ROBUST AND STABLE ROBOTIC FORCE CONTROL

Michael Short

1

and Kevin Burn

2

1

Embedded Systems Laboratory,University of Leicester, UK.

2

Control Systems Centre, University of Sunderland, UK

Keywords: Robotic force control, model following control, stability.

Abstract: To perform many complex tasks, modern robots often require robust and stable force control. Linear, fixed-

gain controllers can only provide adequate performance when they are tuned to specific task requirements,

but if the environmental stiffness at the robot/task interface is unknown or varies significantly, performance

is degraded. This paper describes the design of a robotic force controller that has a simple architecture yet is

robust to bounded uncertainty in the environmental stiffness. Generic stability conditions for the controller

are developed and a simple design methodology is formulated. The controller design is tested on an

experimental robot, and is shown to perform favourably in the presence of large changes in environmental

operating conditions.

1 INTRODUCTION

Traditionally, most industrial robots are designed to

allow accurate and repeatable control of the position

and velocity of the tooling at the device’s end

effector. However, if robots are to perform complex

tasks in a wider range of applications in the future, it

will be essential to accurately control forces and

torques at the end effector/task interface. In addition,

task constraints sometimes require position control

in some degrees-of-freedom (DOF), and force

control in others. Thus, to fulfil these extra demands,

an important area of robotics research is the

implementation of stable and accurate force control.

However, this is often difficult to achieve in

practice, particularly where robots are operating in

unpredictable or disordered environments.

A large number of force control techniques of

varying complexity have been proposed over the last

twenty years (Zang & Hemami 1997; Whitney

1985). The most basic direct methods simply

transform joint-space torques into a Cartesian-space

wrench, either in an open-loop fashion (which do not

require the explicit measurement of forces and

torques) or using inner and outer closed loops for

accurate control of joint torques and Cartesian

forces, respectively. However, since most industrial

robots have position control loops that are not easily

modified, indirect methods are often preferred.

These involve modifying either joint or Cartesian

position demands in order to control forces by

deliberately introducing position control errors and

using the inherent stiffness of the manipulator in

different Cartesian directions. Alternatively, it is

possible to add an outer force control loop in

systems that have a facility for real-time path

modification (Bicker et al. 1994).

Two major problems in the implementation of

practical controllers are stability and robustness.

Stable force control is particularly difficult to

achieve in ‘hard’ or ‘stiff’ contact situations, where

the control loop sampling rate may be a limiting

factor. In an attempt to improve stability various

methods have been proposed, the simplest being the

addition of compliant devices at the robot wrist

(Whitney & Nevins 1979). Another solution is to

employ ‘active compliance’ filters, where force

feedback data is digitally filtered to emulate a

passive spring/damper arrangement (Kim et al.

1992). However, both methods introduce a

potentially unacceptable lag. Robustness is a

problem where environmental uncertainty exists,

and effective force control can only be achieved by

employing an accurate environment stiffness

detection technique and smooth switching between

controller gains (Ow 1997). This slows down task

execution, and can result in unstable contact when

the effective stiffness at the robot/environment

interface (K

e

) varies significantly.

Recent increases in processing power of low-

cost computers has led to an increased interest in

‘intelligent control’ techniques such as those

256

Short M. and Burn K. (2007).

ROBUST AND STABLE ROBOTIC FORCE CONTROL.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 256-261

DOI: 10.5220/0001618302560261

Copyright

c

SciTePress

employing fuzzy logic, artificial neural networks and

genetic algorithms (Linkens & Nyongsa 1996).

Where attempts have been made to employ these

techniques (specifically fuzzy logic) in explicit robot

force controllers, simulation studies have

demonstrated good tracking performance despite

wide variations in environment stiffness, e.g.

(Tarokh & Bailey 1997; Seraji 1998), and for

specific contact situations, e.g. deburring (Kiguchi &

Fukuda 1997). Improved performance using a

hierarchical fuzzy force control strategy has also

been demonstrated for various contact situations,

such as peg-in-hole insertion (Lin & Huang 1998).

