000, the popularity of DE continued to grow in

areas of electrical power distribution (Chang TT,

Chang HC., 2000), and magnetics (Stumberger G. et

al, 2000). 2001 furthered extensions of DE in areas

of environmental science (Booty WG et al, 2000),

and linear system models (Cheng SL, Hwang C.,

2001). By the year 2002, DE penetrated the field of

medical science (Abbass HA., 2002). Most recently

in 2003, there has been a resurgence of interest in

applying DE to problems involving multiple criteria

(Babu BV, Jehan MML. 2003).

Electro-hydraulic servomechanisms are known

for their fast dynamic response, high power-inertia

ratio and control accuracy. In the fluid power area,

neural network systems have been used for control,

identification and modeling of the system (Chen,

1992). The popularity of neural networks can be

attributed, in part, to their ability to deal with non-

linear systems. In addition, a neural network

approach uses a parallel distributed processing

concept

(D.E.Rumelhart, et al, 1986). It has the

capability of improving its performance through a

dynamic learning process and, thus, provides

powerful adaptation ability. Since neural networks

are fashioned after their human neural counterparts,

they can be ‘trained’ to do a specific job by

exposing the networks to a selected set of input–

output patterns. A comparatively convenient

method is to have a reference response model,

which can be the tracking object of the control

system. Following the model reference adaptive

control theory (Franklin, 1984), an adaptive

reference model is used in this study and

implemented in the microcomputer to control a

hydraulic variable motor.

Gain scheduling based on the measurements of

the operation conditions of the process is often a

good way to compensate for variations in the

process parameters or the known nonlinearities of

the process.

The main aim of the following study is to apply

the DE strategy to find the best initial weights of the

proposed neural networks to improve the

performance of position tracking of the reference

model.

The structure of the paper is the following: in

section 2 description of the flexible servo-hydraulic

system, section 3 controller design, section 4

differential evolution algorithm, section 5 presents

the main results of this work, and section 6 draws

conclusions.

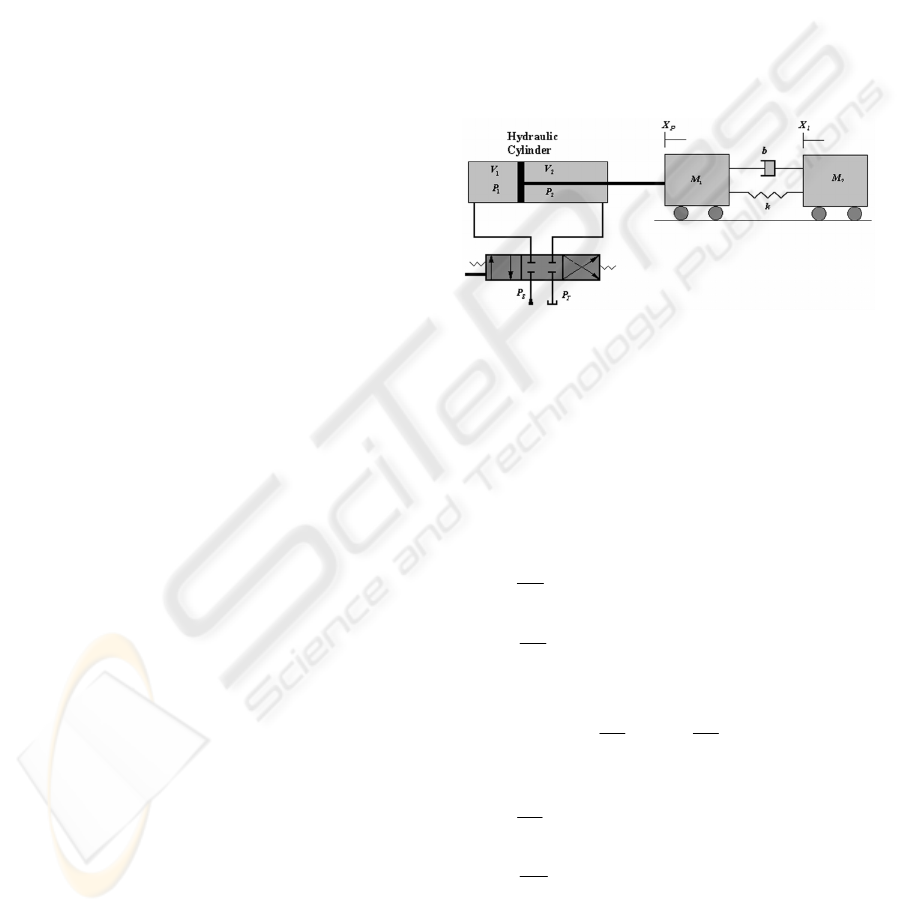

2 SERVO HYDRAULIC SYSTEM

The hydraulic system with flexible load shown in

figure 1 is comprised of a servo-valve, a hydraulic

cylinder and two masses that are connected by a

parallel combination of spring and damper. The

schematic diagram of the system is illustrated in

figure1.

