SENSOR-ASSISTED ADAPTIVE MOTOR CONTROL UNDER

CONTINUOUSLY VARYING CONTEXT

Heiko Hoffmann, Georgios Petkos, Sebastian Bitzer and Sethu Vijayakumar

Institute of Perception, Action and Behavior, School of Informatics, University of Edinburgh, Edinburgh, UK

Keywords:

Adaptive control, context switching, Kalman filter, force sensor, robot simulation.

Abstract:

Adaptive motor control under continuously varying context, like the inertia parameters of a manipulated object,

is an active research area that lacks a satisfactory solution. Here, we present and compare three novel strategies

for learning control under varying context and show how adding tactile sensors may ease this task. The first

strategy uses only dynamics information to infer the unknown inertia parameters. It is based on a probabilistic

generative model of the control torques, which are linear in the inertia parameters. We demonstrate this

inference in the special case of a single continuous context variable – the mass of the manipulated object. In

the second strategy, instead of torques, we use tactile forces to infer the mass in a similar way. Finally, the

third strategy omits this inference – which may be infeasible if the latent space is multi-dimensional – and

directly maps the state, state transitions, and tactile forces onto the control torques. The additional tactile

input implicitly contains all control-torque relevant properties of the manipulated object. In simulation, we

demonstrate that this direct mapping can provide accurate control torques under multiple varying context

variables.

1 INTRODUCTION

In feed-forward control of a robot, an internal inverse-

model of the robot dynamics is used to generate the

joint torques to produce a desired movement. Such

a model always depends on the context in which the

robot is embedded, its environment and the objects it

interacts with. Some of this context may be hidden to

the robot, e.g., properties of a manipulated object, or

external forces applied by other agents or humans.

An internal model that does not incorporate all rel-

evant context variables needs to be relearned to adapt

to a changing context. This adaptation may be too

slow since sufficiently many data points need to be

collected to update the learning parameters. An alter-

native is to learn different models for different con-

texts and to switch between them (Narendra and Bal-

akrishnan, 1997; Narendra and Xiang, 2000; Petkos

et al., 2006) or combine their outputs according to a

predicted error measure (Haruno et al., 2001; Wolpert

and Kawato, 1998). However, the former can handle

only previously-experienced discrete contexts, and

the latter have been tested only with linear models.

The above studies learn robot control based purely

on the dynamics of the robot; here, we demonstrate

the benefit of including tactile forces as additional

input for learning non-linear inverse models under

continuously-varying context. Haruno et al. (Haruno

et al., 2001) already use sensory information, but

only for mapping a visual input onto discrete context

states.

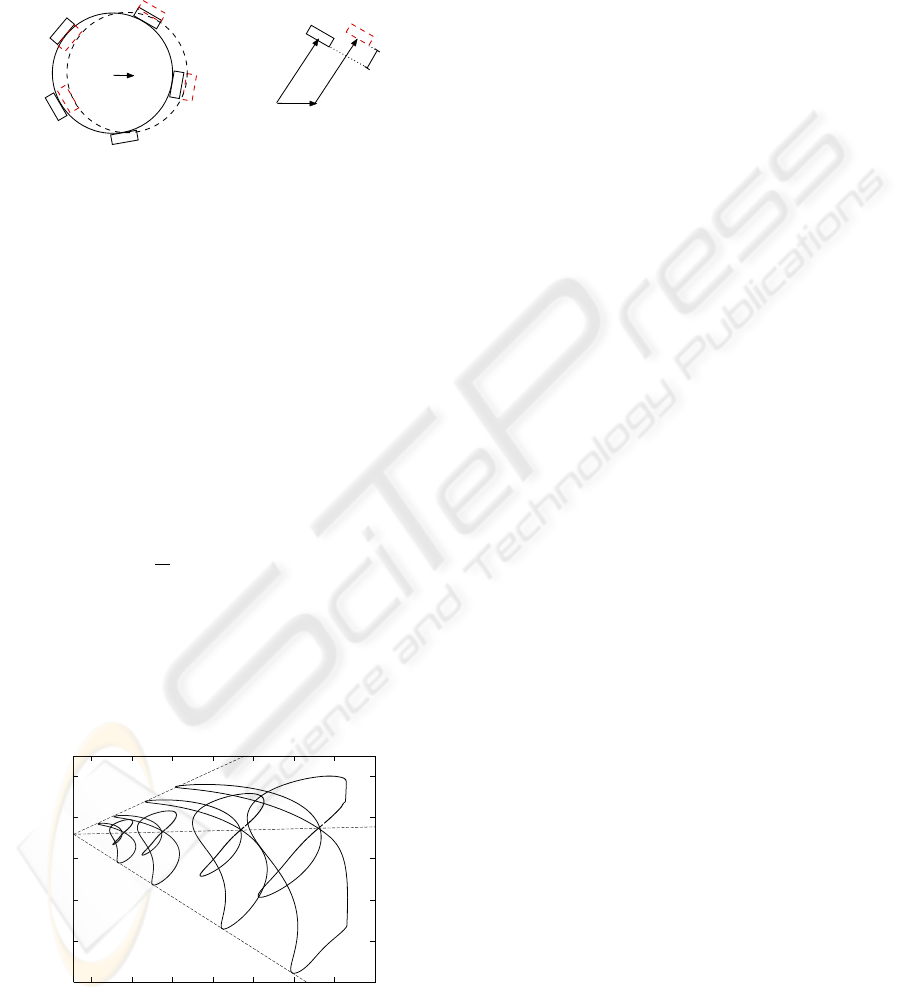

Using a physics-based robot-arm simulation (Fig.

