OBJECT LIST CONTROLLED PROCESS DATA SYSTEM

Anton Scheibelmasser

CAMPUS 02, University of Applied Sciences, Automation Technology, Körblergasse 126, 8021 Graz, Austria

Bernd Eichberger

Graz University of Technology, Department of Electronics, Inffeldgasse 12, 8010 Graz, Austria

Keywords: Object oriented design, process control system, linked object list.

Abstract: The appropriate design of a system is one of the essential topics at the beginning of a new development

project. According to the intended purpose of a device the first step is to model the system in order to get a

structure for the implementation of the required features. In general the implementation of the system

requirements is split in hardware parts and tasks which are done in software. In case of the hardware design

the solutions for the challenges are mostly clear and supported by fundamentals of e.g. digital logic laws and

several design methods. If we think of the software part a lot of problems have to be solved without such

clear fundamentals. Object oriented design is one of the paradigms which promise a way for designing

stable and reliable software. A problem arises in this context if the used microprocessor platform is not

supported with a compiler for an object oriented programming language. In this case only the system

modelling could be done in terms of software objects and their relations, the implementation has to be done

in a procedural language. The following article is based on research work done in the development of a

modular process data system. Based on a sequential main program and interrupt driven hardware interfaces,

a software implementation without an operating system was implemented. By means of special software

structure called Linked Object List, object oriented design was implemented with the procedural language

“C”. Due to this design a reusable and flexible system was achieved which enables a high degree of

flexibility concerning the hardware configuration and system customization at the user site.

1 INTRODUCTION

Controlling a process in an industrial environment

requires the measurement of the relevant process

quantities. The use of process lines helps to master

the often very complex system structure. In order to

master this complexity, distributed small process

controllers operate through a network with a host

computer located at a central point of the plant. The

software design for such remote controllers requires

a high degree of flexibility to handle the various

hardware options. This can be achieved by using

intelligent software algorithms. Depending on the

specific hardware interfaces and the process line, an

adaptation in the field by means of parameterisation

or configuration can be performed easily.

2 DESIGN CONSIDERATIONS

Based on the generic user requirement specification,

at a first step the system requirements were

modelled in hardware and software parts.

In contrast to the hardware design, the software

structure is not so simply derived from the

specifications. On the one hand standard

applications which are available for microcontroller

designs and digital circuits like LCD interfaces or

PC-Card implementations are not available, on the

other hand basic conditions of the system (e.g.

operating system, programming language,

development platform) have to be defined.

One paradigm in the field of software

development is the usage of object-oriented methods

to analyze, model and implement the software

requirements. Object-oriented design (Stroustrup,

1991) requires the modeling of the problem by

means of a data structure called Class. The goals of

351

Scheibelmasser A. and Eichberger B. (2007).

OBJECT LIST CONTROLLED PROCESS DATA SYSTEM.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 351-354

Copyright

c

SciTePress

such a design are to hide the complexity

(abstraction) and to protect the data effectively. If

we model our system according to these principles

we can structure our software into different classes

(objects) and their interfaces (methods). A system

build up in this way supports the developer with a

lot of advantages concerning reuse, maintenance and

stability.

A problem occurs if the used microprocessor

platform is not supported by a compiler for an

object-oriented language. For many controller

platforms only a C-compiler is available but no

C++-compiler. A typical solution for this problem is

a trade-off between the economical/technical

decision for a microcontroller and the software

development restrictions concerning the object-

oriented language. But the missing of an object-

oriented language does not imply that we have to

develop our software without object-oriented

principles. A good practice is to analyze and to

model the software requirements with object

oriented tools and methods (e.g. UML -diagrams).

The implementation is done later in a procedural

language with a few restrictions. For the

implementation of object-oriented designs with the

procedural language C, a trade-off can be achieved

by replacing the C++-class with the C-structure.

The methods (member functions) can be replaced as

function-pointers in such a structure. Protection

mechanisms are possible by putting such a C-

structure into a single C-File and to control the

visibility of the attributes (member variables) by

means of an H-File (header file). Therefore access to

the members of the C-structure is only possible by

means of dedicated member functions (e.g. get(),

set()). Another aspect is the instantiating of classes

as objects. This feature can be implemented with

arrays of such structures.

