A NEURAL-CONTROL SYSTEM FOR A HUMANOID ARTIFICIAL

ARM

Michele Folgheraiter, Giuseppina Gini and Massimo Cavallari

Department of Electronics and Information, Politecnico di Milano, Piazza L. da Vinci 32, Milano, I-20133, Italy

Keywords:

Biorobotics, Artificial Arm, Neural Controller, Humanoids Robotics.

Abstract:

In this paper we illustrate the architecture and the main features of a bio-inspired control system employed

to govern an anthropomorphic artificial Arm. The manipulation system we developed was designed starting

from a deeply study of the human limb from the anatomical, physiological and neurological point of view. In

accordance with the general viewofthe Biorobotics field we try to replicate the structure and the functionalities

of the natural limb. Thanks to this biomimetic approach we obtained a system that can perform movements

similar to those of the natural limb.

The control system is organized in a hierarchical way. The low level controller emulates the neural circuits

located in the human spinal cord and is charged to reproduce the reflexes behaviors and to control the arm

stiffness. The high level control system generates the arm trajectory performing the inverse kinematics and

furnishing the instantaneous muscles reference position. In particular we implemented the Inverse kinematic

using a gradient based algorithm; at each step the actuators movements are arranged in order to decrease the

distance between the wrist and the target position.

Simulation and experimental results shows the ability of the control system in governing the arm to follow a

predefined trajectory and to perform human like reflexes behaviors.

1 INTRODUCTION

Robotics since from the beginning was involved in

replicating the human manipulation capabilities. One

of the first manipulators, designed for research pur-

poses, was the Stanford Arm (Stanford Artificial In-

telligence Laboratory). This robot was furnished of 6

DOFs (Degree Of Freedom), five revolute joints and

one prismatic. Even if the mechanical architecture

was thought with the aim to emulate the human move-

ments we can not consider it as a real anthropomor-

phic system.

In sixties General Motor (the first to employ a

Manipulator in an industrial process) financed a re-

search program at MIT to developed another well

know robotics arm: the PUMA (Programmable Uni-

versal Manipulator for assembly).

We can classify this manipulator as anthropomorphic,

indeed it is possible to compare it to a human arm. At

first we can divide the mechanical structure in three

principal blocks: the shoulder with two DOF, the el-

bow with 1 DOF and the wrist with another three

DOF. The Puma has a dexterity that is quite near to

that of a human arm, even though the human shoulder

has more than two DOF. The analogy between the hu-

man arm and the PUMA manipulator is true only from

a kinematic point of view, because the two systems

have completely different performances. We can as-

sert that this robot is more precise than a human arm,

nevertheless the natural arm is structurally conformed

to perform tasks that require compliant features, like

clean an irregular surface or catch a ball.

A fine regulation of the joint stiffness is therefore

very important also in a Humanoid Robot, indeed if

we want that the robot will be able to perform a task

in collaboration with a human being we have the ne-

cessity to change the joints stiffness in concomitance

with the robot movements. In industrial manipulators

it is possible to set the end-effector compliance using

the information coming from a three axis force sensor

119

Folgheraiter M., Gini G. and Cavallari M. (2007).

A NEURAL-CONTROL SYSTEM FOR A HUMANOID ARTIFICIAL ARM.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 119-126

Copyright

c

SciTePress

installed on the wrist, nevertheless this is quite simi-

lar to a virtual compliance control. In fact, the motors

that equip the manipulator do not present an intrinsi-

cal compliance, normally if the power is switch off the

robot assumes its maximum rigidity. This behavior is

not acceptable for a robot that is thought to operate in

strict contact with a human being.

With this work we want to propose a different

methodology in developing such a systems, not only

we tried to emulate the human arm morphology, but

we implemented also a neural controller that repli-

cates the functionalities of primary motor circuits lo-

cated in the human spinal cord. We are convinced that

combining classical control methodologies with bio-

inspired one may brings a new class of machines that

will perform better.

There are many projects that attempted to design

an arm with human like features and capabilities. At

the Center for Intelligent Systems (Vanderbilt Univer-

sity) Prof. Kawamura and its group are working on

the ISAC humanoid robot. This robot consists of a

human-like trunk equipped with two six-DOF arms

moved by McKibben artificial muscles (Kawamura

et al., 2000). Each joint is actuated by two antago-

nistic actuators that are controlled by a system able to

emulate the electromyogram patterns (EMG) of a hu-

man muscle. The arm, during a fast reaching move-

ment, can avoid an obstacle performing a reflex be-

havior (Gamal et al., 1992), furthermore the phasic

pattern is autonomously adjusted when a reach trajec-

tory doesn’t closely match a desired response. The

main advantage of this bio-mimetic control architec-

ture is the possibility to reduce the joint stiffness dur-

ing a movement execution.

Another project in the same direction is that one at

the Biorobotics Laboratory in Washington University.

Here Prof. Hannaford and his team have worked in-

tensely on the emulation of the human arm (Han-

naford and Chou, 1997) (Hannaford et al., 1995).

The goal of this research is to transfer knowledge

from human neuro-musculo-skeletal motion control

to robotics in order to design an ”anthroform” robotic

arm system.

Following the bio-mimetic approach they devel-

oped and tested new kind of actuators (Klute and Han-

naford, 2000) and sensors (Hannaford et al., 2001)

(Jaax, 2001), whose purpose is to replicate a mam-

malian muscle spindle cell, that measures the contrac-

tion and the muscle velocity.