1), we present and compare three strategies for learn-

ing inverse models under varying context. The first

two infer the unknown property (hidden context) of an

object during its manipulation (moving along a given

trajectory) and immediately use this estimated prop-

erty for computing control torques.

In the first strategy, only dynamic data are used,

namely robot state, joint acceleration, and joint

torques. The unknown inertia parameters of an object

are inferred using a probabilistic generative model of

the joint torques.

In the second strategy, we use instead of the

262

Hoffmann H., Petkos G., Bitzer S. and Vijayakumar S. (2007).

SENSOR-ASSISTED ADAPTIVE MOTOR CONTROL UNDER CONTINUOUSLY VARYING CONTEXT.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 262-269

DOI: 10.5220/0001626602620269

Copyright

c

SciTePress

Figure 1: Simulated robot arm with gripper and force sen-

sors and its real counterpart, the DLR light-weight arm III.

Arrows indicate the three active joints used for the exper-

iments. The curve illustrates the desired trajectory of the

ball.

torques the tactile forces exerted by the manipulated

object. The same inference as above can be carried

out given that the tactile forces are linear in the ob-

ject’s mass. We demonstrate both of these steps with

mass as the varying context. If more context variables

are changing, estimating only the mass as hidden con-

text is insufficient. Particularly, if also the mass dis-

tribution changes, both the center of mass and iner-

tia tensor vary, leading to a high-dimensional latent

variable space, in which inference may be infeasible

given a limited number of data points.

In our third strategy, we use a direct mapping from

robot state, joint accelerations, and tactile forces onto

control torques. This mapping allows accurate con-

trol even with more than one changing context vari-

able and without the need to extract these variables

explicitly.

The remainder of this article is organized as fol-

lows. Section 2 briefly introduces the learning of in-

verse models under varying context. Section 3 de-

scribes the inference of inertia parameters based only

on dynamic data. Section 4 describes the inference

of mass using tactile forces. Section 5 motivates the

direct mapping. Section 6 describes the methods for

the simulation experiments. Section 7 shows the re-

sults of these experiments; and Section 8 concludes

the article.

2 LEARNING DYNAMICS

Complex robot structure and non-rigid body dynam-

ics (e.g, due to hydraulic actuation) can make analytic

solutions to the dynamics inaccurate and cumbersome

to derive. Thus, in our approach, we learn the dy-

namics for control from movement data. Particularly,

we learn an inverse model, which maps the robot’s

state (here, joint angles θ and their velocities

˙

θ) and

its desired change (joint accelerations

¨

θ) onto the mo-

tor commands (joint torques τ) that are required to

produce this change,

τ = µ(θ,

˙

θ,

¨

θ) . (1)

Under varying context, learning (1) is insufficient.

Here, the inverse model depends on a context variable

π,

τ = µ(θ,

˙

θ,

¨

θ, π) , (2)

In Sections 3 and 4, we first infer the hidden context

variable and then plug this variable into function (2) to

compute the control torques. In Section 5, the context

variable π is replaced by sensory input that implicitly

contains the hidden context.

3 INFERRING CONTEXT FROM

DYNAMICS

During robot control, hidden inertia parameters can

be inferred by observing control torques and cor-

responding accelerations (Petkos and Vijayakumar,

2007). This inference can be carried out efficiently

because of a linear relationship in the dynamics, as

shown in the following.

3.1 Linearity in Robot Dynamics

The control torques τ of a manipulator are linear in

the inertia parameters of its links (Sciavicco and Si-

ciliano, 2000). Thus, µ can be decomposed into

τ = Φ(θ,

˙

θ,

¨

θ)π . (3)

Here, π contains the inertia parameters,

π = [m

1

, m

1

l

1x

, m

1

l

1y

, m

1

l

1z

, J

1xx

, J

1xy

, ..., m

n

,

m

n

l

nx

, m

n

l

ny

, m

n

l

nz

, J

nxx

, ..., J

nzz

], where m

i

is the

mass of link i, l

i

its center-of-mass, and J

i

its inertia

tensor. The dynamics of a robot holding different

objects only differs in the π parameters of the combi-

nation of object and end-effector link (the robot’s link

in contact with the object). To obtain Φ, we need to

know for a set of contexts c the inertia parameters π

c

and the corresponding torques τ

c

. Given a sufficient

number of τ

c

and π

c

values, we can compute Φ

using ordinary least squares. After computing Φ, the

robot’s dynamics can be adjusted to different contexts

by multiplying Φ with the inertia parameters π. The

SENSOR-ASSISTED ADAPTIVE MOTOR CONTROL UNDER CONTINUOUSLY VARYING CONTEXT

263

following two sections show how to estimate π once

Φ has been found.

