An Integration Scheme for CPN and Process Algebra

Applied to a Manufacturing Industry Case

Manuel I. Capel, Juan A. Holgado, Agustín Escámez

Department of Software Engineering. University of Granada, Granada (Spain)

Abstract. A semiformal development method for obtaining a correct design of

embedded control and real-time systems is presented. The design is obtained

from a Colored Petri Net (CPN) model of a real-time system, which is

subsequently transformed into a formal system specification using CSP+T

process algebra. The method translates CPN modelling entities into abstract

processes, which allow the expression of concurrency and real-time constraints.

The correct design of a “key“ component (feed belt controller) of a

paradigmatic manufacturing problem (the Production Cell) is discussed as to

show the applicability of our method.

1 Introduction

We present here an approach for modeling and validating embedded control and real-

time systems (ECRTS) at the design stage of the software development cycle. Our

aim is to perform the validation of timing constraints by formal tools based on a timed

Process Algebra, instead of having to wait for the target system to be coded.

Currently, the timing and dependability requirement analysis of ECRTS is carried

out after completely developing a system prototype. The prototype is usually

discarded, particularly first prototypes, and a revision of system specification and

detailed design phases of the life cycle result, therefore the development cost

increases and the delivery date of the final system becomes delayed.

There is nowadays a significant research aimed at using Colored Petri Nets (CPN)

[1] for modeling the behavior of discrete reactive systems, to which ECRTS belong.

In this respect, it is worth mentioning, among many of the current proposals, the work

presented in [2] to model the dynamic of message passing between software

components in a distributed manufacturing system, or the one discussed in [3] to

provide systematic guidelines for using Colored Timed Petri Nets (CTPN) as a

modeling language for soft real-time systems. Another interesting proposal for using

CPN segments to model the dynamic behavior of concurrent software architectures

can be found in [4]. The application of CPN and CTPN has been mainly aimed at

modeling dynamic, discrete event driven systems, possessing soft timing constraints.

On the other part, there are many proposals to obtain a formal specification of ECRTS

by using process algebras [5-7]. In regarding formal specification and probably

correct development of reactive systems, some of the currently most significant work

has been carried out by the authors of [8], who propose to generate a formal

specification from an UML model of the system under development, complemented

I. Capel M., A. Holgado J. and Escámez A. (2005).

An Integration Scheme for CPN and Process Algebra Applied to a Manufacturing Industry Case.

In Proceedings of the 3rd International Workshop on Modelling, Simulation, Verification and Validation of Enterprise Information Systems, pages 39-48

DOI: 10.5220/0002566600390048

Copyright

c

SciTePress

with trace assertions in a CSP-like notation called CSP

jassda

[9]. Differently and yet

complementing the above described methods, we propose a systematic development

method aimed to set the stage for generation of first correct prototypes of ECRTS

from an initial CPN model. By using a CPN model, a description of the system

dynamic behavior can be obtained from an architectural point of view. The model is

subsequently transformed into a detailed system design by using the CSP+T process

algebra notation and coded using the Java programming language. CSP+T process

terms are used here to model real-time processes including the specification of their

timing requirements in order to carry out a further validation by deploying different

industry oriented tools, e.g., 20-SIM [10]; THESIS [11], or FDR [12]. These tools

may complementarily be used to check different sort of properties and to simulate the

execution of the target system as well.

The remainder of the paper is structured as follows. We first give some background

on CPN modeling and CSP+T process algebra, which are necessary to understand the

formal notations on which the system development technique is based. Then, the

proposed method is applied to solve a design problem of an industry case study, the

production cell‘s feed belt control component. The case study shows how the

proposed method can be applied to derive a manufacturing industry system, which

also contains real-time timing constraints. Finally, the conclusions and the ongoing

lines of work are presented.

2 Modelling Methods

2.1 System Specification with CPN

A CPN allows us to describe complex systems by compact and executable models; an

example of a CPN model chart can be seen in figure 4. The states of the system are

modeled by places, which are drawn as circles or ellipses. The actions of a CPN

model are represented by means of transitions, which are drawn as rectangles. A

marking is understood as a state of the model CPN and consists of a distribution of

tokens on the places. There is a distinguished marking, called the initial marking,

which is used to describe the initial state of the system. The initial marking of any

place is written on the upper right or left corner of the place. Compared to Petri Nets

