AN APPROACH TO MULTI-AGENT COOPERATIVE

SCHEDULING IN THE SUPPLY-CHAIN, WITH EXAMPLES

Joaquim Reis

Departamento de Ciências e Tecnologias de Informação, ISCTE, Avenida das Forças Armadas, 1600 Lisboa, Portugal

Keywords: Scheduling, Multi-Agent System

s, Supply-Chain Management.

Abstract: The approach to scheduling presented in this article

is applicable to multi-agent cooperative supply-chain

production-distribution scheduling problems. The approach emphasises a scheduling temporal perspective,

it is based on a set of three steps each agent must perform, in which the agents communicate through an

interaction protocol, and presupposes the sharing of some specific temporal information (among other)

about the scheduling problem, for coordination. It allows the set of agents involved to conclude if a given

scheduling problem has, or has not, any feasible solutions. In the first case, agent actions are prescribed to

re-schedule, and so repair, a first solution, if it contains constraint violations. The resulting overall agent

scheduling behaviour is cooperative. We also include some results of the application of the approach based

on simulations.

1 INTRODUCTION

In this article we present an approach to scheduling

in cooperative supply-chain production-distribution

scheduling environments, including some

unpublished details of the same work.

Scheduling is the allocation of resources over

tim

e to perform a collection of tasks, subject to

temporal and resource capacity constraints (

Baker

1974). For classical, Operations Research (OR)

based, approaches t

o scheduling see (Blazewicz

1994); for more modern approaches, Artificial

In

telligence (AI) based, see (Zweben 1994), for

i

nstance. Planning and coordination of logistics

activities (production, distribution) has been the

subject of investigation since around 1960, in the

areas of OR/Management Science (

Graves 1993).

More recently, som

e attention has been paid to

scheduling in this kind of environments (e.g., see

(

Kjenstad 1998) or (Rabelo 1998)).

In our work, the specific logistics context of

cooperat

ive supply-chain/Extended Enterprise (EE)

(

O'Neill 1996) is considered. The EE is usually

assum

ed to be a kind of Virtual Organisation, or

Virtual Enterprise, where the set of participant

agents (enterprises) is relatively stable (for concepts

and terminology see pages 3-14 in (

Camarinha-

M

atos 1999); in this last work, other approaches to

schedul

ing in this kind of context can be found).

The main features of the scheduling problem are:

a) decision is decentralised and distributed am

ong

multiple autonomous agents, b) problem solution

involves communication and cooperation among

agents, and c) scheduling can be highly dynamic.

For the modelling of the environment we adopt

th

e AI Multi-Agent Systems paradigm (

O'Hare

1996), and consider a network of agents linked

t

hrough client-supplier relationships and

communication channels. Capacity, or manager,

agents, manage, each one, the limited capacity of an

individual resource, specialised in either production

or transportation or store tasks, the last ones with

flexible durations. Producer and transporter agents

are both termed processors, as their capacity is

based on a product rate; store agent capacity is

based on a product quantity. A supervision agent

introduces work in the system, and fictitious retail

and raw-material agents define the frontiers of the

network with the outside at the downstream and

upstream extremes, respectively.

325

Reis J. (2006).

AN APPROACH TO MULTI-AGENT COOPERATIVE SCHEDULING IN THE SUPPLY-CHAIN, WITH EXAMPLES.

In Proceedings of the First International Conference on Software and Data Technologies, pages 325-332

DOI: 10.5220/0001310703250332

Copyright

c

SciTePress

b)

Request-to-Supplier

conversation model.

/

request

4

rejection

/

cancellation

/

/

cancellation

satisfaction

/

31

acceptance

/

2

5

6

r

e

-

r

e

q

u

e

s

t

/

/

r

e

-

a

c

c

e

p

t

a

n

c

e

/

r

e

-

r

e

j

e

c

t

i

o

n

/

r

e

-

r

e

q

u

e

s

t

r

e

-

a

c

c

e

p

t

a

n

c

e

/

r

e

-

r

e

j

e

c

t

i

o

n

/

transitions (message types):

receive / send

transitions (message types):

receive / send

a)

Request-from-Client

conversation model.

request

/

4

/

rejection

cancellation

/

/

cancellation

/

satisfaction

31

/

acceptance

2

6

re-re

quest

/

/

r

e

-

a

c

c

e

p

t

a

n

c

e

/

re

-

r

e

j

ec

t

i

o

n

r

e

-

r

e

j

e

c

t

i

o

n

/

5

/

r

e

-

r

e

q

u

e

s

t

r

e

-

a

c

c

e

p

t

a

n

c

e

/

c) Message types

and description.

request

- product

request, sent by a

client agent to a

supplier agent.

acceptance

- acceptance of

a previously received product

request, sent by the supplier to

the client.

rejection

- rejection of a

previously received product

request, sent by the supplier to

the client.

re-request

-

re-scheduling request,

sent by the supplier

(client) to the client

(supplier), asking to

re-schedule a

previously accepted

product request to a

given due-date.

re-acceptance

- acceptance of a

previously received re-scheduling request,

sent by the receiver to the sender of the

re-scheduling request.

re-rejection

- rejection of a

previously received re-scheduling request,

sent by the receiver to the sender of the

re-scheduling request.

cancellation

- signals giving up a

previously accepted product request, sent by

the supplier (client) to the client (supplier).

satisfaction

- signals delivery of a

previously accepted product request, sent by

supplier to client at the time of the due-date

of the product request.

Our temporal scheduling approach is described

in (

Reis 2001a) for processor agents, (Reis 2001b)]

includes a three-step procedure and processor agent

re-scheduling cases, and (

Reis 2001c) includes store

agent re-scheduling cases (our earlier work is

referred in these articles). Here we include also

some demonstration examples, taken from (

Reis

2002

), which exposes our whole model and

approach. The following sections present: the high

level agent interaction protocol used, basic concepts

underlying the approach, the steps of the approach,

some demonstration examples, and a conclusion.

