VEHICULAR ELECTRONIC DEVICES CONNECTED BY

ONBOARD FIELDBUS TECHNOLOGIES

Miguel A. Domínguez, Perfecto Mariño, Francisco Poza and Santiago Otero

Electronic Technology Department

University of Vigo

E.T.S.I. Industriales, Campus Lagoas-Marcosende, 36280, Spain

Keywords: Vehicular Control, Fieldbuses, CAN, City Public Transport Buses, Multiplexed Solutions.

Abstract: The electrical circuits and their Electronic Control Units (ECUs) in buses and coaches are essential for their

good working. Drive, braking, suspension, opening door, security and communication devices must be

integrated in a reliable and real time information system. The industrial communication networks or

fieldbuses are a good solution to implement networked control systems for the onboard electronics in the

public transport buses and coaches. The authors are working in the design of multiplexed solutions based on

fieldbuses to integrate the body and chassis functions of city public transport buses. An example for the

EURO5 model of the Scania manufacturer is reported in this paper. The authors are also working in the

implementation of new modules based on FPGAs (Field Programmable Gate Arrays) that can be used in

these networked control systems.

1 INTRODUCTION

Nowadays, the commercial buses and coaches are

more and more equipped with electronic devices that

make it easier to drive the vehicle and improve their

security and comfort. These electronic devices are

applied to functions such as Electronic Stability

Program (ESP), braking help system (ABS), gear

control, light control, climate control, opening door

control, navigation and guide (based on GPS: Global

Positioning System and GIS: Geographic

Information System), etc. These functions require

the use of reliable and real time exchange of

information between the different control systems

and the sensors and actuators. Thus, it becomes

necessary the use of an industrial communication

network or fieldbus (Marsh, 1999).

At the beginnings of 1980s the engineers of the

automobile manufacturers assessed the existing

fieldbuses for their using in vehicles. They came to

the conclusion that any of these protocols fulfilled

their requirements. It supposes the development of

new fieldbus protocols (Mariño, 2003).

Each manufacturer has bet for a particular

solution. For example, Bosch developed the CAN

protocol, Volkswagen implemented the A-BUS,

Renault and the PSA Consortium used the VAN

protocol, BMW tried it with the M-BUS and Honda

with the DLCS. The majority of these manufacturers

evolved and adopted for the general purpose

communication the CAN standard (Bosch, 1991)

(ISO 11898, 1992) (ISO 11519-2, 1995).

For other functionalities, such as low speed smart

sensors, multimedia, high speed and safety

applications, the manufacturers are adopting other

protocols in the last years. For example, the Firewire

(IEEE 1394), MOST (Estevez, 2004), D2B optical

and D2B Smartwirex are used for high speed

multimedia applications; TTP, Byteflight and

FlexRay for high speed and safety applications; and

LIN for low speed smart sensor communication

(Marsh, 2005) (Bender, 2004).

2 MULTIPLEXED SOLUTIONS

The buses and coaches used in the city public

transport have a lot of onboard electronic systems,

which must be integrated in an efficient way. These

systems must be connected to a single industrial

communication network with a Central Electronic

Control (CEC) node that manages, in real time, all

the information transmitted from the control

modules installed in the vehicle.

5

A. Domínguez M., Mariño P., Poza F. and Otero S. (2007).

VEHICULAR ELECTRONIC DEVICES CONNECTED BY ONBOARD FIELDBUS TECHNOLOGIES.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 5-10

DOI: 10.5220/0001616200050010

Copyright

c

SciTePress

There are several chassis manufacturers (Man,

Volvo, Scania, Iveco, Renault, Mercedes, etc.) and

every one proposed a different multiplexed solution.

But the use of the CAN protocol and other fieldbus

protocols based on CAN (for example SAE J1939)

(SAE, 2005) is a common point in these solutions.

The multiplexed networks installed in the city-

buses and coaches get an important reduction of the

wiring that involves a reduction in costs, less

breakdown risks and a simple scalability. The

maintenance is easier and the global management of

the technological systems is improved. The

transmission of the information is integrated with a

very low error rate. The control of the systems is in

real time supporting very high elemental information

traffic with command messages for actuators, data

from sensors and alarm events.

