MATHEMATICAL MODEL FOR WALKING ROBOT

WITH SHAPE MEMORY ALLOY ANKLE

Anca Petrişor, Nicu George Bîzdoacă

Faculty of Electromechanical Engineering, University of Craiova, Romania

Daniela Roşca, Sonia Degeratu, Adrian Roşca, Raducu Petrisor

Faculty of Electromechanical Engineering, University of Craiova, Romania

Keywords: Robotics, shape memory alloy applications, robotic ankle, walking robot, mathematical model.

Abstract: The paper presents a simultaneous force and length variation mode in shape memory alloy (SMA) robotic

application.

The robotic ankle contains four SMA actuators and a spherical articulation. In order to assure a

high efficient robotic architecture, the mechanical and the control structure have to assure a real-time

response to the work environment changes. The load variations or the difference between the moment of

full contact step and the non contact moment for a waking robot are the standard situations for a SMA

robotic ankle. The paper is divided in five sections. First section makes a short introduction in the physical

description and conventional applications of shape memory alloy materials. Then, are presented the

mathematical model for robotic ankle, the walking robot geometrical structure and the causality ordering of

the active pair of legs, in this case with one free joint. In the last section some experimental results are

presented. These results were obtained by using MATLAB programs, conceived by authors, for design and

simulation of walking robots control algorithms.

1 INTRODUCTION

The shape memory effect was first noted over 50

years ago; it was not until 1962, however, with the

discovery of a nickel titanium shape memory alloy

by Buehler, that serious investigations were

undertaken to understand the mechanism of the

shape memory effect (Bîzdoacă and Pană, 2004),

(Funakubo, 1987), (Graesser and Cozarelli, 1994),

(Schroeder and Boller, 1993).

The shape memory alloys possess the ability to

unde

rgo shape change at low temperature and retain

this deformation until they are heated, at which point

they return to their original shape.

The nickel titanium alloys, used in the present

researc

h, generally refereed to as Nitinol, have

compositions of approximately 50 atomic % Ni/ 50

atomic % Ti, with small additions of copper, iron,

cobalt or chromium. The alloys are four times the

cost of Cu-Zn-Al alloys, but it possesses several

advantages as greater ductility, more recoverable

motion, excellent corrosion resistance, stable

transformation temperatures, high biocompatability

and the ability to be electrically heated for shape

recovery.

Shape memory actuators are considered to be

low power ac

tuators and such as compete with

solenoids, bimetals and to some degree was motors.

It is estimated that shape memory springs can

provide over 100 times the work output of thermal

bimetals.

The use of shape memory alloy can sometimes

sim

plify a mechanism or device, reducing the

overall number of parts, increasing reliability and

therefore reducing associated quality costs.

Because of its high resistivity of 80 – 89 micro

o

hm-cm, nickel titanium can be self heated by

passing an electrical current through it. The basic

rule for electrical actuation is that the temperature of

complete transformation to martensite M

f

, of the

actuator, must be well above the maximum ambient

temperature expected (Delay and Chandrasekaran,

1987).

319

Petri¸sor A., George Bîzdoac

ˇ

a N., Ro¸sca D., Degeratu S., Ro¸sca A. and Petrisor R. (2007).

MATHEMATICAL MODEL FOR WALKING ROBOT WITH SHAPE MEMORY ALLOY ANKLE.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 319-322

DOI: 10.5220/0001626703190322

Copyright

c

SciTePress

2 MATHEMATICAL MODEL OF

SHAPE MEMORY ALLOY

ANKLE

The robotic researches develop up to the present a

various mechanical architecture for ankle structure.

All projects use the human ankle as model.

The problem in developing efficient ankle

structure, concern the dimension and the efficiency

of actuators.

The proposed robot ankle structure contains units

with SMA actuators. The unit has 4 SMA actuators

and a spherical articulation.

