DEVELOPING A CONFIGURATION MANAGEMENT MODEL

FOR USE IN THE MEDICAL DEVICE INDUSTRY

Fergal McCaffery

Lero – The Irish Software Engineering Research Centre, University of Limerick, Ireland

Rory O’Connor

School of Computing, Dublin City University, Dublin, Ireland

Gerry Coleman

Department of Computing, Dundalk Institute of Technology, Dundalk, Ireland

Keywords: Configuration Management, Medical device, Software Process Improvement, CMMI.

Abstract: This paper outlines the development of a Configuration Management model

for the MEDical device

software industry (CMMED). The paper details how medical device regulations associated with

Configuration Management (CM) may be satisfied by adopting less than half of the practices from the CM

process area of the Capability Maturity Model Integration (CMMI). It also investigates how the CMMI CM

process area may be extended with additional practices that are outside the remit of the CMMI, but are

required in order to satisfy medical device regulatory guidelines.

1 INTRODUCTION

Software is becoming an increasingly important

aspect of medical devices and medical device

regulation. Medical devices can only be marketed if

compliance and approval from the appropriate

regulatory bodies of the Food and Drug

Administration (FDA Regulations, 2002), and the

European Commission under its Medical Device

Directives (European Council Directive, 1993) is

achieved. Medical device companies must produce a

design history file detailing the software components

and processes undertaken in the development of

their medical devices. Due to the safety-critical

nature of medical device software it is important that

a highly efficient CM process is in place within

medical device companies.

CM is the discipline of c

oordinating software

development and controlling the change and

evolution of software products and components

(Ghezzi et al, 2003). It involves the ‘unique

identification, controlled storage, change control,

and status reporting of selected intermediate work

products, product components and products during

the life of a system’ (Jonassen-Hass, 2002). Such

CM procedures are needed to manage the vast

number of elements (source code, documentation,

change requests, etc) that are created and updated

over the lifetime of a software system.

For many software companies, who report CM

p

roblems, CM is the first major process weakness

that they are required to address. For example, as the

company expands, it must fulfil the task of acquiring

new customers whilst satisfying the demands of

existing customers. Often these demands include

product customisations which many young

companies, lacking reliable revenue streams, do not

feel they can ignore. In many situations this results

in companies having to support multiple code bases

and product versions with very limited resources.

Ultimately, a detailed CM process is the only way

this problem can be solved.

A study of a small Danish software firm shows

ho

w it was forced to review the number of products

it developed, and the amount of work it accepted,

because of CM difficulties (Baskerville and Pries-

Heje, 1999). But CM is equally important in large

software companies as a case study of Netscape and

81

McCaffery F., O’Connor R. and Coleman G. (2006).

DEVELOPING A CONFIGURATION MANAGEMENT MODEL FOR USE IN THE MEDICAL DEVICE INDUSTRY.

In Proceedings of the First International Conference on Software and Data Technologies, pages 81-88

DOI: 10.5220/0001311900810088

Copyright

c

SciTePress

Microsoft’s development practices shows

(Cusumano and Yoffie, 1999). Therefore, in a

software company or department without CM to

control product development, there is no process to

assess and no basis for measurement (Fayad and

Laitinen, 1997). To succeed in this area Humphrey

(2000) proposes that a CM plan be developed in

conjunction with the establishment of a

configuration control board to manage changes to all

of the baseline configuration items and to ensure that

configuration control procedures are followed.

A number of ‘best practice’ software process

improvement (SPI) models such as ISO/IEC 15504

(also known as ‘SPICE’) and Capability Maturity

Model Integration (CMMI) have been designed to

help companies manage their software development

activity. For example, CMMI is an SPI improvement

model which specifies recommended practices in

specific process areas – including CM - that have

been shown to enhance software development and

maintenance capability (Chrissis et al., 1991).

This paper will investigate how thorough current

medical device regulations are in relation to

specifying what CM practices medical device

companies should adopt when developing software.

This will be achieved through comparing current

medical device regulations and guidelines for CM

against the formally documented software

engineering ‘best practices’ of the CMMI for the

CM process area.

2 MEDICAL DEVICE INDUSTRY

Medical device companies have to adhere to medical

device regulations in relation to CM. Therefore the

main area of concern for medical device companies

in relation to CM is to ensure that the checklist of

CM elements required by Food and Drug

Administration (FDA) are in place rather than trying

to improve their overall CM practices. GAMP

(2001) details CM practices that medical device

companies may adopt in order to comply with

medical device regulations, however no

documentation exists within the medical device

domain in relation to how such practices could be

improved by incorporating practices from formal

software engineering SPI models for CM.

However, if we investigate other regulated

industries such as the automotive and space

industries we realise that these domains are not

content with satisfying regulatory standards, but

have proactively developed SPI models specifically

for their domain so that they may continuously

improve the development of their information

systems to achieve higher levels of safety, greater

efficiency, and a faster time to market, whilst

seamlessly satisfying regulatory quality

requirements.

The major process improvement frameworks that

currently exist, namely ISO/IEC 15504 and CMMI,

do not address the regulatory requirements of either

the medical device, automotive or space industries.