The nonlinearity of the constitutive equations as

well as the sensitivity of the system’s parameters to

the sign of the voltage fed to the valve make the

control of system too complicated (Viersma, 1980).

2.1 System Model

Figure 1: Schematic Diagram of System.

Applying Newton’s second law for each mass

without consideration of coulomb friction results,

2211

211

)()(

ApAp

XXkXXbXbXm

lplppp

−+

−−−−−=

&&&&&

)()(

plpL2l2

XXkXXbXm −−−−=

&&&&

(1, 2)

Continuity equations for the output ports of the

servo valve results,

⎪

⎪

⎩

⎪

⎪

⎨

⎧

+−=

−=

)(

)(

22

2

2

11

1

1

p

e

p

e

XAQ

V

p

XAQ

V

p

&

&

&

&

β

β

(3)

Introducing two new parameters,

1

C and

2

C ,

defined as,

e

1

1

V

C

β

= ,

e

2

V

2C

β

=

Equation 3 can be written in the form of,

⎪

⎪

⎩

⎪

⎪

⎨

⎧

+−=

−=

)(

1

)(

1

22

2

2

11

1

1

p

p

XAQ

C

p

XAQ

C

p

&

&

&

&

(4)

The volumes between the valve and each side of

piston are calculated as,

01p11

XAV

ν

+

=

02p22

XLAV

ν

+

−

=

)(

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

134

If the tank pressure is set to equal to zero (

0

=

T

p ),

the nonlinear equations of flow rate of valve can be

written in the simplest form, as follow,

⎪

⎩

⎪

⎨

⎧

≥−

=

0u puc

0u ppuc

Q

1v

1sv

1

p

(5)

⎪

⎩

⎪

⎨

⎧

−

≥

=

0u ppuc

0u puc

Q

2sv

2v

2

p

(6)

Table 1: Setup Parameters

Kg 278m

1

=

m

1L =

Kg 110m

2

=

m

Ns

1000b

1

=

24

1

m10048A

−

×= .

m

Ns

500b

2

=

24

2

m10244A

−

×= .

Pa

8

e

104 ×=

β

m

N

136670k =

Mpa14P

s

=

34

01

m10132

−

×= .

ν

3

m

4

02

1007.1

−

×=

ν

)(sVPa

m

102

2

1

3

8−

×=

v

c

Where,

nn

n

v

pu

Q

c

∆

=

The setup parameters of system are shown in

Table1.

Following, the structure of controller for

positioning control of each mass is proposed.

3 CONTROLLER DESIGN

Here, the aim of the controller is position tracking

of a reference model. Classical approaches, like P or

PD regulators for positioning of hydraulic drives, do

not give satisfactory performance. For this reason,

adaptive control techniques, adaptive reference

model, and gain scheduling are used to improve the

performance of Controller (4). The variations of

parameters depending on the change in the sign of

voltage fed to the valve are compensated by gain

scheduling block. The second neural network is

impelled to improve the lack of damping in

hydraulic systems. Following the reference model

and each neural network are proposed.

3.1 Reference Model

The desire linear, second order, reference model

was selected to run parallel with the nonlinear

system. The natural frequency,

n

ω

, of this model set

equal to as 7 rad/sec with the damping ratio,

ζ

, of

0.9.

2

nn

2

2

n

ref

s2s

sG

ωζω

ω

++

=

)( (7)

There are kinds of method to find a reference

model such as ITAE or Bessel transfer functions.

The Bessel transfer functions have not overshot

when

n

ω

is equal to one, but when

n

ω

is greater

than one the overshot appears.

The natural frequency of system was chosen in a

manner that the response of system is as fast as

possible. The chosen damping ratio provides the

minimum overshoot of reference model.