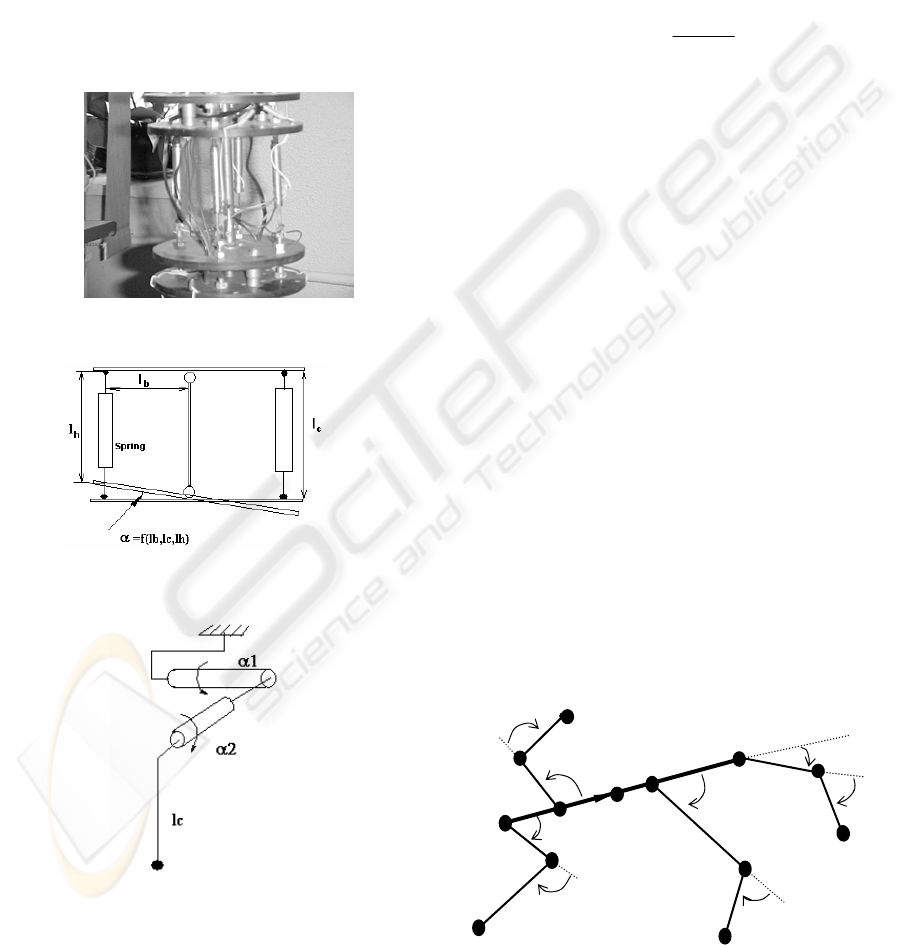

Figure 1: The proposed SMA robotic ankle.

Figure 2: Schematically representation of SMA ankle.

Figure 3: Kinematics representation of SMA ankle.

The mathematical model of the ankle is very

simple:

(

)

H,,l

c

12

ankle

α

α=

22c

12 1 1 2c1

12 1 1 2c 1 2

cosα 0sinα lsinα

sin α sin α cos α sin α cos α lsinα cosα

cosα sin α sin α cosα cos α lcosα cos α

000 1

−−

−

2

2

(1)

Analysing the angle dependence versus the SMA

spring variation, a highly nonlinear function results:

()

()

()

22

2l l

c

b

arcsin cos arctg l arctg l

hh

2l

b

⎡⎤

+

⎢⎥

α= +

⎢⎥

⎣⎦

(2)

where l

h

is the length after the heating process; l

c

is

the spring length after cooling and l

b

the base length.

As the real variation is restricted (between 100%

and 92 %), the linearization can occur because of

linear behaviour for the specified evolution

(Bîzdoacă and Pană, 2003).

