THE ENGINE TO SUPPORT BUILDING CPC SOLUTIONS

Jinmi Jung, Hyun Kim, Hyungsun Kim, Joohaeng Lee

Electronics and Telecommnucations Research Institute, 161 Gajeong-dong, Yuseong-gu, Daejeon, Korea

Keywords: Collaborative Product Commerce, Virtual Enterprise, Product Information, Web Services, XML.

Abstract: In modern business environment, inter-organizational collaborative product development is very important.

CPC (Collaborative Product Commerce) is a new category of software, now emerging, to support inter-

enterprise collaboration through the product life-cycle. But, so far there are not striking solutions to support

collaboration among collaborative engineering groups. In this paper, we describe the engine to support

building a CPC solution which is being developed by the Electronics and Telecommunications Research

Institute (ETRI) as a part of a CPC project. It makes it possible to collaborate among geographically

dispersed enterprises by sharing product information. We look over problems to have to be solved for

designing the engine and propose solutions. In addition, we mention the developed CPC solution using the

engine.

1 INTRODUCTION

Many of today’s enterprises need new business

environment due to the increase of keen competition

among enterprises day by day and pressure from

customers. Many customers are no longer satisfied

with mass-produced goods. They are demanding

customization and rapid delivery of innovative

products (Aberdeen, 1997). The sooner

manufacturers can bring a new product to market,

the more dominant position they hold in their

industries. Consequently many enterprises try to

reduce development time and cost as well as

improve the quality of product by developing a

diverse and complex product through collaboration

with partners having prominent capability rather

than doing independently. That is, multinational

companies that possess expertise in a specific field

form a temporary union called ‘virtual enterprise’ to

jointly develop, produce and market products

(D.Tony, 2001). The most important requirement for

a successful virtual enterprise is the inter-enterprise

collaboration. But, it is not easy to realize because

collaborating organizations are geographically

dispersed and use different computer technology

(e.g. CAD/CAM systems, PDM systems) as shown

in Figure 1.

Formerly, PDM systems which are very

sophisticated IT products with many users in

industry are used to support collaborative

engineering groups. But, they do not provide sharing

of application data at a flexible, user-requested data

granularity level and data files use application

specific formats and may be modified only by their

native applications (Dragan, 2000).

CPC is a newly emerging technology to support

inter-enterprise collaboration. Aberdeen Group

defines that CPC is a class of software and services

that use internet technologies to permit individuals

to collaboratively develop, build, and manage

products throughout their entire life cycle. And it

predicts that manufacturing executives will demand

CPC tools to enable their organizations to respond to

these commercial market pressures (Aberdeen,

1997). But, currently there are not striking CPC

solutions.

In this paper, we propose the engine that support

building the Web-centric CPC solution which is

based on open standards, such as STEP, Web

services, XML, and so on. Section 2 addressed the

problems to be solved for collaboration. Section 3

discusses the framework of the proposed engine.

Section 4 and section 5 describes system design and

implementation, respectively. Section 6 concludes

the paper.

2 PROBLEM DEFINITION

The engine aims at supporting to share and manage

the diverse information and document among virtual

enterprises through the product life cycle for

117

Jung J., Kim H., Kim H. and Lee J. (2005).

THE ENGINE TO SUPPORT BUILDING CPC SOLUTIONS.

In Proceedings of the Second International Conference on e-Business and Telecommunication Networks, pages 117-121

DOI: 10.5220/0001417801170121

Copyright

c

SciTePress

collaboration. For this, the following issues should

be addressed:

z Product data interoperability: product structures

and contents in each collaborating enterprise may

be different. How can business partners share

product data for collaboration when they cannot

understand each other’s product data?

z System application interoperability: though the

problem of the heterogeneity of product data has

been solved, business-to-business application

integration is an important problem. Business

partners manage product data in heterogeneous

applications and platforms. In such a situation,

how can they seamlessly integrate distributed

applications for inter-enterprise collaboration?

Two problems above define how to share

product data and integrate applications across

different enterprises to support dynamic and agile

aspects of virtual enterprises.

Early works investigating sharing product data

and integrating its applications dealt with data

exchange between CAD systems using STEP which

is the standard for the exchange of product model

data and CORBA. Hardwick et al. (Hardwick, 1996)

proposed an information infrastructure that enhances

collaboration in a virtual manufacturing enterprise

using STEP and CORBA. There has been similar

research (Bliznakov, 1996. Urban, 1996. Shah,

1996) to integrate product data and support

collaboration using STEP-based schemas,

commercial databases, and CORBA. Wallace et al.