(PN), the CPN formalism provides the possibility of having different types of tokens

associated to the places of the net. Each one of the colored tokens can transport

information whose type and purpose is interpreted depending on the transitions that

occur at a given instant of the CPN model execution. The model execution consists of

a series of occurrences of enabled transitions. The occurrence of the transition t

removes tokens from the input places (which are given by the input function I(t)), and

adds tokens to the output places (which are given by the input function O(t)), thereby

changing the state (the marking) of the CNP model. The number of tokens of each

type added or removed is given by the evaluation of arc expressions, which are

Standard ML (SML) expressions. An assignment of data values to the free variables

occurring in the arc expressions is called a binding. Transitions may occur in different

modes depending on the possible bindings affecting the expressions associated to

their surrounding arcs. There is also the possibility to attach a predicate, called a

40

guard, which is written within square brackets in the chart, to each transition, so that

only bindings that evaluate the guard to true are accepted when the transition occurs.

It can be proved that a CPN model with color domains of finite cardinality has the

same descriptive power for modeling information systems as the PN formalism, since

it is always possible to build an equivalent PN model of a given CPN by using the

“unfolding algorithm”. Nevertheless, PN models are usually (except for systems with

very few states) huge and difficult to understand and simulate compared with the CPN

ones. The improved compactness and readability of CPN w.r.t. PN is not the only

amendment, but they also have the capability of parameterization of the constructed

models that results quite convenient in the design and analysis stages of software

systems development.

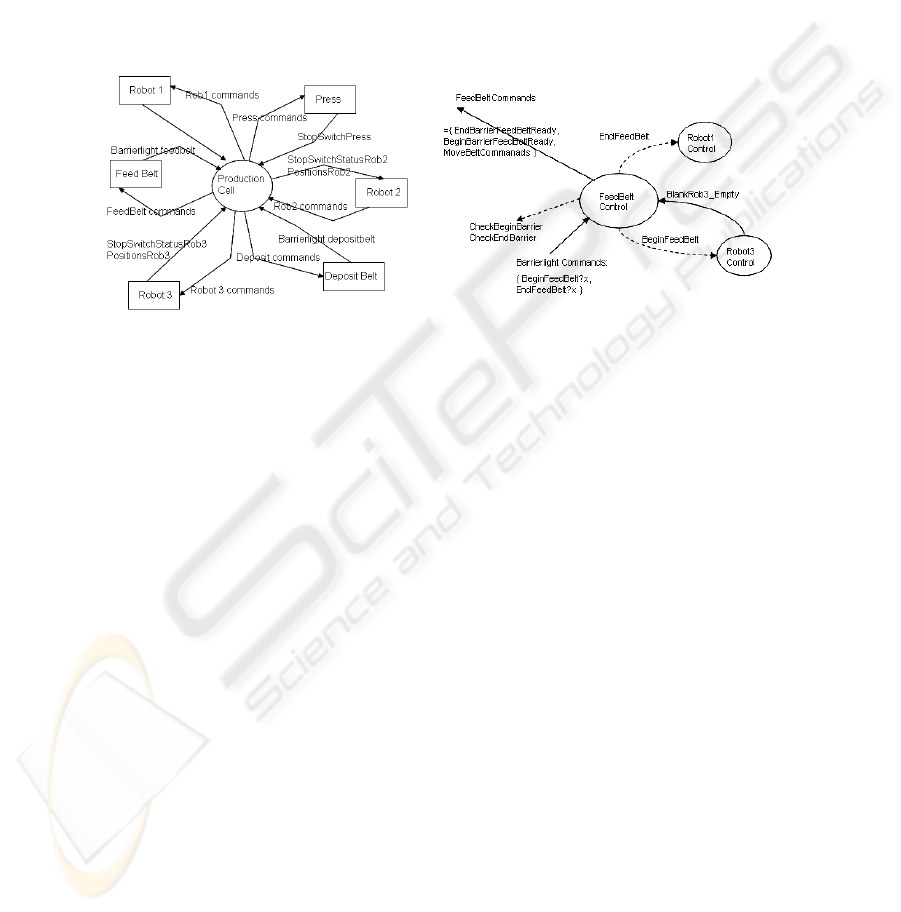

Fig. 1. Production Cell context diagram

2.2 Drawbacks of CPN as a Specification Notation for Real-time Systems

CPN and CTPN lack of specific constructs to fully describe the behavior of hard real-

time systems. Our approach is, by adapting some of its undoubtedly useful modeling

elements, to use these standard notations mainly to specify the behavioral parts of the

system and, by using another compatible format notation, to provide additional

specification of real-time properties that might not be directly addressed by the CPN

model. In this respect, it can be shown that CSP+T process algebra formalizes the

semantics of a substantial subset of CPN by using a set of rules similar to the one

defined in [6].