3 SOFTWARE DESIGN OF THE

PROCESS DATA SYSTEM

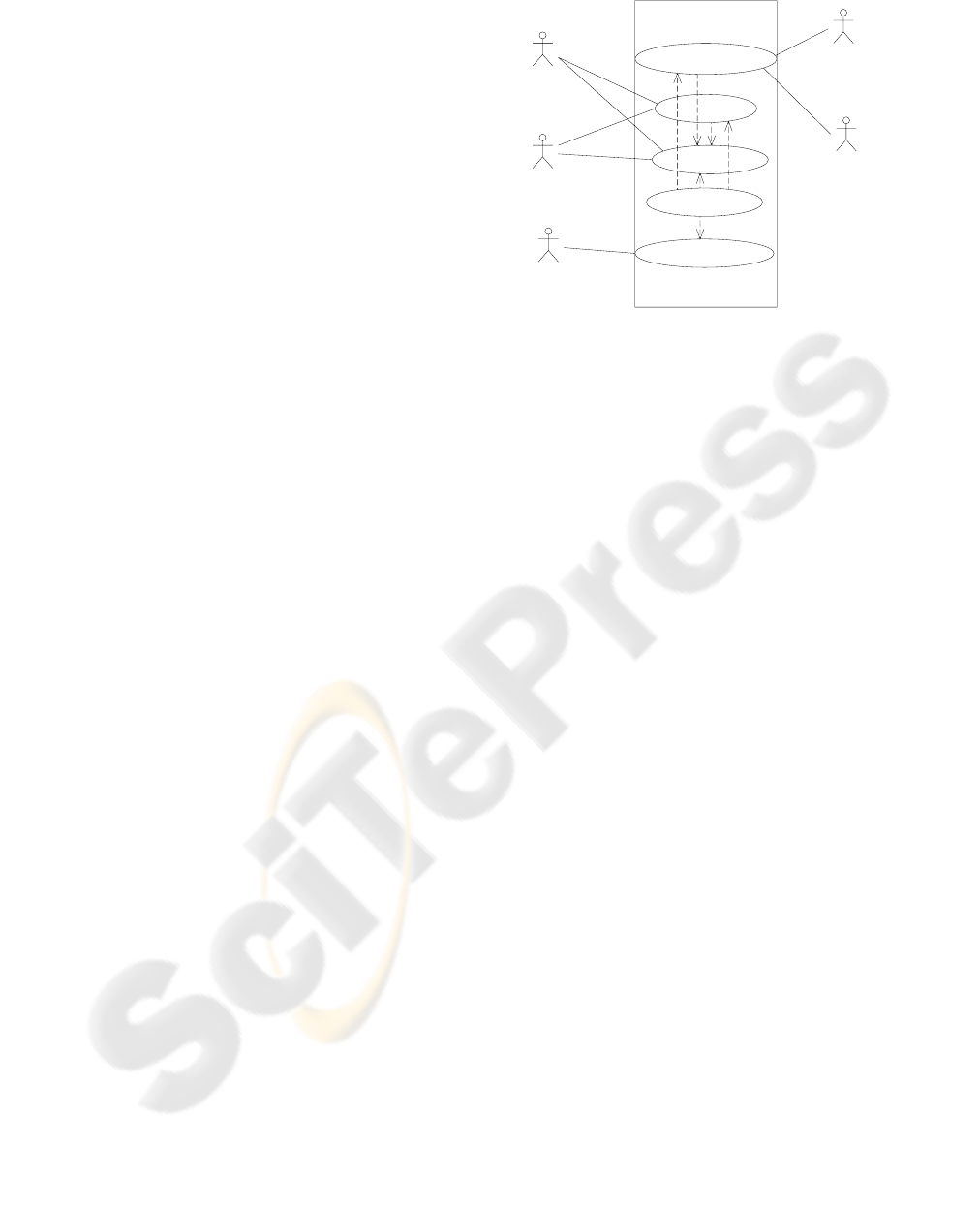

To analyze and model the requirements of the

process data system, UML diagrams (Fowler, 1999)

were taken to get an overview of the system. As a

first result of the requirement analysis the use case

diagram (figure 3) was generated. A central part of

the system represents the application program which

is optionally extendable with programs on a memory

card (update, user applications). Depending on the

configuration of the system, process variables are

measured, calculated and distributed to the host

computer or to the graphical display.