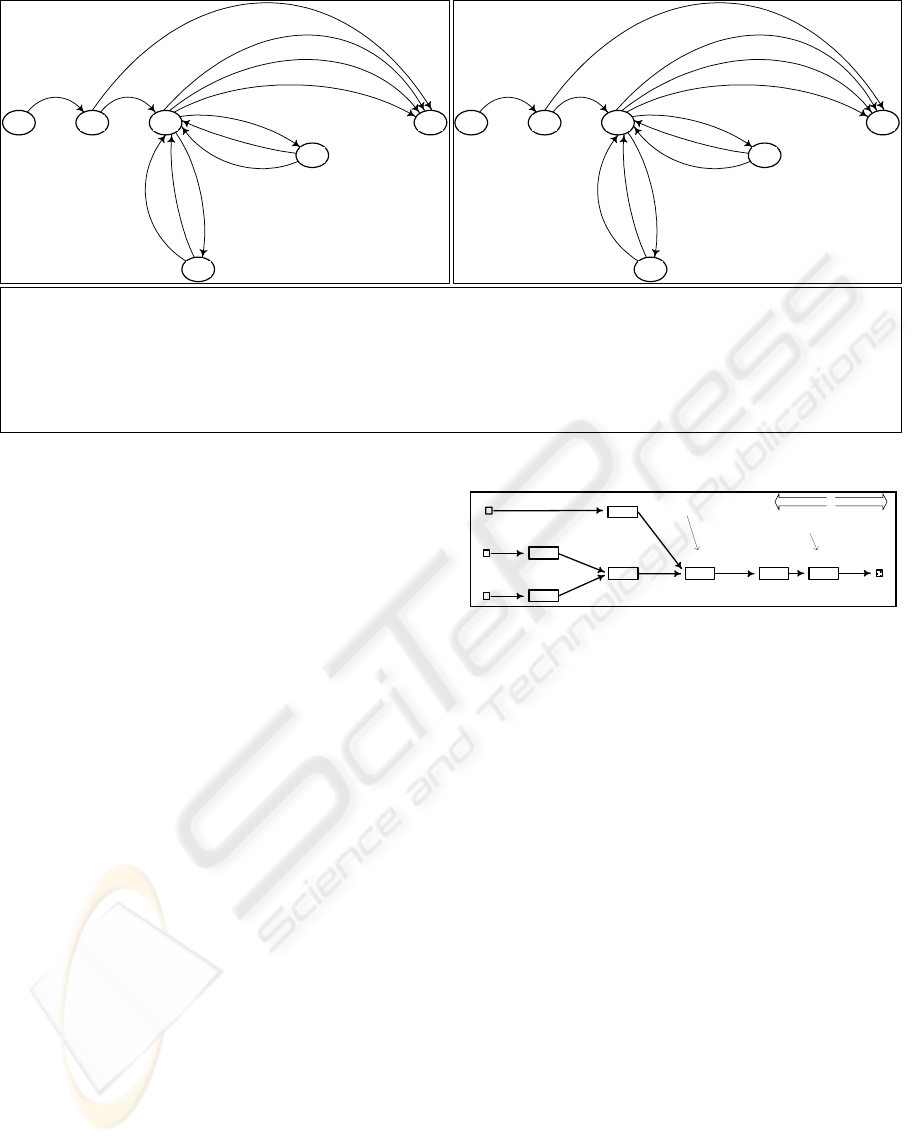

2 INTERACTION PROTOCOL

In Figure 1 we present the high level agent

interaction protocol used by capacity agents, defined

through a pair of symmetrical conversation models

(Request-from-Client and Request-to-Supplier,

shown as state diagrams) in the context of which

certain types of messages (also shown and

described) can be exchanged.

In

Figure 2 we show an example of a network

job built by agents of a hypothetical agent network

for a scheduling problem. The precedence

relationships among the tasks (the arrows forming a

tree) reflect the client-supplier relationships among

the agents.

A scheduling problem is introduced by the

network supervision agent

g

0

, through a global

interval

H=<RD,DD> (where DD and RD are the

global hard temporal limits), and a global request

from outside

d, containing retail agent

identification, product, quantity and date for

satisfaction (the request due-date,

dd=TIME(d)).

In forming the job depicted in

Figure 2, retail agent

g

14

first receives from g

0

values of DD and d, then

sends a

request type message to capacity agent

g

1

, essentially containing d. Starting from g

1

,

agents in the client-supplier tree then perform a set

of communicative actions (sending

request

messages containing local requests to one or more

suppliers to ask for task supplies). This upstream

propagation of local requests ends with the

raw-material agents

g

17

, g

18

and g

19

passing to g

0

the local requests of capacity agents

g

8

, g

11

and g

12

,

as global requests to outside. Subsequently, these

Figure 1: Conversation model state diagrams, in a) and b), and message types for the agent interaction protocol, in c).

P

O

7

i,14

network job

RT

i

,14

P

O

9

i,14

P

O

11

i,14

O

18

i,14

T

O

12

i,14

O

19

i,14

S

T

O

14

i,14

O

1

i,14

O

4

i,14

P

O

8

i,14

O

1

7

i,14

agent

g

7

task

agent

g

1

task

downstream

upstream

Figure 2: Example of a network job: job

RT

i,14

. The task

of a capacity agent

g

k

for the i

th

global request to retail

agent

g

r

is denoted by O

ir

k

,

(this task belongs to a

network job denoted by RT

i,r

); P, T and S denote

production, transportation and store tasks, respectively; the

remaining tasks are fictitious, and belong to retail and

raw-material agents (

g

14

, g

17

, and g

18

, and g

19

, which

define the limits of the agent network at the downstream

and upstream extremes).

ICSOFT 2006 - INTERNATIONAL CONFERENCE ON SOFTWARE AND DATA TECHNOLOGIES

326

agents receive from

g

0

the value of RD, and then,

acceptance messages are propagated

downstream, starting from the raw-material agents.

For each of the capacity agents, an

acceptance

message confirms its task, which is then scheduled.

According to the approach we propose (see ahead),

if any agent in the client-supplier tree detects that

the problem has no feasible solution, or receives a

rejection message from a supplier, it sends a

rejection message to its client and cancels the

accepted requests of its suppliers. This would lead to

failure in establishing the job, with rejection of the

scheduling problem by the agent network as a

whole.

After the establishment of a job for a scheduling

problem,

re-request, re-acceptance and

re-rejection messages can be used by the

agents to ask for, accept or reject re-scheduling

requests to, or from, its client or suppliers, to repair

the initial solution schedule, in the case they locally

detect temporal or capacity constraint violations. As

a last choice, agents can resort to cancellation

messages, if a feasible solution cannot be found.

This can happen because, as the environment is

dynamic, new scheduling problems appear and the

individual agent resource capacities are limited.

O

i,14

1

request

from client

request

to supplier

time

25 2827 29 30 31262420 21 22 23

d

i,14

14,1

d

i,14

1,4

h

i,14

1

H

i,14

1

FEJ

i,14

1

FJ

i,14

1

fij

i,14

1

fim

i,14

1

FEM

i,14

1

FM

i,14

1

b) Store scheduling problem.

RD

i,14

1

=22

DD

i,14

1

=31

O

i,14

7

d

i,14

7,8

d

i,14

7,9

request

from client

requests

to suppliers

fij

i,14

7

d

i,14

4,7

time

15 1817 19 20 21161410 11 12 13

FEJ

i,14

7

FJ

i,14

7

FM

i,14

7,8

fim

i,14

7,9

FEM

i,14

7,9

FM

i,14

7,9

h

i,14

7,9

h

i,14

7,8

H

i,14

7,9

H

i,14

7,8

fim

i,14

7,8

FEM

i,14

7,8

a) Processor scheduling problem.

