A FORMAL APPROACH TO DEPLOY HETEROGENEOUS

SOFTWARE COMPONENTS IN A PLC

Mohamed Khalgui and Emanuele Carpanzano

ITIA - Institute of Industrial Technologies and Automation CNR 20131 Milan, Italy

Keywords:

Component Based Technologies, Industrial Control Systems, Multi-tasking PLCs, Deployment, Real-Time

Scheduling.

Abstract:

This paper deals with an industrial control application following different component-based technologies.

This application, considered as a network of heterogeneous components, has to be deployed in a multi-tasking

PLC. It has classically to respect temporal constraints according to specifications. To deploy the components in

feasible OS tasks of the controller, we propose to fix a formal component model allowing their homogeneous

design. We enrich, in particular, this model to unify well known technologies. The application is considered

then as a network of homogeneous components. We propose to transform this network into a real-time tasks

system with precedence constraints to exploit previous results on real-time deployment.

1 INTRODUCTION

The development of critical industrial control appli-

cations is nowadays a very complicated activity basi-

cally due to the always increasing set of functional

and non-functional requirements. Control applica-

tions have to satisfy stringent real-time constraints

that are difficult to be addressed following the tradi-

tional development approaches. This problem is more

complicated by the continuously increasing demand

for shorter development time. This also imposes the

demand for shorter verification phase. The compo-

nent based development is widely accepted by indus-

try as a successful paradigm to address these require-

ments (Crnkovic and Larsson, 2002).

Nowadays, several component based technologies

have been proposed to develop control applications

(Crnkovic and Larsson, 2002). These technologies

allow to reuse already developed components avail-

able in rich libraries. In addition, they support the

modularity reducing the design complexity. Never-

theless, the majority of these technologies depend on

particular companies or projects (Crnkovic and Lars-

son, 2002). Therefore, the use of the corresponding

libraires is limited.