3.2 Inference of Inertia Parameters

Given the linear equation (3) and the knowledge of

Φ, the inertia parameters π can be inferred. Assum-

ing Gaussian noise in the torques τ, the probability

density p(τ|θ,

˙

θ,

¨

θ, π) equals

p(τ|θ,

˙

θ,

¨

θ, π) =

N (Φπ, Σ) , (4)

where N is a Gaussian function with mean Φπ and

covariance Σ. Given p(τ|θ,

˙

θ,

¨

θ, π), the most probable

inertia parameters π can be inferred using Bayes’ rule,

e.g., by assuming a constant prior probability p(π):

p(π|τ, θ,

˙

θ,

¨

θ) ∝ p(τ|θ,

˙

θ,

¨

θ, π) . (5)

3.3 Temporal Correlation of Inertia

Parameters

The above inference ignores the temporal correlation

of the inertia parameters. Usually, however, context

changes infrequently or only slightly. Thus, we may

describe the context π at time step t + 1 as a small

random variation of the context at the previous time

step:

π

t+1

= π

t

+ ε

t+1

, (6)

where ε is a Gaussian-distributed random variable

with constant covariance Ω and zero mean. Thus, the

transition probability p(π

t+1

|π

t

) is given as

p(π

t+1

|π

t

) =

N (π

t

, Ω) . (7)

Given the two conditional probabilities (4) and (7),

the hidden variable π can be described with a Markov

process (Fig. 2), and the current estimate π

t

can be

updated using a Kalman filter (Kalman, 1960). Writ-

ten with probability distributions, the filter update is

p(π

t+1

|τ

t+1

, x

t+1

) = η p(τ

t+1

|x

t+1

, π

t+1

)

·

p(π

t+1

|π

t

)p(π

t

|τ

t

, x

t

)dπ

t

, (8)

where η is a normalization constant, and x stands for

{θ,

˙

θ,

¨

θ} to keep the equation compact. A variable

with superscript t stands for all observations (of that

variable) up to time step t.

3.4 Special Case: Inference of Mass

We will demonstrate the above inference in the case of

object mass m as the hidden context. This restriction

...

τ

t

π

t

x

t+1

π

t+1

τ

t+1

x

t

...

Figure 2: Hidden Markov model for dependence of torques

τ on context π. Here, the state and state transitions are com-

bined to a vector x = {θ,

˙

θ,

¨

θ}.

essentially assumes that the shape and center of mass

of the manipulated object are invariant. If m is the

only variable context

1

, the dynamic equation is linear

in m,

τ = g(θ,

˙

θ,

¨

θ) +mh(θ,

˙

θ,

¨

θ) . (9)

In our experiments, we first learn two mappings

τ

1

(θ,

˙

θ,

¨

θ) and τ

2

(θ,

˙

θ,

¨

θ) for two given contexts m

1

and m

2

. Given these mappings, g and h can be com-

puted.

To estimate m, we plug (4) and (7) into the fil-

ter equation (8) and use (9) instead of (3). Further-

more, we assume that the probability distribution of

the mass at time t is a Gaussian with mean m

t

and

variance Q

t

. The resulting update equations for m

t

and Q

t

are

m

t+1

=

h

T

Σ

−1

(τ−g) +

m

t

Q

t

+Ω

1

Q

t

+Ω

+ h

T

Σ

−1

h

, (10)

Q

t+1

=

1

Q

t

+ Ω

+ h

T

Σ

−1

h

−1

. (11)

Section 7 demonstrates the result for this inference

of m during motor control. For feed-forward control,

we plug the inferred m into (9) to compute the joint

torques τ.

4 INFERRING CONTEXT FROM

TACTILE SENSORS

For inferring context, tactile forces measured at the

interface between hand and object may serve as a sub-

stitute for the control torques. We demonstrate this in-

ference for the special case of object mass as context.

1

This assumption is not exactly true in our case. A

changing object mass also changes the center of mass and

inertia tensor of the combination end-effector link plus ob-

ject. Here, to keep the demonstration simple, we make a

linear approximation and ignore terms of higher order in m

– the maximum value of m was about one third of the mass

of the end-effector link.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

264

The sensory values s

i

(the tactile forces) are linear

in the mass m held in the robot’s hand, as shown in the

following. In the reference frame of the hand, the ac-

celeration a of an object leads to a small displacement

dx (Fig. 3).

Object

dx

dx

u

h

Sensor

Figure 3: A force on the object held in the robot’s hand

leads to a displacement dx. This displacement shifts each

sensor at position u (relative to the object’s center) by h.