Therefore, a new SPI model (Automotive SIG,

2005) was developed specifically for the automotive

industry, this model was based upon ISO/IEC15504

(ISO, 2003) and is referred to as ‘Automotive

SPICE’. Likewise, a new ISO/IEC15504 based SPI

model was developed specifically for the space

industry, this model is known as SPiCE for SPACE

(Cass and Volcker, 2000). Both of these models

contain reference and assessment information in

relation to how companies may improve their

configuration management practices within their

domain.

This paper will not address the issue of

developing an entire SPI model for the medical

device industry (see McCaffery et al, 2004 for full

discussion), but shall instead focus upon the

individual process area of CM. This work addresses

an opportunity to integrate the regulatory issues and

SPI mechanisms to achieve improvements that are

critical to the CM of software for medical devices.

3 CMMED DEVELOPMENT

The CMMED (Configuration Management model

for the MEDical device software industry) was

initiated by work that one of the authors performed

whilst performing research for the Centre for

Software Process Technologies at the University of

Ulster, Northern Ireland. This work is now

progressing with Lero – the Irish Software

Engineering Research Centre. The initial research

work was assisted by the involvement of a steering

group with a pilot of 5 medical device companies

and a notified standards body (all based in Northern

Ireland). Each of the five companies expressed a

desire to have access to a CM model that would

incorporate software process improvement practices

and could fulfil the relevant medical device

regulatory requirements. However, this work is now

being extended to include medical device companies

in the Republic of Ireland.

The CMMED may be defined as a set of

activities that if performed at a base level will satisfy

the CM guidelines specified in the medical device

standards. However, CMMED also enables medical

device companies to follow a SPI path to achieving

ICSOFT 2006 - INTERNATIONAL CONFERENCE ON SOFTWARE AND DATA TECHNOLOGIES

82

CMMI certification. The CMMED will be flexible

in that relevant elements of the model may be

adopted as required to provide the most significant

benefit to the business. The model is based on the

CMMI, however another model is also being

developed that is based upon ISO/IEC15504. The

regulations used to extend the CMMI framework

will be those of the FDA and the ANSI/AAMI

SW68:2001 (SW68) standard (Medical device

software – Software life cycle processes).

The CMMED will provide a means of assessing

the software engineering capability for the

configuration management process area in relation

to software embedded in medical devices

(FDA/CDRH, 1997, 1999, 2005). The CMMED is

being developed to promote SPI practices into the

CM process adopted by medical device companies.

This is an attempt to improve the effectiveness and

efficiency of CM within medical device companies

through investigating the mapping of medical device

regulatory guidelines against the CMMI CM process

area.

The mappings between the medical device

standards and the CMMI specific practices for the

CM process result in the CMMED being composed

of a number of goals, practices and activities. The

CMMED determines what parts of the CMMI CM

process area are required to satisfy medical device

regulations. It also investigates the possibility of

extending the CMMI process areas with additional

practices that are outside the remit of CMMI, but are

required in order to satisfy medical device regulatory

guidelines.

The following section will detail a mapping of

existing software development and regulatory

guidelines for the medical device industry against

the CMMI for the CM process area.

4 GUIDELINE MAPPING

The FDA provides little insight into how CM should

be performed other than to state that a CM plan

should exist and that this should be adopted to

manage configuration items for medical device

software. Therefore in order to gain a greater

understanding of the CM guidelines that medical

device companies follow in order to achieve

regulatory compliance we referred to the medical

device software life cycle processes (SW68)

standard. This standard was drafted for use in the

medical device sector based on the lifecycle

requirements of ISO/IEC 12207 (ISO, 1995). This

section illustrates the CMMED structure for the CM

process area. In order to achieve this, FDA

regulations & SW68 guidelines (for the rest of the

paper we refer to these together as medical device

standards) were mapped against the goals and

practices of the CMMI CM process area.