RD

i,14

7,9

=11

RD

i,14

7,8

=10

DD

i,14

7

=21

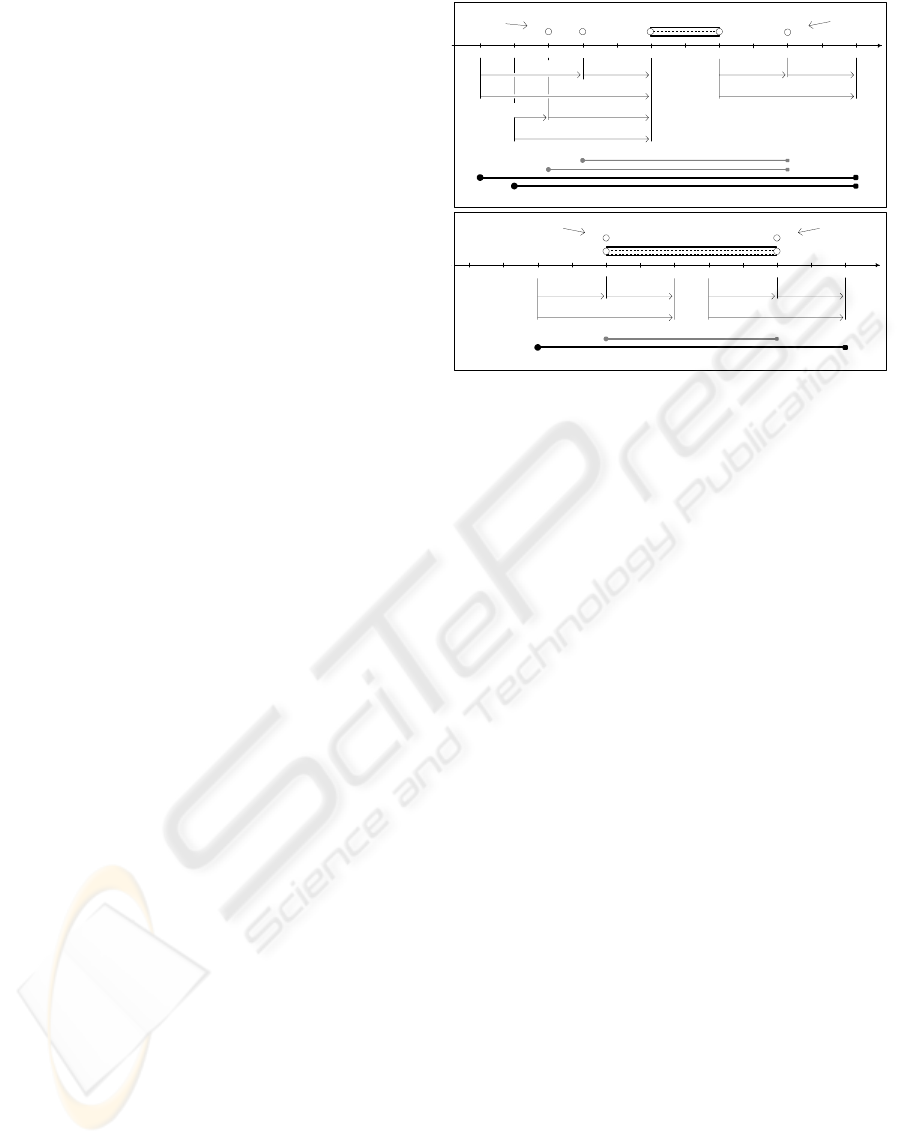

3 COOPERATIVE APPROACH

The approach we propose is similar to some others

that operate through scheduling by repair (a first,

possibly non-feasible, solution is found which is

then repaired through search, if necessary; see

(

Minton 1992), for instance). It is based on a set of

three steps performed by each individual capacity

agent for each scheduling problem involving the

agent (specifically, involving an agent

client-supplier tree that includes the agent),

occurring after the problem is known by the agent,

i.e., after receiving the respective client

request

message. In the first two steps the approach

emphasises scheduling from a temporal perspective

and results in an overall agent cooperative

scheduling behaviour.

In

Figure 3 a set of temporal parameters used in

the approach are represented along timelines for a

processor agent and for a store agent; processor

g

7

and store

g

1

, involved in the job depicted in Figure

2

, are used as an example. Besides the agent task

(labelled

O) and the requests from the client and to

the supplier(s) (labelled

d), a set of temporal

intervals (labelled

h and H) and slacks (labelled FJ,

FEJ, fij, fim, FEM and FM) is shown. These are

defined in the following. In the case of

g

7

, two

suppliers are needed so, there are two

h and two H

intervals:

h

j,7

14,i

=<TIME(d

j,7

14,i

),TIME(d

7,4

14,i

)>

(j=8,9)

H

j,7

14,i

=<RD

j,7

14,i

,DD

7

14,i

> (j=8,9)

where DD

7

14,i

is the local hard temporal limit for the

end time of task

O

7

14,i

(i.e., considering all agent

tasks downstream

g

7

scheduled as late as possible),

and

RD

j,7

14,i

is the local hard temporal limit for the

start time of the

O

7

concerning to supplier

14,i

g

j

(i.e., considering all agent tasks upstream

g

7

,

starting on supplier

g

j

, scheduled as early as

possible); in determining these local temporal limits,

a minimum duration of 1 time unit for store tasks

(which have flexible duration) is considered.

For

g

7

internal downstream and upstream

slacks:

fij

7

14,i

=TIME(d

7,4

14,i

)-END(O

7

14,i

)

fim

j,7

14,i

=START(O

7

14,i

)-TIME(d

j,7

14,i

)

(j=8,9)

For g

7

external downstream and upstream

slacks:

Figure 3: Scheduling problem parameters: a) for processor

agent

g

7

, and b) for store agent g

1

(no relationship is

intended for the values in the two timelines). Symbols

with two upper indexes refer to two agents, e.g., a request

from

g

4

to g

7

in job RT

i,14

is denoted by d

i,

,

14

47

.

AN APPROACH TO MULTI AGENT COOPERATIVE SCHEDULING IN THE SUPPLY CHAIN, WITH EXAMPLES

327

FEJ

7

14,i

=DD

7

14,i

-TIME(d

7,4

14,i

)

FEM

j,7

14,i

=TIME(d

j,7

14,i

)-RD

j,7

14,i

(j=8,9)

For g

7

downstream and upstream slacks:

FJ

7

14,i

=FEJ

7

14,i

+fij

7

14,i

FM

j,7

14,i

=FEM

j,7

14,i

+fim

j,7

14,i

(j=8,9)

For g

1

intervals (stores have one h, and one H):

h

1

14,i

=<TIME(d

4,1

14,i

),TIME(d

1,14

14,i

)>

H

1

14,i

=<RD

4,1

14,i

,DD

1

14,i

>

(with a meaning for DD

1

and

14,i

RD

4,1

14,i

equivalent to

those of

g

7

). g

1

temporal slacks are defined

similarly, except for the internal slacks, which are

defined considering

INTERVAL(O

1

14,i

)=h

1

, 1

time unit minimum duration for the task and the rest

of the effective duration considered as internal slack,

being:

14,i

fij

1

14,i

+fim

1

14,i

=DURATION(O

1

)-1

14,i

Additionally, for any g

k

, we define the total

slack:

FT

k

14,i

=FJ

k

14,i

+FM

k

14,i

where

FM

k

14,i

=FM

j,k

14,i

, using for FM

j,k

14,i

the upstream

slack corresponding to the most restrictive

H

j,k

14,i

, for

processors with more than one supplier.