Another very interesting arm project is that one

developed by Department of Precision Machinery

Engineering in University of Tokyo. The sys-

tem(Toshiki Niino and Higuchi, 1994) is equipped

with a new types of compact, high-power, electrostat-

ically driven actuators.

The actuators have 40 or 50 pairs of sheets inter-

leaved together and enclosed in ready-to-use pack-

ages filled with a dielectric liquid. An electrostatic

artificial muscle consists of two groups of sheets

stacked and interleaved together. Sliding forces are

generated on the surface of each film and are com-

bined into a net force at the bundled edges of the

sheets.

A first type of pulse-drive induction artificial mus-

cle, which utilizes induced charges on highly resistive

films, generated 8N propulsive force and 0.5W me-

chanical power with 110g its own mass. At the Dept.

of Mechanical Engineering (Vrije Universiteit Brus-

sel) Prof. Frank Daerden et al designed a new type

of Pneumatic Artificial Muscle (PMA), namely the

Pleated Pneumatic Artificial Muscle (PPAM) (Daer-

den and Lefeber, 2001). It was developed as an im-

provement with regard to existing types of PAM, e.g.

the McKibben muscle (Klute and Hannaford, 2000).

Its principal characteristic is its pleated mem-

brane. It can inflate without material stretching and

friction and has practically no stress in the direction

perpendicular to its axis of symmetry. Besides these

it is extremely strong and yet very lightweight and it

has a large stroke compared to other designs.

2 THE ARM ARCHITECTURE

AND FEATURES

In 2003 we developed a first prototype of artificial

Arm (MaximumOne Figure 1) with the main aim to

experience the actuation architecture and the control

strategies we theorized.

From the kinematic point of view, if we exclude

the hand, the system presents overall four degrees of

freedom. Three are located in the shoulder that re-

sembles a spherical joint, and one in the elbow that is

a normal revolution joint.

Each joint is actuated by tendons connected with

McKibben artificial muscles. In order to detect the

arm posture and allow to close the control loop, each

actuator is equipped with a position and force sensor.

These devices were developed specifically for this ap-

plication, this because there are not commercial sys-

tem that meet our needs. Furthermore the elbow joint

is furnished of an angular sensor (Figure 1) that mea-

sures the joint position.

The signals coming from the sensors are condi-

tioned and gathered by dedicated boards that per-

form an analog multiplexing and send the informa-

tion to a Target-PC equipped with a real-time ker-

nel. The control system, implemented via software

on a Host-PC, receives and elaborates these informa-

tion via RS-232 serial connection and send back its

output, through the Target-PC, to the electro-valves

module that has the main purpose to set the actuators

pressures. This module is equipped with 14 micro

solenoid-valves that can operate at a maximum fre-

quency of 20Hz. Using a PWM (Pulse Wide Modula-

tion) modulation it is possible to regulate the air flow

that feeds the single actuator and therefore its force

and position.

Figure 1: MaximumOne,the Arm Prototype of the Artifi-

cial Intelligence and Robotics Laboratory, Politecnico di

Milano.

As it is possible to see from the picture (Figure 1),

the arm we developed has an anthropomorphic shape.

This because during the design, we have tried to re-

produce the human arm dimensions and proportions,

the articulation mobilities, the muscle structure, and

the same sensorial capabilities.

2.1 The Actuation System

In order to actuate the arm we used seven artificial

muscles (Figure 2): five are dedicated to the shoulder

joint and two to actuate the elbow. This permits us

to obtain the typical postures and movements of the

natural limb. The five shoulder actuators emulate the

mechanical functionalities of: pectoralis major, dorsal

major, deltoid, supraspinatus and subscapularis mus-

cles. The two elbow actuators emulate the functions

of biceps and triceps muscles.

If we compare the the human arm musculature

with the actuation system of our prototype we can find

out same differences; for example the actuators that

represent the biceps and triceps muscles are mono-

link in the sense that they are dedicated only for the

elbow actuation, instead in the human limb they in-

terest at the same time the shoulder and elbow artic-

ulations. Furthermore shoulder actuators are placed

a. b.

c. d.

Figure 2: (a) The Deltoid Actuator lifts the shoulder. (b)The

Pectoral and Dorsal Actuators allow the adduction and ab-

duction movements. (C)The Supraspinatus and Subscapu-

laris Actuators allow the shoulder rotation. (d) The Biceps

and Triceps Actuators allow the elbow flexion and exten-

sion.

in a manner to maximize the space available for their

movement. Indeed, because of McKibben actuators

can contract only the 20% of their maximum length,

depending on the tendon excursion we need to realize,

their minimum length is fixed.