This mapping is presented as follows: Firstly, we

identify the goals that exist within the CMMI CM

process area. Next the CMMI CM practices are

identified within each CM goal. Then the CM

activities (associated with the current practice) that

have to be performed in order to comply with

medical device regulations are listed. We then

identify the activities that have to performed in order

in to adhere to the CMMI in relation to the current

practice. Finally we lists the CMMI CM activities

that are required in order to meet the medical device

regulatory requirements associated with the current

practice. The composition of the resulting CMMED

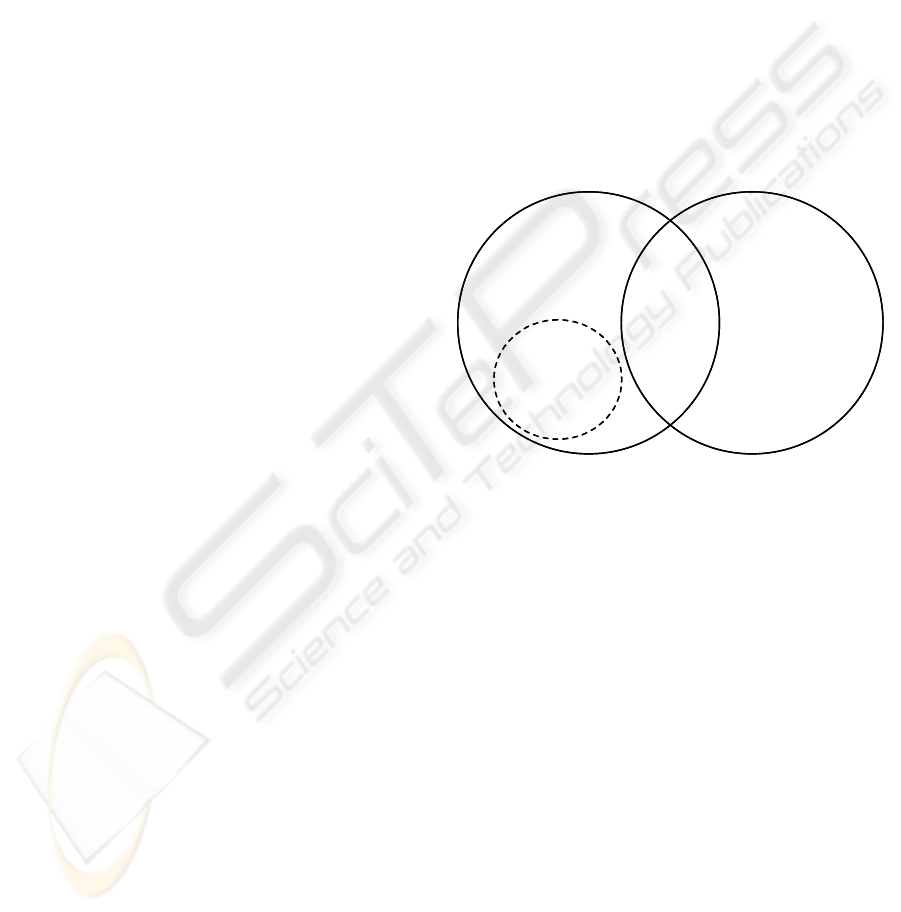

is illustrated in figure 1.

CMMI CM practices

Medical device

regulations for CM

Non-CMMI practices

that are required for

medical device

standards

CMMI

practices

that are

required for

medical

device

standards

Non-required

CMMI practices

with potential

benefit to medical

device software

CMMI practices not

required for medical

device standards

CMMI CM practices

Medical device

regulations for CM

Non-CMMI practices

that are required for

medical device

standards

CMMI

practices

that are

required for

medical

device

standards

Non-required

CMMI practices

with potential

benefit to medical

device software

CMMI practices not

required for medical

device standards

Figure 1: Composition of the CMMED.

It should be noted however, in some instances the

CMMI CM activities associated with the current

practice may not provide full coverage of the

medical device standards and therefore these

additional activities have to be added in order to

achieve the full list of activities required to fulfil the

objectives of CMMED.

The CMMED has three goals: Goal 1: Establish

Baselines, Goal 2: Track and Control Changes and

Goal 3: Establish Integrity. To meet each of these

goals it is necessary for a number of practices and

activities to be performed. Each of the following

sub-sections will present the CM activities required

for each of the 3 goals.

4.1 Goal 1: Establish Baselines

In order to fulfil Goal 1 Establish Baselines the

following practices have to be performed: Identify

Configuration Items, Establish a CM System and

Create or Release Baselines.

DEVELOPING A CONFIGURATION MANAGEMENT MODEL FOR USE IN THE MEDICAL DEVICE INDUSTRY

83

4.1.1 Identify Configuration Items

The 4 activities that have to be performed in order to

achieve regulatory compliance in relation to

identifying configuration items are:

1. Select the configuration items and the work

products that compose them based on

documented criteria

2. Assign unique identifiers to configuration items

3. Specify when each configuration item is placed

under CM

4. Identify Off the Shelf Components

The 5 activities that have to be performed in order to

satisfy the CMMI practice for identifying

configuration items are:

1. Select the configuration items and the work

products that compose them based on

documented criteria

2. Assign unique identifiers to configuration items

3. Specify the important characteristics of each

configuration

4. Specify when each configuration item is placed

under CM

5. Identify the owner responsible for each

configuration item

The 3 activities that are common to both the CMMI

and the medical device standards for identifying

configuration items are:

1. Select the configuration items and the work

products that compose them based on

documented criteria

2. Assign unique identifiers to configuration items

3. Specify when each item is placed under CM

Therefore, in order to adhere to the medical device

standards only 3 out of the 5 activities required for

the CMMI in relation to identifying configuration

items are necessary. However an additional activity

is required in order to identify Off-the-Shelf (OTS)

components as this is not included in the CMMI.

Therefore 4 CMMED activities are required for

identifying configuration items are:

1. Select the configuration items and the work

products that compose them based on

documented criteria

2. Assign unique identifiers to configuration items

3. Specify when each configuration item is placed

under CM

4. Identify Off the Shelf Components. Note: this

activity is not present in the CMMI but is

required in order to fulfil the requirements

specified in the medical device standards.