2.3 Real-Time System Specification with CSP+T

The group of CSP derivatives to describe time intervals includes Timed CSP [7] and

CSP+T [5], the latter being a simpler approach. Providing less descriptive power,

although still powerful enough to formally describe a set of primitive processes with

time constrained behavior, CSP+T is an adequate formal specification language for

the majority of real-time systems.

The syntax of CSP+T, adapted to our method, which is detailed in [6]:

Every process P defines its own set of communication symbols, named

communication alphabet

α

(P).

41

The communication interface comm_act(P) of a given process P contains all the

CSP-like communications ({?, !}) in which P can engage and the alphabet

α

(P).

An operator,

Ë

(star) denotes process instantiation. Given P', the timed version of

P, which is instantiated at time 1, the specification of P' becomes

P'= 1.

Ë→

s.a

→

STOP, where s

∈

[1,

∞

)

An event operator >< to be used jointly with a variable to record the time instant at

which the event occurs, ev

><

v means that the time at which ev is observed is in v.

P= 1.

Ë→

a

><

var

→

STOP

for each process execution, the time at which a occurred will always be var

≥

1.

Each event is associated with a time interval, called the event-enabling interval.

P= 0.

Ë→

[1,2] a

><

v

→

STOP

The value of the marker variable v will satisfy the inequality 1

≤

v

≤

2.

If the preceding event occurs at time t

0

, then rel(x, v)= [x+v-t

0

, v-t

0

], since the

times for events are absolute and for intervals are relative to the preceding event.

P = ... E.P’ . E = {s | s = rel(x, v)}

2.4 Generation of a System Specification from CPN

To derive a detailed system specification in CSP+T from a CPN one, we will adopt a

bottom-up process that consists of the following steps:

1. Identify the main actions that cause a change in the control state of the system, then

define what are the multistates in which the system enters during its execution, as

well as their synchronization restrictions and time constraints.

2. Start by representing the reactive behavior of the lower level subsystems of the

system under development as CPN models. Lower level actions, which are related

between them and modify the state of the controller and/or its environment, must

be grouped within transition instances, according to the CPN formal notation. For

instance, several atomic actions the controller performs can be defined as edges

outing the same transition towards distinct places or the same places but carrying

tokens of different color. Modifications of relevant condition values to the state of

the controller can be modeled by assigning predicates to transitions or by modeling

elaborate data types associated to the color domain of places and transitions in the

CPN.

3. Add simulated blocks to represent external devices or continuous components.

4. Break down each CPN previously built into CSP+T syntactic terms. Each

transition on the CPN can provide several atomic actions and/or communications

when it is translated into process terms. As a general rule, safe subnets of a CPN

should be represented as a single CSP+T process, being their places translated into

named terms according to the CSP+T syntax rules. The subprocesses should be

compounded by the parallel CSP operator. The change of value of predicates, the

modifications of the number or type of tokens situated in a given place are modeled

by CSP communications.

5. Once a CSP+T model has been obtained for every CPN model in which the target

system specification was initially structured, a unique CSP+T process will be

defined to model the complete system. If an scheme has to be included into one of

a higher level, then logically connected subprocess terms must be gathered into

42

more abstract ones by using the hiding and parallel operators, thus progressively

integrating the CSP+T model of the system in an ascending way.

6. The iterative process finishes when a unique process whose communication

interface satisfies the initial abstract specification, e.g., which was usually

described at the requirements specification stage by the user, and informally

defined by a System Context Diagram or an English specification document.