3.2 Neural Network Design

Basic neural networks consist of Neurons, weights

and activation function. The weights are adapted to

achieve mapping between the input and output sets

in the manner to track reference model. Many

neural networks are successfully used for various

control applications. In this study the

backpropagation algorithm with momentum term

was used to update the weights and biases of neural

network (Rumelhart, 1986). The backpropagation

algorithm is a learning scheme in which the error is

backpropagated layer by layer and used to update

the weights. The algorithm is a gradient descent

method that minimizes the error between the desired

outputs and the actual outputs calculated by the

MLP.

The backpropagation training process requires

that the activation functions be bounded,

differentiable functions. One of the most commonly

used functions satisfying these requirements is the

hyperbolic tangent function. This function has a

monotonic increasing in the range of –1 to 1. The

mathematical model of hyperbolic tangent can be

written in the form of,

xx

xx

ee

ee

xf

−

−

+

−

=

)( (8)

The learning procedure requires only that the

change in weights and biases are proportional to the

wE

p

∂

∂

/ . True gradient descent requires that

infinitesimal steps be taken. The constant of

proportionality is the learning rate in the procedure.

The bigger change of this constant, the bigger

change in the weights. For practical purposes we

APPLICATION OF DE STRATEGY AND NEURAL NETWORK - In position control of a flexible servohydraulic system

135

choose a learning rate that is as large as possible

without exciting oscillation. This offers the most

rapid learning. One way to increase the learning rate

without leading to oscillation is to modify the

general delta rule to include a momentum term. This

can be accomplished by the following rule,

)()()( nwo1nw

jipipjji

∆+=+∆

α

δ

η

(9)

where n indicates the presentation number. The

parameter of

η

is the learning rate, and

α

is a

constant which determines the effect of past

changes on the current direction of movement in

weight space.