Assuming agents always maintain non negative

internal (

fij and fim) slacks and, in the case of

store agents, the minimum task duration is 1 time

unit, for temporal constraints to be respected, the

following conditions must hold. For processor

g

7

:

DURING(INTERVAL(O

7

14,i

),h

j,7

14,i

) ∧

DURING(h

j,7

14,i

,H

j,7

14,i

)

(j=8,9)

Similar conditions must hold for store g

1

. The

conditions mean that, for an agent scheduling

problem, an

O interval must be contained in the h

interval(s), and each

h interval must be contained in

the corresponding (same supplier)

H interval. This

is equivalent to say that all values for slacks

FJ, FM,

FEJ and FEM must be non negative. If any of the

conditions described doesn't hold, an agent must

engage in a re-scheduling activity, involving

communicative actions to agree on acceptable

temporal values of requests with the client or the

supplier(s) and, possibly, re-scheduling actions to

correct the temporal position of the task interval

(which must be, at least, inside the

H interval).

However, before engaging in such activity, an agent

must be sure that the problem is time-feasible

(otherwise it must be rejected), i.e., that the most

restrictive

H interval duration is greater than or

equal to the task duration (using for stores a

minimum of 1). This is ensured if, for any agent

g

k

:

FT

k

14,i

≥0

In order to be able to determine the values for

the end-points of

H intervals, an agent receives from

the client (via

request message) the value of the

FEJ slack; then, ensuring non negative internal

slack values for the task to be scheduled, it will send

to each supplier the supplier

FEJ value (via

request messages); the agent FEM slack values

are received from the suppliers (via

acceptance

messages), if they accept the requests; in the case the

problem is time-feasible, the agent finally schedules

its task and sends to the client the client

FEM value

(via

acceptance message). For instance, for

agent

g

7

, the H's end-points are given by

DD

7

14,i

=TIME(d

7,4

14,i

)+FEJ

7

and

14,i

RD

j,7

14,i

=

TIME(

d

j,7

14,i

)-FEM

j,7

14,i

(j=8,9); supplier g

j

FEJ

value is given by

FJ

7

14,i

+fim

j,7

14,i

, and client FEM

value by

9,8j

MIN

=

(FM

j,7

14,i

)+fij

7

14,i

; retail agent g

14

passes the value of

DD-TIME(d) to its supplier

capacity agent

g

1

, as g

1

FEJ value, and each of the

raw-material agents

g

m

(m=17,18,19) passes the

value of

TIME(d

i

km

,

,

14

)-RD to its client capacity

agent

g

k

(k=8,11,12), as g

k

FEM value.

4 STEPS OF THE APPROACH

The approach we propose is a minimal approach,

i.e., agents will only modify a scheduling problem

solution if it contains constraint violations and, in

that case, they operate minimal re-scheduling

corrections. The approach is composed of the

following sequence of three agent steps:

Step 1, Acceptance and initial solution - If any

request to a supplier was rejected, reject the request

from the client, cancel the accepted requests to

suppliers, and terminate the procedure (with failure).

Otherwise, see if the problem is temporally

over-constrained; if it is, terminate the procedure

ICSOFT 2006 - INTERNATIONAL CONFERENCE ON SOFTWARE AND DATA TECHNOLOGIES

328

(with failure) by rejecting the problem, i.e., reject

the request from the client and cancel all accepted

requests to suppliers; if it isn't, establish an initial

solution and proceed to Step 2;

Step 2, Re-schedule to find a time-feasible

solution - If the established solution is time-feasible,

proceed to Step 3. Otherwise, re-schedule requests,

or requests and task, to remove all temporal

constraint violations;

Step 3, Re-schedule to find a feasible solution -

If the solution is resource-feasible (i.e., it has no

capacity constraint violation), terminate the

procedure (with success). Otherwise, try to

re-schedule to remove all capacity constraint

violations, without violating temporal constraints; if

this is possible terminate (with success). As a last

choice, resort to cancellation, together with task

un-scheduling (terminating with failure).

time

15 17161410 11 12 136789

O

i,14

7

d

i,14

7,8

d

i,14

7,9

fim

i,14

7,9

FEM

i,14

7,9

FM

i,14

7,9

h

i,14

7,9

H

i,14

7,9

H

i,14

7,8

h

i,14

7,8

4-a) Processor case 4 situation.

time

15 17161410 11 12 136789

O

i,14

7

d

i,14

7,8

d

i,14

7,9

4-b) Situation after minimal re-scheduling.

O

i,14

7

time

15 1817161410 11 12 136789

d

i,14

7,8

d

i,14

7,9

fim

i,14

7,9

FEM

i,14

7,9

FM

i,14

7,9

h

i,14

7,9

H

i,14

7,8

h

i,14

7,8

H

i,14

7,9

2-a) Processor case 2 situation.

time

15 1817161410 11 12 136789

O

i,14

7

d

i,14

7,9

d

i,14

7,8

2-b) Situation after minimal re-scheduling.

time

15 1817 19 2016

O

i,14

7

d

i,14

4,7

1-b) Situation after minimal re-scheduling.

time

15 1817 19 2016

O

i,14

7

d

i,14

4,7

fij

i,14

7

FEJ

i,14

7

FJ

i,14

7

h

i,14

7,9

h

i,14

7,8

H

i,14

7,9

H

i,14

7,8

1-a) Processor case 1 situation.

time

1

51817 19 2016

O

i,14

7

d

i,14

4,7

3-b) Situation after minimal re-scheduling.

fij

i,14

7

O

i,14

7

d

i,14

4,7

time

1

51817 19 2016

FEJ

i,14

7

FJ

i,14

7

h

i,14

7,9

H

i,14

7,8

h

i,14

7,8

H

i,14

7,9

3-a) Processor case 3 situation.

p 1141

g8

Input

fim d fij g7 g4 g1

g11 1 2 1 fim d fij fim d fij fim d fij

fimdfij 232 121 010

131 g9 4

fim d fij g0

g12 131 H client

fim d fij 2 RD DD dd

111 01025

a) Input data.

Table 1 Step 1: Scheduling an Initial Solution p

dd = 25 1141

H = <0,10> Messages exchanged among agents

message type from to contents

request g14 g1 dd = 25 FJM / FEJ = -15

request g1 g4 dd = 24 FJM / FEJ = -15

request g4 g7 dd = 20 FJM / FEJ = -13

request g7 g8 dd = 13 FJM / FEJ = -9

request g7 g9 dd = 11 FJM / FEJ = -7

request g9 g11 dd = 6 FJM / FEJ = -5

request g9 g12 dd = 5 FJM / FEJ = -4

request g8 g17 dd = 9 FJM / FEJ = -7

request g11 g18 dd = 1 FJM / FEJ = -3

request g12 g19 dd = 2 FJM / FEJ = -2

acceptance g17 g8 FMJ / FEM = 9

acceptance g18 g11 FMJ / FEM = 1

acceptance g19 g12 FMJ / FEM = 2

rejection g11 g9

acceptance g12 g9 FMJ / FEM = 4

acceptance g8 g7 FMJ / FEM = 11

rejection g9 g7

rejection g7 g4

rejection g4 g1

rejection g1 g14

cancelation g7 g8

cancelation g8 g17

cancelation g9 g12

cancelation g11 g18

cancelation g12 g19

Figure 4: Examples of Step 2 re-scheduling cases 1, 2, 3

and 4, for a processor agent, with situations before, and

after, minimal re-scheduling actions.