3 WALKING ROBOT

GEOMETRICAL STRUCTURE

It is considered the walking robot structure as

depicted in Fig.4, having three normal legs

and a head equivalent to another leg, L

ijp

L,L,L

0,

containing the robot centre of gravity, G, placed in

its foot. The robot body RB is characterized by two

position vectors O

0

, O

1

and the leg joining points

denoted R

i

, R

j

, R

p

. The joining point of the head, L

0

,

is the central point O

0

, R

0

= O

0

, so the robot body RB

is univocally characterized by the set,

01ijp0

RB {O , O , , , , }

=

λλλ λ

(3)

where

0

0

λ

= .

u

1,0

G

0

=G

R

p

Figure 4: Geometrical structure of the robot.

u

1,j

u

1,i

u

2,i

G

i

O

1

O

0

R

j

u

2,j

u

1,p

G

p

u

2,p

u

2,0

R

0

R

i

G

j

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

320

The robot position in the vertical plane is defined

by the pair of the position vectors O

0

, O

1

where

, or by the vector O

10

|O O | 1−=

0

and the scalar θ,

the angular direction of the robot body.

Each of the four robot legs is

characterized by a so-called Existence Relation

ER(L) depending on specific variables as it is

presented in (Petrişor, 2005), (Petrişor, Marin,

Bîzdoacă and Cazacu, 2006).

ijp0

L,L,L ,L

The mathematical model of this object is a

Variable Causality Dynamic Systems VCDS and it

is analiyzed from this point of view.

A pair of legs {L

i

, L

j

} constitutes the so called

Active Pair of Legs (APL) if the robot body position

is the same irrespective of the feet position of all the

other legs different of

i

L

and

j

L

. A label is assigned

to each possible APL. The APL label is expressed

by a variable called Index of Activity (IA), which

can take N

q

a

values, numbers or strings of characters.

All the other legs that at a time instant do not belong

to APL are called Passive Legs (PL). The leg in

APL, having a free joining point is called slave leg,

the opposite of the motor leg whose both joining

points are external controlled.

4 CAUSALITY ORDERING OF AN

ACTIVE PAIR OF LEGS WITH

ONE FREE JOINT

In this structure, only one angle is free so three joints

are external controlled (EC).It is denoted this by

q'ij'=

,

p

c [motor12, motor01, c ]=

(4)

This causality ordering is corresponded to the

state having the leg L

i

as a motor leg which controls

two degree of freedom and the leg L

j

, a slave leg,

which can control only one scalar component , so

the angle is free and the angle is EC.

2, j

u

1, j

u

In this structure is obtained from the

following relations:

2, j

u

2, j j

2j

2, j

(t)

2, j j

2j

ˆ

if u (t ) 0 s up

u

ˆ

if u (t ) 0 s down

⎧

ψ−ε>⇔

⎪

=

⎨

−ψ −ε ≤ ⇔ =

⎪

⎩

=

(

5)

2j 2j 2j 2j

2, j

(t)

2j 2j 2j 2j

dacă 0

u

dacă 0

−ϕ + ψ −ϕ + ψ ≤

⎧

⎪

=

⎨

−ϕ +ψ −π −ϕ +ψ >

⎪

⎩

(6)

2j 2j 2j 2j

2, j

(t)

2j 2j 2j 2j

dacă 0

u

dacă 0

−ϕ + ψ + π −ϕ + ψ ≤

⎧

⎪

=

⎨

−ϕ + ψ −ϕ + ψ >

⎪

⎩

(7)

Therefore, in this causality structure the

kinematics restriction

ji

ij

RR r

−

=

is accomplished

by changing the value of

u at giving by the

equation (5), (6), (7).

2, j 2, j

u

5 EXPERIMENTAL RESULTS

The causal ordering c=[motor12, motor 01, c

p

] is

implemented together with other causal orderings, in

the RoPa platform for design and simulation of

walking robots control algorithms. The RoPa

platform is a complex of Matlab programs to

analyze and design walking robots, evolving in

uncertain environments according to a new control

approach called Stable State Transition Approach

(SSTA), also conceived by the authors.