This displacement pushes each sensor by the

amount h

i

depending on the sensor’s position u

i

. Let

e

i

be a vector of unit length pointing in the direction

of u

i

, then h

i

= e

T

i

dx. Our sensors act like Hookean

springs; thus, the resulting force equals f

i

= κh

i

e

i

,

with κ being the spring constant. Since the object is

held such that it cannot escape the grip, the sum of

sensory forces f

i

must equal the inertial force ma,

ma =

n

∑

i=1

f

i

= κ

∑

i

(e

T

i

dx) e

i

. (12)

This linear equation allows the computation of dx,

dx =

m

κ

(E

T

E)

−1

a , (13)

where E is a matrix with row vectors e

i

. Thus, each

f

i

is proportional to m. The total force measured at a

sensor equals f

i

plus a constant grip force (whose sum

over all sensors equals zero). Therefore, the sensory

values s can be written as

0.007

0.008

0.009

0.01

0.011

0.012

0.011 0.012 0.013 0.014 0.015 0.016 0.017 0.018

sensor 2

sensor 1

Figure 4: Two-dimensional projection of sensor values dur-

ing figure-8 movements with four different masses. From

left to right, the mass increases as 0.005, 0.01, 0.02, and

0.03.

s = s

0

+ mϕ(θ,

˙

θ,

¨

θ) , (14)

where ϕ is a function depending on the state and ac-

celeration of the robot arm. This linearity is illus-

trated in Fig. 4 using data from our simulated sensors.

Based on (14), the same inference as in Section 3 is

possible using (10) and (11), and the estimated m can

be used for control by using (9).

5 DIRECT MAPPING

The above inference of mass fails if we have addi-

tional hidden context variables, e.g., if the robot hand

holds a dumb-bell, which can swing. In this general

case, we could still use the inference based on dy-

namics. However, since for the combination of end-

effector and object, both the inertia tensor and the cen-

ter of mass vary, we need to estimate 10 hidden con-

text variables (Sciavicco and Siciliano, 2000). Given

the limited amount of training data that we use in our

experiments, we expect that inference fails in such a

high-dimensional latent space.

As alternative, we suggest using the sensory val-

ues as additional input for learning feed-forward

torques. Thus, the robot’s state and desired acceler-

ation are augmented by the sensory values, and this

augmented input is directly mapped on the control

torques. This step avoids inferring unknown hidden

variables, which are not our primary interest; our

main goal is computing control torques under vary-

ing context.

The sum of forces measured at the tactile sensors

equals the force that the manipulated object exerts

on the robotic hand. This force combined with the

robot’s state and desired acceleration is sufficient in-

formation for predicting the control torques. Thus,

tactile forces contain the relevant effects of an un-

known varying context. This context may be, e.g.,

a change in mass, a change in mass distribution, or

a human exerting a force on the object held by the

robot.

Depending on the number of sensors, the sensory

input may be high-dimensional. However, since the

sensors encode only a force vector, the intrinsic di-

mensionality is only three. For learning the mapping

τ(θ,

˙

θ,

¨

θ, s), regression techniques exist, like locally-

weighted projection regression (Vijayakumar et al.,

2005), that can exploit this reduced intrinsic dimen-

sionality efficiently. In the following, we demonstrate

the validity of our arguments in a robot-arm simula-

tion.

SENSOR-ASSISTED ADAPTIVE MOTOR CONTROL UNDER CONTINUOUSLY VARYING CONTEXT

265

6 ROBOT SIMULATION

This section describes the methods: the simulated

robot, the simulated tactile sensors, the control tasks,

the control architecture, and the learning of the feed-

forward controller.

6.1 Simulated Robot Arm

Our simulated robot arm replicates the real Light-

Weight Robot III designed by the German Aerospace

Center, DLR (Fig. 1). The DLR arm has seven

degrees-of-freedom; however, only three of them

were controlled in the present study; the remain-

ing joints were stiff. As end-effector, we attached a

simple gripper with four stiff fingers; its only pur-

pose was to hold a spherical object tightly with the

help of five simulated force sensors. The physics

was computed with the Open Dynamics Engine

(

http://www.ode.org

).

6.2 Simulated Force Sensors

Our force sensors are small boxes attached to damped

springs (Fig. 1). In the simulation, damped springs

were realized using slider joints, whose positions

were adjusted by a proportional-derivative controller.

The resting position of each spring was set such that

it was always under pressure. As sensor reading s,

we used the current position of a box (relative to the

resting position).

6.3 Control Tasks

We used two tasks: moving a ball around an eight fig-

ure and swinging a dumb-bell. In the first, one context

variable was hidden, the mass of the ball. The maxi-

mum mass (m = 0.03) of a ball was about one seventh

of the total mass of the robot arm. In the second task,

two variables were hidden: the dumb-bell mass and

its orientation. The two ball masses of the dumb-bell

were equal.

In all tasks, the desired trajectory of the end-

effector was pre-defined (Figs. 1 and 5) and its in-

verse in joint angles pre-computed. The eight was

traversed only once lasting 5000 time steps, and for

the dumb-bell, the end-effector swung for two peri-

ods together lasting 5000 time steps and followed by

1000 time steps during which the end-effector had to

stay in place (here, the control torques need to com-

pensate for the swinging dumb-bell). In both tasks,

a movement started and ended with zero velocity and

acceleration. The velocity profile was sinusoidal with

one peak.

For each task, three trajectories were pre-

computed: eight-figures of three different sizes (Fig.

1 shows the big eight; small and medium eight are 0.9

and 0.95 of the big-eight’s size, see Fig. 11) and three

lines of different heights (Fig. 13). For training, data

points were used from the two extremal trajectories,

excluding the middle trajectory. For testing, all three

trajectories were used.