2.1 Structure of the Network

A generic structure of communication used in the

multiplexed solutions implemented currently in city

public transport buses is presented in this section.

The main problem in the public transport buses is

the increase of the requirements imposed to the

electronic and electrical systems. It is getting more

and more difficult to find adequate places for

plugging the components with the corresponding

wiring. The installation of circuits based on relays,

diodes and resistors is very complicate.

Other topic to take into account is the satisfaction

of the customer needs in a flexible and fast way. It is

difficult and expensive. A manual process according

to the documentation must implement the relay

switching. The electromechanical circuits have a

limited lifetime. The use of electronic switches in

power circuits is a good solution because achieve the

life time of the vehicle, increasing their reliability

and reducing the time out of service.

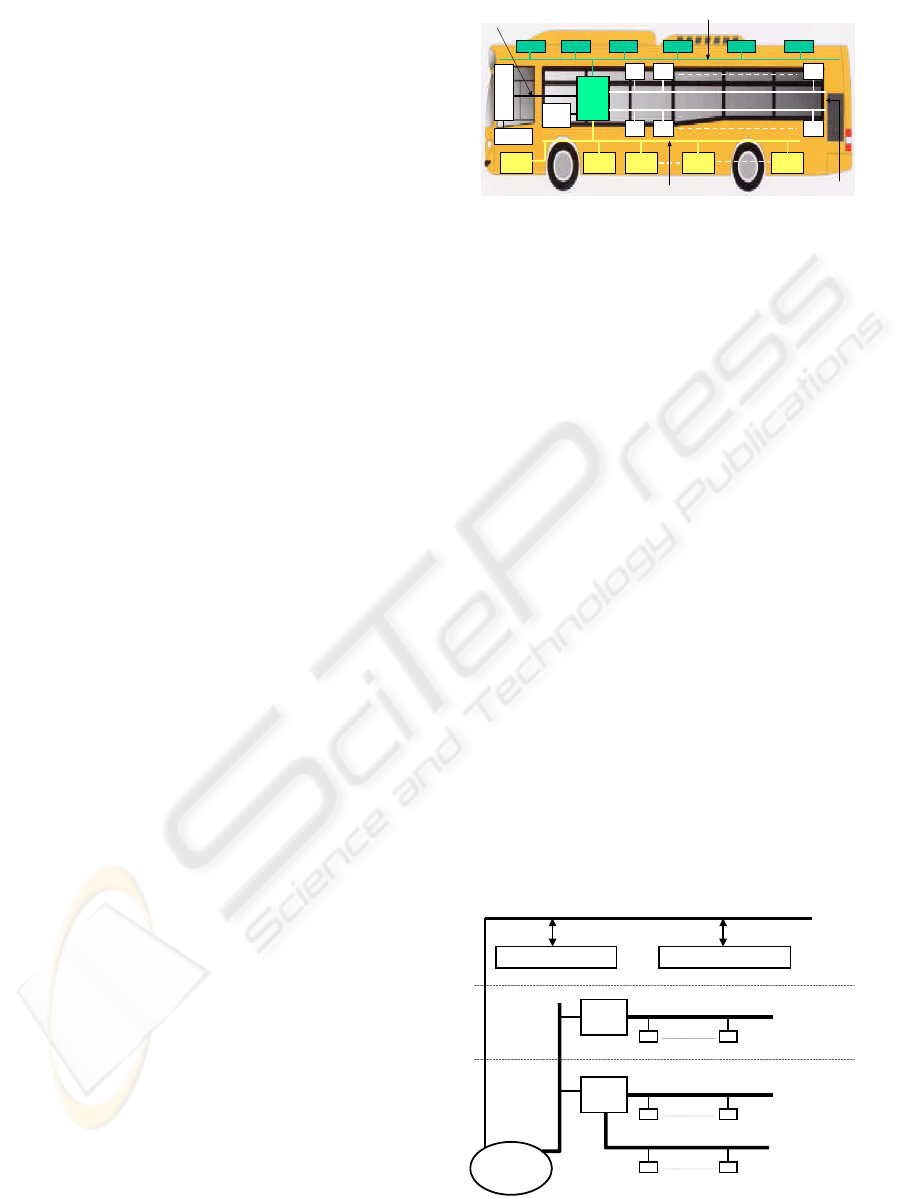

Due to the problems related before, the CAN

data bus has become into the automobile technology.