3 CONFIGURATION OF THE

CONTROL SYSTEM

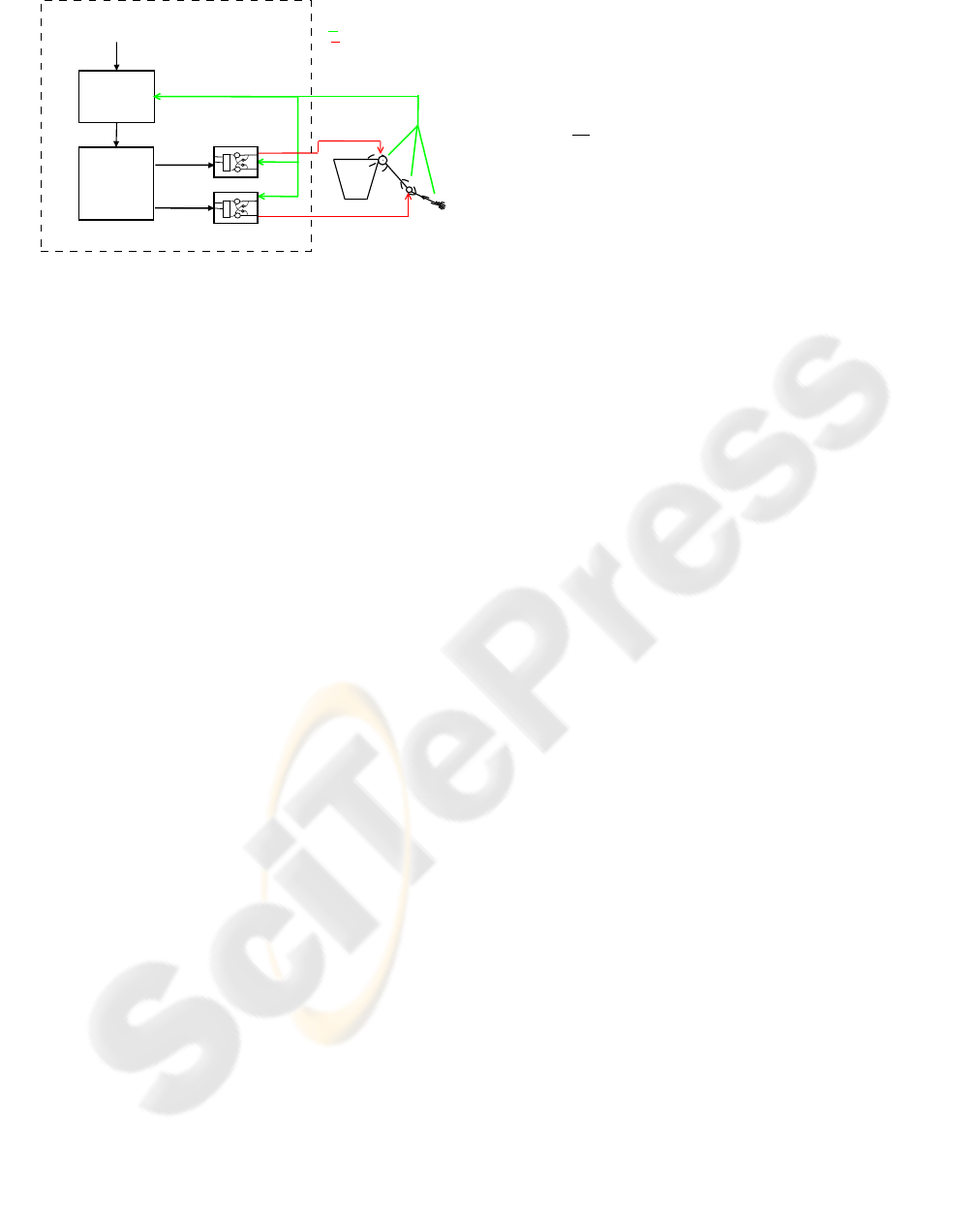

The control system of the arm is organized in a

modular and hierarchical fashion. At the bottom

level (Figure 3) there are the artificial reflex mod-

ules(Michele Folgheraiter, 2004) that govern the ac-

tuator’s contraction and force. These modules receive

inputs from the joint path generator, which in turn is

fed by the Inverse Kinematic module that computes

the target actuators lengths. The inputs of the en-

tire control system are: the final hand position in the

cartesian space, and the P signal that scales the level

of artificial muscles co-activation (simultaneously ac-

tivation of the muscle that govern the same joint ).

From a hierarchical point of view, we can distin-

guish three main levels:

• High level controller: composed by the Inverse

Kinematic modules

• Medium level controller: composed by the path

generator module

• Low level controller: composed of the reflex

modules that control the artificial muscles activ-

ities

Shoulder

Elbow

Hand

Sensory Information

Control Commands

Trajectory Generator

and

Inverse Kinematic

Module

Shoulder Reflex

Module

Elbow Reflex

Module

Path Generator

Module

Control Architecture

M1

M2

M1

M2

Wrist Trajectory

and

joints stifness

L(t),V(t)

E(t)

L

Figure 3: Control System Architecture.

The signals transmitted from one module to an-

other are expressed in a vectorial form, where each

vector component corresponds to one of the seven

artificial muscles that compose the actuation system.

Therefore L

T

represents the target lengths vector for

the actuators, V

T

represents the target velocity vec-

tor, E

L

represents the length vector error, and P is the

stiffness command vector. At the level of each single

module these signals are decomposed in their compo-

nents and sent to the appropriate submodules.

4 ARTIFICIAL NEURAL

CIRCUITS TO IMPLEMENT

THE REFLEXES BEHAVIORS

Reflex behaviors are accomplished by two modules

that implement a simplified model of the natural cir-

cuits present in the human spinal cord. One module is

dedicated to the control of the artificial muscles activ-

ities that govern the shoulder joint, the other takes un-

der control muscles that actuate the elbow joint. Since

the artificial muscle is constituted by only one func-

tional fiber the biological organization of the natural

muscle in motor units is neglected in our model. The

artificial muscle activity is therefore regulated by only

one motoneuron. The same consideration can be done

also for the sensorial system in the muscle, that in this

case is constituted by only one artificial spindle organ

and only one artificial Golgi tendon organ.