However, fuzzy techniques are not without

problems. In addition to problems associated with

dimensionality, i.e. large numbers of rules that must

be evaluated in the inference process, the

performance and stability of fuzzy systems are often

difficult to validate analytically (Cao et al. 1998;

Wolkenhauer & Edmunds 1997). Additionally, when

compared to more ‘traditional’ control methods such

as LQR (Frankin et al. 1994), the resulting fuzzy

designs are more complex, have larger memory

requirements and larger execution times (Bautista &

Pont 2006).

Recent years have seen increased interest in the

use of model following control (MFC) techniques.

Due to its conceptually simple design and powerful

robustness properties, this type of controller has

been found to be particularly suited to industrial

applications such as robotics and motion control

(e.g. Li et al. 1998; Osypiuk et al. 2004). As such, it

would seem that MFC-based techniques may prove

to be applicable in the force control domain. This

idea shall be explored in this paper, and a simple and

stable MFC-based technique for force control is

presented.

The paper is organised as follows. Section 2

presents a short overview of common difficulties in

practical robotic force control. Following this,

Section 3 gives a brief description of the MFC-based

force controller, and generic stability conditions are

developed. In section 4 this technique is applied to a

robotic test facility and results are presented. Finally,

conclusions and suggestions for further work are

outlined.

2 FORCE CONTROL

Prior to examining the robust approach, it is

beneficial to outline the force control problem under

consideration and describe a conventional solution.

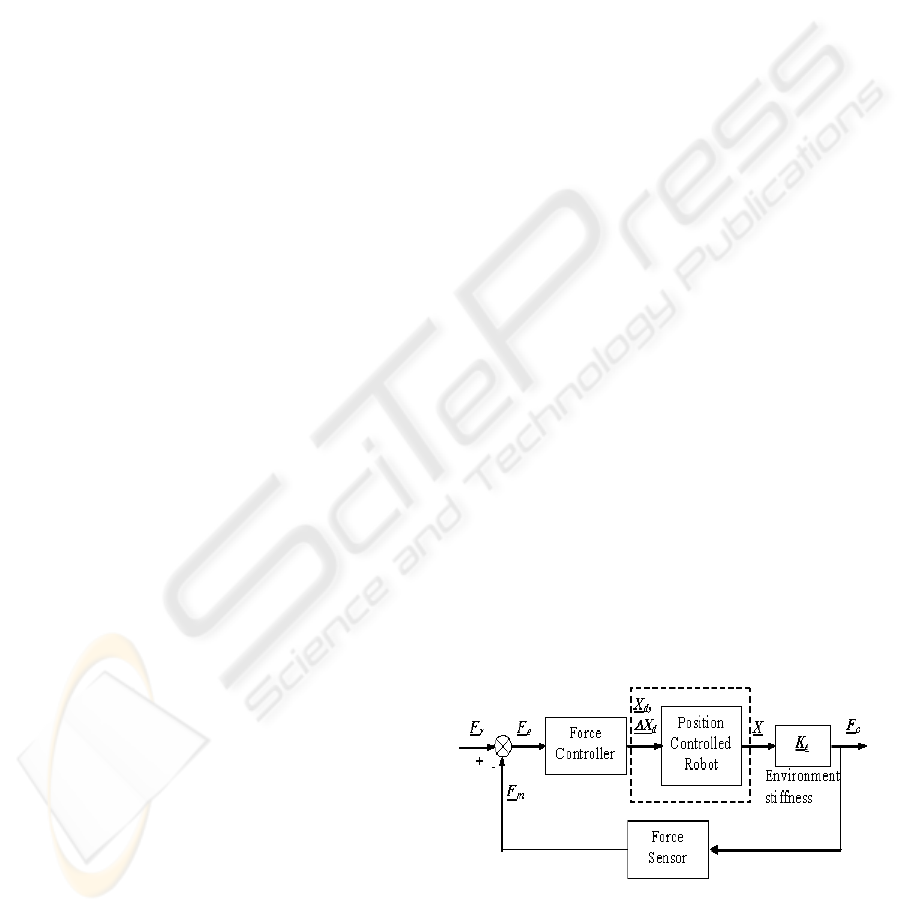

A typical conventional force control scheme is

shown in Figure 1. The combined stiffness at the end

effector/task interface in the direction of the applied

force is K

e

. This varies between a minimum value,

determined by the objects in the environment with

which the robot is in contact, and a maximum value,

limited by the stiffness of the arm and torque sensor.