Thus, an example of a multiplexed solution based on

the CAN protocol for data communication in a city

public transport bus is shown in figure 1.

Independent data fieldbuses are used for the

different areas in the system.

The bus manufacturers have trend towards the

use of the VDV (Verband Deutscher

Verkehrsunternehmen) recommendation 234 (VDV,

1996) for the onboard information system integrated

in the dashboard. Therefore, the central unit must be

equipped with a VDV interface module.

CENTRAL

UNI T

DASHBOARD

Tachometer

Ge ar b ox EBS EDC

ECAS

EFR

RAS- EC

VDV

Interface

BM1 BM2 BMx

BM1 BM2 BMx

Door Plat form DoorCl i ma t e Cl i ma t e Cl i mat e

125 Kbps I-CAN

250 Kbps M-CAN

125 Kbps

B- CAN 1 and 2

125 Kbps B-CAN 3

Figure 1: An example of multiplexed solution.

The central unit must execute the classic

functions for the vehicle control and manage the

data traffic from the different CAN fieldbuses. Thus,

the central unit can report a full onboard diagnosis.

A typical multiplexed solution must consider the

integration of a video surveillance system and the

information for the passengers. This integration can

be implemented using a CAN network or other

fieldbuses more adequate for multimedia

information (J1708, WorldFIP, IEEE 1394/Firewire,

etc.). An example of the levels in a complete

communication system is shown in figure 2.

2.2 Reliability

The chassis and body electronic reliability is very

important in the public transport buses and coaches.

The central unit should not connect and disconnect

any power circuit. Based on city-bus manufacturers

knowledge, under this rule, the central unit will only

be implicated in one of each one thousand failures.

Three body CAN buses are contemplated to

communicate several body modules with the aim to

reduce the consequences of a breakdown. These

body modules should be protected against a global

overload with two security devices. Therefore, the

effects in case of failures are minimized.

PUBLIC TRANSPORT SYSTEM VIDEO SURVEILLANCE SYSTEM

PASSENGERS

ISO 11898 CAN network, J1708, WorldFIP, Firewire, ...

BODY

MODULE

BODY

CHASSIS

MODULE

CHASSIS

DASHBOARD

ISO 11898 CAN network

ISO 11898 CAN network

ISO 11898 CAN network

(SAE J1939)

ISO 11898 CAN network

(SAE J1939)

Figure 2: Levels in a typical city public transport bus.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

6

The modules control their outputs according to

the programmed emergency function when failures

are detected in the data fieldbus. In this way, the

outputs can be permanent connected, permanent

disconnected, intermittent connected or maintaining

the last state.

Other important application to get a good

reliability is that the body and chassis electronic

system supports a wide diagnostic. The central unit

should manage all the CAN networks and implement

their own diagnostic of the body and chassis

electronic system. Every output of the body modules

should be revised periodically to check that there are

not short circuits, overloads and interruptions. The

inputs should be controlled according to the

technical possibilities of the connected sensors.

2.3 Challenges

Every chassis manufacturer has developed its own

multiplexed solution based on CAN. The great

inversions made from manufacturers imply that

every one wants to impose its solution. The

integration problem is for the coachbuilder that

works with chassis from different manufacturers (ten

or more chassis). Each chassis has a different

multiplexed solution and only the modules chosen

by the manufacturer can be used. It involves that the

coachbuilder cannot have their own CAN system (an

unified management for the electrical part of the

body and chassis) and must use the modules chosen

by the manufacturer with a non-competitive price.

The SAE Truck and Bus Control and

Communications Sub-committee has developed the

J1939 standard. The J1939 standard is necessary to

sort the codifications that each manufacturer has

used to specify the same peripheral unit (device,

sensor) or the set of the units connected to the CAN

network in the city-buses and coaches. Besides of

the codification of the terminals, the standard

defines several common parameters and data rates.

Thus, the J1939 standard enables to the coachbuilder

connecting different modules to the CAN system

independently of the manufacturer.