(Senin, 1997) introduced object-based modelling

and evaluation of design problems in a network-

oriented design environment. Kim et al. (Kim, 1999)

proposed a framework for process-centric

collaborative design in a distributed environment.

There have also been studies on product data

management (PDM). Liu et al. (Liu, 2001) discussed

the integration of PDM methodology with Web

architecture to enhance a traditional PDM system.

Yeh et al. (Yeh, 2002) proposed an integrated data

model and an implementation approach for a PDM

system that uses the STEP as a standard for the

exchange of product data. Several research efforts

have addressed how inter-enterprise applications

should be integrated to support business information

sharing and collaboration. However, their systems

have been mainly built on the assumption that

information and systems to be integrated were

known at the time of software design because

collaboration partners had been previously organized.

Therefore, they dealt with information-sharing under

tightly-coupled system architecture. But if we take

dynamic and agile aspects of virtual enterprises, we

need to consider more flexible and open architecture

in which the autonomy of each enterprise is more

guaranteed. It means information-sharing under

loosely-coupled structure should be considered.

3 FRAMEWORK OF THE

ENGINE

In order to solve the problems discussed in prior

section, we propose product metadata for product

data interoperability and CPC adaptor for system

application interoperability.

3.1 Product metadata

Because different enterprises manage product

information in different ways, semantic and

schematic conflicts may be occurred in sharing

information. We propose a standard data schema of

Figure 1: Interoperability problems in product data and application systems.

ICETE 2005 - GLOBAL COMMUNICATION INFORMATION SYSTEMS AND SERVICES

118

common use to support the interoperability of

product data and call it ‘product metadata.’ Different

data schema managed in different enterprises is

mapped into it. Product metadata includes data such

as product model, product configuration, product

item, product structure, product properties,

engineering change, document, project, organization,

and alias that are minimal information shared among

enterprises to collaborate one another.

For product metadata to serve efficiently as a

common data schema, it is desirable that product

metadata comply with standards to be supported by

commercial systems. So, we made it based on ISO

STEP PDM Schema (Jim, 2000) which is a

reference information model for the exchange of a

central, common subset of the data being managed

within a PDM system. In STEP, expression is

represented with EXPRESS language. But, it is not

appropriate for Web-centric system. So we translate

product metadata into XML schema which provides

a means for defining the structure, content, and

semantics of XML documents.

3.2 CPC adaptor

To get product information from geographically

dispersed organizations which are using different

system applications (e.g. CAD/CAM/CAE, PDM

system, File system) and map it into product

metadata, the method how to acquire and distribute

product information from/to organizations is needed.

Distributed computing middleware such as

CORBA, RMI, or DCOM has been proposed to

solve the application interoperability problem, but it

is not suitable for enterprise-to-enterprise

applications. CORBA, RMI, and COM are all

designed for tightly-coupled applications. They are

based on an RPC model and assume a great deal of

similarity between the calling and called systems.

They may depend on the conventions of particular

programming languages (such as Java) or platforms

(such as Windows). In addition, they require a

special network protocol such as IIOP. Thus,

firewall problems may occur in the applications of

enterprise-to-enterprise communication.

Considering the features of virtual enterprise,

more loosely-coupled system integration is required.

Web services (Web) is targeted specifically at

providing a loosely-coupled architecture designed

for exchanging information over the Internet. One of

the goals of Web services is to realize a distributed

architecture across the Web in a platform-

independent manner.

So, we use CPC adaptor which is a set of Web

services to solve system application interoperability.

CPC adaptor extracts product information from a

legacy application such as PDM, CAD, or ERP,

translates it into product metadata and puts it to the

repository of the engine. There is also an adaptor

implemented using Web services in legacy

application to communicate with CPC adaptor.

These adaptors are managed in a CPC service

registry, which is based on a UDDI registry. From

the WSDL of the adaptor, the information such as

operations, I/O data type, service URL, and so on,

may be acquired.