4.1.2 Establish a CM System

The 2 activities that have to be performed in order to

achieve regulatory compliance in relation to

establishing a configuration management system

(CMS) are:

1. Store and retrieve configuration items in the

CM system

2. Store, update, and retrieve CM records

The 8 sub-practices that have to be performed in

order to satisfy the CMMI practice for establishing a

CMS are:

1. Establish a mechanism to manage multiple

control levels of CM

2. Store / retrieve configuration items in the CMS

3. Share and transfer configuration items between

control levels within the CMS

4. Store and recover archived versions of

configuration items

5. Store, update, and retrieve CM records

6. Create CM reports from the CMS

7. Preserve the contents of the CMS

8. Revise the CM structure as necessary

There are 2 activities that are common to both the

CMMI and the medical device standards for

establishing a CMS. Therefore, in order to adhere to

the medical device standards, only 2 of the 8

activities required by the CMMI for establishing a

CMS are necessary. The main differences are that

CMMI requests the usage of multiple control levels

of CM, as well as archiving and restoration

procedures to be in place. The 2 CMMED activities

for establishing a CMS are:

1. Store and retrieve configuration items in the

CM system

2. Store, update, and retrieve CM records

4.1.3 Create or Release Baseline

There is only a single activity that has to be

performed in order to adhere to the medical device

standards in relation to creating or releasing

baselines - Document the set of configuration items

that are contained in a baseline. Whereas there are 4

activities that have to be performed in order to

satisfy the CMMI practice for creating or releasing

baselines:

1. Obtain authorisation from the CCB before

creating or releasing baselines of configuration

items

2. Create or release baselines only from

configuration items in the CM system

3. Document the set of configuration items that are

contained in a baseline

ICSOFT 2006 - INTERNATIONAL CONFERENCE ON SOFTWARE AND DATA TECHNOLOGIES

84

4. Make the current set of baselines readily

available

There is only single CMMED activity that is

common to both the CMMI and medical device

standards for creating or releasing baselines.

Therefore, in order to adhere to the medical device

standards only one of the 4 activities - Document the

set of configuration items that are contained in a

baseline – is required for the associated CMMI

practice is necessary.

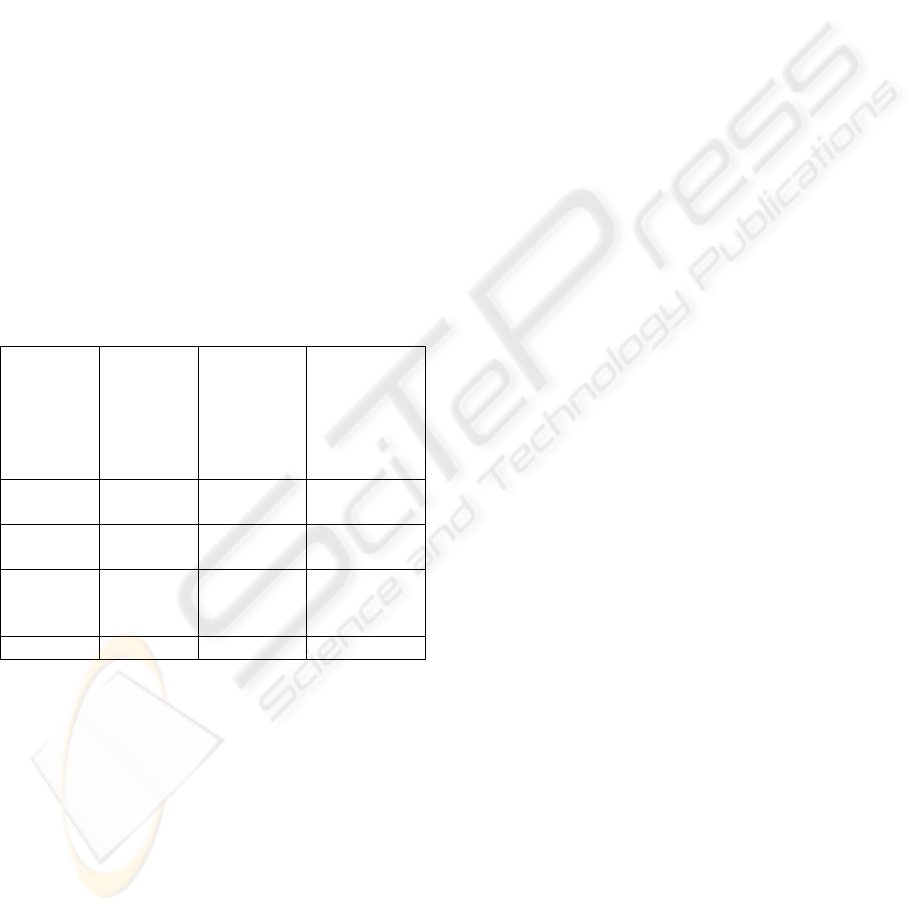

4.1.4 Summary of CMMED Goal 1

Table 1 summarises goal 1 of CMMED (Establish

Baselines). It may be observed from table 1 that not

all of activities of the CMMI have to be performed

in order to satisfy the medical device regulations (in

fact only 6 of the 17 CMMI activities have to be

performed). However, in order to satisfy the

objectives of the CMMED 1 additional (medical

device specific) activity had to be added (i.e. to

satisfy goal 1 of the CMMED).