In this paper, we propose to reduce the realiza-

tion time of applications by exploiting the advan-

tage and also the component library of each one of

the known component-based technologies. Therefore,

a control application is a network of heterogeneous

components following different technologies. These

components have classically to respect functional and

temporal constraints described in specifications. To

our knowledge, there is no approach considering such

functional architecture of component-based applica-

tions. The problem that we tackle in this paper is how

can we validate the application components whereas

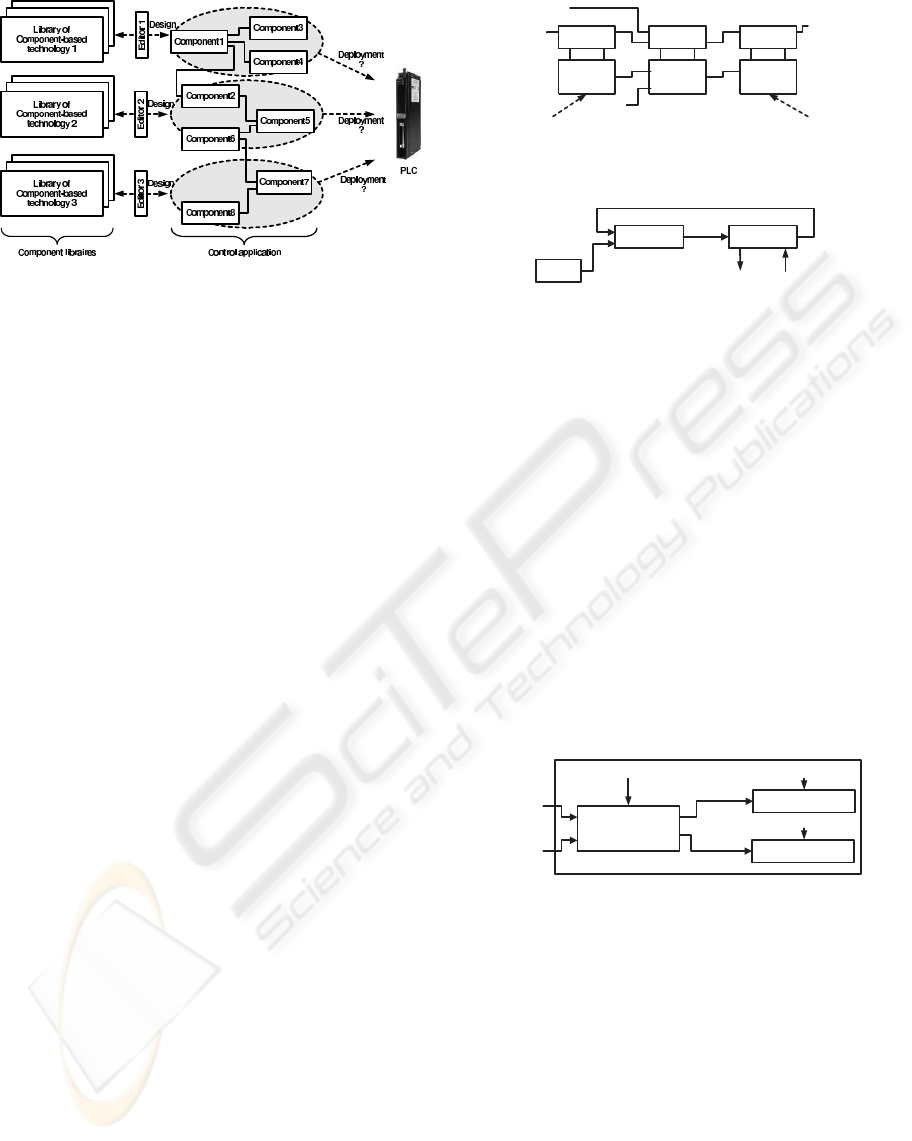

they are developed using different technologies (fig-

ure 1)? Moreover, how can we deploy these compo-

nents in feasible OS tasks of a PLC ?

To resolve this problem, we propose to fix a for-

mal component model (Sifakis, 2005) to unify all the

known component-based technologies. In addition,

we enrich this model to take into account character-

istics of these technologies. Thanks to this model,

the application is transformed then into a network of

homogeneous components having the same charac-

teristics. To correctly deploy these components, we

propose to transform them into a real-time tasks sys-

tem with precedence constraints. The purpose is to

exploit previous results on deployment and schedul-

ing of component-based applications (Khalgui et al.,

207

Khalgui M. and Carpanzano E. (2007).

A FORMAL APPROACH TO DEPLOY HETEROGENEOUS SOFTWARE COMPONENTS IN A PLC.

In Proceedings of the Second Inter national Conference on Software and Data Technologies - SE, pages 207-212

DOI: 10.5220/0001340502070212

Copyright

c

SciTePress

Figure 1: Deployment of a control application based on het-

erogeneous components.

2006).

In the section 2, we briefly present the well known

industrial component-based technologies. Then, we

detail a particular approach that we exploit in all the

continuation as a unifying component model. In the

section 4, we propose to enrich this formal approach

to be compliant with the known industrial technolo-

gies. To deploy a control application, we propose in

the section 5 to transform the corresponding homoge-

neous components into a subtasks system with prece-

dence constraints.

2 COMPONENT-BASED

TECHNOLOGIES

Nowadays, several component-based technologies

have been proposed to develop industrial control ap-

plications (Crnkovic and Larsson, 2002). These tech-

nologies depend often on particular industrial compa-

nies or projects. Each one proposes a particular char-

acterization of the component concept. In this section,

we briefly present the most known technologies in in-

dustry.

