VALUE ADDED WEB SERVICES FOR INDUSTRIAL

OPERATIONS AND MAINTENANCE

Mika Viinikkala, Veli-Pekka Jaakkola, Seppo Kuikka

Institute of Automation and Control, Tampere University of Technology, P.O.Box 692, 33101 Tampere, Finland

Keywords: Web service, operation and maintenance, O&M, service oriented architecture, SOA

Abstract: Efficient information manag

ement is needed at industrial manufacturing plants that compete in the present

demanding business environment. Requirements to enhance operation and maintenance (O&M) information

management emerge from problems within internal information flows of a plant, supporting the networked

organization of O&M, and accomplishing the new demand-driven business model. O&M information

management of an industrial process plant is here proposed to be enhanced by value added web services. A

service framework will work as a supporting architectural context for the value added services. Information

from existing systems, such as automation, maintenance, production control, and condition monitoring

systems, is analyzed, refined and used in control activities by the services.

1 INTRODUCTION

From the phases of the life cycle of an industrial

manufacturing plant, the operational phase is the

longest and during it the plant is expected to pay

back all costs of its life time and produce profit for

its owner. Changing operating environment,

squeezing global markets, and decreasing profit

margins, among others, place challenges in fulfilling

these expectations. To remain competitive,

manufacturers need to adopt advanced and

integrated operation and maintenance (O&M) of a

plant.

O&M means activities that are performed during

o

perational phase of a plant. The primary goal of

O&M is to secure the undisturbed operation of a

production plant and to make manufacturing as

profitable as possible. Critical aspect in reaching this

goal is information management and application of

modern information technology. Manufacturers

should be able to fully utilize the information in

O&M information systems. Achieving this requires

the ability to easily integrate these systems.

An effort called OpenO&M For Manufacturing

Joint Work

Group has been recently formed by three

non-profit organizations, MIMOSA, the OPC

Foundation, and the Instrumentation and

Automation Society (ISA) SP95 committee to

harmonize the various existing standards from these

organizations (OpenO&M, 2004). The goal of the

joint effort is to provide the standards and

technology that form an interoperable framework for

exchange of O&M information.

In addition to standards, technologies which

en

able integration functionalities are also needed.

Web services provide standard means for

interoperating between heterogeneous information

systems utilizing different platforms, programming

languages, and component models (Booth et al.,

2004).

2 O&M INFORMATION

MANAGEMENT

In this chapter, current state and problems of O&M

information management are discussed. From these,

requirements for integration are derived. Discussion

is based both on literature and a set of production

plant interviews (Viinikkala, Jaakkola, 2004) that

were conducted in order to examine O&M

information management at Finnish industrial plants.