The latter is dominant when the robot is touching a

surface of very high stiffness, i.e. in a hard contact

situation. Designing a fixed-gain conventional

controller to meet a chosen specification for a

specific value of K

e

is, in principle, a relatively

straightforward task. A problem arises when K

e

is

unknown or variable, as shown in Figure 2. For

example, consider the case where the system is

tuned to achieve a specified performance at an upper

limit of K

e

- at low K

e

the system will be

overdamped with a relatively high settling time.

Conversely, if the system had been tuned for the

desired performance at the lower limit of K

e

,

significant overshoot and oscillatory behaviour

would have occurred at higher stiffness values.

In practical robotic systems these effects often

have serious consequences, mainly in relation to

system stability. In particular, the finite and

relatively low sampling rates of many industrial

robot control systems can result in unstable

behaviour, a situation exacerbated by the presence of

noise, non-linearities and other factors. For this

reason, force controllers of the type described

usually require some form of environment stiffness

detection technique to enable the controller gains to

be switched accordingly. The main problem with

this process is that it is time consuming, often

involving ‘guarded moves’ to contact in order to

enable sufficient data to be collected for the

algorithm to work. Such methods can also be

unreliable in the presence of transducer noise, and

are not very effective in situations where K

e

is

variable or rapidly changing.

Figure 1: Robot force control.