The IEC 61499 standard (Crnkovic and Larsson,

2002) is a component-based standard allowing the de-

velopment of distributed control applications. Ac-

cording to this standard, a function block is a an event

triggered component owning data and an application

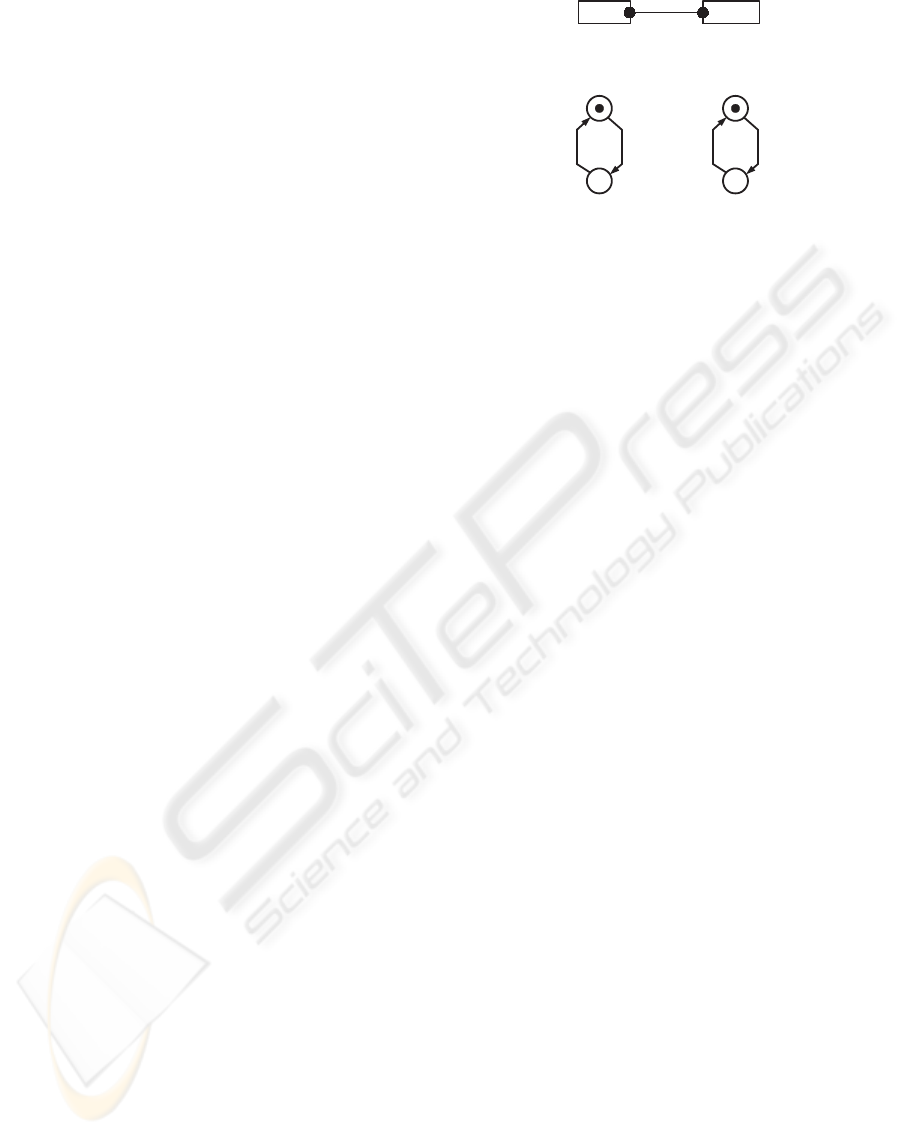

is a network of blocks. In the figure 2, we present

a simple example of a Temperature Regulator pro-

posed in (Lewis, 2002). This regulator is composed

of two interfaces blocks (Input1 and Output1) and a

regulation block PID1. A detailed description of this

example is available in (Lewis, 2002).

The Carnegie Mellon university proposes also its

owner component concept named Port Based Object

(Crnkovic and Larsson, 2002). This technology is of-

ten used to develop industrial control applications in

E_RunE_Exo E_Init

E_Run

E_Exo

E_Exo

E_ExoE_Run

Out

PV

SP

Out

Out

E_Init

Setpoint

Input1 Output1PID1

Temperature sensor Heater actuator

Figure 2: A FB Component : TemperatureRegulator.

Regulate Interface

Cyclic

Actuator Actuator

V

mesured

V

desired

V

regulated

V

mesured

Figure 3: A PBO Component : Speed Regulator.

robotics. A PBO component is a particular case of

a Function Block. The figure 3 presents the Speed

Regulator as a simple example of PBO components

regulating the vehicle speed. The component Cyclic

sends periodically the desired values to Regulate

which regulates the values measured from the com-

ponent Inter face (Crnkovic and Larsson, 2002).

The Arcticus Systems propose also another com-

ponent model called ”Rubus” (Crnkovic and Larsson,

2002). This technology allows to consider functional

and temporal constraints on application components.

In the figure 4, we present BrakeSystem as a simple

example of Rubus components to use in a vehicle.

The component BrakeLe ftRight allows to brake left

or right by considering the pressure and also the speed

of the vehicle.

Task :

BrakeLeftRight

Task :

OutputBrakeleft

Pressure

Speed

Task state information Task state information

brake left

brake right

Task :

OutputBrakeright

Task state information

Figure 4: A Rubus Component : BrakeSystem.