O

i,14

1

d

i,14

1,4

time

252420 21 22 231918

d

i,14

14,1

fim

i,14

1

FEM

i,14

1

FM

i,14

1

h

i,14

1

H

i,14

1

4-a) Store case 4 situation.

time

252420 21 22 231918

O

i,14

1

d

i,14

1,4

d

i,14

14,1

4-b) Situation after minimal re-scheduling.

time

25 2827 29 30262420 21 22 231918

O

i,14

1

d

i,14

14,1

d

i,14

1,4

2-b) Situation after minimal re-scheduling.

O

i,14

1

d

i,14

14,1

time

25 2827 29 30262420 21 22 231918

d

i,14

1,4

fim

i,14

1

FEM

i,14

1

FM

i,14

1

h

i,14

1

H

i,14

1

2-a) Store case 2 situation.

O

i,14

1

d

i,14

1,4

time

2420 21 22 231918

d

i,14

14,1

FEJ

i,14

1

FJ

i,14

1

fij

i,14

1

h

i,14

1

H

i,14

1

1-a) Store case 1 situation.

time

2420 21 22 231918

O

i,14

1

d

i,14

1,4

d

i,14

14,1

1-b) Situation after minimal re-scheduling.

time

25 2827262422 23

O

i,14

1

d

i,14

14,1

d

i,14

1,4

3-b) Situation after minimal re-scheduling.

O

i,14

1

d

i,14

14,1

time

25 2827262422 23

d

i,14

1,4

FEJ

i,14

1

FJ

i,14

1

fij

i,14

1

h

i,14

1

H

i,14

1

3-a) Store case 3 situation.

b) Messages exchanged among agents during Step 1. Note the

rejection and cancellation messages.

Table 2 Step 1: Scheduling an Initial Solution p

dd = 25 Local scheduling problem 1141

H = <0,10> (for each capacity agent) Temporal slacks

capacity suppliers client dates task

agent RD rd dd DD s d e FM FEM fim fij FEJ FJ FT

g8

g17 g7 0 9 13 4 10 2 12 10 9 1 1 -9 -8 2

g11

g18 g9 01612352111-5 -4 -2

g12

g19 g9 02513143211-4 -3 0

g9

g11 g7 -- 6 11 4 7 3 10 -- -- 1 1 -7 -6 --

g12 1 5 6 4 2

g7

g8 g4 2 13 20 7 15 3 18 13 11 2 2 -13 -11 --

g9 -- 11 -- -- 4

g4

g7 g1 -- 20 24 9 21 2 23 -- -- 1 1 -15 -14 --

g1

g4 g14 -- 24 25 10 24 1 25 -- -- 0 0 -15 -15 --

Figure 5: Examples of Step 2 re-scheduling cases 1, 2, 3

and 4, for a store agent, with situations before, and after,

minimal re-scheduling actions. In order to detect cases 1

and 3, the minimum duration task interval is considered

shifted to the extreme left, and for cases 2 and 4 shifted to

the extreme right, relatively to the effective task interval.

c) Schedule data in Step 1 (incomplete, as Step 1 was terminated

with failure). Note the negative value for total slack

FT=-2,

detected by agent

g

11

.

Figure 6: Scheduling problem 1141 input and Step 1

data. Step 1, was terminated with failure, in this case.

AN APPROACH TO MULTI AGENT COOPERATIVE SCHEDULING IN THE SUPPLY CHAIN, WITH EXAMPLES

329

Table 3 Step 2: Re-scheduling for a p

dd = 25 Time-Feasible Solution 1155

H = <4,22> Messages exchanged among agents

message type from to contents

re-request g1 g14 dd = 22 FJ = -3

re-request g1 g4 rd = 21 FJ = -3

re-request g4 g1 dd = 21 FJ = -2

re-request g4 g7 rd = 19 FJ = -2

re-request g7 g4 dd = 19 FEJ = -1

re-request g9 g11 rd = 7 FEM = -1

re-request g11 g9 dd = 7 FM = -2

re-request g11 g18 rd = 4 FM = -2

re-request g12 g19 rd = 4 FM = -1

a) Messages exchanged among agents during Step 2.

Table 4 Step 2: Re-scheduling for a Time-Feasible Solution p

dd = 25 Local scheduling problem 1155

H = <4,22> (for each capacity agent) Temporal slacks

capacity suppliers client dates task

agent RD rd dd DD s d e FM FEM fim fij FEJ FJ FT

g8

g17 g7 4 9 13 16 10 2 12 6 5 1 1 3 4 10

g11

g18 g9 44713437001166 6

g12

g19 g9 44513415001188 8

g9

g11 g7 7711167310001156 6

g12 5 5 2 0 2

g7

g8 g4 6 13 19 19 15 3 18 9 7 1 1 0 1 6

g9 10 11 5 1 4

g4

g7 g1 13 19 21 21 19 2 21 6 6 1 1 0 0 6

g1

g4 g14 1521222221 1 22 6 6 1 1 0 0 6

b) Schedule data after Step 2.

For a time-feasible scheduling problem, this

procedure results in the agents of the client-supplier

tree building first, an initial, possibly flawed,

solution (in Step 1), which can then be repaired (in

Step 2), if necessary. Steps 1 and 2 are oriented to a

temporal perspective and concern only to a single

problem of an individual agent; Step 3 is oriented to

a resource perspective and involves all problems of

the agent at Step 3, as all the tasks of the agent

compete for its resource capacity.