ROBUST AND STABLE ROBOTIC FORCE CONTROL

257

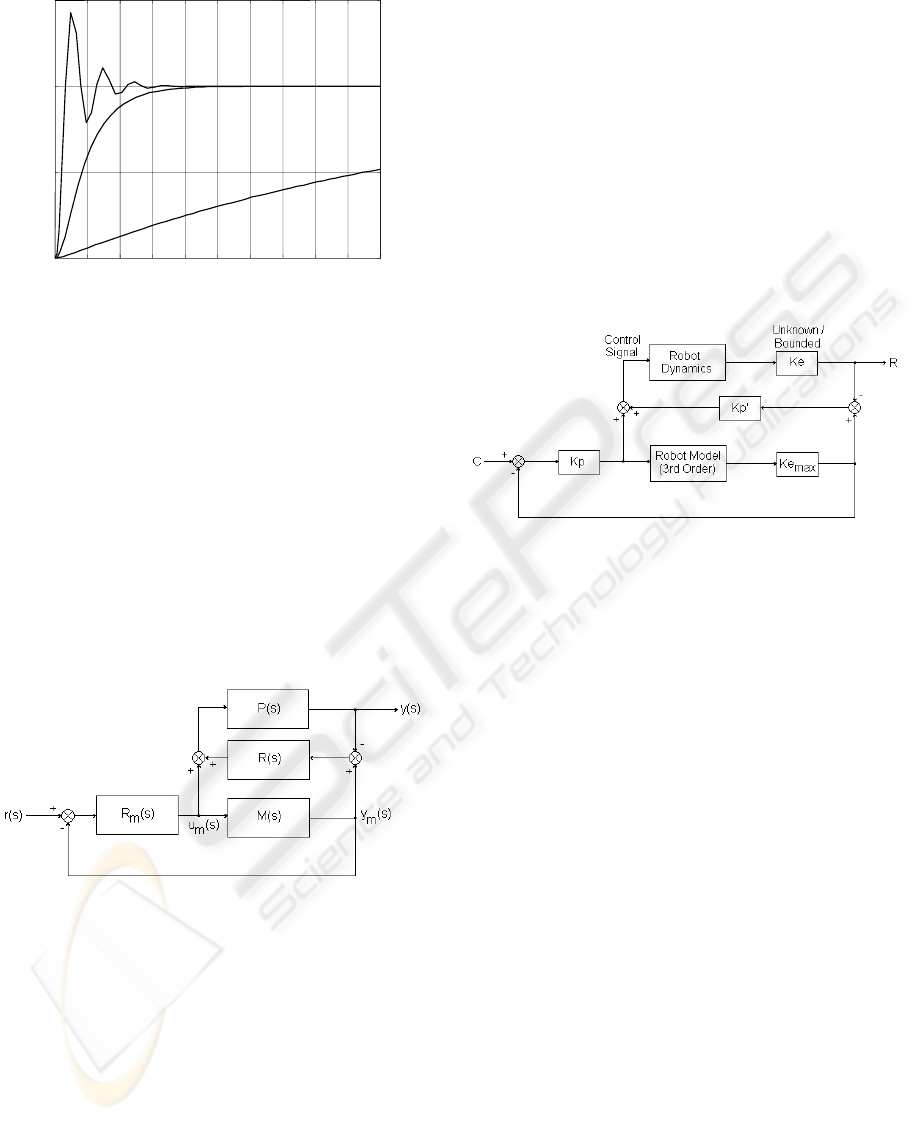

0

1.0

1.5

Time

(

s

)

Force

(

N

)

0.5

0.2 0.4 0.6 0.8 1.0

Hard contact, system tuned

for low K

e

Soft contact, system tuned

for high K

e

Tuned response

Figure 2: Effect of environmental stiffness.

3 ROBUST FORCE CONTROL

3.1 Principle

In this section we present the proposed robust force

controller. It is loosely based around the robust PID

strategy discussed in detail by Scokzowski et al.

(2005). The original strategy is based upon a two-

loop MFC, containing a nominal model of the

controlled plant and two PID controllers. The block

diagram of a basic MFC controller is shown in

Figure 3.

Figure 3: Robust PID based on MFC.

In this type of control, the model compensator

R

m

(s) is tuned to a nominal model of the plant M(s);

the actual plant P(s) contains bounded uncertainties.

The auxiliary controller R(s) acts on the difference

between the actual process output and the model

process output to modify the model control signal

u

m

(s), which is also fed to the plant.

As shown in Figure 1, when adding an outer

force control loop, it is common to use a velocity

signal as the input to the robot. In this case the

model M(s) is simply the second order motion

control loop dynamics augmented by a free

integrator, and a known value of environment

stiffness. The bounded uncertainty in the plant is

then just the environment stiffness K

e

, varying

between Ke

max

and Ke

min

.

If the two loop controllers R(s) and R

m

(s) are

simple proportional gains, as shown in Figure 4,

then the MFC structure is considerably simplified.

The model loop gain Kp can be tuned for Ke

max

, (a

relatively trivial task) whilst the auxiliary loop gain

Kp’ can be tuned to provide an additional control

signal should the actual value of K

e

be less than

Ke

max

. In the following section we will consider the

stability criteria for this controller structure and

provide a bound on the maximum value for Kp’.

Figure 4: Robust force controller.

3.2 Design for Stability

If the ‘model loop’ controller R

m

(s) is tuned for

stability using a nominal design method on the plant

P(s) augmented by the maximum environmental

stiffness gain Ke

max

, then we know that the stability

of the overall control strategy is restricted by the

roots of the equation:

0)](1)[()(1 =Δ+

+

ssMsR

(1)

Where Δ(s) denotes the model perturbations

(uncertainty). The objective is to find for a given

plant and bounded uncertainty in the stiffness gain a

maximum bound on |R(s)| that will maintain

stability. In the case where the uncertainty

exclusively resides in the environment stiffness gain

K

e

, then if the original loop is tuned for Ke

max

then

M(s)[1+Δ(s)] in (1) reduces to:

max

)()()](1)[(

e

KsGsPssM =

=

Δ

+

(2)

The robot dynamics have the form (due to the

free integrator in the forward path):

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

258

sss

sG

nn

n

2

23

2

2

)(

ωξω

ω

++

=

(3)

And the controller R(s) in this case is a single

gain, Kp’, using (2) and (3) we can re-write equation

(1) as follows:

0'2

max

22

23

=+++ KeKpsss

nnn

ωωξω

(4)

Applying the Routh-Hurwitz stability criterion

(Pippard 1997) for a cubic equation, we know that

the system is stable if all the co-efficients in the left

of (4) are positive, and the following criterion is

satisfied:

max

22

'2 KeKp

nnn

ωωξω

≥

(5)

Re-arranging (5) gives a stability limit for the

controller gain Kp’

max

as follows:

max

max

2

'

Ke

Kp

n

ξω

=

(6)

Thus if the gain Kp’ is chosen between the

limits:

max

'' KpKpKp <<

(7)

The controller will be stable for unknown

environment gains in the range 0 < K

e

< K

emax

; as for

all gains below Ke

max

, the stability criteria of (5)

holds.