4 SYSTEM ARCHITECTURE

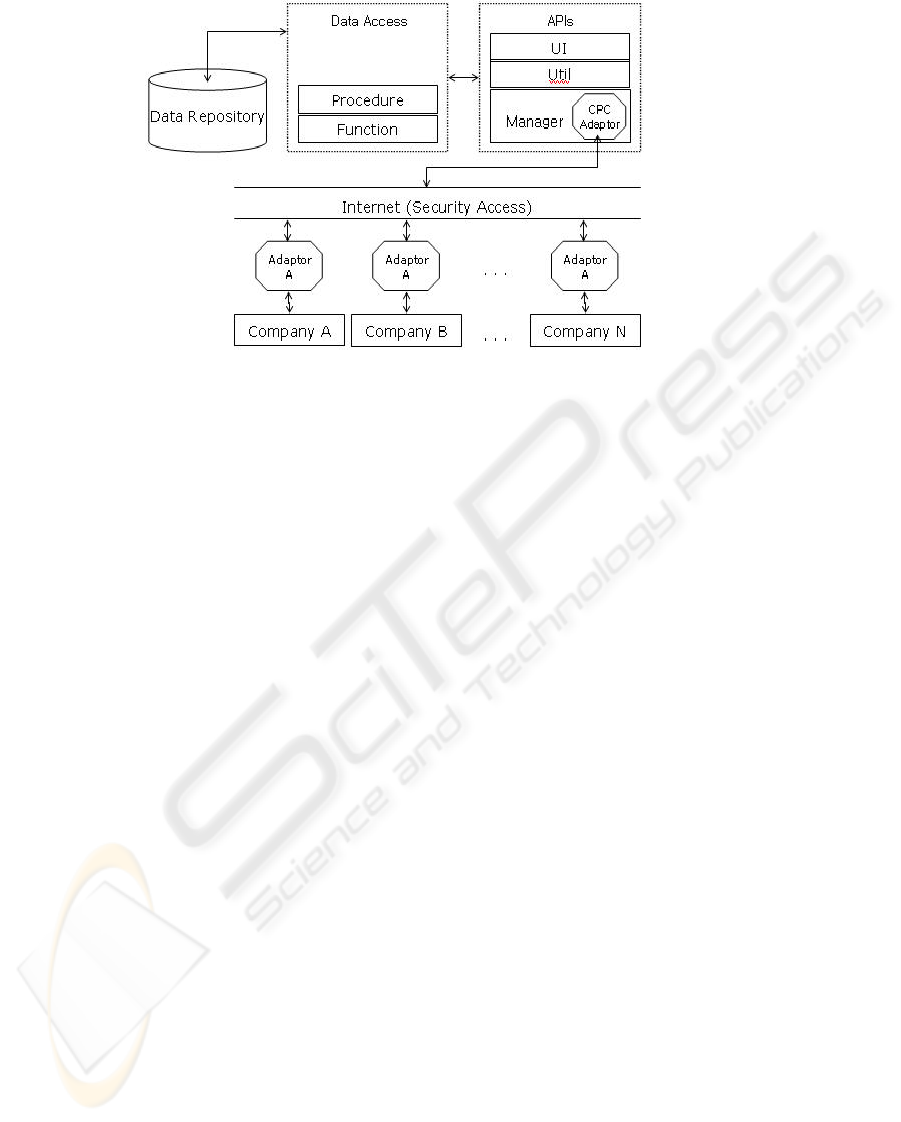

The architecture of the proposed engine in this paper

is like Figure 2. It is composed of the data repository

Figure 2: System Architecture.

THE ENGINE TO SUPPORT BUILDING CPC SOLUTIONS

119

for storing product metadata, the APIs used to

program user interfaces, and the procedures for

accessing and manipulating data in repository.

Figure 2 also shows the phase of sharing information

among enterprises through CPC Adaptor.

z Data Repository: we use a relational database as

a data repository and its schema is based on

product metadata. Product metadata and any

other information to be shared across enterprises

for collaboration are stored into this repository.

The process to map product metadata represented

as XML schema into relational database schema

has been progressed.

z APIs: APIs provided by the engine are a type of

C# class and classified into three packages.

Manager package is used to make programs to

transfer user input to stored procedure for

inserting, modifying and deleting data in the

repository. By using the APIs in Manager

package, the CPC solution developer can

implement the functions such as project

management, engineering change order, user

management, organization management, data

access control. And there are also APIs to make

CPC adaptor for sharing product metadata. UI

package provide the interface to display the data

retrieved from repository on a web page. For

example, hierarchical data may be displayed in

the shape of tree. Util package provide methods

for connecting to the data repository.

z Stored Procedure: it makes SQL queries,

accesses to the data repository, executes queries

and returns results. These stored procedures are

called by the programs made with APIs in

Manager package. The programs transfer user

input to the procedure as parameters and receive

the query results. Result type is not a set of rows

but XML. SQL Query which is simple or used

repeatedly is made as function for reusability. In

case query is complex or many queries have to

be executed in turn, it is made as procedure.