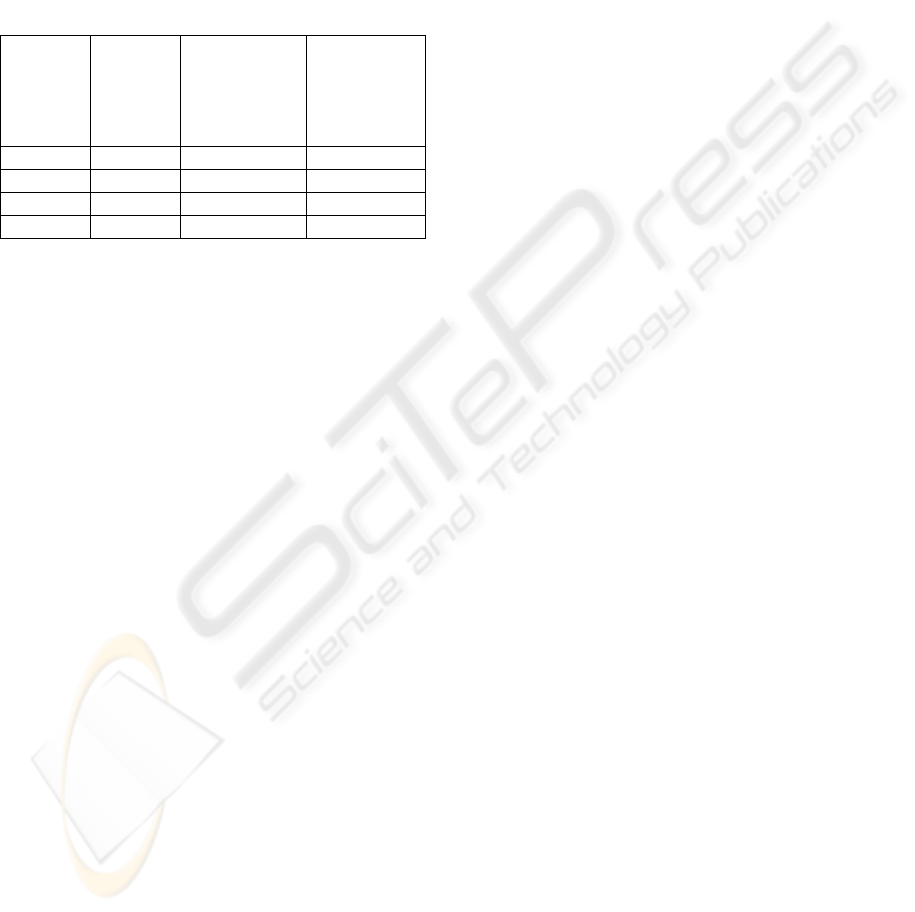

Table 1: Summary of CMMED Goal 1.

Practice CMMI

activities

CMMI

activities to

meet

medical

device

standards

Additional

activities to

meet medical

device

standards

Identify

CM items

5 3 1

Establish

a CMS

8 2 0

Create or

delete

Baselines

4 1 0

Total 17 6 1

4.2 Goal 2: Track and Control

Changes

In order to adhere to the CMMED goal 2 of tracking

and controlling changes, the following specific

practices have to be performed: Track Change

Requests and Control Configuration Items.

4.2.1 Track Change Requests

The 5 activities that have to be performed in order to

achieve regulatory compliance in relation to tracking

change requests:

1. Initiate and record change requests in the

change request database

2. Analyse the impact of changes and fixes

proposed in the change requests.

3. Review change requests that will be addressed

in the next baseline with those who will be

affected by the changes and get their agreement.

4. Track the status of change requests to closure.

5. Each upgrade, bug fix, or patch for OTS

software shall be evaluated, and the evaluation

shall be documented

There are 4 activities that have to be performed in

order to satisfy the CMMI practice for tracking

change requests:

1. Initiate and record change requests in the

change request database

2. Analyse the impact of changes and fixes

proposed in the change requests.

3. Review change requests that will be addressed

in the next baseline with those who will be

affected by the changes and get their agreement.

4. Track the status of change requests to closure.

There are 4 activities that are common to both the

CMMI and the medical device standards for tracking

change requests:

1. Initiate and record change requests in the

change request database

2. Analyse the impact of changes and fixes

proposed in the change requests.

3. Review change requests that will be addressed

in the next baseline with those who will be

affected by the changes and get their agreement.

4. Track the status of change requests to closure.

Therefore, in order to adhere to the medical device

standards all of the activities required for this CMMI

practice are necessary, but not always to the same

level of detail. However an additional practice is

required in order to ensure that each upgrade, bug

fix, or patch for OTS software is identified and

evaluated, and that the evaluation is documented, as

this is not included in the associated CMMI practice.

The CMMED activities for tracking change

requests are:

1. Initiate and record change requests in the

change request database

2. Analyse the impact of changes and fixes

proposed in the change requests.

3. Review change requests that will be addressed

in the next baseline with those who will be

affected by the changes and get their agreement.

4. Track the status of change requests to closure.

5. Each upgrade, bug fix, or patch for OTS

software shall be evaluated, and the evaluation

shall be documented. Note: this activity is not

present in the CMMI but is required in order to

DEVELOPING A CONFIGURATION MANAGEMENT MODEL FOR USE IN THE MEDICAL DEVICE INDUSTRY

85

fulfil the requirements specified in the medical

device standards.