4 EXPERIMENTAL TESTING

4.1 Test Facility

A research facility, previously described in detail

(Short 2003), has been developed in the form of a

planar robot arm and PC-based open architecture

controller. The robot joints are actuated by brushless

servomotors (with digital servoamplifiers), and the

control loop for each axis is closed via a

multitasking DSP embedded in a Delta Tau®

Programmable Multi-Axis Controller (PMAC)

motion control card, installed into the PC

Each axis has an individual PID controller with

feedforward control to enable accurate velocity and

position profile following. A six-axis force/torque

sensor was developed in-house for the project, and

used in this study. The robot arm is shown in Figure

5. For this work, a one-axis version of the system

was employed by attaching the sensor to the wrist of

the second link, which was then locked at 90° to the

first link.

Figure 5: Test facility.

In this paper, we apply the controller proposed in

the previous section to this facility. The controller

was coded in C and added into the control library.

Each experiment involved a contact situation, where

the robot first approached a surface then applied a

force of 25 N. The contact surface was varied in

each experiment, and we used two surfaces; hard

(steel) and soft (plastic). In order to reliably detect

the contact surface, the end effector was fitted with a

Baumer Electric® photoswitch which was calibrated

to signal with high accuracy when an object was

5mm away. The robot thus approached the contact

surface at a slow jog speed until this signal was

made, then switched to force control mode. The

sample rate was 200 Hz in each experiment. In the

following section we describe the parameters that

were used.

4.2 Controller Design

From a previous identification exercise, the

parameters of the robot arm model and the

environment stiffness limits were determined to be

as follows (Short 2003):

ROBUST AND STABLE ROBOTIC FORCE CONTROL

259

mmNKmmNK

srad

ee

n

/11,/168

,1,/244

minmax

==

=

=

ξ

ω

(8)

Using these parameters, the nominal loop gain

Kp was tuned to a value of 0.02 to give the desired

transient performance – a 95% rise time of

approximately 2 seconds with minimal (ideally zero)

overshoot. Using (6), Kp’

max

was determined to be

2.9. We therefore chose a value of Kp’ = 1.5 for the

experiments.