3 DESIGN OF A NETWORKED

CONTROL SYSTEM

The authors are working in the design of a

networked control system that is a multiplexed

solution to integrate the onboard electronic devices

present in a typical city public transport bus. This

system should integrate all the sensors and actuators

present in the vehicle in an optimum way. Besides, it

must resolve those particular functions that actually

are not integrated in the multiplexed solutions of the

chassis manufacturers (Domínguez, 2006).

The paper will describe an example of design for

a vehicle of the Sweden chassis manufacturer

Scania. The features of the system, used modules,

software and requirements that must be taken into

account will be commented in the next paragraphs.

3.1 Implementation of the System

The aim of the project exposed in this paper is to

implement an onboard network in a city public

transport bus. This network allows the control of the

ECUs simplifying the wiring, removing electrical

components, improving the reliability and the

diagnostic and getting an open system.

There are different types of modules that are

necessary in the system: dashboard and chassis and

body modules (figure 2). The dashboard is where the

information about the devices of the bus is displayed

to the driver and also allows to the driver the control

of the system through switch packs. The dashboard

is usually made up of an Information Control Unit

(ICU) and a Screen Control Unit (SCU). It includes

a LCD or TFT VGA display where the information

is shown to the driver. The dashboard also has

multifrequency audio devices and LEDs to give

information about state of the devices and alarms.

The French firm ACTIA supplies the chassis and

body modules used in this design. There are master

modules or CAMUs (Central Management Units)

and slave modules or IOUs (Input/Output Units) and

are shown in figure 3. These modules have several

inputs and outputs of different types and implement

the CAN V2.0 B protocol. These modules must be

ready to work in the conditions of a vehicle in

motion. Thus, the protection level must be high

(IP65) and must endure the vibrations and fulfil the

electromagnetic compatibility standards.

CAMU

IOU

Figure 3: Chassis and body modules.

VEHICULAR ELECTRONIC DEVICES CONNECTED BY ONBOARD FIELDBUS TECHNOLOGIES

7

3.2 Inputs and Outputs

The first step in the design is the identification of the

electrical signals of the bus that must be connected

to the networked control system. These signals must

be described in detail with their location in the bus.

Some of the signals included in the control system in

the Scania bus of the project are listed in table 1.

The signals are named according to a specified

format. The first part of the name defines some

characteristics of the signal. Some prefixes used in

Table I are: IB (Input Binary) and OB (Output

Binary). For example, the signal IB_STOPREQ is a

binary (B) input (I) that is activated when a stop is

requested. The column type shows additional

information about the signals. For inputs, VBAT or

GND active indicates whether the signal when

activated is connected to the power supply or to the

ground. For outputs there can be types like: signal

(digital signals not intended for powering devices),

lights, inductive (protection needed against power

peaks), valve, etc.

Once the signals have been defined, the next step

is to choose the number of required CAMUs and

IOUs, their location in the bus and where the

electrical signals will be connected (the connector

pin of a specific CAMU or IOU). The designer must

bear in mind the different types of inputs and outputs

of the modules. The CAMUs and IOUs have the

following types of inputs and outputs:

Table 1: Some electrical z in the SCANIA city-bus.

Name Type I/O Power

IB_MSDOOR1 VBAT

ACTIVE

Input -

IB_MSDOOR2 VBAT

ACTIVE

Input -

IB_MSDOOR3 VBAT

ACTIVE

Input -

IB_STOPREQ VBAT

ACTIVE

Input -

IB_RAMPREQ VBAT

ACTIVE

Input -

IB_HANDBRAKE GND

ACTIVE

Input -

IB_ALTERNATOR VBAT

ACTIVE

Input -

IB_SMCSEC CAN Input -

OB_REARMDOOR1 VALVE Output 25 W

OB_DOOR1 SIGNAL Output -

OB_DOOR2 SIGNAL Output -

OB_DOOR3 SIGNAL Output -

OB_POSLIGHTS1 LIGHTS Output 25 W

OB_ENGINEON INDUCTIVE Output 240 W

OB_HANDBRAKEBUZZ INDUCTIVE Output 3 W

- Wake up inputs:

The signals that should wake up the system

are connected in these inputs.