p 1155

g8

Input

fim d fij g7 g4 g1

g11 1 2 1 fim d fij fim d fij fim d fij

fimdfij 232 121 010

131 g9 4

fim d fij g0

g12 131 H client

fim d fij 2 RD DD dd

111

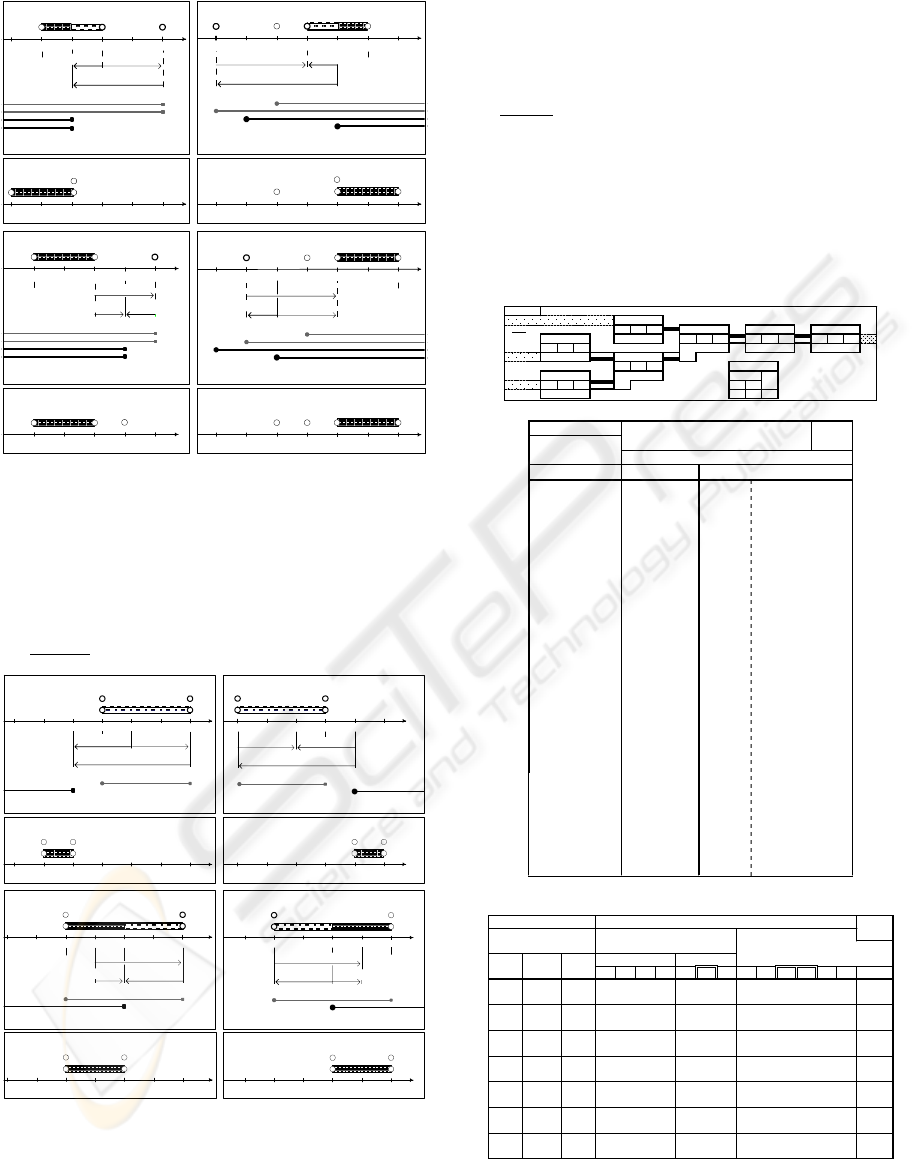

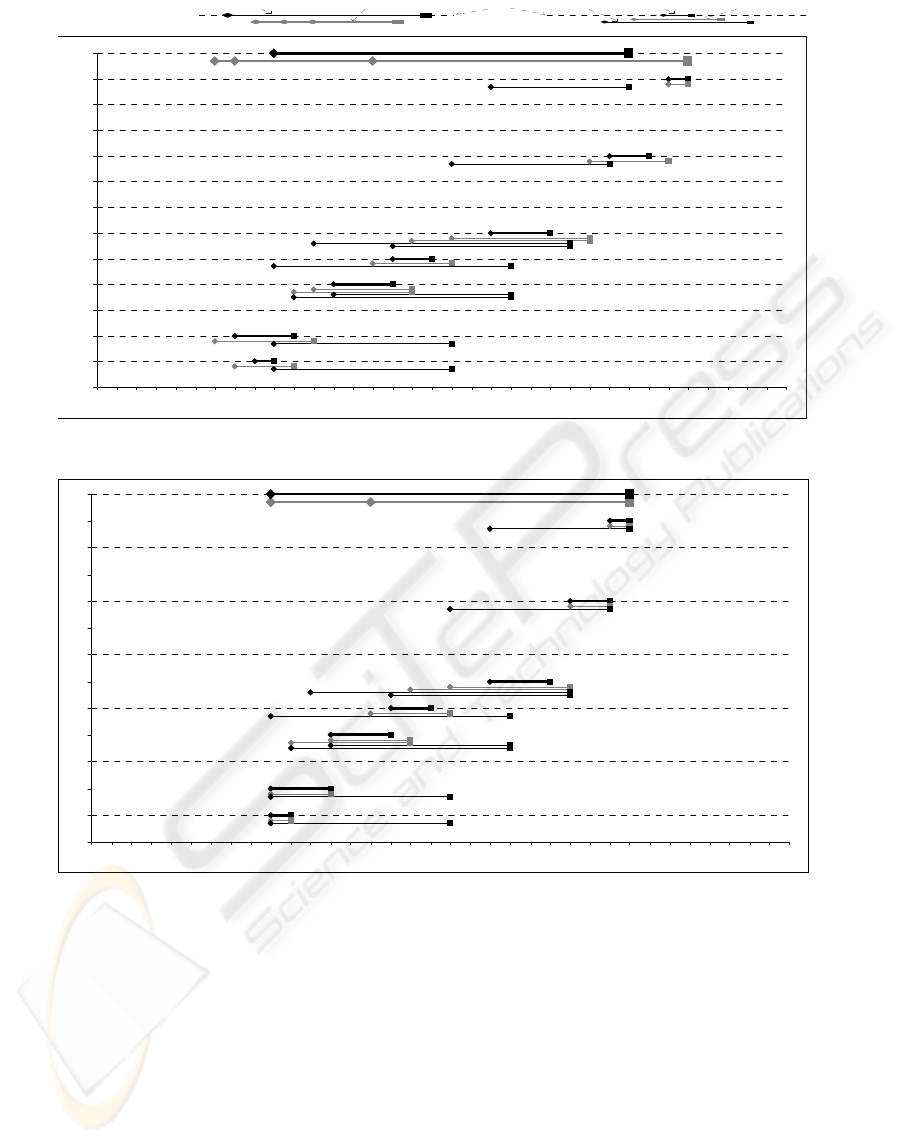

4

In Step 2, with temporal constraint violations,

there are four possible re-scheduling cases:

case 1,

negative

FJ slack; case 2, negative FM slack(s); case

3, negative FEJ slack, and case 4, negative FEM

slack(s) (cases 1 and 2 must be tested first by the

agent, as they involve also, less critical, negative

FEJ or FEM). The cases are depicted in Figure 4 (for

processor agents) and

Figure 5 (for store agents),

together with the appropriate minimal re-scheduling

actions, using agents

g

7

and g

1

as an example.

2225

a) Input data.