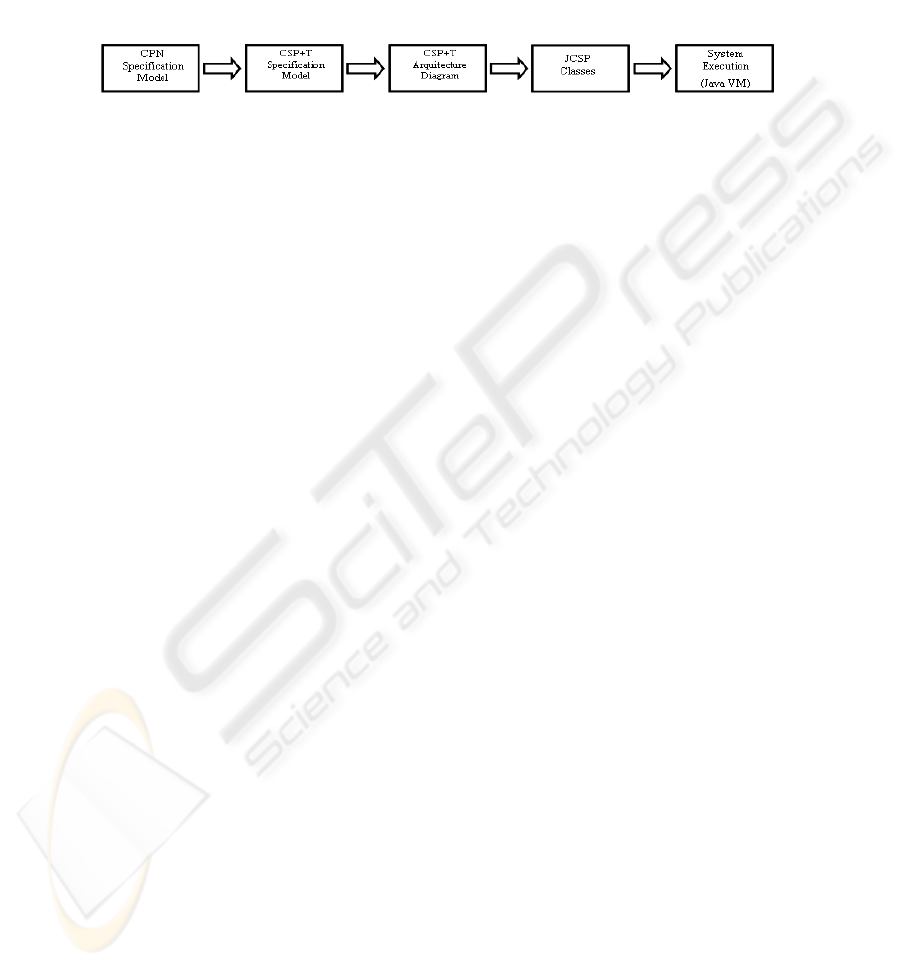

Fig. 2. Development levels

To carry out an execution of a complete specification in CSP+T of the target system

by a simulation tool, additional blocks must be added to the final model. These blocks

represent the external entities of the system and must be modeled according to the

specific physical devices (actuator or sensor) that supply signals (data or event)

to/from the system.

3 Production Cell Feed Belt Control Subsystem: a Case Study

The production cell is a well-known realistic manufacturing industry oriented

problem [13], where safety requirements regarding the fulfillment of timing-

constraints by the different concurrent movements of the cell components (robot

arms, conveyor belts, press, etc.) are of paramount importance in order to have a

useful design of the target system. The proposed configuration of the production cell

is a closed loop feedback control system composed of three robot arms, two conveyor

belts and a press (figure 3 (a)); the blanks are circularly conveyed through both belts

by following a continuous loop, so that the system can indefinitely function without

intervention of the operator. The step-by-step system functioning is as follows: after a

metal blank is placed on the feed belt, it is moved towards the other end of the belt,

the first robot arm takes the blank when it reaches the end and places it on the press,

the press forges the metal blank (actually, the press simulates this action) and opens

again, forged metal plates are taken out of the press and put on a deposit belt by a

second robot arm, and, finally, a third robot arm picks the blank up and puts it again

on the feed belt to close the circular path that the blanks follow. A physical simulation

of the proposed system was performed using a scaled-down industry model built from

“construction kits” of Fischertechnik© (figure 3 (b)). This allows us to have a fully

functional model that mimics the operations of the system.

In this paper only a description of the detailed specification, design and

implementation of the subsystem feed belt control of the production cell is presented,

since the design of the entire system is too big to be discussed in a comprehensible

way within the pages of a paper. To carry out the movement of objects from one place

of the industrial plant that holds the production cell to another one, the feed belt

device contains two sensors and one actuator. The actuator is a DC motor that moves

the conveyor belt towards a pre-selected direction, i.e., to the right if the deposit belt

43

moves, or to the left if the feed belt does so. The two sensors are lightbarriers or

photosensors placed at the beginning (L1) and at the end (L2) of the conveyor belt.

The actuator and sensors of the feed belt device are driven by an embedded

microcontroller, which sends the states of the sensors and receives software

commands from the main system through a serial communication line.