The causal ordering developed in this paper is

activated by selecting the causal variable

cz=[12 1 0]. The RoPa platform allows animation,

recording of the evolutions and playback them.

In the following there are presented some

experimental results of walking robot behaviour

considering this causal ordering.

4

3

2

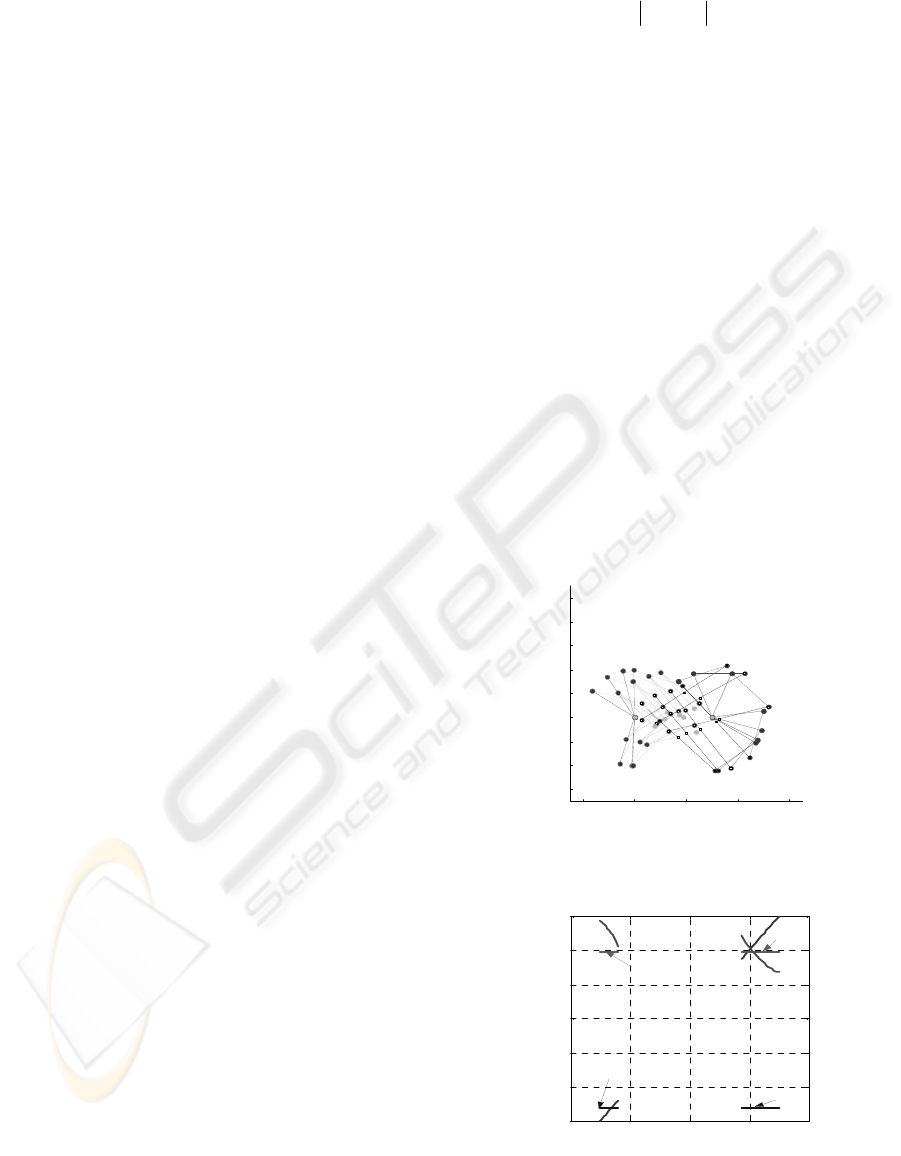

Figure 5: The robot kinematics evolution.