The most important cells of the neural circuit are

the motoneurons whose outputs set the actuators pres-

sures. With respect to other models in literature (Ster-

ratt, 2001),(Kuntimad and Ranganath, 1999),(Fol-

gheraiter and Gini, 2001) or to hardware solutions

(Omura, 1999) we decided to neglect the spike be-

havior of these cells, instead we concentrated our at-

tention on modelling its membrane potential.

Each motoneuron receives its inputs from almost

all the cells that compose the circuit. In equation 1 M

i

represents the potential (membrane potential) of the

motoneuron i.

d

dt

M

i

= (1−M

i

)(exc

i

) − M

i

(inh

i

) (1)

where the terms exc

i

and inh

i

are the excitatory

and inhibitory inputs for the motoneuron.

The neuron output is represented by equation 2

Mo

i

= Th(M

i

) (2)

where the threshold function is defined by equa-

tions 3 :

Th(x) =

x if 0 ≤ x ≤ 1

0 if x ≤ 0

1 if x ≥ 1

(3)

For more details about this model see (blind).

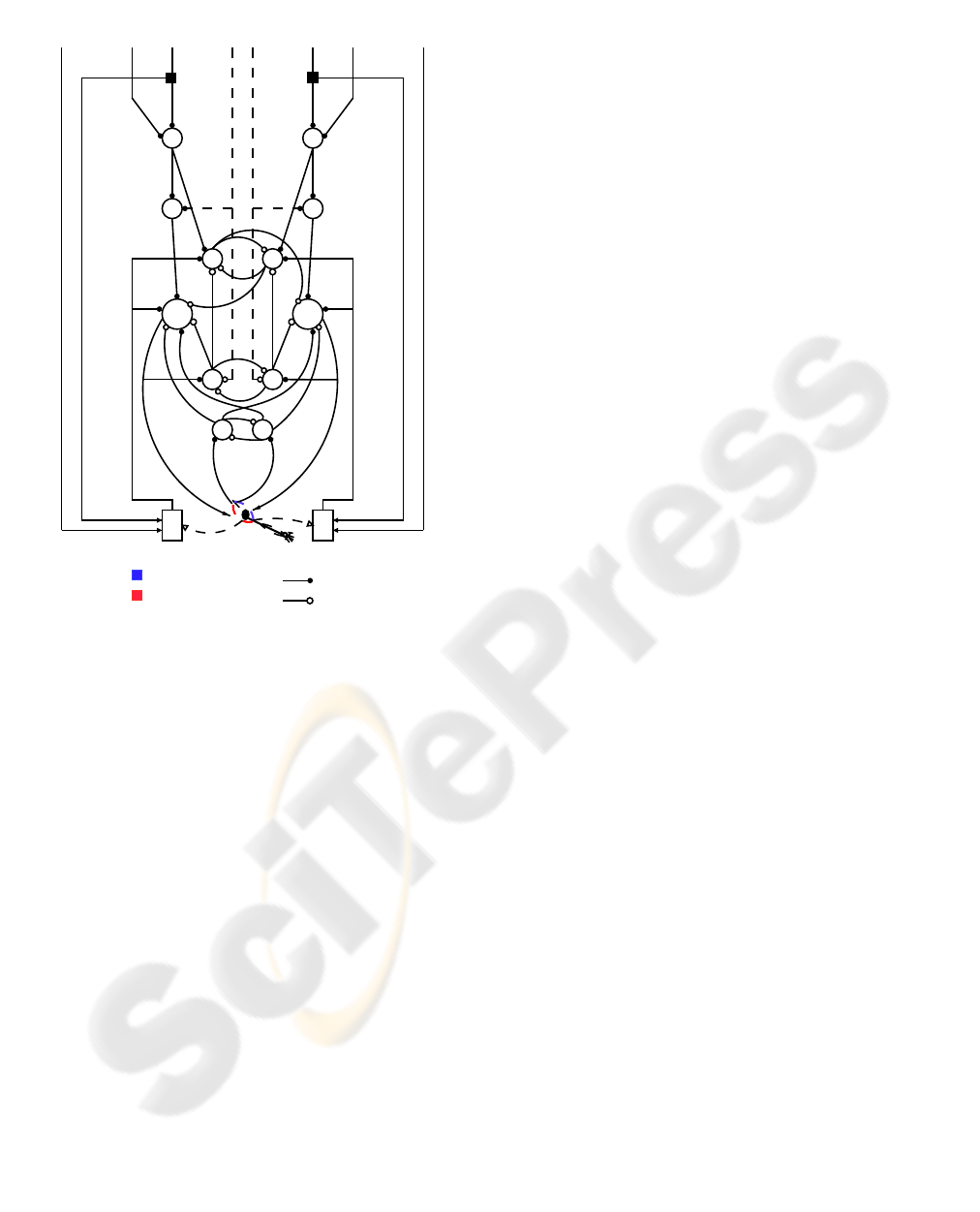

4.1 Elbow Neural Circuit

The reflex module that governs the elbow muscle is

represented in figure 4. It implements an opponent

force controller whose purposes are to provide inputs

for the path generator module, measure movements

error and return error signals when the execution is

different from the desired movement.