- Logic inputs:

The detection of a “0” logic is from 0 V up to

1.8 V, and a “1” logic from 7 V up to 32 V.

- Analog inputs to ground:

The voltage in the input of the

microprocessor is directly proportional to the

value of the resistive load.

- Analog inputs to positive voltage:

These inputs consist in a resistive divisor.

- Frequency inputs:

These inputs can be used for PWM signals, as

for example the measurement of speed.

- High state and low state outputs:

The maximum direct current of these outputs

can be 9 A, 7 A, 5 A, 3.2 A, 2 A and 1.5 A.

- Free wheel diode output:

It is dedicated to inductive loads (relays,

electro valves) as for example wiper fast.

- Switched and unswitched outputs:

The power supply of the output interface of

high state signals can be unswitched

(connected directly to the battery) or switched

(connected after the master relay).

- PWM (Pulse Wide Modulation) outputs:

There are several outputs that can be used for

PWM (0-100% with 10% step) or frequency

(50-500 Hz with 50 Hz step) outputs.

- Bridge outputs:

They are used for bidirectional motors

(electrical windows, external wing mirror,

etc.) or for current measurements.

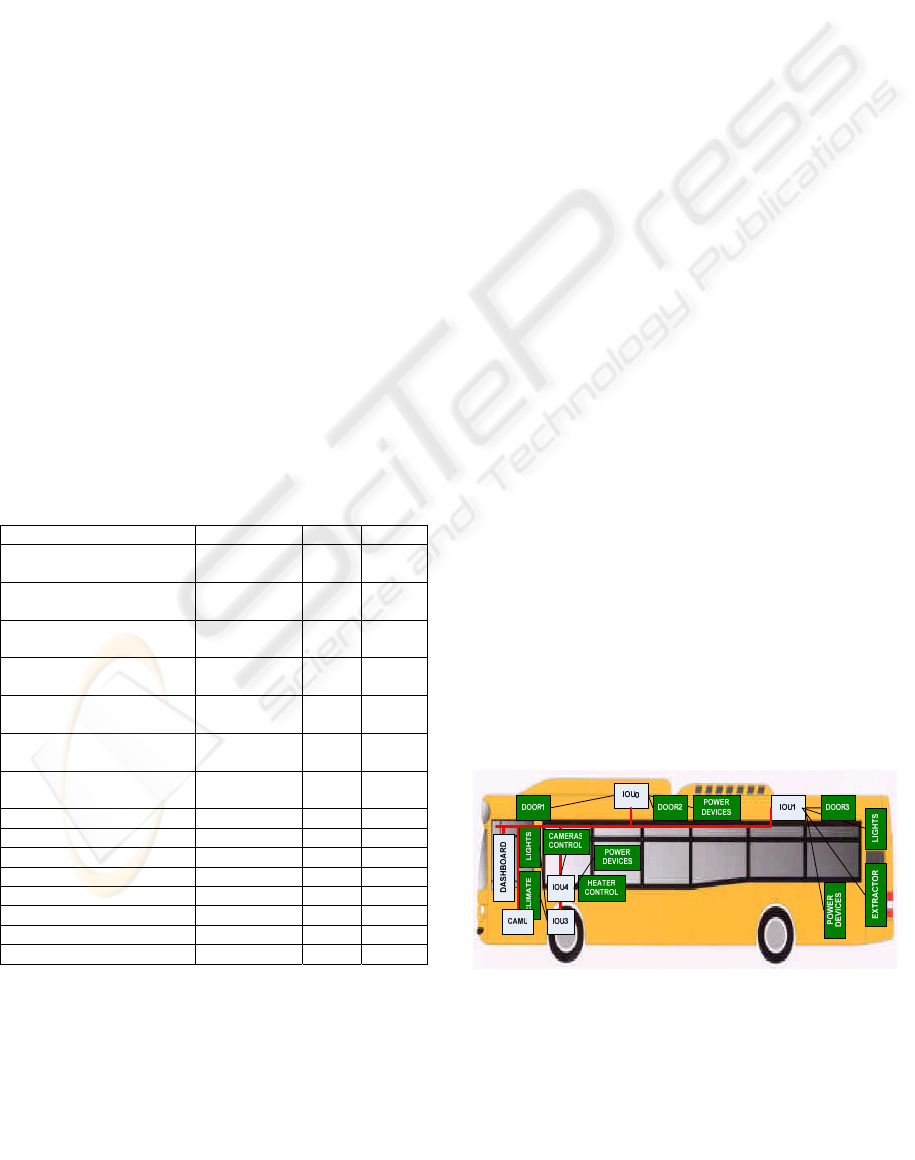

The number of CAMus and IOUs must be choice

taking into account the distribution of the signals in

the bus and also the power consumption, because the

modules define the maximum dissipated power by

group of outputs, the maximum total dissipated

power and the maximum permanent current.

Therefore, 1 CAMU and 4 IOUs have been required

in this design. The location of the modules and the

distribution of the signals are shown in figure 4.

Figure 4: Structure of the networked control system

onboard the bus.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

8

3.3 Software Tools

There are several software tools used for the coding

of the modules, validation and their installation:

ActiGRAF (the wiring definition and inputs/outputs

assignment), ISaGRAF (the functions specification),

Multitool (diagnostic of the ECUs and CAN nodes)

and Telemux (programming the ECUs).

For the design of a networked control system,

ActiGRAF is the project manager and ISaGRAF is

the programming environment. Thus, ISaGRAF is a

tool used for ActiGRAF for developing the

embedded software in the CAN modules of the

control system. ISaGRAF supports the whole

programming languages of the IEC 61131 standard.

An example of how the specification and

implementation of functionality is made using

Function Block Diagram (FBD) programming

language is shown in figure 5. The user indicates the

activation condition of the outputs depending on the

state of the inputs with typical function blocks.

Figure 5 shows a programming example where the

aisle lights of the bus are switched on if there is

battery voltage higher than 20 V (the master relay

has been activated), the parking lights are turned on

and the switch of the aisle lights is activated.

When the user designs the networked control