Figure 6: Controlled angles with respect to the input angle.

-2 0 2 4 6

-3

-2

-1

0

1

5

RoPa1Ex2S1V1q132cz1210

x

y [m]

[

m

]

3

-4 -2 0 2 4

-3

-2

-1

0

1

←

u

2,3

u

1,3

2

u

1,1

u

1,1

u

2,1

u

1,3

u

2,3

G

1

= 0

G

3

= 3

←

u

1,1

u

2,1

u

1,3

←

u

2,3

u

2,1

MATHEMATICAL MODEL FOR WALKING ROBOT WITH SHAPE MEMORY ALLOY ANKLE

321

Figure 7: Robot body position with respect to the input

angle.

Figure 8: Joints positions with respect to the input angle.

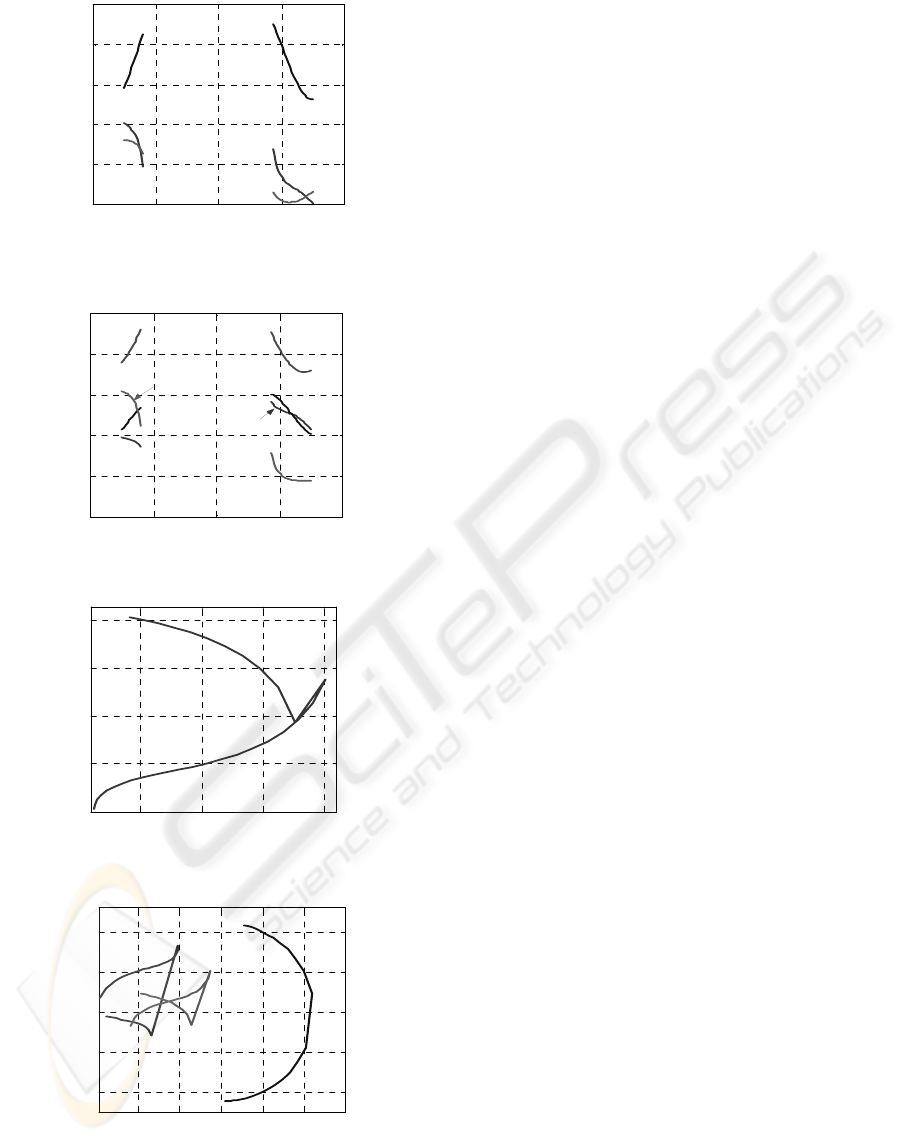

Figure 9: Reference point O

0

locus in evolution scene.