In figure 4 M

6

and M

7

are the motoneurons that con-

trol the contraction rate and force of the triceps and

biceps actuators respectively. I

a

6 and I

a

7 are the in-

terneurons that receive the error signals from the ar-

tificial spindles and project, with inhibitory synapses,

to the motoneurons of the antagonist muscles M

7

and

M

6

respectively. R

6

and R

7

represent the Renshaw

cells that receive the error signals from spindles and

inhibit the corresponding motoneuron and I

a

cell, they

are important to reduce oscillations of the joint around

the target angular position. I

b

6 and I

b

7 are interneu-

rons that receive the signals coming from the artifi-

cial Golgi tendon organs (that in this system are rep-

resented by a normalized force measurements). I

ns

6

and I

ns

7 are the interneurons that integrate informa-

tion of stiffness and target length commands.

Finally M

s

6 and M

s

7 represent the artificial muscle

spindle receptors. As inputs they receive the muscle

velocity command, the muscle target length command

and the actual muscle length and in turn excite the cor-

responding motoneuron and I

a

interneurons.

In this work we do not consider the other inputs

(show in the neural circuit schema) for more details

see (Folgheraiter, 2003).

Elbow Joint

Μ6

Μ7

R6

R7

Ia6

Ia7

Ib6

Ib7

Inc6

Inc7

Ins6

Ins7

Ms6

Ms7

Lt6

Lt7

P6

P7

Cs6

Cs7

Vt6

Vt7

Biceps Actuator

Triceps Actuator

Excitatory

Inhibitory

Figure 4: Architecture of the Elbow Reflex Module.

5 TRAJECTORY GENERATION:

DIRECT AND INVERSE

KINEMATIC

In order to test the efficacy of the control system we

developed two kind of arm models:

• The Kinematic Model: it is used in the inverse

kinematic algorithm to calculate the distance be-

tween the target position and the actual position

for the wrist.

• The Dynamic Model: it represents a realistic

model of the arm and takes into account the dy-

namic features of the actuators and of the arm

links.

In this paper we will briefly describe only the Di-

rect Kinematic model, because of it is required to de-

velops the Arm Inverse Kinematic algorithm.

6 DIRECT KINEMATICS

Find the Direct Kinematics of the arm means to find

the function that relates the actuator lengths vector

with the wrist position. In this case the orientation is

not considered because, if we do not take into account

the hand, the kinematic chain, with only four DOF

(three in the shoulder and one in the elbow), does not

allows to set arbitrarily both the position and orien-

tation of the wrist. It is possible to find the Direct

Kinematic of the arm solving a system of equations,

where each one imposes a constraint on the arm posi-

tion. As an example, if we consider the pectoral and

dorsal actuators we can obtains equation 4.

(

(x− Opc

x

)

2

+ (y− Opc

y

)

2

+ (z− Opc

z

)

2

− Lpc

2

= 0

(x− Odo

x

)

2

+ (y− Odo

y

)

2

+ (z− Odo

z

)

2

− Ldo

2

= 0

(x− S

x

)

2

+ (y− S

y

)

2

+ (z− S

z

)

2

− (kS− Opck)

2

= 0

(4)

In equation (Eq. 4 ) (x, y, z) is the position where

the two actuators are connected to the upper-arm,

Opc and Odo represent the origins of the pectoralis

and dorsal respectively, Lpc and Ldo are the actuator

lengths, and S is the shoulder position. All the quan-

tities are referred to the Arm reference system. The

first two equations impose that the distance between

the two extremities of the artificial muscle are equal

to the required distance, instead the third equation im-

poses the condition that at the end of the movement

the position of the attachment of the artificial mus-

cles compared to the bone doesn’t result modified.

As it is possible to see equation 4 has two solutions

and should be recalculated every time the position of

the upper arm changes, indeed it depends on (x, y, z) a

point located on the first robot link.