Process Data System

Data Evaluation

Process Control

Update, User Application

Sytem Configuration

Application Program

Data Distributer

LCD, Keyboard

Host Computer

PCMCIA User

Transmitters

Process Equipment

Cadifra Evaluation

www.cadifra.com

Figure 1: Use Case Diagram of the Process Data System.

The configuration process is one of the central tasks

in the system. Program handling, data measurement

and distribution as well as the handling of the

transmitter and process environment options should

be handled according to the configuration data. To

manage the versatility of transmitters, process lines

and process equipments a generic algorithm was

necessary.

3.1 Process Data Object

In a next step of the software development process

the modelling of the system by means of classes

(objects) has to be done. In order to handle the

demanded versatility, a Data Object Class was

introduced. Every process parameter, variable or

constant should be an instance (object) of this class.

A few attributes of the object control the behaviour

of the process value in the device. For every

component of the system one attribute of the class is

responsible for controlling the data handling. For

instance, if the process variable

density should be

measured and shown on the display a member

variable

HARDWARE-MASK and DISPLAY-MASK has

to be set appropriately. Depending on this object

definition, every module in the software has to be

written generically. This implies that the respective

program part has to evaluate the attributes of the

data object before handling the process value.

Process Data Objects are very flexible concerning

their handling in terms of definition. Hence user

specific object definitions are able to extend the

constant object definitions of the main system.

Therefore a flexible way of customizing the default

system is possible. For instance, the system software

can be extended by means of an external data

memory which stores additional Process Data

Objects.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

352

A Device Builder component, implemented by

means of a state machine, prepares the basic state

values for the Process Objects. The state function of

the Device Builder interacts with several

components in a sequential way. Starting with the

invocation of the measurement tasks, the application

program, the visualisation and the host

communication, interfaces of the respective

components are used. The Process Object

component plays a central role in the system. Every

component has to evaluate the attributes of the

handled process data objects to get information

about the intended use, the type and the specific

handling of the values.

3.2 Implementation Issues

Based on the system modelling and the demanded

requirements, a few basic conditions have to be

defined. One decision concerns the usage of an

operating system, another one the selection of the

appropriate programming language.

In order to meet economical aspects and

based on experiences from former projects, a

decision was made not to use an operating system.

Supported by the fact that the given requirement

does not need operating system support like e.g. file

system, network stack or multitasking, lower

memory requirements have been achieved. The real

time aspect in this context has already been solved in

a former project with the implementation of the

measurement tasks based on interrupt driven

transmitter routines.

The second question concerning the

programming language was solved with the

selection of the used microprocessor for

economical/technical reasons. As the development

platform of this microcontroller (Keil, 2007)

supports only the procedural language “C”, the

object oriented design has to be implemented as a

trade-off in a procedural way. Based on these

decisions the main frame of the software was

implemented as a sequential main()-procedure

supported with interrupt driven routines for

interfacing the process equipment (e.g. transmitters).

To support distributed development and reuse for

further projects, the graphical system for the LCD

was implemented as separated procedures and linked

by means of a software-interrupt (Graphic-BIOS).

One of the central points in this context was the

implementation of the Process Data Object class by

means of arrays of C-structures.

3.3 Procedural Object Class

Implementation

According to the language “C” the Process Data

Object was implemented as C-structures. As there

are a lot Process Data Objects in the system, a

constant array of such structures was defined.

Instead of instantiating objects, a constant array of

structures was defined which represents the main

definitions of the system’s behaviour. Every

structure incorporates a name, a type and behaviour

attributes for the process data. Based on the type of

data a method, implemented e.g. as a function

pointer, is responsible to access the respective value.

Based on the requirement to extend the software at

the customer site special process data objects were

introduced with the object type

OBJ-LINK, and

OBJ-LAST. Due to this definition it was possible to

connect several Process Data Object arrays in a way

which is called Linked-List. By means of this inked

object list it was possible to extend the basic

definitions of the system behaviour with customer

definitions at compile time or later in the field by

means of structures located at the mobile memory

card. A central procedure was introduced to search

for an object in this linked list.