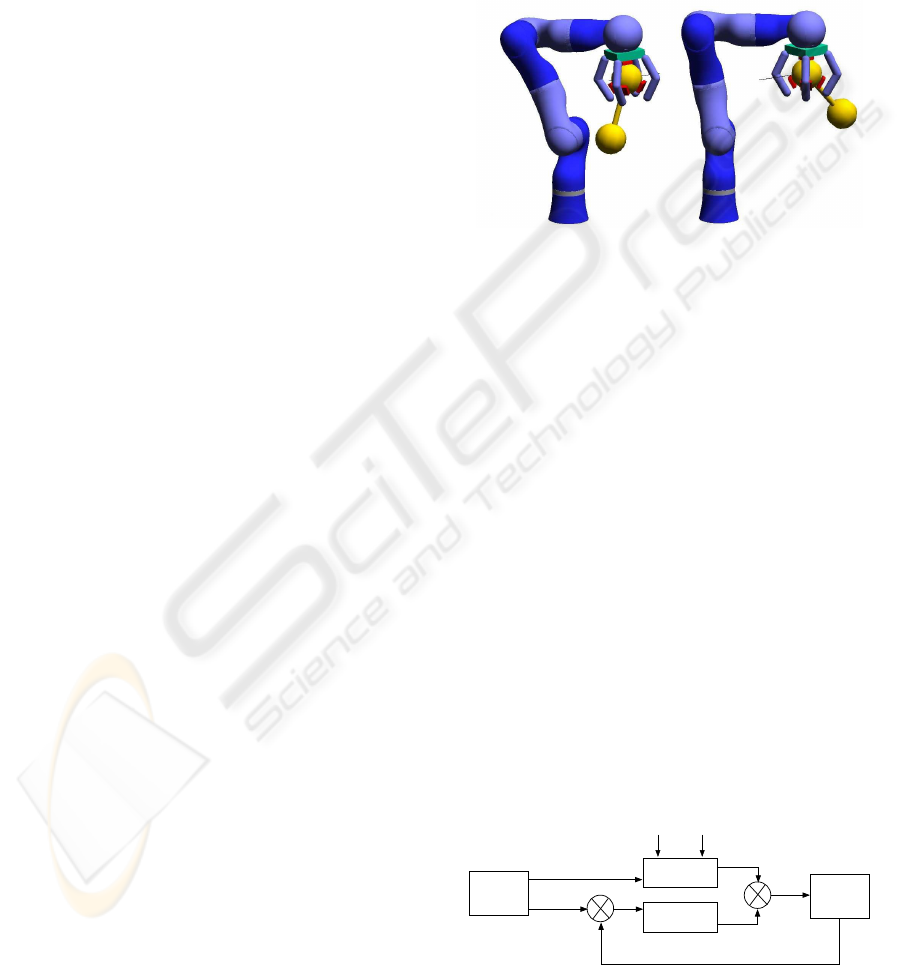

Figure 5: Robot swinging a dumb-bell. The black line

shows the desired trajectory.

6.4 Control Architecture

We used an adaptive controller and separated train-

ing and test phases. To generate training patterns, a

proportional-integral-derivative (PID) controller pro-

vided the joint torques. The proportional gain was

chosen to be sufficiently high such that the end-

effector was able to follow the desired trajectories.

The integral component was initialized to a value that

holds the arm against gravity (apart from that, its ef-

fect was negligible).

For testing, a composite controller provided the

joint torques (Fig. 6). The trained feed-forward con-

troller was put in parallel with a low-gain error feed-

back (its PD-gain was 1% of the gain used for training

in the ball case and 4% in the dumb-bell case). For

those feed-forward mappings that require an estimate

of the object’s mass, this estimate was computed us-

ing a Kalman filter as described above (the transition

Motion

plan

Controller

Plant

+

_

+

+

θ

d

.

θ

d

..

θ

d

θ

d

.

θ

d

.

θ

τ

ff

fb

τ

τ

Sensorm

or

θ

PD

Figure 6: Composite control for the robot arm. A feed-

forward controller is put in parallel with error feed-back

(low PD gain).

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

266

noise Ω of m was set to 10

−9

for both dynamics and

sensor case).

6.5 Controller Learning

The feed-forward controller was trained on data col-

lected during pure PID-control. For each mass con-

text, 10000 data points were collected in the ball case

and 12000 data points in the dumb-bell case. Half

of these points (every second) were used for training

and the other half for testing the regression perfor-

mance. Three types of mappings were learned. The

first maps the state and acceleration values (θ,

˙

θ,

¨

θ)

onto joint torques. The second maps the same input

onto the five sensory values, and the third maps the

sensor augmented input (θ,

˙

θ,

¨

θ, s) onto joint torques.

The first two of these mappings were trained on two

different labeled masses (m

1

= 0.005 and m

2

= 0.03

for ball or m

2

= 0.06 for dumb-bell). The last map-

ping used the data from 12 different mass contexts (m

increased from 0.005 to 0.06 in steps of 0.005); here,

the contexts were unlabeled.

Our learning task requires a non-linear regres-

sion technique that provides error boundaries for each

output value (required for the Kalman-filtering step).