Robot 1

Robot 2

Robot 3

Deposit Belt

Feed Belt

Press

Fig. 3. The Production Cell: (a) proposed configuration, (b) view of the physic model

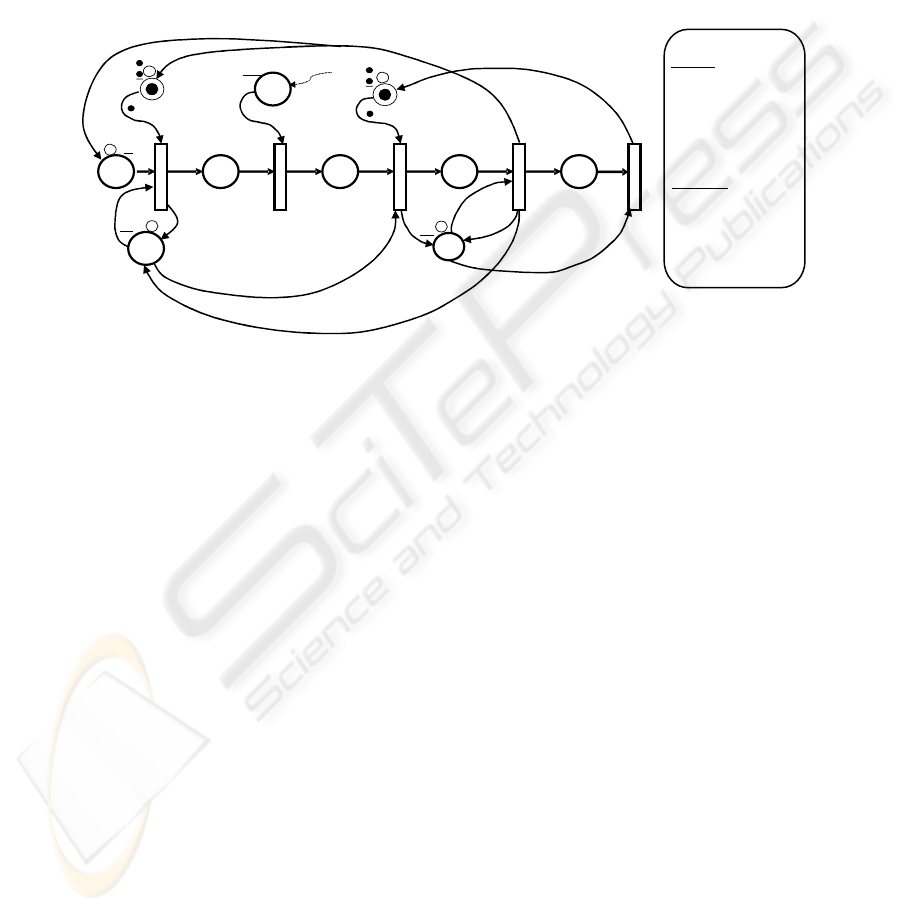

3.1 System Specification as a CPN Model

To formally specify the Feed Belt Control (FBC), a CPN model according to our

methodology is shown below. The objective of this control process is to ensure that

the feed belt can reach safety positions for blanks regarding the concurrent

movements of the robot arms, which could collide with the conveyed blanks on the

belts if no control of their movements is defined, i.e., one blank cannot be moved until

the robot retracts the arm after having dropped it on the belt. Obviously, process

design must guarantee that the behavior of an implemented process satisfies the

specification of the production cell. The CPN describing the time-dependent

behaviour of the belt control can be seen in figure 4. The sequence of states and

transition between states represented by the CPN are summarized as follows:

− the initial marking represents the starting state of the different devices to which the

feed belt has to interact during FBC process execution, sensors (places L1, L2) and

actuators (motor commands yielded by firing T3 and T4) are tested while the

control is in this state;

− the belt control waits in place A for the arrival of a blank, which is dropped on one

of its two ends by the robot 3 arm;

− robot 3 arm drops the object on the belt (T2) and pulls back its arm in a safe way

(while the model control is marking place C);

− the motor starts moving the object towards the lightbarrier L2 (T3);

− once the blank reaches L2, the feed belt motor is commanded to stop (T4);

− the controller waits for robot 1 picks up the blank (while the model control is

marking place E);

− finally, the control returns to its initial state (T5).

A specification of the Feed Belt Control in terms of CSP+T is next obtained by

applying a similar set of rules presented as the one in [6]. One CSP+T syntactic term

44

must be specified for each place and its outing transition in figure 4. In the

WaitingBlank specification, the “Begin_Feed_Belt _Full_true >< tBeginFeedBelt”

CSP+T construct is used to represent a transition going to the next state, which

includes the activation condition Begin_Feed_Belt_Full_true, known as marker event,

and the variable tBeginFeedBelt used to record the time instant at which the marked

event occurs. Regarding the specification of enabling intervals, the enabling interval

I(DtakingoutRob3, t_beginfeed) on the output transition of the TakingOut state

represents the delay interval, named DTO in figure 4, needed to pull back the robot 3

arm before the motor starts moving the blank towards the end of the belt.