5 SYSTEM IMPLEMENTATION

AND BUILDING CPC

SOLUTION

The APIs are implemented using C#. Currently,

there are 21 classes in Manager package, 26 in UI

package, 3 classes in Util package. The code of

Figure 3 shows the usage of APIs. It retrieves

projects which is managed by the current log in user

from the repository and displays project IDs on a

web page. GetAll() method of

Figure 3: Example of the Engine API usage.

(a) The first page

(b) Product Information

Figure 4: CPC portal site

ICETE 2005 - GLOBAL COMMUNICATION INFORMATION SYSTEMS AND SERVICES

120

Mgr_OrganizationalProject class in Manager

package need one parameter, user’s loginId, and

returns all projects according to that.

Getorganizational_projectCount() method of

UI_ArrayofProjects class in UI package returns the

counts of returned projects by GetAll() method.

To demonstrate the functionality of the engine,

we built the CPC solution with the engine. It is a

kind of Web portal site that provides GUIs for user.

In Figure 4, (a) is the first page of CPC portal site

and (b) is the snapshot of displaying the product

structure acquired from other application system

through CPC adaptor. Collaborating enterprises can

manage and share a lot of information during the

entire product life cycle at this portal site. It has been

developed using Microsoft’s ASP.Net and Microsoft

SQL Server is used as a data repository.

Especially, to test for sharing product

information across enterprises, an adaptor for

SmarTeam (

SmarTeam), a commercial PDM system,

and an adaptor for SolidWorks (

SolidWorks), a

commercial CAD system, are developed together.

For security communication between adaptors, each

adaptor encrypts data and includes digital signature

using X509SecurityToken of WSE 2.0.

5 CONCLUSIONS

The engine proposed in this paper supports building

CPC solutions. We solved product data

interoperability and system application

interoperability that is required to collaborate across

enterprises with common data schema following

ISO STEMP PDM Schema and CPC adaptor which

is a set of Web services, respectively. The CPC

solution built using the engine can provide project

management, engineering change order, user and

organization management, data access control, data

search, and so on. Specially, it also provides the

functions of sharing information that is deficiency of

existing PDM systems. We constructed CPC

solution, a kind of Web portal site, with the engine

ourselves.

REFERENCES

Aberdeen group., 1997. Collaborative Product Commerce:

Delivering Product Innovations at Internet Speed.

MARKET VIEWOPINT Volume 12/Number 9.

D.Tony L, X.William X., 2001. A review of web-based

product data management systems. Computers in

Industry 44, pp 251-262.

Dragan S. D., Miao C. Y., Chee F., Yew C.,2000. An

Infrastructure for Inter-Organizational Collaborative

Product Development. Proceedings of the 33

rd

Hawaii

International Conference on System Sciences.

Jim, k., Markus, H., Rogerio, B., 2000. Usage Guide for

the STEP PDM Schema. PDM Implementor Forum.

Web Services Activity. http://www.w3.org/2002/ws

Hardwick M, Spooner DL, Rando T, Morris, 1996.

Sharing manufacturing information in virtual

enterprises. Commun ACM 39(2):46–54.

Bliznakov PI, Shah JJ, Urban SD, 1996. Integration

infrastructure to support concurrence and collaboration

in engineering design. Proceedings of the ASME

DETC and CIE Conference.

Urban SD, Shah JJ, Liu H, Rogers M, 1996. The shared

design manager, interoperability in engineering design.

Integr Comput Aided Eng 3(3):158–177.

Shah JJ, Jeon DK, Urban SD, Bliznakov P, Rogers M,

1996. Database infrastructure for supporting

engineering design histories. Comput Aided Des

28(5):347–360.

Senin N, Borland N, Wallace DR, 1997. Distributed

modeling of product design problems in a ollaborative

design environment. CIRP International Design

Seminar Proceedings.

Kim H, Lee JY, Han S-B, 1999. Process-centric istributed

collaborative design based on the Web. Proceedings of

ASME DETC and CIE Conference.

Liu DT, Xu XW, 2001. A review of web-based product

data management systems. Comput Ind 44(3):251–262.

Yeh SC, You CF, 2002. STEP-based data schema for

implementing product data management system. Int J

Comput Integr Manuf 15(1):1–17.

SmarTeam. http://www.smarteam.com/homepage.asp

SolidWorks. http://www.solidworks.com

THE ENGINE TO SUPPORT BUILDING CPC SOLUTIONS

121