Among the possible techniques, we chose locally-

weighted projection regression (LWPR)

2

(Vijayaku-

mar et al., 2005) because it is fast – LWPR is O(N),

where N is the number of data points; in contrast,

the popular Gaussian process regression is O(N

3

) if

making no approximation (Rasmussen and Williams,

2006).

7 RESULTS

The results of the robot-simulation experiments are

separated into ball task – inference and control under

varying mass – and dumb-bell task – inference and

control under multiple varying context variables.

7.1 Inference and Control Under

Varying Mass

For only one context variable, namely the mass of the

manipulated object, both inference strategies (Sec-

2

LWPR uses locally-weighted linear-regression. Data

points are weighted according to Gaussian receptive fields.

Our setup of the LWPR algorithm was as follows. For each

output dimension, a separate LWPR regressor was com-

puted. The widths of the Gaussian receptive fields were

hand-tuned for each input dimension, and these widths were

kept constant during the function approximation. Other

learning parameters were kept at default values.

tions 3 and 4) allowed to infer the unknown mass ac-

curately (Figs. 7 to 10).

-0.005

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0 1000 2000 3000 4000 5000

mass

time step

true mass

dynamic estimate

0

0.01

0.02

0.03

nMSE

Figure 7: Inferring mass purely from dynamics. The in-

ference results are shown for all three trajectories. The in-

set shows the normalized mean square error (nMSE) of the

mass estimate. The error bars on the nMSE are min and

max values averaged over an entire trajectory.

-0.005

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0 1000 2000 3000 4000 5000

mass

time step

true mass

sensor estimate

0

0.01

0.02

0.03

nMSE

Figure 8: Inferring mass using tactile sensors. For details

see Fig. 7.

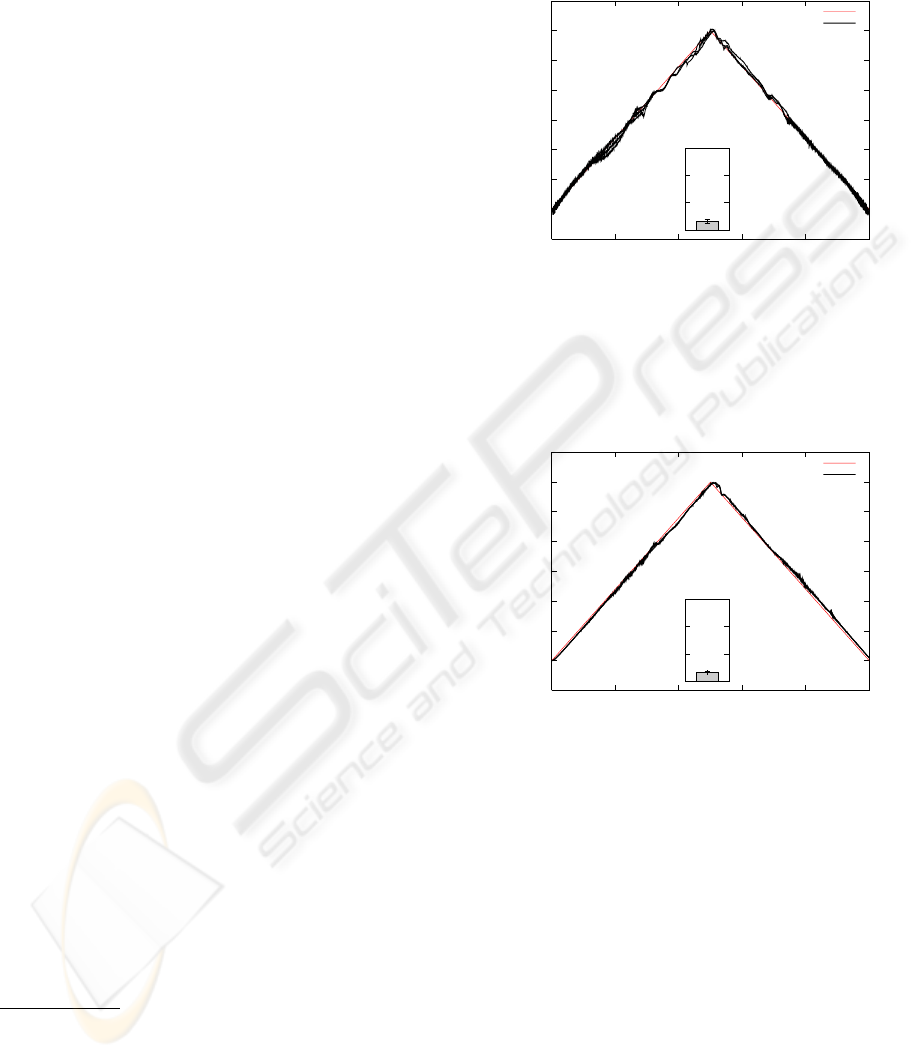

Both types of mappings from state and acceler-

ation either onto torques or onto sensors could be

learned with low regression errors, which were of

the same order (torques with m = 0.005: normalized

mean square error (nMSE) = 2.9 ∗ 10

−4

, m = 0.03:

nMSE = 2.7∗ 10

−4

; sensors with m = 0.005: nMSE =

1.3∗ 10

−4

, m = 0.03: nMSE = 2.2∗ 10

−4

). The error

of the inferred mass was about the same for dynamics

and sensor pathway. However, the variation between

trials was lower in the sensor case.