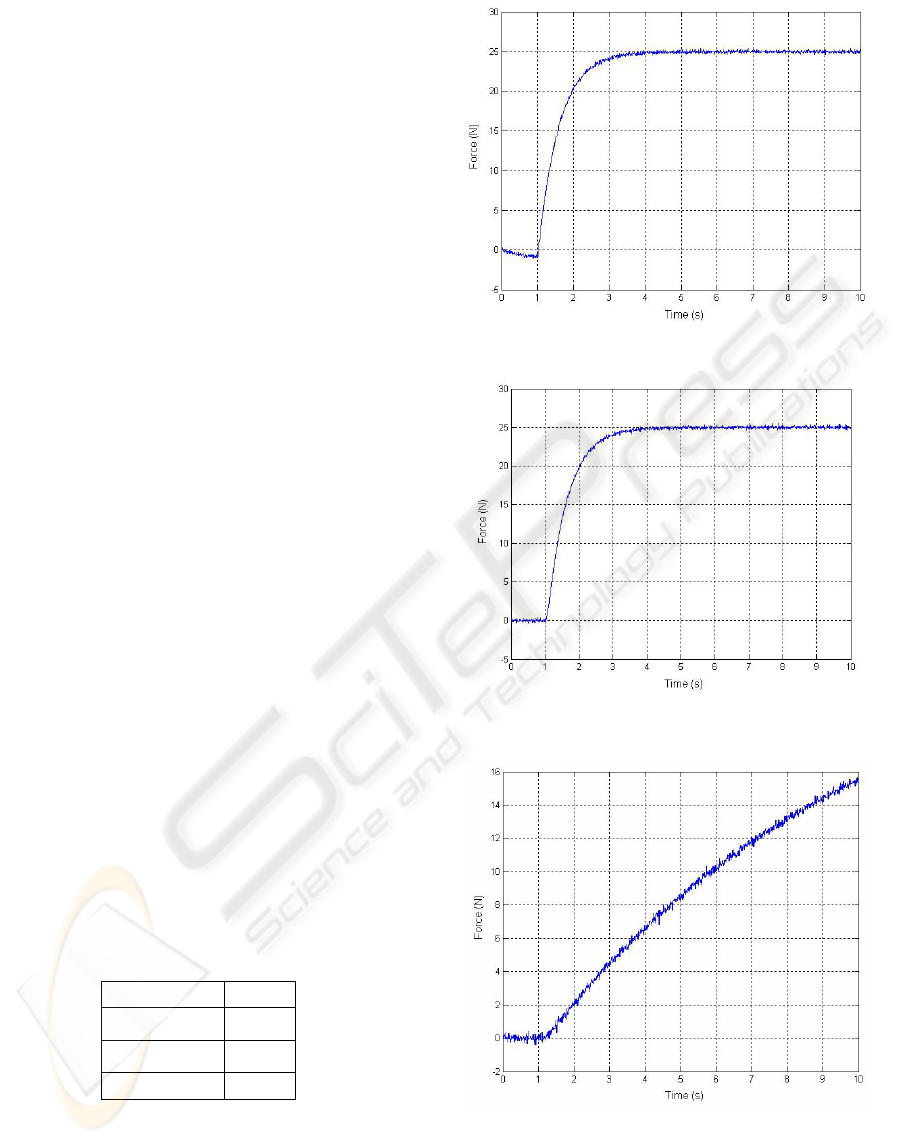

4.3 Experimental Results

Figure 6 shows the response of the system when

applying a force to the hard (steel) surface. The very

small negative force indicated before contact with

the surface was made (at approx 1s) was due to a

small drift in the calibration of the force sensor

whilst moving in free space. Figure 7 shows the soft

(plastic) case. We also show, for completeness, the

contact situation for a single loop controller tuned

for high K

e

in the soft contact case. This is shown in

figure 8.

These figures demonstrate the effectiveness of

the approach. Comparing Figures 7 and 8, the

compensation added by the extra loop can clearly be

seen; in Figure 7 we see an almost identical transient

to Figure 6. Additionally, in Figure 6 the controller

demonstrates no signs of instability as Kp’ was kept

below the maximum amount. We also measured the

integral of time by absolute error ITAE (Franklin et

al. 1994) for the responses shown in Figures 6, 7 and

8. This is shown in Table 1. From this the closeness

of the proposed robust controller transient responses

can be seen (R). The response of the normal (N)

controller is also shown in the table. The poor

quality of control is clearly highlighted by this vastly

increased value.

Table 1: ITAE measures for contact situations.

System ITAE

(R) Low K

e

23.61

(R) High K

e

23.95

(N) Low K

e

666.5

Figure 6: Hard contact situation.

Figure 7: Soft contact situation.

Figure 8: Soft contact situation (normal controller).

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

260

5 CONCLUSIONS

In this paper a distinct method for robotic force

control has been proposed and tested using an

experimental test robot. The method has been shown

to improve system performance where a high degree

of environmental uncertainty exists, without the

need for a stiffness detection routine. The method is

conceptually simple and extremely easy to

implement; its simplicity also lends itself to easy

analytical analysis.

The practical realisation of robotic force control

remains a problematic area of research. However,

the potential of simple, stable controllers to

overcome fundamental difficulties associated with

applications where environmental uncertainty exists

has been demonstrated.

However, work is required to further validate the

control method. This will include analysis of

situations where PD controllers are used as the loop

compensators, and forces are applied in Cartesian

coordinates. We will also consider the effects of

model mismatch (which is inevitable if the

methodology is to be applied to industrial robots).