By studying these component-based technologies,

the component concept is quietly the same from a

technology to another. In addition, these technolo-

gies provide rich libraries. Therefore, it is interesting

to exploit them in the order to reduce the realization

time of an industrial control application. In all the

continuation, we consider a control application as a

network of heterogeneous components following dif-

ferent technologies.

ICSOFT 2007 - International Conference on Software and Data Technologies

208

3 FORMALIZATION

To cover all the component-based technologies, we

propose to fix a formal approach unifying the compo-

nent concept. Nowadays, several formal approaches

have been proposed. In this paper, we select the best

one that supports a detail specification of interactions

between components (Sifakis, 2005). This approach

defines classically a component as interfaces and an

implementation. Let us consider an application con-

taining K components. According to (Sifakis, 2005),

the application is characterized by a set of actions A

supporting its different functionalities. An application

component comp

i

i ∈ [1,K] is a subset of actions A

i

(A

i

⊂ A). An action is implemented by an algorithms

sequence in the component. We note, in addition, that

the application components are with disjoined subsets

of actions (A

i

∩ A

j

=

/

0). To specify an application,

(Sifakis, 2005) proposes the following models :

• Interaction model : defines the interactions be-

tween the application components.

• Behavior model : defines the behavior of each

application component.

• Execution model : defines a fixed priority policy

allowing the execution of the application compo-

nents.

In this paper, we just describe the two first models.

3.0.1 Interaction Model

To specify interactions between components, (Sifakis,

2005) defines the connector concept. A connector c

defines a maximally compatible set of interacting ac-

tions between components. It is a non empty subset

of A such as

∀i ∈ K,

|

A

i

∩ c

|

≤ 1

Given a connector c, an interaction α of c is de-

fined in (Sifakis, 2005) as any term of the form

α = a

1

|a

2

....|a

n

,{a

1

,...., a

n

} ⊆ c

The operator ”|” is a binary associative and com-

mutative operator. It is used to denote a composition

of actions. The interaction a

1

|a

2

....|a

n

is the result

of simultaneous occurrences (or execution) of the ac-

tions a

1

,....., a

n

. Note that if α = a

1

|a

2

....|a

n

is an

interaction of a connector, then any term correspond-

ing to a subset of {a

1

,a

2

....,a

n

} is also an interaction.

Finally, one denotes by I(c) (resp, I(C)) the set of in-

teractions corresponding to a connector c (a set C of

connectors).

Producer Consumer

put get

Figure 5: Producer / Consumer composition.

putprod consget

Producer

Consumer

Figure 6: The behavioral model.

3.0.2 Behavioral Model

According to (Sifakis, 2005), the behavior of an ap-

plication component is defined as a transitions sys-

tem. This system is classically characterized by a

triple (Q,I(A),→) where,

• Q is a set of states,

• I(A) is a set of interactions between actions of A,

• →⊆ QXI(A)XQ is a transition relation. As usual,

one writes q

1

α

→

q

2

to denote a transition be-

tween q

1

and q

2

.

3.1 Example

To illustrate these two models, we present in the figure

5 the classic example of Producer/Consumer. These

two components interact together through the put|get

of the connector {put, get}. We present in the fig-

ure 6 the behavioral models of the two components.

We note that prod and cons are internal actions of the

components Producer and Consumer.

4 EXTENSIONS AND

ASSUMPTIONS

Although this formal approach is expressive to model

component based applications, it is not compli-

ant with the known component-based technologies.

Therefore, we propose to enrich this approach by sev-

eral concepts. We propose to classify first of all the

component actions in input, internal and output ac-

tions. In addition, we propose a functional and tem-

poral characterization of a control application.

4.1 Component Actions

Let c be a component of a control application. We

propose the following sets to characterize the corre-

A FORMAL APPROACH TO DEPLOY HETEROGENEOUS SOFTWARE COMPONENTS IN A PLC

209

sponding actions :

• external(c) : the set of input/output actions (in c)

interacting with outside.

• internal(c) : the set of internal actions (in c). An

internal action can be activated by more than one

input action.

We define for each internal action act of a compo-

nent c (act ∈ internal(c)) the following external ac-

tions :

• input(act) : a set of input actions activating act

(input(act) ⊆ external(c)).

• output(act) : a set of output actions to activate

once the execution of act finishes (output(act) ⊆

external(c)).

Finally, we denote by In

Act (resp, Out Act) the

set of input (resp, output) actions in the application (∀

act ∈ internal(c), input(act) ⊂ In Act, output(act)

⊂ Out

Act).