4.2.2 Control Configuration Items

The 4 activities that have to be performed in order to

achieve regulatory compliance in relation to

controlling configuration items are:

1. Control changes to configuration items

throughout the life of the product

2. Obtain appropriate authorisation before changed

configuration items are entered into the CM

system

3. Perform reviews to ensure that changes have not

caused unintended effects on the baselines

4. Record changes to configuration items and the

reasons for the changes as appropriate

The 5 activities that have to be performed in order to

satisfy the CMMI practice to control configuration

items are:

1. Control changes to configuration items

throughout the life of the product

2. Obtain appropriate authorisation before changed

configuration items are entered into the CM

system

3. Check in and check out configuration items

from the CM system for incorporation of

changes in a manner that maintains the

correctness and integrity of the configuration

items

4. Perform reviews to ensure that changes have not

caused unitended effects on the baselines

5. Record changes to configuration items and the

reasons for the changes as appropriate

As the control of configuration items is very

important in terms of ensuring the integrity of

medical device software it is no surprise that 4 of the

5 activities required for this CMMI practice are

necessary in order to adhere to the medical device

standards.

The following list shows the mapping of the

medical device standards against each of the

activities required by the CMMI practice for

controlling configuration items:

1. Control changes to configuration items

throughout the life of the product

2. Obtain appropriate authorisation before changed

configuration items are entered into the CM

system

3. Perform reviews to ensure that changes have not

caused unitended effects on the configuration

baselines

4. Record changes to configuration items and the

reasons for the changes as appropriate

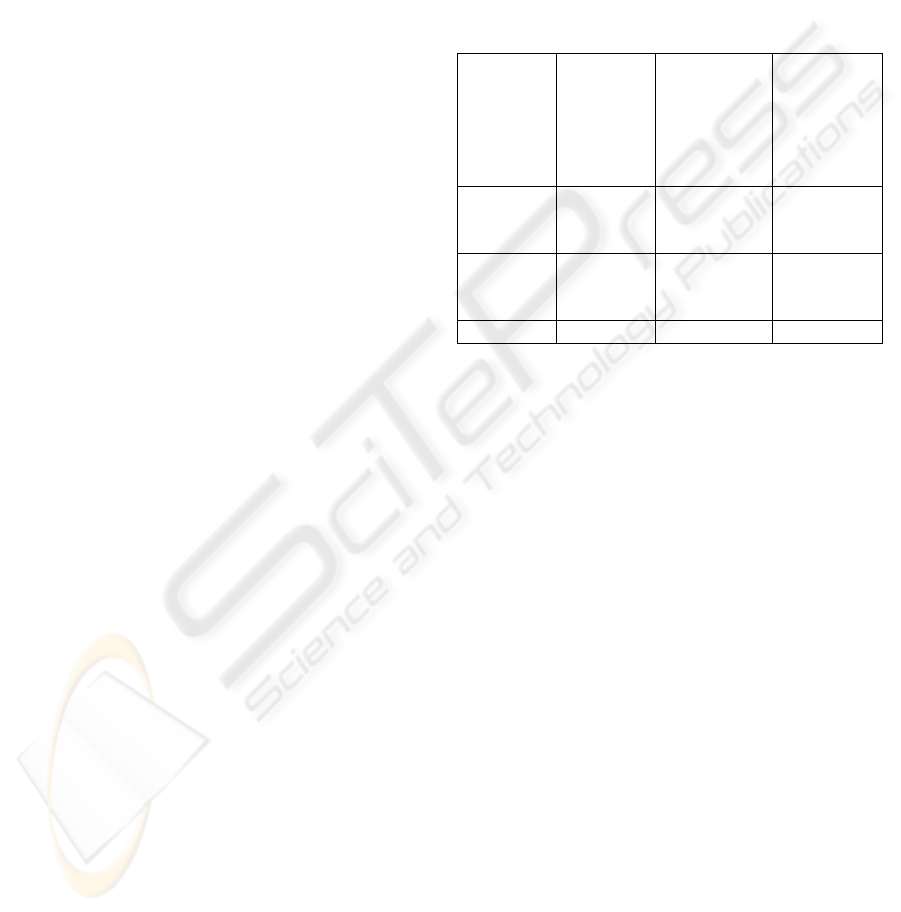

4.2.3 Summary of CMMED Goal 2

Table 2, summarises goal 2 of the CMMED (Track

and Control Changes). It may be observed that

almost all of the activities of this CMMI goal will

have to be performed in order to satisfy the medical

device standards (in fact 8 of the 9 CMMI sub-

practices will have to be performed). However, in

order to satisfy the objectives of CMMED 1

additional sub-practice had to be added.

Table 2: Summary of CMMED Goal 2.

Practice CMMI

activities

CMMI

activities to

meet

medical

device

standards

Additional

activities to

meet

medical

device

standards

Track

change

requests

4 4 1

Control

Config

items

5 4 0

Total 9 8 1

4.3 Goal 3: Establish Integrity

In order to fulfil CMMED goal 3: Establish Integrity

the following specific practices have to be

performed: Establish CM Records and Perform

Configuration Audits.

4.3.1 Establish CM Records

The 3 activities that have to be performed in order to

achieve regulatory compliance in relation to

establishing CM records are:

1. Record CM actions in sufficient detail so the

content and status of each configuration item is

known and previous versions can be recovered

2. Identify the version of the configuration items

that constitute a particular baseline.

3. Revise the status and history of the

configuration item as necessary

The 6 activities that have to be performed in order to

satisfy the CMMI practice for establishing CM

records are:

1. Record CM actions in sufficient detail so the

content and status of each configuration item is

known and previous versions can be recovered

2. Ensure that relevant stakeholders have access to

and knowledge of the configuration items

3. Specify the latest version of the baseline.

ICSOFT 2006 - INTERNATIONAL CONFERENCE ON SOFTWARE AND DATA TECHNOLOGIES

86

4. Identify the version of the configuration items

that constitute a particular baseline.