2.1 Information systems

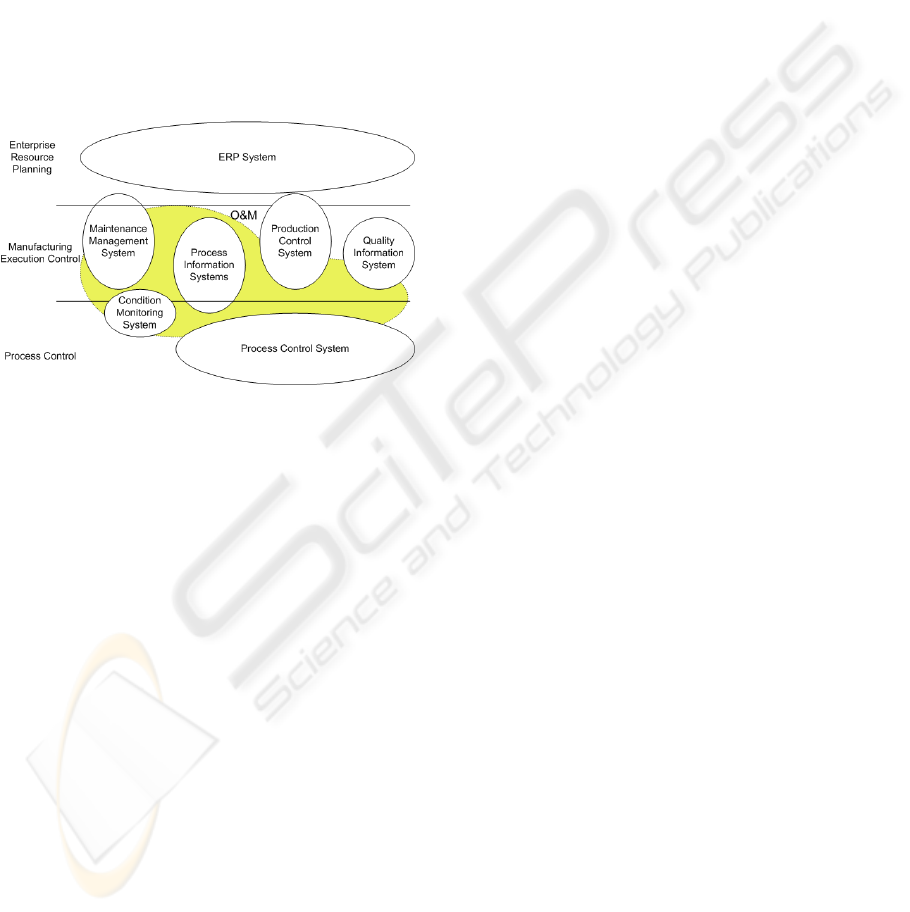

Figure 1 depicts the information systems used on

different levels of manufacturing organization,

which are defined in (ISA SP95, 2004). The

information systems function as repositories of

various kind of information about the past and

present state of the production plant. Information

361

Viinikkala M., Jaakkola V. and Kuikka S. (2005).

VALUE ADDED WEB SERVICES FOR INDUSTRIAL OPERATIONS AND MAINTENANCE.

In Proceedings of the Seventh International Conference on Enterprise Information Systems, pages 361-365

DOI: 10.5220/0002528203610365

Copyright

c

SciTePress

concerning the process, its state, control signals and

measurements, is collected and stored by the

distributed control system (Paunonen, 1997).

Maintenance activities are supported by

Computerized Maintenance Management Systems

(CMMS), which are basically database systems that

usually contain information about maintenance work

orders, equipment maintenance history, and

preventive maintenance schedules among other

things related to maintenance.

Charasteristic for the information systems at

industrial plants, though alike in their database

centricity, is that they are built with different

techniques on different software platforms and are

not thus inherently interoperable.

2.2 Integration of operations

Production and maintenance are not separate, but

related and parallel activities. The production

process requires energy, materials, and work force as

its primary inputs, but also production capability as

its secondary input. This is produced by

maintenance. On the other hand, the secondary

output of the production process is the need for

maintenance which is the input for maintenance

(Jonsson, 1999). Ideally, related operations should

be supported by information systems.

Many information systems exist at a plant, but

they are rarely considered as a whole. A given

system serves the needs of a particular activity only

– not the O&M of the whole plant. The starting point

for integration is poor in this sense, because legacy

systems have not been designed to support

integration.

Also, because of the information fragmentation

and due to lack of standard interfaces, finding the

relevant information to support O&M decision

making from various information systems is hard.

For example, maintenance history knowledge may

be fragmented to several information systems (Mäki,

2000).

Some custom links that are typically not based on

any standard interface have been developed in order

to integrate a system with another system. By using

this kind of point-to-point approach, information can

be exchanged between two information systems.

However, each system has its own data model,

which has to be made compatible with each other.

Thus, the point-to-point approach based on non-

standard interfaces is laborious and inefficient and

thus expensive.

Information that is read from a system or a set of

systems could be analyzed by some intelligent

entity. Based on the result of the analysis,

information could be written into some other system,

thus accomplishing automatic transactions between

participating systems. This kind of intelligent co-

operation, orchestrated by intelligent entities, does

not exist at industrial plants yet.

Majority of information flows between systems

are currently accomplished manually by means of a

human mediator. This situation causes latencies in

information flows between systems. Human effort is

required even in routine information exchanges

between information systems.

In order to overcome these problems, integration

of the existing systems is required. Going further,

information is required to be accessed by using

standard interfaces, which the information systems

are required to provide. Further, information is

required to be processed by services that use the

standard interfaces to access the information. Such

services are required to contain business logic or

intelligence to accomplish the information

integration or to implement the required co-

operation among systems.

Figure 1: O&M information systems. Modified from

(ISA SP95, 2004) and (Viinikkala, Jaakkola, 2004)

2.3 Networked O&M

The responsibility for maintaining the production

equipment is transferring from proprietary

organizations of the production plant to dedicated

service providers (Viitamo, 2000). The traditional

arrangement, especially in the heavy process

industry, has been organizing maintenance with

plant maintenance personnel.

Responsibility for equipment effectiveness

requires the awareness of the equipment condition

and production state. Thus constant information

exchange between the external service provider and

the production plant is needed. The current

information systems and the integration techniques

that are used in operation and maintenance do not

adequately respond to this need. The collaborative

ICEIS 2005 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

362

efforts of O&M rely on the collaboration of human

experts and the plant operators.