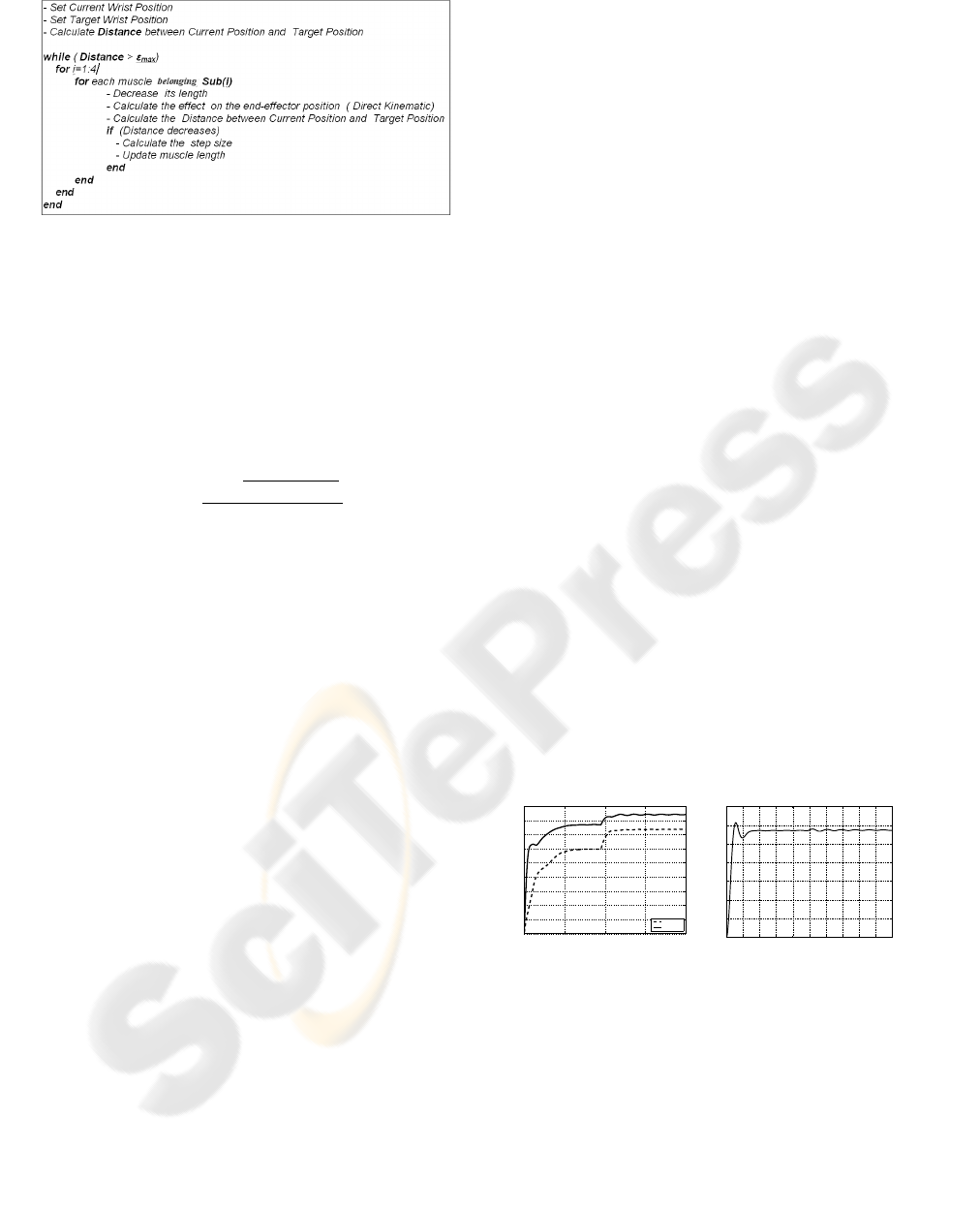

7 INVERSE KINEMATICS

Inverse Kinematics allows the calculation of the mus-

cles lengths vectors when a target position in the robot

workspace is assigned.

The algorithm we implemented for the Inverse

Kinematics is based on the gradient descent method,

this in order to calculate the minimum of the distance

function between the current and the target wrist po-

sition. It approaches a local minimum by taking steps

that are proportional to the negative of the gradient.

We can codify the algorithm using the pseudo-code of

figure 5.

Where ε

max

is the maximum error allowed in

reaching the target position, and subsets Sub(i) rep-

resents a couple of actuators chosen with a specific

Figure 5: The Algorithm that implement the Arm Inverse

Kinematics. .

logic from the set of all arm actuators.

As it is possible to see the actuator length is de-

creased of a value D specified by equation 5 only if

its decreasing allows to approach the target position,

if not its antagonist actuator is considered at the next

step.

D = −

1− e

−(TargetP−WrisP)

K

1

K

2

(5)

As it is possible to see from equation 5 depending

from the two constant K

1

and K

2

the muscle length

variation decreases according to the decreasing of the

distance between the wrist position (WristP) and the

target position (TargetP).

At each cycle the Direct Kinematic should be cal-

culated and this requires a certain amount of time, in

simulation this does not represent a problem, but may

be critical during the normal arm operation. Never-

theless we can avoid to calculate the direct kinemat-

ics installing on the robot a vision system that can ap-

proximate the distance between the wrist and the tar-

get position. This strategy is very similar to that one

performed by humans when it is required to perform

a motor path in order to reach a target object. At least

during the learning phase, humans being take advan-

tage of the visual feedback to estimate the distance

between the object and the hand.

8 STIFFNESS CONTROL AND

TRAJECTORY FOLLOWING

Here we report the results of some simulations con-

ducted on the robot models. The dynamic model was

developed using the tool SimMechanics in Simulink

environment, we chose an integration step of 1ms in

order to comply with the arm dynamic. At first we

tested the ability of the neural circuit in regulating the

elbow stiffness, in this case a noise force was applied

on the wrist. In the second part of our experiments

we tested the performance of the controller in follow-

ing an assigned trajectory, changing the precision we

show that the algorithm time complexity will decrease

exponentially.

8.1 Joint Stiffness Regulation

The control of the joint’s stiffness is very important

during the execution of a certain task with the robot’s

arm. This is true for industrial robots, but is partic-

ulary important for humanoid robots. Usually indus-

trial manipulators operate in a protected environment

where humans have a restricted access, in order to

guarantee a safe operation for the robot and for the

human. It is difficult to control the joint stiffness for

an industrial manipulator and even if this is possible

the inertia force that acts during the movement can be

lethal for a human being hit by the robot. Humanoid

robots are expected to operate and collaborate with

humans, during a task execution, therefore the robot

must not be dangerous; Humans usually can reduce

or increase the joint stiffness when they are perform-

ing a certain task. For example catching a heavy ob-

ject that is moving fast requires a stiffness increase

of the lower and upper body articulations, while mak-

ing a caress to someone requires a low stiffness for

the arm’s articulations. The articulation’s stiffness, in

turn, is regulated by the muscle cocontraction.