Based on the object’s type in the structure this

procedure was able to evaluate the

OBJ-LINK type

and to connect several arrays of structures.

Depending on the start point of the search (e.g.

system memory, customer memory, PC-Card card) a

certain priority was achieved which is usable to

override (customize) basic system definition.

For instance with the introduction of new object

definitions on the memory card, new process data

readings or menu items are available in the process

data system. The following code fragments are

intended to give an impression of the structure

definition and the outlook of the object list.

typedef struct

{

NAME name;

union

{

unsigned long c_li;

NVPARA * p;

FUNC_adr funct;

unsigned long * i;

float * df;

char * str;

NAME * nstr;

} data;

char d_name[MAX_DLEN+1];

char d_unit[MAX_DLEN+1];

char d_format[MAX_DLEN+1];

char hierarchy[MAX_BRANCH+1];

unsigned char hardware_mask;

OBJECT LIST CONTROLLED PROCESS DATA SYSTEM

353

unsigned char handle_attrib;

unsigned char obj_type;

} OBJECT;

const OBJECT Test_Object_Table[] =

{

{

"Main-Menu", NULL,

"","","",

{0,0,0,0,0,0,0,1},

TM_NONE,

D_MENU,

OBJ_MENU },

{

"Temp",(float*)&MEAS_results.pte,

" Temp."," [ \xf8""C ]","%8.2f",

{0,0,1,5,5,6,ALL,13},

TM_NONE,

D_MENU | A_ASSIGN,

OBJ_FLOAT }

// a lot of additional objects …

}

As shown in this structure and their definitions, not

only attributes concerning the visualisation and the

hardware are available but also definitions for the

format and the hierarchies in menu trees. The Device

Builder component was implemented as a state

machine in the main() -procedure of the program.

Depending on the state function (Data Visualisation,

Menu Selection, Parameter Edit or Adjustment,

System Configuration) criteria are set which

influence the search procedure (e.g. getobject()). So

if every component uses the Linked Object List with

the process data definitions, a pure generic system is

established which enables a high degree of dynamic

concerning the implementation of hardware- or

software options.

4 RELATED WORKS

Innumerable publications describe different methods

of achieving reusable object-oriented software

designs. One of these methods is called Design

Patterns (Gamma, 1994). The idea is to use elegant

and proven solutions for dedicated problems to

model the core of the software at the start of the

design. The method of mastering the complexity and

the high dynamical efforts of hardware/software

options in the system by means of Object List

controlled procedures is similar but not identical to a

design pattern called Command (Gamma, 1994).

This pattern is described as an encapsulation of a

request in an object. By means of this pattern clients

could issue request to objects without knowing

anything about the operation requested. In this

context process data objects can be seen as such

requests to other clients (components of the system).

In this work the idea was modified and extended

with features of linked lists to handle the demanded

customization. A further idea was the

implementation of such a pattern in a procedural

language.

5 CONCLUSIONS

In the development of a new process data system

high requirements concerning the implementation of

different hardware options and customization

features were fulfilled. The introduction of an

“Object List Control” structure has significantly

enhanced the stability, robustness, maintenance and

extensibility of the software structure. Depending on

this structure a high degree of flexibility was

achieved and the requirements concerning

customization at the vendor’s site and in the field

were met. The object list structure has proved its

capability to solve the problem of customization by

binding different device configurations (object lists)

at compile or at runtime. Based on this list control

new device features can be added by means of

mobile data cards. From our point of view this

method is advisable if there are a lot of configurable

options defined in the system or in case of weak or

partial requirement specifications. In both cases a

high degree of flexibility in software design is

needed. The open “Linked Object List” is a generic

approach which allows upgrading the system

behaviour without recompiling the whole software.

REFERENCES

Stroustrup B., 1991. What is “Object-Oriented

Programming?”. AT&T Bell Laboratories Murray

Hill, New Jersey 07974.

Fowler M.,UML Distilled, Second Edition, 1999, Addison-

Wesley

CADIFRA, UML Editor, 2005, www.cadifra.com

KEIL GmbH, 2007, C166 Development Tools,

www.keil.com

Gamma E., Helm R., Johnson R., Vlissides J., Design

Patterns, 1994, Addison-Wesley

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

354