Fig. 4. Feed Belt Control CPN Specification.

3.2 System Specification in CSP+T

The processes BeginContinuousProcess and EndContinuousProcess that appears

included in the specification are extra intermediate processes introduced to model in

CSP+T the continuous flows BeginBarrierFeedBelt and EndBarrierFeedBelt.

Feed_Belt_Movement = start_time.→start; InitFeedBelt

InitFeedBelt= EndBarrierFeedBelt_Ready !false

→BeginBarrierFeedBelt_Ready!true → Waiting_Blank

Waiting_Blank = (CheckBeginBarrier → BeginFeedBelt ? x

→if(x=BeginFeedBelt_Full) then BeginFeedBelt_Full_true;

Waiting_Blank

| BeginFeedBelt_Full_true ><t_BeginFeedBelt;

BeginFeedBelt →BeginFeedBelt_Time!t_BeginFeedBelt;

WaitingBlank?resume())

TakingOut_Rob3=BlankRob3_Empty →

BeginFeedBelt_Time? t_BeginFeedBelt → I(DtakingOutRob3,

t_BeginFeedBelt); EndBarrierFeedBelt_Ready!true →

BeginBarrierFeedBelt_Ready!false→

→Sync?EndFeedBeltCleraded();MoveBelt!left;

MovingFeedBelt)

MovingFeedBelt= (CheckEndBarrier → EndFeedBelt ? x

→ if(x=EndFeedBelt_Full) then EndFeedBelt_Full_true end;

MovingFeedBelt

2

T

x

R

bf

0’e

x

(If blanks follows a circular path)

1’e

1

A

B

C

DE

R

3

T

1

2

T

3

T

4

x

x

x

t

t

x

x

x

bf

x

L

1

1’e

1’e

[

x

=

bf

]

now

[

-

t > DTO ]

ef

[

x

=

]

]

ee

[

x

=

1’e

x

true

false

0’e

0’e

BC

:

R

esume

()

Æ

R

BeginFeedBelt_Full

Æ

bf

EndFeedBelt_Cleared

Æ

BC

Æ

bf

ef

Æ

ee

DTakingOut

Æ

DTO

:

C

olor E

=

with

e

C

olor U

=

with

bf

|

ef

|

ee

C

olor B

=

with

true

|

false

Color T = real

Var

x : U

Var

t : T

0

1

1

1’e

1’e

1

T

5

EndFeedBelt_Empty

EndFeedBelt_Full

BeginFeedBelt_Full

Notation

Definitions

true

L

0’e

0’e

45

| EndFeedBelt_Full_true → MoveBelt!stop;

BeginBarrierFeedBelt_Ready!true → TakingOut_Rob3)

Unloading_Blank= (CheckEndBarrier → EndFeedBelt ? x →

if (x=EndFeedBelt_Empty) then EndFeedBelt_Full_false;

Unloading_Blank

| EndFeedBelt_Full_false → EndBarrierFeedBelt_Ready !false →

EndFeedBelt; WaitingBlank!resume();

Sync!EndFeedBeltCleraded();UnloadingBlank)

The Feed Belt Control (FBC) must be obtained by the parallel composition of its

component subprocesses without any additional re-structuring of the specification. All

the internal events must be hidden using the hiding operator \, so that the

communication interface of FBC coincides with the flows in figure 1 (b). The FBC

process is modelled by:

FBC = Feed_Belt_Movement\{start}||InitFeedBelt||WaitingBlank\

{BeginFeedBelt_Full_True, BeginFeedBelt_Time}||

TakingOut_Rob3\{BeginFeedBelttime}||

Moving_Feed_Belt\{EndFeedBelt_Full_true }||

Unloading_Blank\{EnFeedBelt_Full_false,

Waiting_blank!resume(), WaitingBalnk?resume(),

Sync!EndFeedBeltCleraded(),Sync?EndFeedBeltCleraded()}

so the communication interface of the FBC is:

Interface (FBC) = {EndBarrierFeedBeltReady!false,

BeginBarrierFeedBelt_Ready!true,

BeginBarrierFeedBelt_Ready!false, CheckBeginBarrier,

CheckEndBarrier, BeginFeedBelt?x,BeginFeedBelt,

BlankRob3?empty, EndFeedBelt?x, MoveBelt!stop,

EndFeedBelt,}

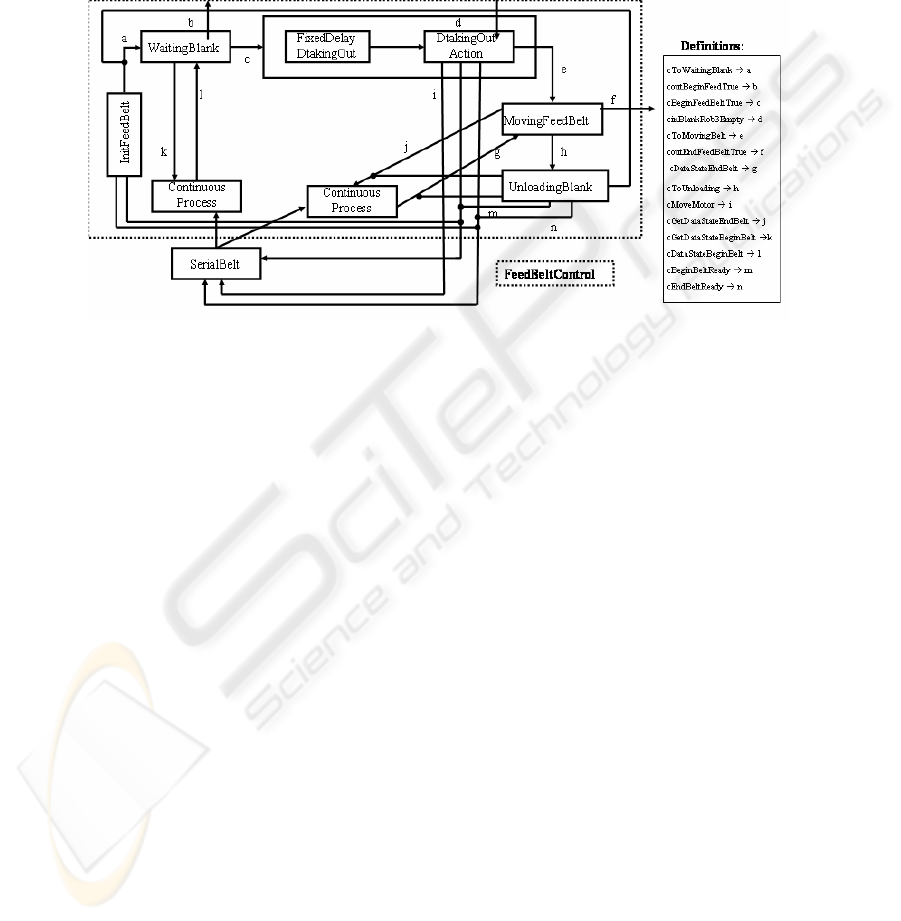

3.3 CSP Process Architecture Diagram

In order to obtain an executable implementation of the CSP+T terms specification we

use the library of Java classes JCSP[14], which is a correct implementation of the

CSP distributed parallel programming model [7]. The complexity of the specification

of a set of concurrent communicating processes can be handled by using the JCSP

library, which implements the CSP programming primitives at the level of

applications programmed in the Java programming language.

Each JCSP process is encapsulated in an independent active class derived from

CSProcess Java interface that overrides the functionality of the method run() and

defines, as the parameters of the constructor method, input and output channels used

by the process to communicate with other processes. In order to facilitate the

modeling of the JCSP processes from a given system specification in terms of

CSP+T, a software graphical tool has been implemented in pure Java, so that the

translation of CSP+T processes, mainly when there are multiple levels of nested

processes, becomes easier and less error prone. With this application, we begin

modeling in a graphical way the high layer of CSP+T processes that represents the

production cell and the processes necessary for handling the communications with

each interacting device; the model obtained after the accomplishment of this action

corresponds to the stage given by the initial system context diagram (SCD) shown in

figure1, but it gives a more complete and precise information, including an

46

architectural view, of the system. Then, the channels that constitute the

communication interface of a process can be defined and connected with other

processes to obtain a net of processes. Once all the processes are designed, according

to the previous system specification in CSP+T, the behavior of each process is

implemented directly in Java. An execution of the built model of the entire system can

be performed within the framework of the proposed software tool, or the code

generated by compiling the classes that represents the JCSP processes of the system

can be downloaded and run into an embedded microcontroller.