Given the inferred mass via the torque and sensory

pathways (Sections 3 and 4), our controller could pro-

vide accurate torques (Fig. 11). The results from both

pathways overlap with the desired trajectory. As illus-

trated in the figure, a PID controller with a PD-gain

as low as the gain of the error feed-back for the com-

SENSOR-ASSISTED ADAPTIVE MOTOR CONTROL UNDER CONTINUOUSLY VARYING CONTEXT

267

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0 1000 2000 3000 4000 5000

mass

time step

true mass

dynamic estimate

0

0.01

0.02

0.03

nMSE

Figure 9: Inferring mass purely from dynamics. For details

see Fig. 7.

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0 1000 2000 3000 4000 5000

mass

time step

true mass

sensor estimate

0

0.01

0.02

0.03

nMSE

Figure 10: Inferring mass using tactile sensors. For details

see Fig. 7.

0.4

0.6

0.8

1

1.2

1.4

-0.6 -0.4 -0.2 0 0.2 0.4 0.6

z-coordinate

y-coordinate

target

low-gain PID

sensor estimate

dynamic estimate

wrong mass

Figure 11: Following-the-eight task. The figure com-

pares low-gain PID control (on large eight only) with the

composite-controller that uses either the predicted mass es-

timate (from dynamics or sensors) or a wrong estimate

(m = 0.03, on large eight only). The true mass decreased

continuously from 0.03 to 0. The results for composite con-

trol based on the predicted mass overlap with the target for

all three test curves.

posite controller was insufficient for keeping the ball

on the eight figure. The figure furthermore illustrates

that without a correct mass estimate, tracking was im-

paired. Thus, correctly estimating the mass matters

for this task.

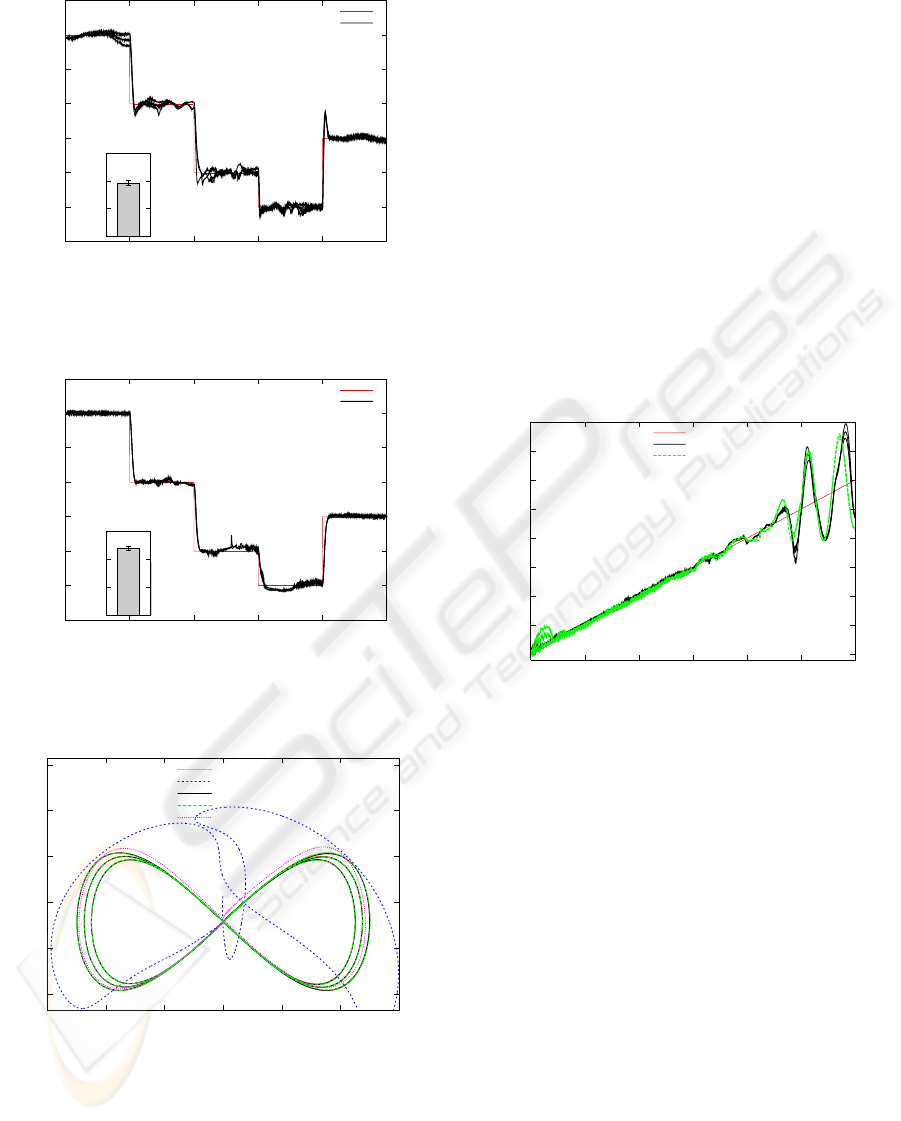

7.2 Inference and Control Under

Multiple Varying Context

The inference of mass based on a single hidden vari-

able failed if more variables varied (Fig. 12). We

demonstrate this failure with the swinging dumb-bell,

whose mass increased continuously during the trial.