5. Describe the differences between successive

baselines

6. Revise the status and history of the

configuration item as necessary

The process of establishing CM records is very

important in terms of providing the traceability

evidence that is required to meet the regulatory

requirements associated with medical device

software. Half of the activities (3 out of 6) required

for this CMMI practice are necessary in order to

adhere to the medical device standards and are

therefore included in CMMED.

The CMMED activities for establishing CM

records are:

1. Record CM actions in sufficient detail so the

content and status of each configuration item is

known and previous versions can be recovered

2. Identify the version of the configuration items

that constitute a particular baseline.

3. Revise the status and history of the

configuration item as necessary

4.3.2 Perform Configuration Audits

The medical device standards do not specify any

activities that have to be performed in order to

achieve regulatory compliance in relation to

performing configuration audits. The list of the sub-

activities that have to be performed in order to

satisfy the CMMI practice for performing

configuration audits are:

1. Assess the integrity of the baselines

2. Confirm configuration records correctly identify

the configuration of the configuration items

3. Review the structure and integrity of the items

in the CM system

4. Confirm the completeness and correctness of

the items in the CM system

5. Confirm compliance with applicable CM

standards and procedures

6. Track action items from the audit to closure

This practice in CMMI has no equivalent practice

within the medical device regulations. The medical

device regulations do not specify any need for

auditing the CM processes and activities. Therefore

CMMED contains no activities, as a result of

mapping the regulatory medical device requirements

for CM against each of the activities required for the

CMMI practice relating to performing configuration

audits.

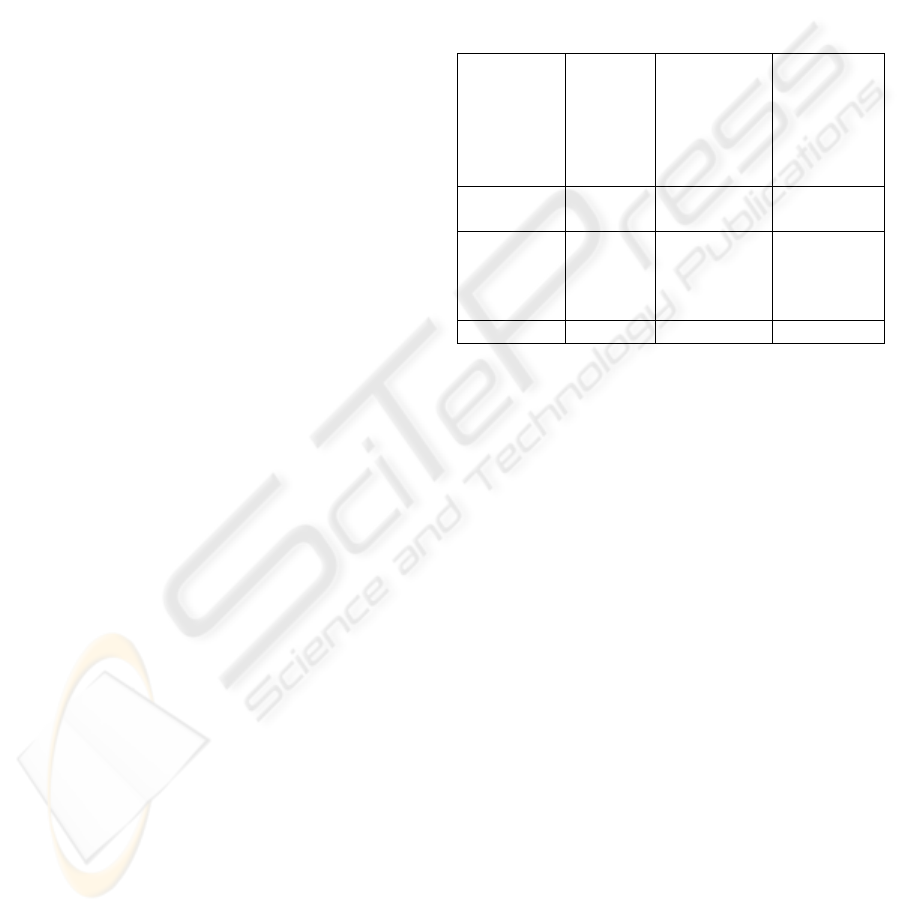

4.3.3 Summary of CMMED Goal 3

Table 3 summaries goal 3 of the CMMED (Establish

Integrity). It may now be determined that in order to

satisfy medical device standards that not all of

activities of this CMMI goal have to be performed

(in fact only 3 of the 12 CMMI activities have to be

performed. Additionally, no additional (medical

device specific) activities have to be added in order

to satisfy the objectives of CMMED.

Table 3: Summary of CMMED Goal 3.

Practice CMMI

activities

CMMI

activities to

meet

medical

device

standards

Additional

activities to

meet

medical

device

standards

Establish

CM records

6 3 0

Perform

configurati

on

audits

6 0 0

Total 12 3 0

5 PRELIMINARY FEEDBACK

In order to assist with preliminary feedback, the CM

process outlined by this paper has been compared

against the existing practices within an Irish medical

device company. A high level summary of their

comments are included below.