4.2 Composition of Components

To be compliant with several industrial component-

based technologies, we enrich the functional architec-

ture of a control application.

4.2.1 Container Concept

In several component-based technologies (Crnkovic

and Larsson, 2002), the container concept is proposed

to gather application components controlling physical

processes. A container is a logical execution unit cor-

responding to time slots of the processing unit. In this

paper, we propose the following definition of a con-

tainer.

Definition. a container is a set of application

components sharing the control of physical processes.

It is characterized by a sequencing function defining

the static scheduling of the internal components. We

apply a non-preemptive policy to process this func-

tion.

In the operational architecture, we propose to con-

sider a container as an OS task. This task imple-

ments all the possible execution scenarios of the in-

ternal components. The sequencing function of the

container is the ”main()” function of this task.

4.2.2 Temporal Constraints

We propose the function cause specifying causalities

between output actions of application components

and input actions of another ones. Two actions are

under a causality constraint if they belong to a same

interaction of a connector.

∀ia ∈ In

Act,

cause(ia,c) = {ϕ ∈ Out

Act/∃i ∈ I(C),{ia} ∪ ϕ ∈ i}

In the Producer/Consumer example, we note that

cause(get,consumer) = {put}. According to specifi-

cations, we define End to End Response Time Bounds

between periodic readings from sensors and the acti-

vation of the corresponding actuators. The scheduling

of the application components has to take into account

these bounds.

Finally, by considering this formal approach, each

control application (following different technologies)

becomes a network of homogeneous components dis-

tributed on several containers of a controller. Ac-

cording to specifications, these components have to

respect bounds on their response times.