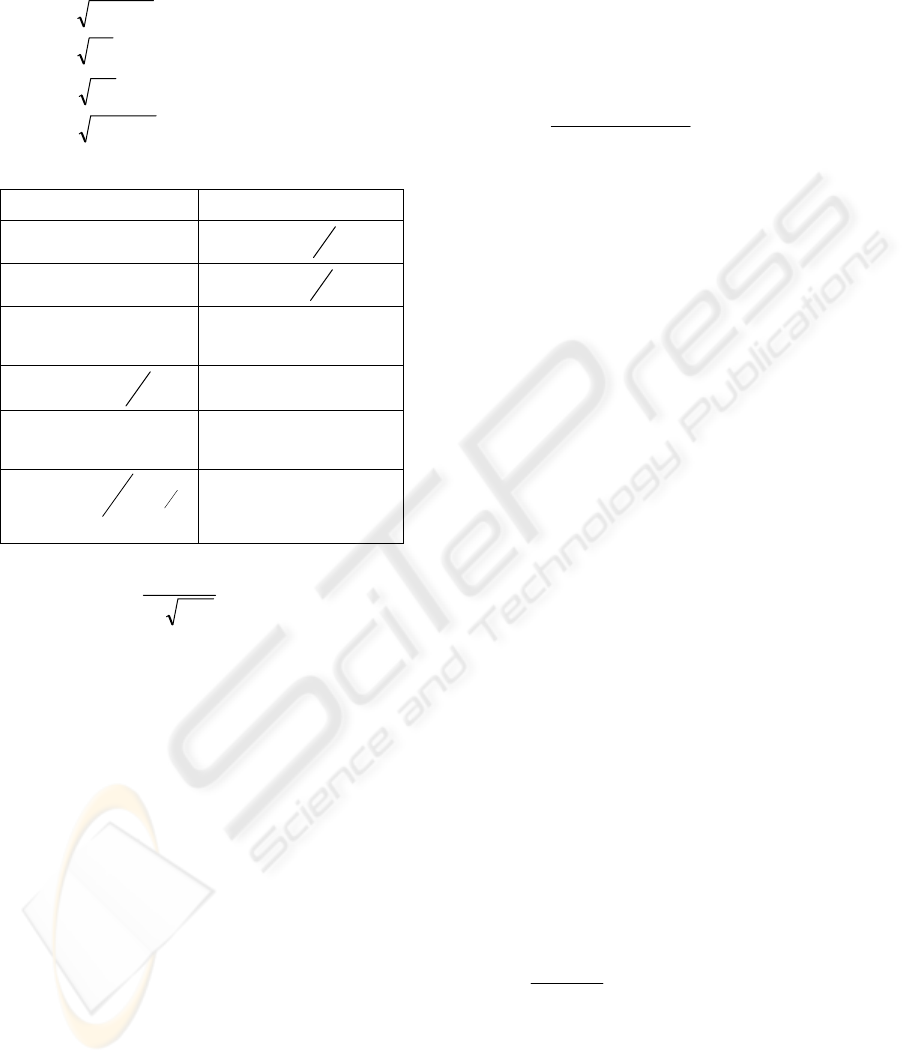

The proposed controller depicted in figure 2,

composed of two neural networks, shown as blocks

Neural Networks and Gain Scheduling. Neural

Network Block is used as acceleration feed back to

improve the dynamic behavior of system (lack of

damping).

Figure 2: Schematic Diagram of Neural Controller

Neural networks parameters are updated online by

learning rate and momentum factors. As it shown in

figure, the proposed neural network has two hidden

layers, figure3, one input and one output layer. The

inputs of neural network are two accelerations

( )(ka

i

, )( 1ka

i

− ) and the output of pervious

step, )1( −ku

n

. Several kinds of structure with one

or three hidden layers were tested. The proposed

structure has this ability to emulate the acceleration

feedback and improve the dynamic behavior of

system.

The second neural network, gain scheduling

network, has the same structure as pervious one, but

the inputs are the two controller errors (

)(ke ,

)( 1ke − ) and the output of last step, )( 1ku

G

−

.

Due to the poor results of p-controller in return

stage the second neural network tried to compensate

this matter. Finally, the controller output,

summation of

N

u and

G

u , is fed to the system.

Choosing the initial weights are too important in

back-propagation algorithm. To avoid local minima

problem, the genetic algorithm is used to find the

off-line weights (Corne. 1999).

Figure 3: Structure of Neural Network

For online training with backpropagation algorithm

the learning rate of

6

102

−

×=

η

and 00010.=

α

are

used. The simulation results are depicted in result

section.

Following the results of using new controller is

compared with common p-controller.

4 DE STRATEGY

Differential evolution (DE) is a simple yet powerful

population based, direct-search algorithm for

globally optimizing functions defined on totally

ordered spaces, including especially functions with

real-valued parameters. Real parameter optimization

comprises a large and important class of practical

problems in science and engineering.

There are two variants of DE that have been

reported, DE/rand/1/bin and DE/best/2/bin. The

different variants are classified using the following

notation:

DE

/x /y/z;

where

• x indicates the method for selecting the

parent chromosome that will form the base

of the mutated vector. Thus, DE

/rand/y/z

selects the target parent in a purely random

manner. In contrast, DE

/best/y/z selects the

best member of the population to form the

base of the mutated chromosome.

• y indicates the number of difference

vectors used to perturb the base

chromosome.

• z indicates the crossover mechanism used

to create the child population. The

bin

acronym indicates that crossover is

controlled by a series of independent

binomial experiments.

Following, the schematic procedure of a class of DE

( DE/rand/1/bin) is presented.

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

136

()

[]

)((lo)

max

,x:bounds initial

and 1,0CR , 1,0F ,4,G D,

:

hi

x

NP

Input

∈+∈≥

D= number of parameters.

NP= population size.

F=scale factor.

CR= crossover control constant.

G

max

=Maximum number of generation.

hi, lo= upper and lower initial parameter bounds,

respectively.

[]

()

⎪

⎩

⎪

⎨

⎧

−+=

≤∀∧≤∀

=

)((hi)

j

)(

,

oGi,j,

x. 1,0x

:Dj NPi

:

lo

j

lo

ij

xrandx

Initialize

(11)

: NPi

GG While

max

≤∀

p

{}

()

[

)

⎪

⎪

⎪

⎪

⎪

⎪

⎪

⎪

⎩

⎪

⎪

⎪

⎪

⎪

⎪

⎪

⎪

⎨

⎧

⎪

⎩

⎪

⎨

⎧

≤

=

⎪

⎪

⎩

⎪

⎪

⎨

⎧

=∨

−+

=

≤∀

≠≠≠

∈

++

+

+

otherwise

)()F(u if

:

otherwise

)jj 1,0(rand If

.

u

: Dj

ieach once selectedrandon j

irrr :except

selectedrandomly ,,...,2,1,,r

:ionRecombinat and Mutate

,

,1Gi,1,

1,

,,

rj

,,,,,,

1Gj,i,

r

321

321

213

Gi

GiGi

Gi

Gij

GrjGrjGrj

x

xFu

x

Select

x

CR

xxFx

NPrr

p

(12)

1+= GG (13)

The aforementioned algorithm finds the global

minima more reliable than the other methods. Note

that these kinds of algorithms are useful in off-line

training as the speed of approaching in not fast.