Table 1 Step 1: Scheduling an Initial Solution p

dd = 25 1155

H = <4,22> Messages exchanged among agents

message type from to contents

request g14 g1 dd = 25 FJM / FEJ = -3

request g1 g4 dd = 24 FJM / FEJ = -3

request g4 g7 dd = 20 FJM / FEJ = -1

request g7 g8 dd = 13 FJM / FEJ = 3

request g7 g9 dd = 11 FJM / FEJ = 5

request g9 g11 dd = 6 FJM / FEJ = 7

request g9 g12 dd = 5 FJM / FEJ = 8

request g8 g17 dd = 9 FJM / FEJ = 5

request g11 g18 dd = 1 FJM / FEJ = 9

request g12 g19 dd = 2 FJM / FEJ = 10

acceptance g17 g8 FMJ / FEM = 5

acceptance g18 g11 FMJ / FEM = -3

acceptance g19 g12 FMJ / FEM = -2

acceptance g11 g9 FMJ / FEM = -1

acceptance g12 g9 FMJ / FEM = 0

acceptance g8 g7 FMJ / FEM = 7

acceptance g9 g7 FMJ / FEM = 1

acceptance g7 g4 FMJ / FEM = 7

acceptance g4 g1 FMJ / FEM = 9

acceptance g1 g14 FMJ / FEM = 9

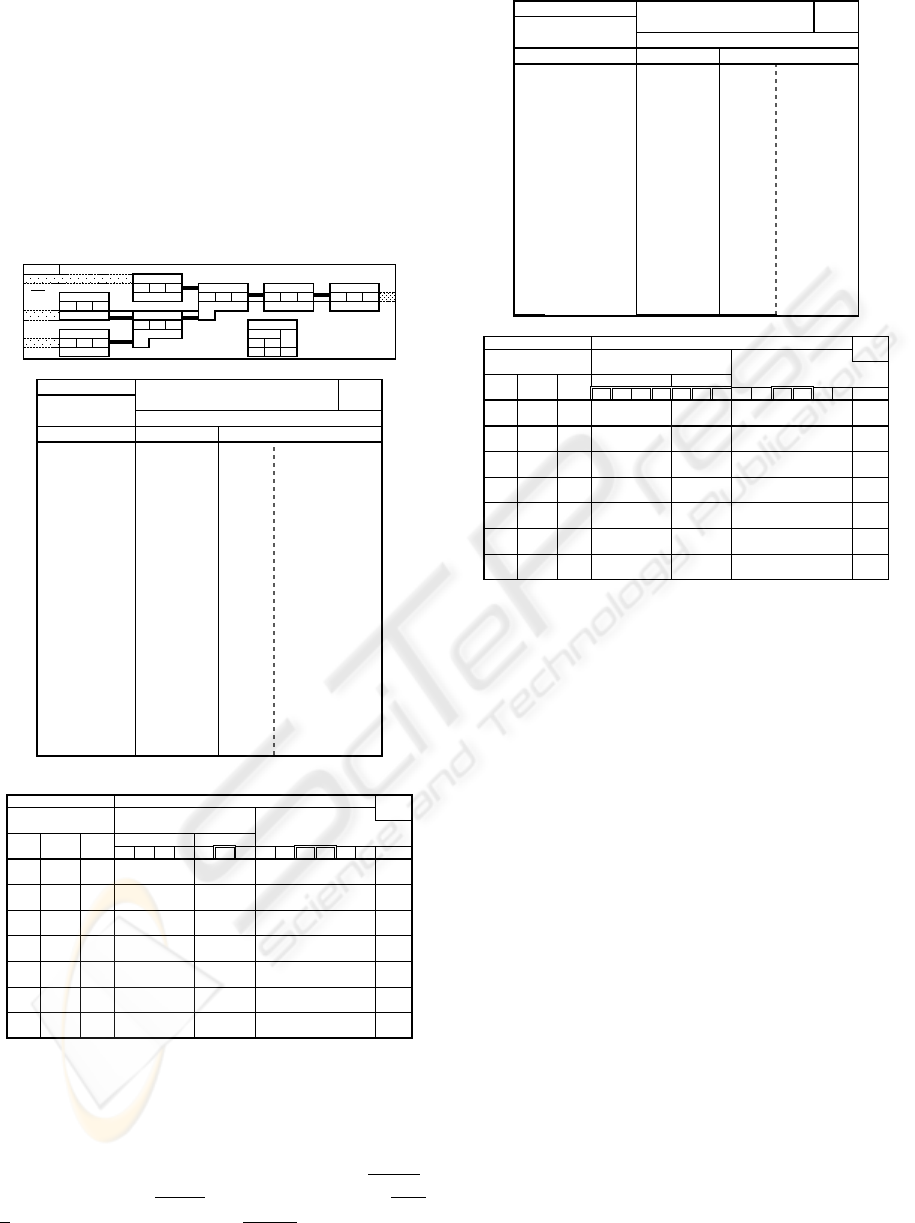

5 EXAMPLES

We now present two network scheduling problem

simulation cases, together with the results of the

application of the three-step procedure described,

assuming the job depicted in

Figure 2 (see Figure 6

for the first problem, and

Figure 7, Figure 8 and

Figure 9 for the second). As input data for problem

simulation, global temporal parameters (

RD and DD

of global

H interval and date value dd=TIME(d)

of the global request from outside), as parameters

for agent

g

0

, and task durations (d) and initial

values for internal slacks (

fij and fim, which can

be further changed by agents) for each capacity

agent are given.

Figure 6 shows the initial data (a), and the

messages exchanged (b) and resulting schedule data

(c) in Step 1, for the first problem (labelled problem

b) Messages exchanged among agents during Step 1. There are

no rejection or cancellation messages.

Table 2 Step 1: Scheduling an Initial Solution p

dd = 25 Local scheduling problem 1155

H = <4,22> (for each capacity agent) Temporal slacks

capacity suppliers client dates task

agent RD rd dd DD s d e FM FEM fim fij FEJ FJ FT

g8

g17 g7 49131610212651134 10

g11

g18 g9 41613235-2 -3 1178 6

g12

g19 g9 42513314-1 -2 1189 8

g9

g11 g7 7 611167 3100-1 1 1 5 6 6

g12 5 5 2 0 2

g7

g8 g4 6 13 20 19 15 3 18 9 7 2 2 -1 1 6

g9 10 11 5 1 4

g4

g7 g1 13 20 24 21 21 2 23 8 7 1 1 -3 -2 6

g1

g4 g14 1524252224 1 25 9 9 0 0 -3 -3 6

c) Schedule data after Step 1. No agent detected a negative value

for total slack

FT.

Figure 7: Scheduling problem 1155 input and Step 1 data.

Step 1, was terminated with success, in this case.

Figure 8: Scheduling problem 1155 Step 2 data. Some

requests were re-scheduled to remove temporal

constraint violations (the negative slacks in

Figure 7-c).

ICSOFT 2006 - INTERNATIONAL CONFERENCE ON SOFTWARE AND DATA TECHNOLOGIES

330

H

interval

h

intervals

timelines

H

intervals

h

intervals

task interval

for agent

g

0

(whole network) for a capacity agent

legends fo

r

schedule intervals

network schedule 1

24 25

2524

15 2 2

21 23

2420

13 2 1

15 18

2011

6 19

10 12

913

4 16

710

116

115

25

61

413

34

52

413

2013

716

25

921

4 22

1910

5 16

0

1

2

3

4

5

6

7

8

9

10

11

12

13

-5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

time

agent

a) Schedule resulting from Step 1 (built from data in Figure 7-c). Concerning to temporal constraint violation situations experienced by the

agents, as shown, agents

g

1

and g

4

have a case 1 situation, agent g

7

has a case 3 situation, agent g

9

has a case 4 situation and agents g

11

and

g

12

have a case 2 situation.

network schedule 2

2221

21 22

2215

2119

19 2 1

2113

1815

13 19

1911

1210

139

164

107

711

511

74

47

134

54

45

134

6 19

167

449

22

224

10 19

165

0

1

2

3

4

5

6

7

8

9

10

11

12

13

- 5 - 4 - 3 - 2 - 1 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 2 0 2 1 2 2 2 3 2 4 2 5 2 6 2 7 2 8 2 9 3 0

b) Schedule resulting from Step 2 (built from data in Figure 8-b). All temporal constraint violations were removed.