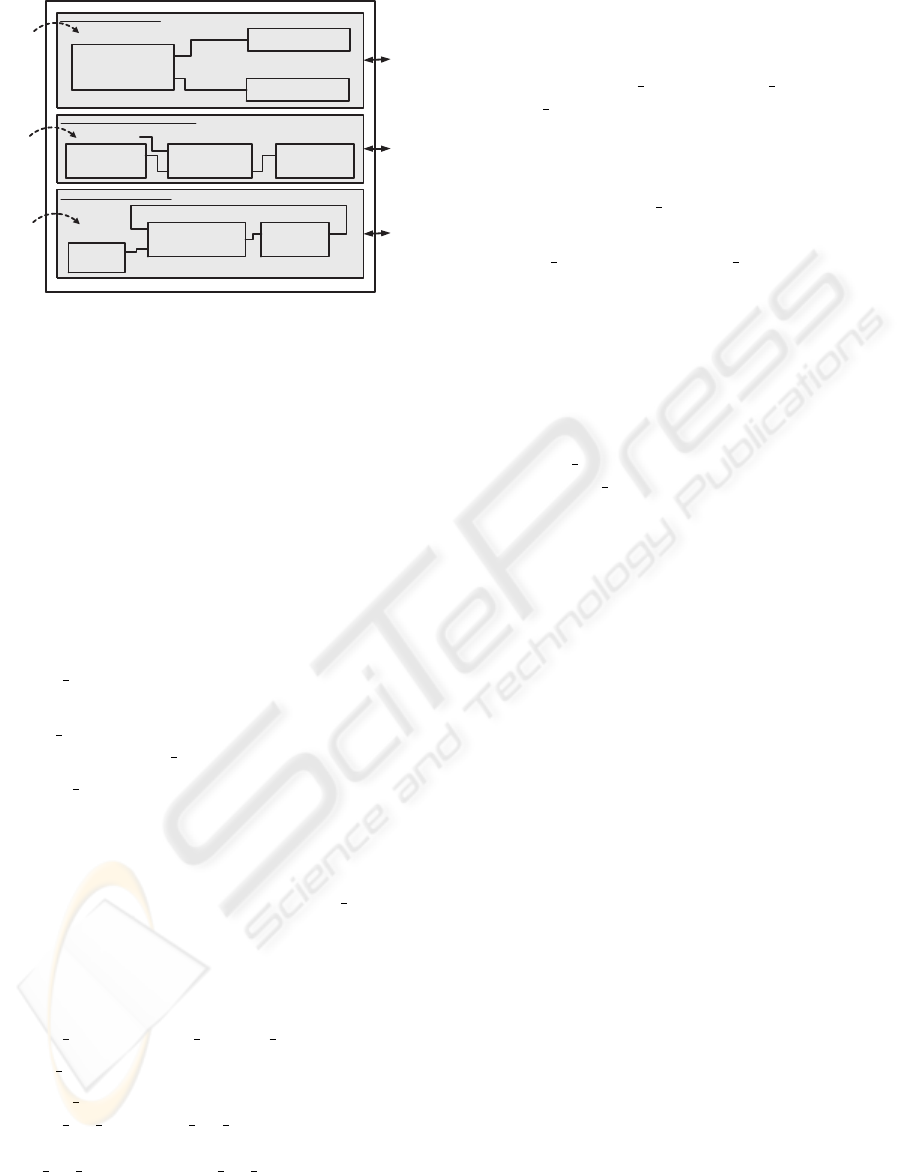

Running example. In all the continuation, we

consider as an example a control application embed-

ded in a vehicle. This application is composed of the

following sub-applications to distribute on three con-

tainers :

• The temperature regulator developed while fol-

lowing the IEC 61499 technology.

• The speed regulator developed while following the

PBO technology.

• The brake system developed while following the

Rubus technology.

To deploy the application in OS tasks of the exe-

cution support, we have to transform the correspond-

ing heterogeneous components into formal homoge-

neous ones (figure 7). In the container 1 containing

components controlling the break system, we distin-

guish two interactions : act

out le ft | act left and

act

out right | act right. In this container, when the

input actions (act

pres and act speed) of Comp1 are

activated, we have to execute the internal action Act1

deducing the brake to activate. Once the execution

ends, we activate act

out le ft OR act out right de-

pending on the data pressure and speed.

5 SUBTASKS SYSTEM

Once the heterogeneous components of the applica-

tion are unified in a same model, the remaining prob-

lem is to deploy them in feasible OS tasks of the ex-

ecution support. We propose to transform first of all

these components into a subtasks system with prece-

dence constraints. The purpose is to exploit previous

results on the real-time scheduling. We define the fol-

lowing concepts characterizing such system.

ICSOFT 2007 - International Conference on Software and Data Technologies

210

Act1

Act2

brake left

brake right

Act3

act_pres

act_speed

act_out_left

act_out_right

Comp1

Comp2

Comp3

act_left

act_right

container 1 : BrakeSystem

Act4

act4_run act4_exo

Init, Act5

act5_init

act5_run

act5_exo1

act5_exo2

Act6

act6_run act6_exo

container 2 : Temperature regulator

Comp4 Comp5 Comp6

Act8

act_mesured

act_desired

act_reg

Act7

out_cyc

Act9

act_reg act_mes

V

mesured

V

desired

container 3 : Speed regulator

Device

Comp7

Comp8 Comp9

PBO

technology

FBs

technology

Rubus

technology

Brakes

Heater

Regulator

Figure 7: Distribution of the formal components on con-

tainers of the execution support.

5.1 Subtask

An application subtask, denoted by sub, corresponds

to an execution of a component c when corresponding

input actions are activated. In addition to these ac-

tions, the subtask sub implements the corresponding

internal and output actions of the component. To gen-

erate the different subtasks of a component, we have

quite simply to analyze the corresponding behavioral

model. In this paper, we propose the following func-

tions defining a subtask of a component.

• cause

of (sub) : defines the input actions activat-

ing the execution of sub.

• code o f(sub) : defines the internal actions to exe-

cute once the cause

of (sub) actions are activated.

• e f fect

of (sub) : defines supersets of output ac-

tions. These sets are generated while applying an

analysis of the interaction model. Each set repre-

sents a possible execution scenario of the compo-

nent. At run-time, we have to execute only one of

them depending on the execution of code

of (sub)

actions.

Running example. In the example, we define for

the componentComp1 a subtask Sub1. We character-

ize this subtask as follows,

• cause

of (sub) = {act pres,act speed}

• code

of (sub) = {Act1}

• e f fect

of (sub) =

{{act

out le ft},{act out right}}. Once the

execution of Act1 finishes, we have to execute

act out left OR only act out right.

Let Σ be the set of the application subtasks. We

propose to characterize a component subtask sub as

follows,

• WCET(sub) (resp, BCET(sub)) : the Worst

(resp, Best) Case Execution Times of the

algorithms implementing the actions be-

longing to cause

of (sub), code of (sub) and

ef fect

of (sub).