Here, the numbers of initial weights for each neural

network are 49. Following is the selected

parameters for this strategy,

D= 49,

NP=5

× 49 ≈ 250,

F=0.8,

CR=0.7,

The initial upper and lower bounds are 1,-1,

respectively.

The results show that DE can find the global

minimal cost for the system. Depend on the

expected value of cost, the DE will find the proper

weights. Here the cost of system is defined as

follow,

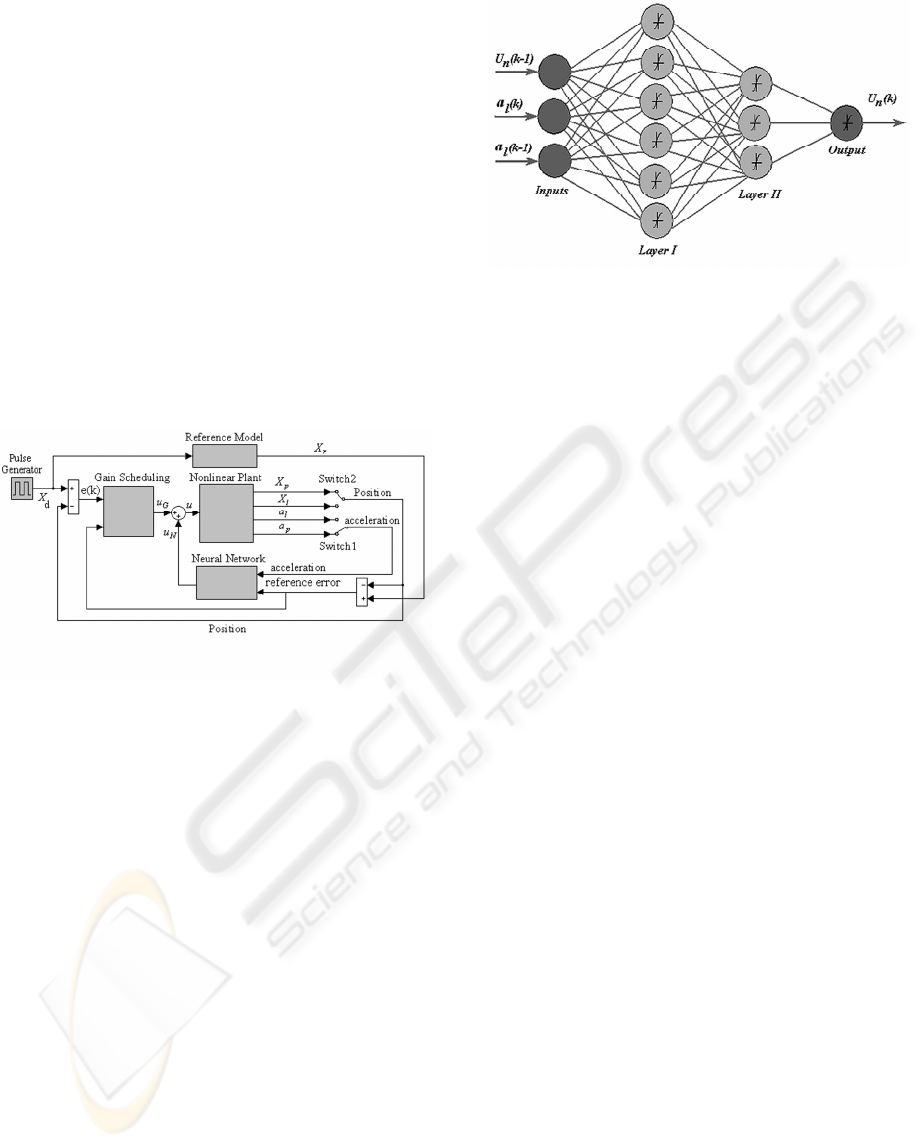

Figure 4: Cost of System against the Number of its

Iterations

∑

=

=

=

2000

1

,

)()(

K

k

Gi

kexF (14)

Where,

)()()( kXkXke

lr

−= (15)

The desire input (

d

X ) is pulse input with the

amplitude of 0.3 (m) and period of 4 (sec.). In the

first step the weights of neural network compensator

were found. To do that, the gain scheduling was

replaced with a constant around 5 and then the cost

for half of period was calculated. The sampling time

here is one millisecond, so the cost will be

calculated 2000 times in each iteration.