system of a bus, the ActiGRAF tool is used to

specify the central network of the vehicle (all the

master modules or CAMUs), the intra-system

network (all the slave modules or IOUs), the inter-

system network and other networks that can be

necessaries according to the requirements for the

electrical architecture of the vehicle. After, the

opening of the communication ports should be made

(enable the CAN and J1939 drivers) and the input

and output signals should be declared. The

ISaGRAF tool is used to define the whole

functionalities of the chassis and body functions of

the bus using the more adequate programming

language of the above mentioned.

Once the whole functionality and the wiring are

defined, it is necessary to build the application that

will be executed inside the modules. ActiGRAF uses

a C compiler for compiling the source code

generated by ISaGRAF. The compiler used for these

tasks is from the Keil Company. The used version is

for the C166 platform along with the RTX166. The

binary code generated by the compiler is loaded

using the Telemux application. Only the CAMU is

reprogrammed with the binary code. As soon as the

system is restarted, the CAMU automatically sends

the new application and wiring data to all the IOUS

of the system.

Figure 5: Example of the specification of a function in a

bus using the ISaGRAF tool.

4 FUTURE WORKS

The authors are working in the design and

implementation of new communication modules to

improve the multiplexed networks used currently in

city public transport buses. These modules should

integrate all the sensors and actuators in an optimum

way. Besides, these modules must resolve those

particular functions that are not integrated in the

multiplexed solutions of the chassis manufacturers.

These new communication modules will be

designed using reconfigurable circuits technology as

for example FPGAs (Lías, 2000). The

implementation of communication processors for

fieldbuses using FPGAs has a lot of advantages on

account of their reconfiguration ability (Valdés,

2004).

The modules will be designed to enable the

integration of the whole functions existent in the

public transport buses and to add other new ones that

are interesting for the coachbuilder such as closed-

circuit TV, infrared control for doors, modules with

outdoor connection, etc.

All these new functions must be integrated in the

driver display. Thus, it is interesting the

development of a system to integrate in the

dashboard of the city-buses a PDA with the VDV

protocol and that complements the information of

the display included in the dashboard. The PDA

could be integrated in the CAN networked control

system using a VDV node that transmits the

information to the PDA using a Bluetooth link. The

VDV module can be designed with a FPGA that

VEHICULAR ELECTRONIC DEVICES CONNECTED BY ONBOARD FIELDBUS TECHNOLOGIES

9

implements the CAN protocol in accordance to the

J1939 standard and that manage the communication

of a simple Bluetooth device (Flooks, 2005).