• pred(sub) : a set of sub-tasks to execute in the

application before sub. These subtasks belong to

components that contain the output actions acti-

vating those of cause

of (sub).

pred(sub) = {sub

′

∈ Σ/∃ia ∈

cause

of (sub),∃ψ ∈ ef fect o f(sub

′

),∃oa ∈

ψ,oa ∈ cause(ia)}

• succ(sub) : a set of subtasks sets. Each subtasks

set corresponds to a possible execution scenario

(ie. only one subtasks set between all ones is ex-

ecuted at run-time). The subtasks of a set have to

be executed once the execution of sub is finished.

succ(sub) = {φ ⊂ Σ/∃ψ ∈

ef fect

of (sub),∀oa ∈ ψ, ∃sub

′

∈ φ,∃ia ∈

cause

of (sub

′

),oa ∈ cause(ia)}

Let σ be a subset of Σ. This subset corresponds

to a particular container of the application. We de-

note by first(σ) (resp last(σ)) the set of subtasks with

no predecessors (resp successors) in σ. In this paper,

we propose particularly to characterize each subtask

sub of first(σ) by a release time r(sub) and a period

p(sub).

Running example. In the followed example, the

subtask sub1 is with no predecessors. In addition,

once it is executed, we have to execute the subtasks

sub2 OR sub3 depending on the pressure and the

Speed.

pred(sub1) =

/

0; pred(sub2) = {sub1}

succ(sub1) = {{sub2},{sub3}}

5.2 Subtasks Trace

By considering the precedence constraints between

subtasks, we define a trace tr of σ the following se-

quence,

tr = sub

0

, sub

1

...., sub

n−1

such as,

• ∀sub

i

∈ [1,n− 1],sub

i−1

∈ pred(sub

i

).

• sub

0

∈ first(σ) and sub

n−1

∈ last(σ).

The trace tr implements a possible execution sce-

nario of σ. Such execution has to respect a particular

end to end response time bound (between the activa-

tion of sub

0

and the execution end of sub

n−1

) accord-

ing to specifications.