Ideally in case of a problem, the required

knowledge and information to solve it is available

immediately, and the necessary notifications to all

relevant directions are sent automatically. Means to

also external interest groups to access O&M

information in a controlled way are needed. The way

of accessing information should be the same for both

internal usage and external interest groups.

Currently, the friction in operations that require the

attention of several people leads to latencies in

various stages of the situation, which causes

unnecessary loss of equipment availability.

To reach the ideal performance in collaborative

O&M, the operations must make use of new kinds of

information processing solutions that support them

in a holistic manner. These solutions must not

override the existing information systems

infrastructure but include them as an essential

sources and storages of data.

2.4 Visibility into operations

The business model that the manufacturers prefer

has changed from a model, in which products are

made to stock, to a model, in which production is

entirely based on orders and customer needs.

Currently, supply chains are becoming faster and

more integrated with support of e-business.

Demand-driven business model cannot be

accomplished without information from lower

automation levels at plants. In enterprise resource

planning-level, which can be seen from figure 1,

plans, that satisfy customer needs, are designed.

These plans can not be accurately made without

knowledge about O&M operations and status.

Forrester recently published results from a survey

of the top 50 global manufacturing executives, in

which they were asked to answer the question:

“What are your biggest problems with global

manufacturing?” The biggest problem the survey

indicated was “poor visibility into plant operations”

(38%). (Forrester, 2000) Thus, the biggest concern

at the enterprise resource planning level is that

managers and other personnel are not seeing the

right information to make the best possible decisions

on how to run the plant. As supply chains are

becoming more efficient, the plant and its operations

are becoming the bottleneck of the whole value

chain. Current systems, as they are, are inadequate in

providing the required visibility into operations.

Also this viewpoint emphasizes the integration

requirement.

2.5 Architectural requirements

The general integration requirement discussed in

previous sections implies further requirements for

the integration architecture.

The integration architecture should enable

extending the existing information systems, which

will continue to serve the plant level functions. The

extension functionality must be generic so that it can

be reasonably provided by parties other than

information system vendors.

Due to the heterogeneous nature of the existing

information systems, the architecture must abstract

the existing information systems and expose their

data content in a unified form. Therefore the

architecture must define a mechanism for describing

the data content that is exchanged. The technology

with which the connectivity is implemented must be

independent of software platforms and operating

systems.

Standardization efforts should be used as

guidelines for defining the data content that is used

inside the integration architecture. Great input to the

vertical integration can be extracted from ISA SP95,

but for integration of O&M activities on the factory

floor level, the standardization work is still ongoing.

Results can be anticipated from the OpenO&M

consortium, for example.

3 SERVICES AND SERVICE

FRAMEWORK

Service Oriented Architectural style (SOA) is a

software paradigm developed around the Web

Services technology. In service oriented

architectures, data and functionality are decoupled

from each other, and dependencies between the

service requesters and providers are minimized. The

requesters and providers are said to be “loosely

coupled”. (Booth, D. et al., 2004)

The service oriented approach suits well the

business environment of industrial operation and

maintenance. Services that do not themselves hold

any significant amounts of data, but transform it, can

be implemented by the external service providers.

The functionality of these services represents the

special maintenance knowledge held by the service

providers. This knowledge can be applied at various

process plants, and it should not therefore be tightly

coupled with data, which is always plant specific.

VALUE ADDED WEB SERVICES FOR INDUSTRIAL OPERATIONS AND MAINTENANCE

363

3.1 Value added services for O&M

O&M value added services are pieces of software

that utilize the existing information system

infrastructure in a production plant to create value

addition to their users. The value addition is

obtained of the existing O&M information systems

by integrating them with these services, instead of

using them solely for their original purpose.

In practice, the value addition can be anything

from data access facilitation to complex process

analysis and automatic control actions. A common

denominator of the aforementioned is that the

services help to make the O&M operations more

integrated and effective. The value added services

provide functionality, which is at its best when

deployed outside the existing information systems.

They are sensitive to the state of the production

process and available production and maintenance

resources. Therefore process, production and

maintenance information systems are the key

sources of information for the value added services.

The value added services generate new

information that flows back to the production plant

and partner organizations and information systems.

They can also generate notifications and perform

automatic control actions. The services can be

configured by the human users of both parties of the

partnership model to produce value addition. The

configurability of the services is a very important

issue from the partnership perspective, because it

makes possible for the services to encapsulate

knowledge that might not be available for the other

partner.

The information exchange requires consensus on

the data models to be used. OPC XML DA provides

a great basis for conveying single data items such as

process measurements. On more complex data, such

as maintenance work orders or condition monitoring

data, other standardization efforts have a crucial

role.