Figure 4 shows the amount of cost against its

iteration number. The result indicates that at the

earlier iteration the amount of cost is too big. Also

the algorithm finds new child generations with

lower cost to fast (cost bigger than 30). To find the

lower cost, the number of iterations must growth up.

As it shown, when the number of iteration is around

30000, the related cost is around 17.6, after around

34000 iterations the cost will be fixed at 15.6. This

cost will be constant and its related weights has the

global minimum cost for the proposed neural

compensator.

After aforementioned step for tuning the neural

network, using the same strategy, the weights of

neural gain scheduling will be found.

In the next section the proposed neural networks

will be impelled to position controlling of the

system. The important factor in DE is factor of F.

The iteration number is incredibly related to this

factor. However, the change of crossover factor has

not essential effect in decreasing the number of

iterations. The chosen value is recommended in

many cases to be useful. In this study, the number

of generation was 1973 times during 100000

iterations.

APPLICATION OF DE STRATEGY AND NEURAL NETWORK - In position control of a flexible servohydraulic system

137

5 RESULTS AND DISCUSSIONS

In this section the results of using proposed

controller for two cases are provided. These

controllers are tracking the reference model for

piston tracking (

1

m ), case I, and flexible load

tracking (

2

m ), case II, respectively.

The desire input (

d

X ) is pulse input with the

amplitude of 0.3 (m) and period of 4 (sec.).