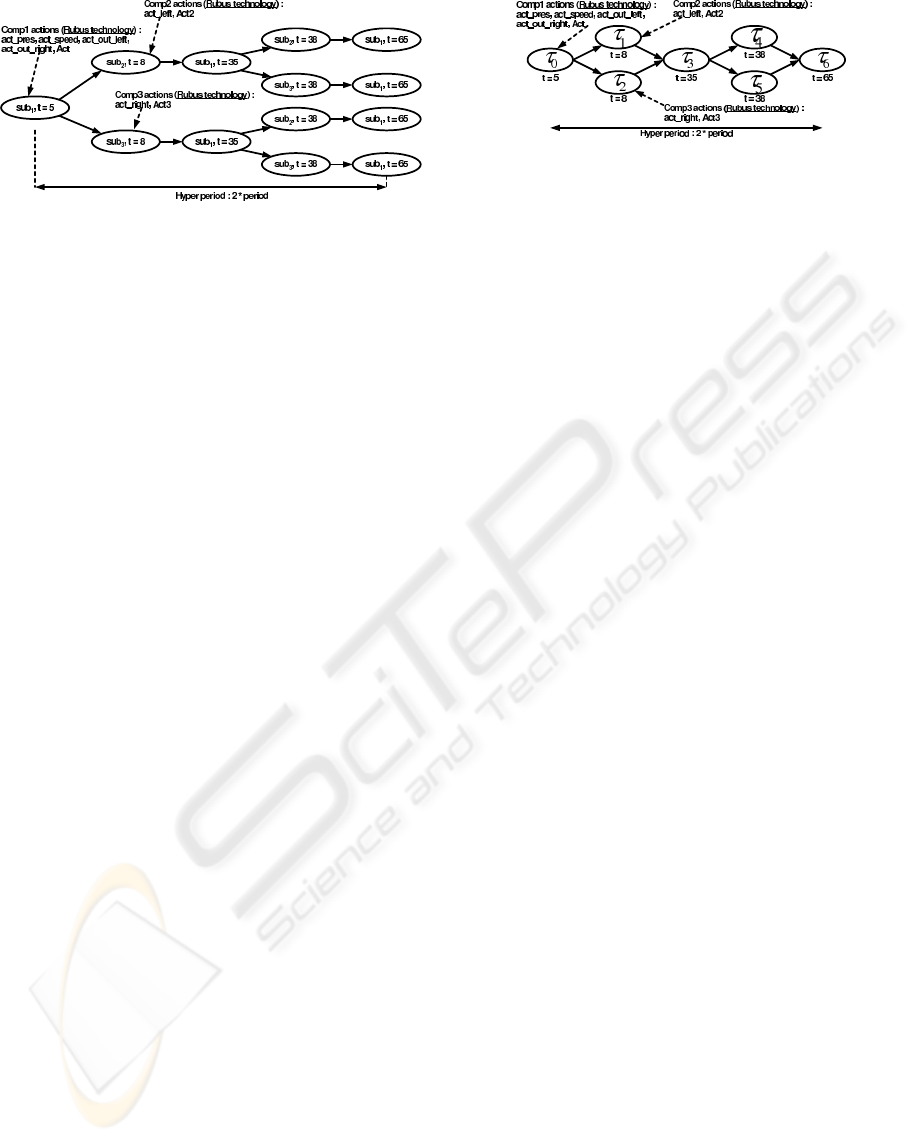

Running example. In the same followed example,

we distinguish two traces in the first container.

A FORMAL APPROACH TO DEPLOY HETEROGENEOUS SOFTWARE COMPONENTS IN A PLC

211

Figure 8: Temporal validation of the container1 containing

Rubus components

trace

1

= sub

1

,sub

2

and trace

2

= sub

1

,sub

3

6 DEPLOYMENT OF

COMPONENTS

Once the application components are correctly trans-

formed into a system of subtasks with precedence

constraints, the problem is to deploy them in feasible

OS tasks of a PLC. We propose to apply the approach

particularly proposed in (Khalgui et al., 2006) for the

deployment of systems of real-time subtasks. Accord-

ing to this approach, we apply a schedulability anal-

ysis on each container to check the internal blocks.

This analysis is based on a generation of an accessi-

bility graph that we propose. Once all the containers

are feasible, we propose to transform them into inde-

pendent OS tasks before checking their on-line pre-

emptive feasibility (Khalgui et al., 2006).

Running example. In the followed example, we

suppose periodic readings of the pressure and the

speed values (the release time r = 5 and the pe-

riod p = 30). Moreover, we suppose that the worst

and best case execution times of each action act

(act ∈ Σ) are bcet(act) = wcet(act) = 1. Therefore,

BCET(sub

1

) = WCET(sub

1

) = 3. In the figure 8,

we present the accessibility graph corresponding to

the container 1. Once the container 1 is temporally

validated, we construct a corresponding OS task that

implements the different execution scenarios of the in-

ternal components (figure 9). The processed sequenc-

ing function is the main() function of this task where

each subtask implements a set of application actions

(Khalgui et al., 2006).

7 CONCLUSION

This paper deals with the deployment of industrial

control applications following different component-

Figure 9: OS task implementing the first container contain-

ing Rubus components.

based technologies. The purpose is to reduce the real-

ization time by exploiting the advantages and the dif-

ferent libraries of these technologies. To deploy the

application on a multi-tasking PLC while satisfying

the specifications constraints, we propose to fix a par-

ticular formal component-based approach in the or-

der to cover all the known technologies. We propose

also to enrich this approach to be compliant with these

technologies. Therefore, the heterogeneous compo-

nents of the application are considered as homoge-

neous formal ones. We propose to transform them

into a subtasks system with precedence constraints to

construct corresponding feasible OS tasks in the PLC.

In the future works, we plan to extend our research

by considering re-configurable applications following

different technologies. We have, first of all, to de-

fine the different reconfiguration scenarios of the het-

erogeneous components of the application. Then we

have to study their deployment for each scenario case.

REFERENCES

Crnkovic, I. and Larsson, M. (2002). Building reliable

component-based software systems. Artech House.

London.

Khalgui, M., Rebeuf, X., and Simonot-Lion, F. (2006).

Component-based deployment of industrial control

systems : an hybrid scheduling approach. In ETFA06,

Czech.

Lewis, R. (2002). Modelling Control Systems using

IEC61499. The institution of Electrical Engineers.

Sifakis, J. (2005). A Framework for Component-based Con-

struction. 3rd IEEE International Conference on Soft-

ware Engineering and Formal Methods (SEFM05).

ICSOFT 2007 - International Conference on Software and Data Technologies

212