Fig. 5. CSP+T Architecture Diagram of the Feed Belt Control Process

To implement the Feed Belt Control Subsystem of the production cell and,

therefore, to execute it, other processes apart from the FBC process must be designed.

We need to specify additional processes, as these to drive the communication to each

external device (which appear as terminators in the SCD), or intermediate CSP+T

processes to represent necessary control interactions not included yet. A reduced

implementation of the Feed Belt Control Subsystem is carried out by only adding a

SerialBelt process to hide the serial communication to the controller that handles the

actuators and sensors of the device as can be seen in figure 5. Therefore, the design of

the CSP+T architecture obtained with the proposed software tool must be seen as a

more abstract, configurationally oriented, structure of the CSP+T processes or JCSP

processes that constitute the system under development.

4 Conclusions and Future Work

We have presented a development method for obtaining a correct design of embedded

control and real-time systems (ECRTS) from a high level CPN model aimed at

describing their dynamic behavior. The drawbacks that presents the CPN notation

when applied to real-time modeling has been overcome by transforming the initial

CPN model into an equational specification made up of syntactic terms in CSP+T

process algebra, so that hard timing constraints on the execution of a target system

under development can be reflected in this formal specification. As to show the

applicability of the method, the detailed design of a key component of a paradigmatic

47

manufacturing example has been discussed. Our future plans are twofolded, firstly,

starting from their CSP+T specification, to generate Java code for ECRTS in several

computing platforms; secondly, to automate the generation of CSP+T specifications

from CPN models.

Acknowledgement

This work is funded by the research project MAT2004-06872-C03-03.

References

1. JENSEN, K. Colored Petri Nets: Basic Concepts, Analysis Methods and Practical Use.

Monographs in Theoretical Computer Science. Springer, 1992.

2. LIN, E.Y., ZHOU, C.: Modeling and Analysis of Message Passing in Distributed

Manufacturing Systems. IEEE Transactions on Systems, Man and Cybernetics, Part C:

Applications and Reviews, 29,2, 1999, pp.250-262.

3. CHOPPY, C., PETRUCCI, L.: Towards a Methodology for Modeling with Petri Nets.

Proceedings on Practical Use of Colored Petri Nets, Aarhus, Denmark, 2004, pp.39-56.

4. PETTIT, R.G., GOMAA, H.: Validation of Dynamic Behaviour in UML Using Coloured

Petri Nets. UML 2000 Dynamic Behavior Workshop, England, 2000.

5. ŽIC, J.J.: Time-Constrained Buffer Specifications in CSP+T and Timed CSP. ACM

TOPLAS, 16, 1994, 6, pp.1661-1674.

6. CAPEL, M.I., HOLGADO, J.A.: Transforming SA/RT Graphical Specification into the

CSP+T Formalism: Obtaining a Formal Specification from Semi-formal SA/RT Essential

Models. Proceedings of ICEIS 2005 (to appear), Miami, USA, May 24-26, 2005, 8 pages.

7. HOARE, C.A.R.: Communicating Sequential Processes, Prentice-Hall, Englewood Cliffs

(N.J.), 1985

8. MOELLER, M., OLDEROG, E.R., RASCH, H., WEHRHEIM, H. Linking CSP-OZ with

UML and Java: A Case Study. In IFM’2004. LNCS 2999, Springer-Verlag, 2004, pp.267-

286.

9. MOELLER, M.: Specifying and Checking Java using CSP. In FTfJP’2002: Workshop on

Formal Techniques for Java-like Programs. Computing Science Department, U. of

Nijmegen, 2002, Technical Report NIII-R0204

10. BROENINK, J.F.: Modeling, Simulation and Analysis with 20-SIM. Journal A of the

special issue on CASD, 1997, pp.22-25.

11. WIJBRANS, K.C.J., VAN AMERONGEN, J., BAKKERS, W.P., BROENINK, J.F.:

Tweente Hierarchical Embedded Systems Implementation by Simulation (THESIS): A

Structured Approach to Controller Realisation on Transputers. Journal A, 34, 1, 1993, pp.

51-59.

12. FDR. Formal Systems (http://www.fsel.com)

13. LEWERENTZ, C., LINDNER, T: Formal Development of Reactive Systems: Case Study

Production Cell. LNCS 891, Springer-Verlag, January 1995.

14. WELCH, P.: Process Oriented Design for Java: Concurrency for All. In: Parallel and

Distributed Processing Techniques and Applications, PDPTA 2001, Las Vegas, Nevada,

USA, 2001.

48