In the reflex modules the stiffness is regulated by the

P

i

signals that excite the Ins interneurons. In order

to demonstrate such a capability in the reflex module

I increased the P

i

signals for the elbow actuators to

the maximum value possible, 1. Picture 6a shows the

forces increasing due to the P command.

0 5 10 15 20

0

10

20

30

40

50

60

70

80

90

Time [s]

Force [N]

Triceps

Biceps

0 2 4 6 8 10 12 14 16 18 20

0

0.2

0.4

0.6

0.8

1

1.2

1.4

Time [s]

Elbow Angular Position [rad]

a. b.

Figure 6: (a) Biceps and Triceps forces during the applica-

tion of a dangerous force to the hand. (b) Elbow angular

position during the increasing of the joint’s stiffness.

The forces in the biceps and triceps actuators in-

crease at the same time, in order to avoid the joint

movement. We can observe also that the triceps in-

creases its force more than the biceps; the important

thing is that the total momentum exercised on the el-

bow joint is equal to zero in order to guarantee its

position (Figure 6b). As it is possible to note, the

elbow position does not change when its stiffness is

increased. We can also observe a collateral effect due

to the stiffness increasing: for a certain period there

are some little oscillations in the elbow joint. Sur-

prisingly this phenomena is present also in humans.

When the muscles are very highly co-contracted, a

tremor will occur in the arm.

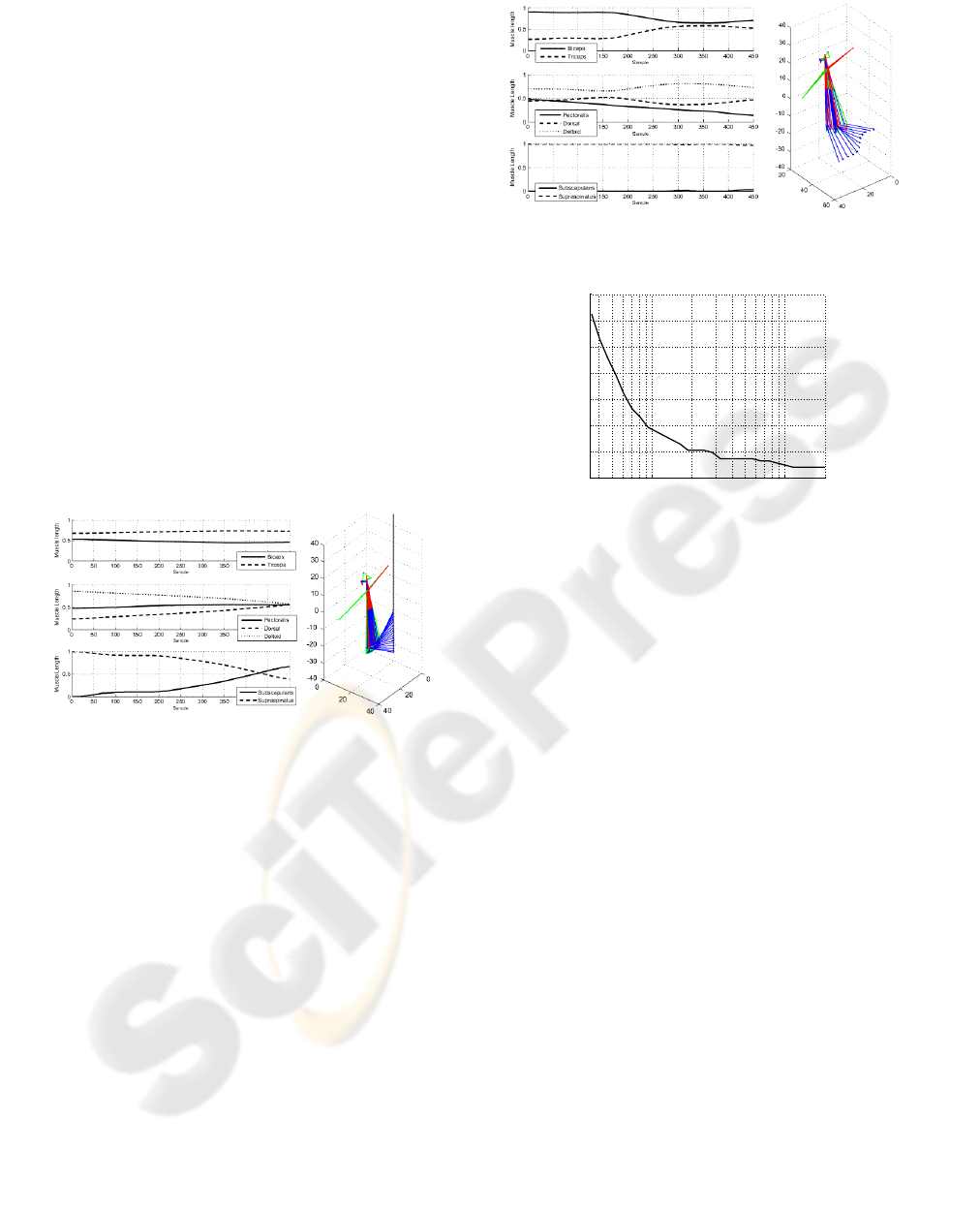

8.2 Trajectory Following

In the first simulation (Figure 7) the arm follows a

straight trajectory from the position (0.46,-14) to the

position (0.46,9), all the quantities are expressed rela-

tively to the robot workspace. In this case we impose

a maximum deviation from the reference trajectory of

6mm, the average error is 5mm. We can increase the

precision, but this will also increase exponentially the

computational time require to calculate the trajectory.