They liked the structure of the CMMED and in

particular how it enabled them to create a list of all

the CM practices that they should adopt in order to

adhere to the medical device standards. They also

made positive comments in relation to CMMED

providing additional information in relation to how

their existing CM practices could be improved by

incorporating guidance from the CM CMMI process

area in relation how mandatory medical device

activities may be performed.

Upon further consultation with the authors it has

also been decided that in order to assist with SPI

within the company that a process diagram shall be

created, this will provide a graphical representation

of the logical flow of the practices within their CM

process.

DEVELOPING A CONFIGURATION MANAGEMENT MODEL FOR USE IN THE MEDICAL DEVICE INDUSTRY

87

6 SUMMARY AND CONCLUSION

Table 4 provides a summary of the 3 goals within

CMMED. There are 40 activities required by

CMMED, consisting of 38 CMMI and 2 medical

device specific activities. In order to satisfy the

mandatory medical device CM requirements, 19 of

these activities have to be adhered to (17 CMMI and

2 medical device specific activities).

Table 4: Summary of CMMED Goals.

CMMED

goal

CMMI

activities

CMMI

activities to

meet medical

device

requirements

Additional

activities to

meet medical

device

requirements

Goal 1 17 6 1

Goal 2 9 8 1

Goal 3 12 3 0

Total 38 17 2

It is clear that following the guidelines specified in

the medical device regulations will at best, only

partially meet the specific goals of this CMMI

process area (this would only fulfil 17 of the 38

activities required by CMMI). Since failure to

perform any specific practice implies failure to meet

the specific goal, with respect to CMMI, it is clear,

that the goals of CM cannot be obtained by

satisfying medical device regulations and guidelines

during software development. But is the opposite

true, can meeting the CMMI goals for CM

successfully meet FDA and SW68 guidelines? With

the exception of 2 sub-practices, performing the

CMMI specific practices for CM would in general

more than meet the FDA and SW68 guidelines for

this area.

If a medical device company follows the CMMI

guidelines for CM (with the exception of 2

activities), this will more than fulfil the CM

requirements specified in the medical device

regulations. However, only a fraction of the CMMI

guidelines for CM will be satisfied by adhering to

the medical device regulations for CM

ACKNOWLEDGEMENTS

This research is supported by the Science

Foundation Ireland (SFI) funded project, Global

Software Development in Small to Medium Sized

Enterprises as part of Lero - the Irish Software

Engineering Research Centre (http://www.lero.ie).

REFERENCES

Automotive SIG, The SPICE User Group Automotive

Special Interest Group, Automotive SPICE Process

Reference Model, 2005.

Baskerville R. and Pries-Heje J., Knowledge Capability

and Maturity in Software Management, in The Data

Base for Advances in Information Systems, Spring

1999, Vol. 30, No. 2, 26-43.

Cass, A. and Volcker C., SpiCE for SPACE: A method of

Process Assessment for Space Projects, SPICE 2000

Conference Proceedings, http://www.synspace.com

Chrissis, M.B., Konrad, M. & Shrum, S., CMMI:

Guidelines for Process Integration and Product

Improvement, Addison Wesley, 2003

Cusumano M. and Yoffie D., Software Development on

Internet Time, IEEE Computer, Vol. 32, No. 10, Oct.

1999, 60-69.

European Council Directive 93/42/EEC Concerning

Medical Devices, 14 June 1993.

Fayad M. and Laitinen M., Process Assessment

Considered Wasteful, Communications of the ACM,

Vol. 40, No. 11, 1997, 125-128.

FDA Regulations, Code of Federal Regulations 21 CFR

Part 820, Food and Drug Administration, June 1997.

FDA/CDRH Guidance Document, General Principles of

Software Validation, FDA, June 1997.

FDA/CDRH Guidance Document, Guidance for Off-the-

Shelf Software Use in Medical Devices, FDA,

September 1999

FDA/CDRH Guidance Document, Guidance for the

Content of Premarket Submissions for Software

Contained in Medical Devices, FDA, May 2005.

GAMP, Guide for Validation of Automated Systems

(GAMP 4), International Society for Pharmaceutical

Engineering, December 2001

Ghezzi C., Jazayeri M. and Mandrioli D., Fundamentals of

Software Engineering, Prentice Hall, 2003.

Humphrey W., Introduction to the Team Software

Process, Addison Wesley, 2000.

ISO/IEC 15504, Information Technology – Process

Assessment – Part 5: An exemplar Process Assessment

Model, ISO/IEC JTC1/SC7, October 2003.

ISO/IEC 12207, Information technology - Software

lifecycle processes Amendment 2, International

Standards Organisation, 1995.

Jonassen-Hass M.E., Configuration Management

Principles and Practice, Addison Wesley, 2002.

Medical device software life cycle processes, American

National Standard / Association for the Advancement

of Medical Instrumentation, SW68, 2001.

McCaffery F., Donnelly P., Dorling A. and Wilkie G., A

Software Process Development, Assessment and

Improvement Framework for the Medical Device

Industry, Proceedings Fourth International SPICE

Conference on Process Assessment and Improvement,

Lisbon, Portugal, April 2004.

ICSOFT 2006 - INTERNATIONAL CONFERENCE ON SOFTWARE AND DATA TECHNOLOGIES

88