5.1 Piston Tracking

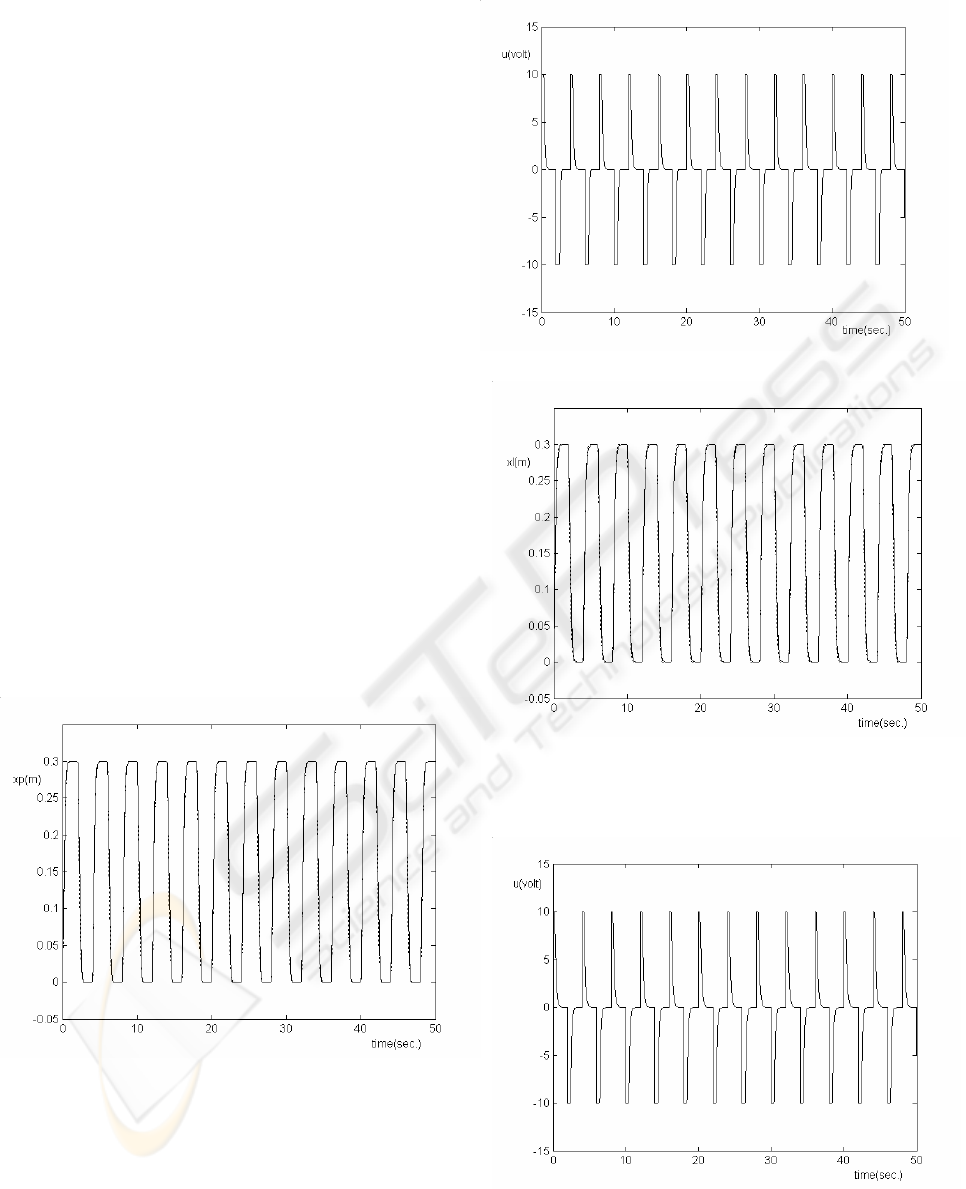

Figure 5 is the piston tracking of the reference

model using neural network with gain scheduling.

Figure 6 is its controller effort that will be fed to

nonlinear system.

The maximum and minimum voltages fed to the

valve are limited to

10± (Volt). As it shown in

figure 6, the maximum and minimum of voltage are

banded because of valve restriction.

5.2 Fexible Load Tracking

In this section the results of using second controller

to track of reference model for flexible load is

presented. Figure 7 is the flexible load tracking of

the reference model using neural network with gain

scheduling.

Figure 5: Result of Mass Load Tracking Using Neural

Network with Gain Scheduling. The Solid Line Shows the

Reference Model and Dots Line Show Mass Load

Position

Figure 6: Controller Effort Using Neural Controller with

Neural Gain Scheduling

Figure 7: Simulation Result of Flexible Load Tracking

Using Neural Network with Gain Scheduling. The Solid

Line Shows the Reference Model and Dots Line Show

Mass Load Position.

Figure 8: Controller Effort Using Neural Controller with

Gain Scheduling

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

138

Figure 8 is its controller effort that will be fed to the

system.

The acceleration of flexible load is used for the

neural network block. The results are satisfactory

and illustrate the capability of the neural network in

controlling and compensating the dynamic of the

servo hydraulic systems.

As it was shown in the figure 5, in rising and

falling stages, the flexible load tracking is similar to

that of the piston tracking.

Figure 7 shows that the neural network with the

gain scheduling has very good performances during

the rising and falling. The aforementioned controller

can track the reference model very well. Figure 8

shows the output of controller is smooth and has not

any oscillation.

6 CONCLUSIONS

In the present paper the application of DE and back-

propagation algorithm in position control of a

flexible servo-hydraulic system was studied. The

results suggest that neural network has good

performance if the initial weights of system are set

correctly. To avoid the local minima, Differential

Evolution Algorithm is essential. These kinds of

algorithms are too slow, so they are useful only in

off-line training.

In this article the Differential Evolution

Algorithm for handling multiple nonlinear functions

was proposed and demonstrated with a set of two

difficult test problems. With all test cases, the

algorithm demonstrated excellent effectiveness,

efficiency and robustness. The architectures and the

number of hidden layers are the other essential keys

to have a well-performed neural network. If the

number of hidden layers or neurons in each layer is

not enough the results will be poor. Several

structures were tested and the aforementioned

architecture was adapted.

In light of above, using neural network to

compensate the dynamic of hydraulic systems is an

essential factor to improve their performances.

Also, the implementing of the gain scheduling

overcomes the variations of parameters during its

perform.