The operation and maintenance value added

services can be categorized to three levels according

to their complexity and the value added. Services on

the lowest complexity level simply combine the

information to one customizable view. The value

addition provided by these services is the ease of

access to the relevant information. The second level

of service complexity is that the services refine the

collected data and in this way create new

information. The second level services can be used

to produce key figures, such as OEE (Overall

Equipment Efficiency), from the process of interest.

Services at this level must possess and apply

knowledge about how the information is calculated.

They must also be able to maintain state and

preserve process information. The third and the

highest level services interact autonomously with

their environment. Services at this level can act as

high abstraction level controllers that control the

work processes of production and maintenance.

A prototype of an intelligent value added service,

called Reasoning Service, has been implemented by

us. The service refines process measurement data

into new, more abstract information, and into

automatically performed actions that control the

workflows of O&M. The transformation of data was

performed using a fuzzy inference system, which

can be used for both function approximation and

classification tasks. The exemplary service is

presented in detail in (Jaakkola, 2004). The

prototype demonstrates the potential of standard

interfaces such as OPC XML-DA as the enablers of

systems integration. It also shows how modern AI

techniques can be utilized within O&M value added

services.

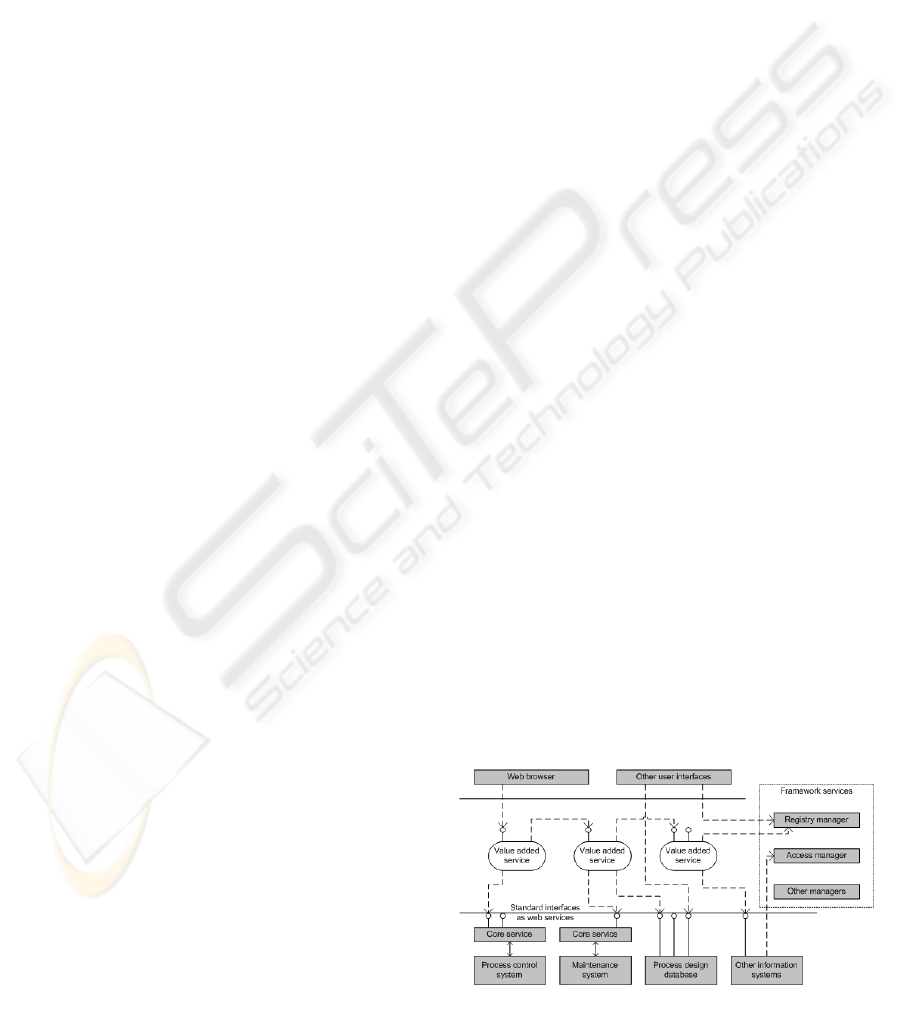

3.2 Service framework

A web service based framework provides supporting

infrastructure for value added services (Kondelin,

Karhela, and Laakso 2005). Figure 2 depicts layers

of the developed service framework architecture.

The framework is independent of organizations

and software platforms and therefore promotes the

interoperation of information systems, exceeding the

organizational boundaries. The common interface

description and data model specification allow the

value added services to connect to the data contents

of other services.