Figure 10: Joints points' locus in evolution scene.

6 CONCLUSIONS

-4 -2 0 2 4

-1

0

1

2

3

4

u

1,1

Im(O

0

) Re(O

0

)

θ

G

1

= 0

G

3

= 3

←

Im (O

0

)

←

Re(O

0

)

←θ

←

Re(O

0

)

←

Im (O

0

)

←θ

Shape memory alloy ankle add to the walking robot

architecture additional control possibility for

adapting the structure to various environment.

The causal ordering developed in the paper is

useful when it must control the shoulder position R

i

irrespective of the other variables. It can be

controlled by the angle u

1,j

, the shoulder angle of the

second active leg L

j

.

The approach of the kinematics structure by

complex number representation of the variables

allowed to solve the equations system that describe

the position of the variables that are involved,

between witch there are kinematics correlations. In

this way, it is obtained an explicit representation of

the input-output dependence, in this causality

structure.

-4 -2 0 2 4

-4

-2

0

2

4

6

u

1,1

Im(R

1

) Re(R

1

) Im(R

3

) Re(R

3

)

G

1

= 0

G

3

= 3

←

Im (R

1

)

←

Re(R

1

)

Im (R

3

)

←

Re(R

3

)

←

Re(R

3

)

Im (R

1

)

←

Re(R

1

)

←

Im (R

3

)

As it can be seen from the above experimental

results, this causal ordering is perfectly integrated in

the RoPa structure proving the correctness of the

theoretical results.

The mathematical model developed in the

paper becomes an element of the VCDS walking

robot model. The simulations used MATLAB

environment show the robustness of the

mathematical model.

2 2.5 3 3.5

-1

-0.5

0

0.5

1

Real(O

0

)

Imag(O

0

)

G

1

= 0

G

3

= 3

←

Imag(O

0

)

REFERENCES

Bîzdoacă, N., Pană D., 2003. Shape memory alloy tendon

driven finger. In Proceedings of the 14th international

conference on control systems and computer science,

CSCS15, Bucharest, Romania, May 25-27.

Bîzdoacă, N., Pană D., 2004. Shape Memory Alloy Based

Robotic Ankle. In Proceedings of the 5th International

Carpathian Control Conference, ICCC 2004, Vol. I.

Delay, L., Chandrasekaran M., 1987. Les Editions

Physique. Les Ulis.

Funakubo, H., 1987. Shape Memory Alloys. Gordon and

Breach Science Publishers.

1 2 3 4 5

-2

-1

0

1

2

Re(R

1

) Re(R

3

) Re(R

2

)

Im(R

1

) Im(R

3

) Im(R

2

)

G

1

= 0

G

3

= 3

←

Im (R

1

)

←

Im (R

3

)

←

Im (R

2

)

Graesser, E.J., Cozarelli F.A., 1994. Journal of Intelligent

Material Systems and Structures, no.5.

Petrişor, A., 2005. Walking mouvement with controlled

style of the passive leg. In Proceedings of the 15th

international conference on control systems and

computer science, CSCS15, Bucharest, Romania, May

25-27, 2005, pag.483-487.

Petrişor, A., Marin, C., Bîzdoacă, N., Cazacu, D. 2006.

Variable Causality Dynamic System Approach for

Robot Control. WSEAS Transactions on Systems and

Control Journal, Issue 1, Volume 1, Nov., pp.26-30

Schroeder, B., Boller, Ch., 1998. Comparative Assessment

of Models for Describing the Constitutive Behaviour

of Shape Memory Alloy, Smart Materials and

Structures.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

322