7 NOMENCHLACHERS

1

A piston area in chamber one

2

A piston area in chamber two

i

B biases (

i

=1, 2, 3)

0

b viscous friction coefficients of cylinder

1

b viscous friction coefficient of flexible load

v

c flow coefficient

k spring constant

p

k proportional gain

L stroke

1

m mass of rigid body

2

m mass of flexible load

1

p pressure in chamber one

2

p pressure in chamber two

s

p pressure supply

T

p tank pressure

1

Q flow rate in chamber one

2

Q flow rate in chamber two

n

Q nominal flow

u

control signal

1

u proportional controller signal

2

u neural network controller signal

n

u nominal controller signal

1

V compressed volume of chamber one

2

V compressed volume of chamber two

ji

w neural network weights ( i =1,2,3)

l

x load position

p

x piston position

r

x reference position

d

X desire position

n

p

∆

nominal pressure difference

α

momentum rate

e

β

effective bulk modulus

η

learning rate

0

ν

volume of pipe between valve and cylinder

port

n

ω

natural frequency

REFERENCES

Abbass HA., 2002. An Evolutionary Artificial Neural

Networks Approach for Breast Cancer Diagnosis.

Artificial Intelligence in Medicine, 25, 265–281.

Babu BV, Jehan MML. 2003. Differential Evolution for

Multi-Objective Optimization. Proceedings of 2003

Conference on Evolutionary Computation (CEC-

2003), Canberra, Australia, 2696–703.

APPLICATION OF DE STRATEGY AND NEURAL NETWORK - In position control of a flexible servohydraulic system

139

Babu BV, Sastry KKN., 1999. Estimation of Heat Transfer

Parameters in a Trickle-Bed Reactor Using

Differential Evolution and Orthogonal Collocation.

Computers and Chemical Engineering, 23(3), 327–

339.

Bergey PK., 1999. An Agent enhanced Intelligent

Spreadsheet Solver for Multi-Criteria Decision

Making. Proceedings of AIS AMCIS 1999: Americas

Conference on Information Systems, Milwaukee, USA,

966–8.

Booty WG, D Lam CL, Wong IWS, Siconolfi P., 2000.

Design and Implementation of an Environmental

Decision Support System. Environmental Modeling

and Software, 16(5), 453–458.

Cafolla AA., 1998. A New Stochastic Optimization

Strategy for Quantitative Analysis of Core Level

Photoemission Data. Surface Science, 402–404,561–

565.

Chang TT, Chang HC., 2000. An Efficient Approach for

Reducing Harmonic Voltage Distortion in

Distribution Systems with Active Power Line

Conditioners. IEEE Transactions on Power Delivery,

15(3), 990–995.

Chen, S. and Billings, S. A., 1992. Neural Networks for

Dynamical System Modeling and Identification. Int.

J. Control, 56(2), 319-346.

Cheng SL, Hwang C., 2001. Optimal Approximation of

Linear Systems by a Differential Evolution

Algorithm. IEEE Transactions on Systems, Man and

Cybernetics, Part A, 31(6), 698–707.

David Corne, Marco Dorigo and Fred Glover, 1999, The

book. New Ideas in Optimization, McGraw-Hill.

D.E.Rumelhart, et al, 1986. Learning Internal

Representations: by Error Propagation. Parallel

Distributed Processing Explorations in the

Microstructures of Cognition, 1,318-362.

Gene F. Franklin, et al., 1986, The Book. Feedback

Control of Dynamic Systems, Addison-Wesley.

Schmitz GPJ, Aldrich C., 1998. Neuro-Fuzzy Modeling

of Chemical Process Systems with Ellipsoidal Radial

Basis Function Neural Networks and Genetic

Algorithms. Computers & Chemical Engineering, 22,

1001–1004.

Schwefel, H.P., 1995, The Book, Evolution and Optimum

Seeking, John Wiley.

Storn R., 1999. System Design by Constraint Adaptation

and Differential Evolution. IEEE Transactions on

Evolutionary Computation, 3(1), 22–34.

Storn, R. and Price, K.V.,1995. Differential evolution - a

Simple and Efficient Adaptive Scheme for Global

Optimization over Continuous Spaces, Technical

Report TR-95-012, ICSI.

Stumberger G, Pahner U, Hameyer K., 2000.

Optimization of Radial Active Magnetic Bearings

Using the Finite Element Technique and the

Differential Evolution Algorithm. IEEE Transactions

on Magnetics, 36(4), 1009–13.

Taco J. Viersma, 1980, The Book. An analysis, Synthesis

and Design of Hydraulic Servosystems and Pipelines,

Elsevier.

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

140