Core services transform data from underlying

legacy systems to the common data model of the

framework. This way they bring the data content

from existing information systems infrastructure to

the reach of the value added services. The core

services of the service framework are to some extent

analogous with the vendor specific adapters of

MIMOSA (MIMOSA, 2004). The core services,

however, do not usually interact with each other

directly, but through value added services. Also the

Figure 2: Service framewor

k

ICEIS 2005 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

364

data model of the service framework is not as

explicit as the one of MIMOSA, but rather a generic

meta-model.

The OPC XML-DA interface (OPC Foundation,

2003) has been chosen to be the data access interface

of the service framework. Therefore, an OPC XML-

DA wrapper, which relays Web service messages to

an OPC DA interface, can be considered as a core

service of the simplest kind.

Access control and the discovery of services are

examples of issues that cannot be resolved in the

web service environment only between the client

and the service. The framework must thus include

services that provide functionality for these issues.

In the service framework, these kinds of services are

called Framework Services. Framework services are

common to all, and they do not represent any system

or organization. Access Manager is a framework

service that controls the authorization of users to the

data content of the core services and value added

services. Access control is especially important

when the integration of information systems exceeds

organizational boundaries. The discovery activity

that is essential to the web service architecture is in

the responsibility of the Registry Manager. The

Registry manager provides similar functionality as

UDDI, but typically its services are used at runtime

instead of design time.

4 CONCLUSIONS AND FUTURE

WORK

Based on requirements derived from current state of

the art, a solution conforming to the ideas of SOA

was proposed. The concept of value added services

for O&M and the supporting service framework

were thus introduced.

It can be concluded that the web service based

architecture enhance the information management

issues discussed. Firstly, internal information flows

can be automated thus leading to enhanced internal

collaboration of integrated operations. Secondly, the

solution supports the organizational changes that

have lead to networked O&M. Finally, better

visibility from top floor into the O&M information

is obtained, alleviating potential bottleneck problems

of the value chains that characterize the current

demand-driven business model.

Web services provide independent means to

create interoperability between heterogeneous

systems of industrial plants. However, in order to

provide more advanced and dynamic reasoning and

services, information must be semantically enriched.

While information can certainly be better managed

by utilizing the proposed solution, the tacit

knowledge, present at plants and within partners still

remains largely unexploited. Currently, we have

begun is to research technologies that are

semantically more advanced and to use these

technologies in the challenging domain of O&M.

REFERENCES

Booth, D. et al., 2004. Web Services Architecture, W3C

Working Group Note 11 February 2004, W3C.

http://www.w3.org/TR/ws-arch/ (20.10.2004)

Forrester, 2000. Forrester Research.

http://www.forrester.com/

ISA, 2004. The Instrumentation, Systems, and Automation

Society, http://www.isa.org/ (20.10.2004)

ISA SP95, 2004. ISA Draft 95.00.03, Enterprise Control

System Integration Part3: Activity Models of

Manufacturing Operation Management, The

Instrumentation, Systems, and Automation Society.

Jaakkola, V-P., 2004. An Intelligent Web Service for

Operation and Maintenance, Master of Science

Thesis, Tampere University of Technology,

Department of Automation. Tampere.

Jonsson, P., 1999. The Impact of Maintenance on the

Production Process – Achieving High Performance,

Dissertation, Division of Production Management.

Lund University.

Kondelin, K., Karhela, T., Laakso P., 2004. Service

Framework Specification for Process Plant Lifecycle,

VTT Research Notes 2277, Espoo 2004.

MIMOSA, 2004. http://www.mimosa.org/ (20.10.2004)

Mäki, K. M., 2000. Kunnossapidon historiatiedon

hallinnan kokonaismalli, Licentiate Thesis, Tampere

University of Technology, Department of Mechanical

Engineering. Tampere.

OPC Foundation, 2003. OPC XML-DA Specification,

version 1.00, http://www.opcfoundation.org/

OpenO&M, 2004. Condition Based Operations for

Manufacturing, OpenO&M For Manufacturing Joint

Work Group. http://www.mimosa.org/papers/

OpenO&M Whitepaper-CBO for Manufacturing-

Final.pdf. (20.10.2004)

Paunonen, H., 1997. Roles of Information Process Control

Systems. Doctoral Thesis. Tampere University of

Technology. Department of Automation.

Viinikkala, M., Jaakkola, V-P., 2004. O&M: State of the

Art, ProServ project documentation.

Viitamo, E., 2000. Services in the Forest cluster –

competitiveness analysis, The Research Institute of the

Finnish Economy. Helsinki.

VALUE ADDED WEB SERVICES FOR INDUSTRIAL OPERATIONS AND MAINTENANCE

365