In the last part of the trial, when the dumb-bell was

heavy and swung, the mass inference was worst. The

wrong mass estimate further impaired the control of

the robot arm (see Fig. 13).

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0 1000 2000 3000 4000 5000 6000

mass

time step

true mass

sensor estimate

dynamic estimate

Figure 12: Inference of mass in the dumb-bell task.

During the last part of the movement, tracking was

better with the direct mapping from (θ,

˙

θ,

¨

θ, s) onto

torques. For this mapping, the results still show some

deviation from the target. However, we expect this

error to reduce with more training data.

8 CONCLUSIONS

We presented three strategies for adaptive motor con-

trol under continuously varying context. First, hidden

inertia parameters of a manipulated object can be in-

ferred from the dynamics and in turn used to predict

control torques. Second, the hidden mass of an object

can be inferred from the tactile forces exerted by the

object. Third, correct control torques can be predicted

by augmenting the input (θ,

˙

θ,

¨

θ) with tactile forces

and by directly mapping this input onto the torques.

We demonstrated the first two strategies with ob-

ject mass as the varying context. For more context

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

268

0.52

0.53

0.54

0.55

0.56

0 1000 2000 3000 4000 5000 6000

z-coordinate

time step

target

low-gain PID

dynamic estimate

direct mapping

Figure 13: Swinging-the-dumb-bell task. The figure com-

pares low-gain PID control (shown only on the middle tra-

jectory) with the composite-controller that uses either the

predicted mass estimate from dynamics or a direct mapping

from (θ,

˙

θ,

¨

θ, s) onto torques. For the estimate from sen-

sors, the results were similar to the dynamics case and are

omitted in the graph to improve legibility. The true mass

increased continuously from 0 to 0.06.

variables, inferring the mass failed, and thus, the con-

trol torques were inaccurate. In principle, all iner-

tia parameters could be inferred from the dynamics,

but this inference requires modeling a 10-dimensional

latent-variable space, which is unfeasible without ex-

tensive training data.

On the other hand, the direct mapping onto

torques with sensors as additional input could predict

accurate control torques under two varying context

variables and in principle could cope with arbitrary

changes of the manipulated object (including exter-

nal forces). Further advantages of this strategy are its

simplicity (it only requires function approximation),

and for training, no labeled contexts are required.

In future work, we try to replicate these findings

on a real robot arm with real tactile sensors. Real sen-

sors might be more noisy compared to our simulated

sensors; particularly, the interface between sensor and

object is less well controlled.

ACKNOWLEDGEMENTS

The authors are grateful to the German Aerospace Center

(DLR) for providing the data of the Light-Weight Robot III

and to Marc Toussaint and Djordje Mitrovic for their con-

tribution to the robot-arm simulator. This work was funded

under the SENSOPAC project. SENSOPAC is supported

by the European Commission through the Sixth Framework

Program for Research and Development up to 6 500 000

EUR (out of a total budget of 8 195 953.50 EUR); the SEN-

SOPAC project addresses the “Information Society Tech-

nologies” thematic priority. G. P. was funded by the Greek

State Scholarships Foundation.

REFERENCES

Haruno, M., Wolpert, D. M., and Kawato, M. (2001).

Mosaic model for sensorimotor learning and control.

Neural Computation, 13:2201–2220.

Kalman, R. E. (1960). A new approach to linear filtering

and prediction problems. Transactions of the ASME -

Journal of Basic Engineering, 82:35–45.

Narendra, K. S. and Balakrishnan, J. (1997). Adaptive con-

trol using multiple models. IEEE Transactions on Au-

tomatic Control, 42(2):171–187.

Narendra, K. S. and Xiang, C. (2000). Adaptive con-

trol of discrete-time systems using multiple mod-

els. IEEE Transactions on Automatic Control,

45(9):1669–1686.

Petkos, G., Toussaint, M., and Vijayakumar, S. (2006).

Learning multiple models of non-linear dynamics for

control under varying contexts. In Proceedings of

the International Conference on Artificial Neural Net-

works. Springer.

Petkos, G. and Vijayakumar, S. (2007). Context estimation

and learning control through latent variable extraction:

From discrete to continuous contexts. In Proceedings

of the International Conference on Robotics and Au-

tomation. IEEE.

Rasmussen, C. E. and Williams, C. K. I. (2006). Gaussian

Processes for Machine Learning. MIT Press.

Sciavicco, L. and Siciliano, B. (2000). Modelling and Con-

trol of Robot Manipulators. Springer.

Vijayakumar, S., D’Souza, A., and Schaal, S. (2005). In-

cremental online learning in high dimensions. Neural

Computation, 17:2602–2634.

Wolpert, D. M. and Kawato, M. (1998). Multiple paired

forward and inverse models for motor control. Neural

Networks, 11:1317–1329.

SENSOR-ASSISTED ADAPTIVE MOTOR CONTROL UNDER CONTINUOUSLY VARYING CONTEXT

269