Further work will also consider implementation on a

6-DOF manipulator to confirm its performance in a

range of industrial tasks, and to contrast the

approach with other methodologies.

REFERENCES

Bautista, R., Pont, M.J., 2006. Is fuzzy logic a practical

choice in resource-constrained embedded control

systems implemented using general-purpose

microcontrollers? In Proceedings of the 9th IEEE

International Workshop on Advanced Motion Control,

Istanbul, Volume 2, pp.692-697.

Bicker, R., Burn, K., Glennie, D., Ow, S.M., 1994.

Application of force control in telerobotics. Proc Int

Conf EURISCON '94, Malaga, Spain.

Cao, S.G., Rees, N.W., Feng, G., 1998. Lyapunov-like

stability theorems for continuous-time fuzzy control

systems, Int J Control. Vol. 69(1), pp. 49-64.

Franklin, G.F., Powell, J.D., Emani-Naeini, A., 1994.

Feedback Control Of Dynamic Systems. Addison-

Wesley Publishing, Reading Massachusetts, third

edition.

Kiguchi, K., Fukuda, T., 1997. Intelligent position/force

controller for industrial robot manipulators –

application of fuzzy neural networks. IEEE Trans

Industrial Electronics, Vol. 44(6), pp. 753-761.

Kim, W.S., Hannaford, B., Bejczy, A.K., 1992. Force

Reflection and Shared Compliant Control in Operating

Telemanipulators with Time Delay. IEEE Trans on

Robotics and Automation, Vol. 8(2), pp. 176-185.

Li, G., Tsang, K.M., Ho, S.L., 1998. A novel model

following scheme with simple structure for electrical

position servo systems. Int. J. Syst. Sci., Vol. 29, No.

9, pp. 959–969.

Lin, S.T., Huang, A.K., 1998. Hierarchical Fuzzy Force

Control for Industrial Robots. IEEE Transactions on

Industrial Electronics, Vol. 45, No. 4, pp. 646-653.

Linkens, D.H., Nyongesa, H.O., 1996. Learning systems

in intelligent control: an appraisal of fuzzy, neural and

genetic algorithm control applications. IEE Proc

Control Theory Appl, Vol. 143(4), pp. 367-386.

Osypiuk, R., Finkemeyer, B., Wahl, F.M., 2004. Forward-

model based control system for robot manipulators.

Robotica, Vol. 22, No. 2, pp. 155–161.

Ow, S.M., 1997. Force Control in Telerobotics. PhD

Thesis, University of Newcastle upon Tyne, UK.

Pippard, A.B., 1997. Response & Stability: An

Introduction to the Physical Theory. Cambridge

University Press.

Seraji, H., 1998. Nonlinear and Adaptive Control of Force

and Compliance in Manipulators. Int J Robotics

Research, Vol. 17(5) pp. 467-484.

Short, M., 2003. A Generic Controller Architecture for

Advanced and Intelligent Robots. PhD. Thesis,

University of Sunderland, UK.

Skoczowski, S., Domek, S., Pietrusewicz, K., Broel-Plater,

B., 2005. A Method for Improving the Robustness of

PID Control. IEEE Transactions On Industrial

Electronics, Vol. 52, No. 6.

Tarokh, M., Bailey, S., 1997. Adaptive fuzzy force control

of manipulators with unknown environment

parameters. J Robotic Sys, Vol. 14(5), pp. 341-353.

Whitney, D.E., 1985. Historical Perspective and State of

the Art in Robot Force Control.

Int J Robotics Res,

Vol. 6(1), pp. 3-14.

Whitney, D.E., Nevins, J.L., 1979. What is the Remote

Centre Compliance (RCC) and what can it do? Proc

Int Symp on Industrial Robots, Washington DC, pp.

135-152.

Wolkenhauer, O., Edmunds, J.M., 1997. A critique of

fuzzy logic in control. Int J Electrical Engineering

Education, Vol. 34(3), pp. 235-242.

Zhang, G., Hemami, A, 1997. An Overview of Robot

Force Control. Robotica, Vol. 15, pp. 473-482.

ROBUST AND STABLE ROBOTIC FORCE CONTROL

261