Other important improvement to be taking into

account in the design of these modules is the

possibility of integration of the localization and fleet

management systems by GPRS, GSM, radio, etc.

The integration of these systems enables the

localization of the vehicles from the head office, the

automation of the displaying systems for driver and

passengers, the notification of next stop, estimated

time to arrive to the bus stop, etc.

5 CONCLUSIONS

The main objectives of the work exposed in this

paper is the improvement of the control system

onboard the public transport buses. The authors

design a networked control system based on

modules with CAN communication. Thus, the

advantages of this system used to integrate the

electronic devices in a real time and reliable

information system are:

- Development of a networked control system

that satisfies the maximum demands of any

public transport enterprise.

- Reduction of cables and number of electrical

components (relays, fuses, etc.).

- Unification of the electronic equipment.

- The system has a central memory for the

registration of alarms and maintenance.

- Autodiagnostic of the system.

- Improvements in the vehicle working control

and the maintenance management.

- Improvements in the comfort.

- Best reliability of the components.

- Less maintenance costs.

- A flexible and modular system is obtained.

The design of modules based on FPGAs and

fulfilling the J1939 standard and the VDV

recommendation 234 is a very interesting solution

for the coachbuilders. Accordingly, they can have

their own CAN networked control systems and

install in the public transport buses their own

compatible devices to control the different chassis

and body functionalities.

ACKNOWLEDGEMENTS

This work has been sponsored by an R&D project

from the Autonomous Government (Galicia, Spain),

Ref.PGIDIT05TIC011E. This work has been made

in collaboration with the coachbuilder enterprise

Castrosua S.A. and the Actia S.A. Company.

REFERENCES

Bender, M., September 2004. Introducing the MLX4: a

microcontroller for LIN. EDN Europe, pp. 22-26.

Bosch, September 1991. CAN specification Version 2.0,

Robert Bosch GmbH.

Domínguez, M.A., Mariño, P., Poza, F., Otero, S., 7-10

November 2006. Industrial communication system in

technology control for public transport vehicles. In

Proceedings of 32

nd

Annual Conference of IEEE

Industrial Electronics Society (IECON´06), ISBN 1-

4244-0136-4, pp. 585-590.

Estevez, M., October 2004. MOST and MPEG: a perfect

relationship?. Embedded Systems Europe, pp. 36-38.

Flooks, S., June 2005. Putting EDR to the test. Electronic

Design Europe, pp. 8-9.

ISO 11898, 1992. Road Vehicles – Interchange of digital

information – Controller Area Network for high-speed

communication, ISO.

ISO 11519-2, 1995. Road Vehicles – Low-speed serial

data communication – Part 2: Low-speed Controller

Area Network (CAN), ISO.

Lías, G., Valdés, M.D., Domínguez, M.A., Moure, M.J.,

September 2000. Implementing a fieldbus interface

using a FPGA. LNCS 1896, Springer-Verlag, pp. 175-

180.

Mariño, P., 2003. Enterprise communications: Standards,

networks and services, Ed. RA-MA. Madrid, second

edition.

Marsh, D., September 1999. Automotive design sets

RTOS cost performance challenges. EDN, pp. 32-42.

Marsh, D. (editor), July 2005. Engines of change, EDN

Europe, pp. 58-73.

SAE J1939, Revised January 2005. Surface Vehicle

Recommended Practice, SAE.

Valdés, M.D., Domínguez, M.A., Moure, M.J., Quintáns,

C., September 2004. Field Programmable Logic and

Applications: A reconfigurable communication

processor compatible with different industrial

fieldbuses. Lecture Notes in Computer Science 3203,

Springer-Verlag, pp. 1011-1016.

Verband Deutscher Verkehrsunternehmen (VDV), June

1996. Driver’s Workplace in the Low-Floor Line-

Service Bus – Recommendation 234, ISO/TC 22/SC

13/WG 3 N226.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

10