P 1141). The problem was rejected in Step 1 (with

the initiative taken first by capacity agent

g

11

), as it

is temporally over-constrained.

Figure 7 shows the initial data (a), and the

messages exchanged (b) and resulting schedule data

(c) in Step 1, for the second problem (labelled

problem P 1155). As

Figure 7-c shows, no capacity

agent detected a negative value for total slack

FT, so

the problem is not temporally over-constrained.

As a result, no rejection or cancellation messages

are exchanged until the end of Step 1, see

Figure

7

-b. The resulting network schedule in Step 1 is

shown in

Figure 9-a. In Step 2, temporal constraint

violation situations of case 1 for agents

g

1

and g

4

, of

case 3 for agent

g

7

, of case 4 for agent g

9

, and of

case 2 for agents

g

11

and g

12

are detected. Solution

repair is accomplished by agents through inter-agent

local request re-scheduling (for all those agents),

and additional agent task re-scheduling (only for

agents

g

1

, g

4

, g

11

and g

12

), according to the

minimal actions prescribed.

Figure 8 shows the

messages exchanged (a) and resulting schedule data

(b), and

Figure 9-b shows the resulting schedule in

Step 2, for this problem. As shown by

Figure 9-b, all

temporal constraint violations found in the initial

solution (

Figure 9-a) disappeared.

Figure 9: Schedules for problem P 1155: a) after Step 1 (terminated with success), and b) after Step 2.

AN APPROACH TO MULTI AGENT COOPERATIVE SCHEDULING IN THE SUPPLY CHAIN, WITH EXAMPLES

331

6 CONCLUSION

We described an approach to multi-agent scheduling

in a cooperative supply-chain environment. The

approach presupposes the use of an agent interaction

protocol (also described), is based on a three-step

procedure prescribed for each agent involved in a

scheduling problem, and results in an individual

cooperative scheduling behaviour. In Step 1 agents

detect if the problem is temporally over-constrained

and, if it isn't, they schedule an initial, possibly non

time-feasible, solution (otherwise, they reject the

problem). The exchange of specific temporal slack

values, besides product, quantity and due-date

information, used as a scheduling coordination

mechanism, allows the agents to locally perceive the

hard global temporal constraints of the problem, and

rule out non time-feasible solutions in the

subsequent steps. Each of these pieces of

information exchanged in Step 1 corresponds, for a

particular agent, to a sum of slacks downstream and

upstream the agent in the agent network, and cannot

be considered private information of any agent in

particular. If necessary, in Step 2, agents repair the

initial solution, through re-scheduling, in order to

obtain a time-feasible one. In Step 3 any capacity

constraint violation must be removed, either through

re-scheduling, or by giving up the problem.

No specific details were given for Step 3. In fact,

this is the matter of our current and future work.

Step 3 can be refined to accommodate additional

coordination mechanisms for implementing certain

solution search strategies. For instance, strategies

based on capacity/resource constrainedness (see

[

Sycara 1991] or [Sadeh 1994]), to lead the agents on a

fast convergence to both time and capacity-feasible

solutions, including solutions satisfying some

scheduling preferences, or optimising some criteria,

either from an individual agent perspective, or from

the global perspective of the overall system.

REFERENCES

Baker 1974. Baker, K.R., Introduction to Sequencing and

Scheduling, Wiley, New York, 1974.

Blazewicz 1994. Blazewicz, J.; Ecker, K.H. ;Schmidt, G.;

Weglarz, J., Scheduling in Computer and

Manufacturing Systems, Springer Verlag, 1994.

Camarinha-Matos 1999. Camarinha-Matos, L.M.;

Afsarmanesh, H. (eds.), Infrastructures for Virtual

Enterprises, Networking Industrial Enterprises,

Kluwer Academic Publishers, Dordrecht, The

Netherlands, 1999.

Graves 1993. Graves, S.C.; Kan, A.H.G. Rinnooy; Zipkin,

P.H., (eds.), Logistics of Production and Inventory,

Handbooks in Operations Research and Management

Science, Volume 4, North-Holland, Amsterdam, 1993.

Kjenstad 1998. Kjenstad, Dag, Coordinated Supply Chain

Scheduling, PhD. Thesis, Norwegian University of

Science and Technology, 1998, Trondheim, Norway.

Minton 1992. Minton, Steven, et al, Minimizing Conflicts:

a Heuristic Repair Method for Constraint Satisfaction

and Scheduling Problems, Artificial Intelligence 58,

1992, 161-205.

O'Hare 1996. O'Hare, G.M.P.; Jennings, N.R.,

Foundations of Distributed Artificial Intelligence,

John Wiley & Sons, Inc., 1996, New York, USA.

O'Neill 1996. O'Neill, H.; Sackett, P., The Extended

Enterprise Reference Framework, in Balanced

Automation Systems II, Camarinha-Matos, L.M. and

Afsarmanesh, H. (Eds.), 1996, Chapman & Hall,

London, UK, 401-412.

Rabelo 1998. Rabelo, R.J.; Camarinha-Matos, L.M.;

Afsarmanesh, H., Multiagent Perspectives to Agile

Scheduling, Basys'98 Int. Conf. on Balanced

Automation Systems, Prague, Czech Republic, 1998.

Reis 2001a. Reis, J.; Mamede, N.; O’Neill, H., Locally

Perceiving Hard Global Constraints in Multi-Agent

Scheduling, Journal of Intelligent Manufacturing,

Vol.12, No.2, April 2001, 227-240.

Reis 2001b. Reis, J.; Mamede, N., Multi-Agent Dynamic

Scheduling and Re-Scheduling with Global Temporal

Constraints, Proceedings of the ICEIS’2001, Setúbal,

Portugal, 2001, Miranda, P., Sharp, B., Pakstas, A.,

and Filipe, J. (eds.), Vol. I, 315-321.

Reis 2001c. Reis, J.; Mamede, N., Scheduling, Re-

Scheduling and Communication in the Multi-Agent

Extended Enterprise Environment, accepted for the

MASTA'01 Workshop, EPIA'01 Conference,

December, 17-20, 2001, Porto, Portugal.

Reis 2002. Reis, J., Um Modelo de Escalonamento

Multi-Agente na Empresa Estendida, PhD thesis (in

portuguese), ISCTE 2002, Lisbon, Portugal.

Sadeh 1994. Sadeh, N., Micro-Oportunistic Scheduling:

The Micro-Boss Factory Scheduler, in Intelligent

Scheduling, Morgan Kaufman, 1994, Chapter 4.

Sycara 1991. Sycara, Katia P.; Roth, Steven F.; Sadeh,

Norman; Fox, Mark S., Resource Allocation in

Distributed Factory Scheduling, IEEE Expert,

February, 1991, 29-40.

Zweben 1994. Zweben, Monte; Fox, Mark S., Intelligent

Scheduling, Morgan Kaufmann Publishers, Inc., San

Francisco, California, 1994.

ICSOFT 2006 - INTERNATIONAL CONFERENCE ON SOFTWARE AND DATA TECHNOLOGIES

332