Figure 7: Following a straight trajectory.

In figure 7 are showed also the normalized val-

ues for the actuators lengths, as it is possible to note

the biceps and triceps actuators lengths do not change

considerably. There is instead a big upper arm ro-

tation (relative to an axis which direction is equal to

the first link direction), due to a big variation of the

supraspinatus and subscapularis actuators lengths.

In the second simulation (8) we give as reference a

more complex trajectory (useful for example to avoid

an obstacle in the workspace), also in this case the

trajectory is well followed by the wrist.

Finally figure 9 shows the trend for the compu-

tational time complexity relative to the precision in

reaching the target position. As it is possible to see

the trend is exponential, this means that the chose of

the robot precision is a critical factor for the control

system.

.

Figure 8: Following a complex trajectory.

10

−1

10

0

0

100

200

300

400

500

600

700

Precsion [cm]

Number of Direct Kinematic call

Figure 9: Trend for the time complexity.

9 CONCLUSION AND FUTURE

DEVELOPMENTS

In this paper we describe the architecture and the

main features of an anthropomorphic artificial arm in-

tended for applications in the field of the Humanoid

Robotics. In particular we analyzed its actuation sys-

tem, that emulates the arrangement of the human mus-

culature, and its control system that is organized in a

modular and hierarchical way. The high level con-

troller is charged to generate the arm trajectory and to

perform the inverse kinematic, the low level controller

sets the muscles lengths and the joints stiffness. In or-

der to perform the inverse kinematics we used the gra-

dient descent method, this to calculate the minimum

of the distance function between the current and the

target wrist position. Results show that the arm can

perform different kind of trajectories allowing also

to regulate, during the movement execution, the joint

stiffness. This is very important especially for the ex-

ecution of specific tasks in collaboration with human

beings. Future works will require to test the control

system on the real arm and to compare the experi-

mental results with the simulations conducted on the

arm models.

REFERENCES

Daerden, F. and Lefeber, D. (2001). The concept and design

of pneumatic artificial muscles. International Journal

of Fluid Power, 2:41–50.

Folgheraiter, M. (2003). Study of an anthropomorphic arti-

ficial arm for application in humanoid robotics. Ph.D

Thesis.

Folgheraiter, M. and Gini, G. (2001). Human-like hierar-

chical reflex control for an artificial hand. Proc. IEEE

Humanoids 2001, Waseda University, Tokyo.

Gamal, M. E., Kara, A., Kawamura, K., and Fashoro, M.

(1992). Reflex control for an intelligent robotics sys-

tem. Proceeding of the 1992 IEEE/RSJ Intelligent

Robots and System, 2:1347–1354.

Hannaford, B., andChing Ping Chou, J. M. W., and Marbot,

P.-H. (1995). The anthroform biorobotic arm: A sys-

tem for the study of spinal circuits. Annals of Biomed-

ical Engineering, 23:399–408.

Hannaford, B. and Chou, C.-P. (1997). Study of human

forearm posture maintenance with a physiologically

based robotic arm and spinal level neural controller.

Biological Cybernetics, 76:285–298.

Hannaford, B., Jaax, K., and Klute, G. (2001). Bio-inspired

actuation and sensing. Robotics, 11:267–272.

Jaax, K. N. (2001). A Robotic muscle spindle: neurome-

chanics of individual and ensemble response. Phd the-

sis, University of Washington.

Kawamura, K., II, R. P., Wilkes, D., Alford, W., and Rogers,

T. (2000). Isac: Foundations in human-humanoid in-

teraction. IEEE Intelligent Systems, 15(4):38–45.

Klute, G. K. and Hannaford, B. (2000). Accounting for

elastic energy storage in mckibben artificial muscle

actuators. ASME Journal of Dynamic Systems, Mea-

surement, and Control,, 122(2):386–388,.

Kuntimad, G. and Ranganath, H. S. (1999). Perfect image

segmentation using pulse coupled neural networks.

IEEE Transaction on Neural Network, 10(3):591–598.

Michele Folgheraiter, G. G. (2004). Human-like reflex con-

trol for an artificial hand. BioSystem Journal, 76(1-

3):65–74. 2004.

Omura, Y. (1999). Neuron firing operations by a new

basic logic element. IEEE Electron Device Letters,

20(5):226–228.

Sterratt, D. C. (2001). Locust olfaction synchronous oscil-

lations in excitatory and inhibitory groups of spiking

neurons. Emergent Neural Computational Architec-

tures, 2036:270–284.

Toshiki Niino, Saku Egawa, H. K. and Higuchi, T. (1994).

Electrostatic artificial muscle: Compact, high-power

linear actuators with multipli-layer structures. Micro

Electro Mechanical Systems, 1994, MEMS ’94, Pro-

ceedings, IEEE Workshop on, pages 130–135.