MODELING AND OPTIMAL TRAJECTORY PLANNING OF A

BIPED ROBOT USING NEWTON-EULER FORMULATION

David Tlalolini, Yannick Aoustin and Christine Chevallereau

Institut de Recherche en Communications et Cybern

´

etique de Nantes

CNRS, Ecole Centrale de Nantes, Universit de Nantes, 1 rue la No, 44321 Nantes, France

Keywords:

3D biped, cyclic walking gait, parametric optimization, constraints.

Abstract:

The development of an algorithm to achieve optimal cyclic gaits in space for a thirteen-link biped and twelve

actuated joints is proposed. The cyclic walking gait is composed of successive single support phases and

impulsive impacts with full contact between the sole of the feet and the ground. The evolution of the joints are

chosen as spline functions. The parameters to define the spline functions are determined using an optimization

under constraints on the dynamic balance, on the ground reactions, on the validity of impact, on the torques

and on the joints velocities. The criterion considered is represented by the integral of the torque norm. The

algorithm is tested for a biped robot whose numerical walking results are presented.

1 INTRODUCTION

The design of walking gaits for legged robots and par-

ticularly the bipeds has attracted the interest of many

researchers for several decades. Due to the unilateral

constraints of the biped with the ground and the great

number of degrees of freedom, this problem is not

trivial. Intuitive methods can be used to obtain walk-

ing gaits as in (Grishin et al., 1994). Using experi-

mental data and physical considerations, the authors

defined polynomial functions in time for a prototype

planar biped. This method is efficient. However to

build a prototype and to choose the appropriate actu-

ators or to improve the autonomy of a biped, an op-

timization algorithm can lead to very interesting re-

sults. In (Rostami and Besonnet, 1998) the Pontrya-

gin’s principle is used to design impactless nominal

trajectories for a planar biped with feet. However the

calculations are complex and difficult to extend to the

3D case. As a consequence a parametric optimisation

is a useful tool to find optimal motion.

The choice of optimisation parameters is not

unique. The torques, the Cartesian coordinates or

joint coordinates can be used. Discrete values for the

torques defined at sampling time are used as optimiza-

tion parameters in (Roussel et al., 2003). However

it is necessary, when the torque is an optimised vari-

able, to solve the inverse dynamic problem to find the

joint accelerations and integrations are used to obtain

the evolution of the reference trajectory in velocity

and in position. Thus this approach require many cal-

culation : the direct dynamic model is complex and

many evaluations of this model is used in the inte-

gration process. In (Beletskii and Chudinov, 1977),

(Bessonnet et al., 2002), (Channon et al., 1992), (Zon-

frilli et al., 2002), (Chevallereau. and Aoustin, 2001)

or (Miossec and Aoustin, 2006) to overcome this diffi-

culty, the parametric optimization defines directly the

reference trajectories of Cartesian coordinates or joint

coordinates for 2D bipeds with feet or without feet.

An extension of this strategy is given in this paper for

a 3D biped with with twelve motorized joints. The

dynamic model is more complex than for a 2D biped,

so its computation cost is important in the optimisa-

tion process and the use of Newton-Euler method to

calculate the torque is more appropriate than the La-

grange method usually used. Since the inverse dy-

namic model is used only to evaluate the torque for

the constraints and criterion calculation, the number

of evaluation of the torque can be limited. The de-

sired motion is based on the solution of an optimal

problem whose constraints depend on the nonlinear

multibody system dynamics of the 12 DoF biped and

physical contact constraints with the environment.

76

Tlalolini D., Aoustin Y. and Chevallereau C. (2007).

MODELING AND OPTIMAL TRAJECTORY PLANNING OF A BIPED ROBOT USING NEWTON-EULER FORMULATION.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 76-83

DOI: 10.5220/0001628200760083

Copyright

c

SciTePress

A half step of the cyclic walking gait is com-

posed uniquely of a single support and an instanta-

neous double support that is modelled by passive im-

pulsive equations. This walking gait is simpler that

the human gait, but with this simple model the cou-

pling effect between the motion in frontal plan and

sagittal plane can be studied. A finite time double

support phase in not considered in this work currently

because for rigid modelling of robot, a double support

phase can usually be obtained only when the velocity

of the swing leg tip before impact is null. This con-

straint has two effects. In the control process it will

be difficult to touch the ground with a null velocity,

as a consequence the real motion of the robot will be

far from the ideal cycle. Furthermore, large torques

are required to slow down the swing leg before the

impact and to accelerate the swing leg at the begin-

ning of the single support. The energy cost of such

a motion is higher than a motion with impact in the

case of a planar robot without feet (Chevallereau. and

Aoustin, 2001), (Miossec and Aoustin, 2006).

Therefore a dynamic model is calculated for the

single phase. An impulsive model for the impact on

the ground with complete surface of the foot sole of

the swing leg is deduced from the dynamic model

for the biped in double support phase. It takes into

account the wrench reaction from the ground. This

model is founded on the Newton Euler algorithm,

considering that the reference frame is connected to a

stance foot. The evolution of joint variables are cho-

sen as a spline function of time instead of usual poly-

nomial functions to prevent oscillatory phenomenon

during the optimization process (see (Chevallereau.

and Aoustin, 2001), (Saidouni and Bessonnet, 2003)

or (L. Hu and Sun, 2006)). The coefficients of the

spline functions are calculated as function of initial,

intermediate and final configurations and initial and

final velocities of the robot which are optimization

variables. Taking into account the impact and the fact

that the desired walking gait is cyclic, the number of

optimization variables is reduced. The criterion con-

sidered is the integral of the torque norm. During the

optimization process, the constraints on the dynamic

balance, on the ground reactions, on the validity of

impact, on the limits of the torques, on the joints ve-

locities and on the motion velocity of the biped robot

are taken into account. The paper is organized as fol-

lows. The 3D biped and its dynamic model are pre-

sented in Section II. The cyclic walking gait and the

constraints are defined in Section III. The optimiza-

tion parameters, optimization process and the crite-

rion are discussed in Section IV. Simulation results

are presented in Section V. Section VI contains our

conclusion and perspectives.

2 MODELS OF THE STUDIED

BIPED ROBOT

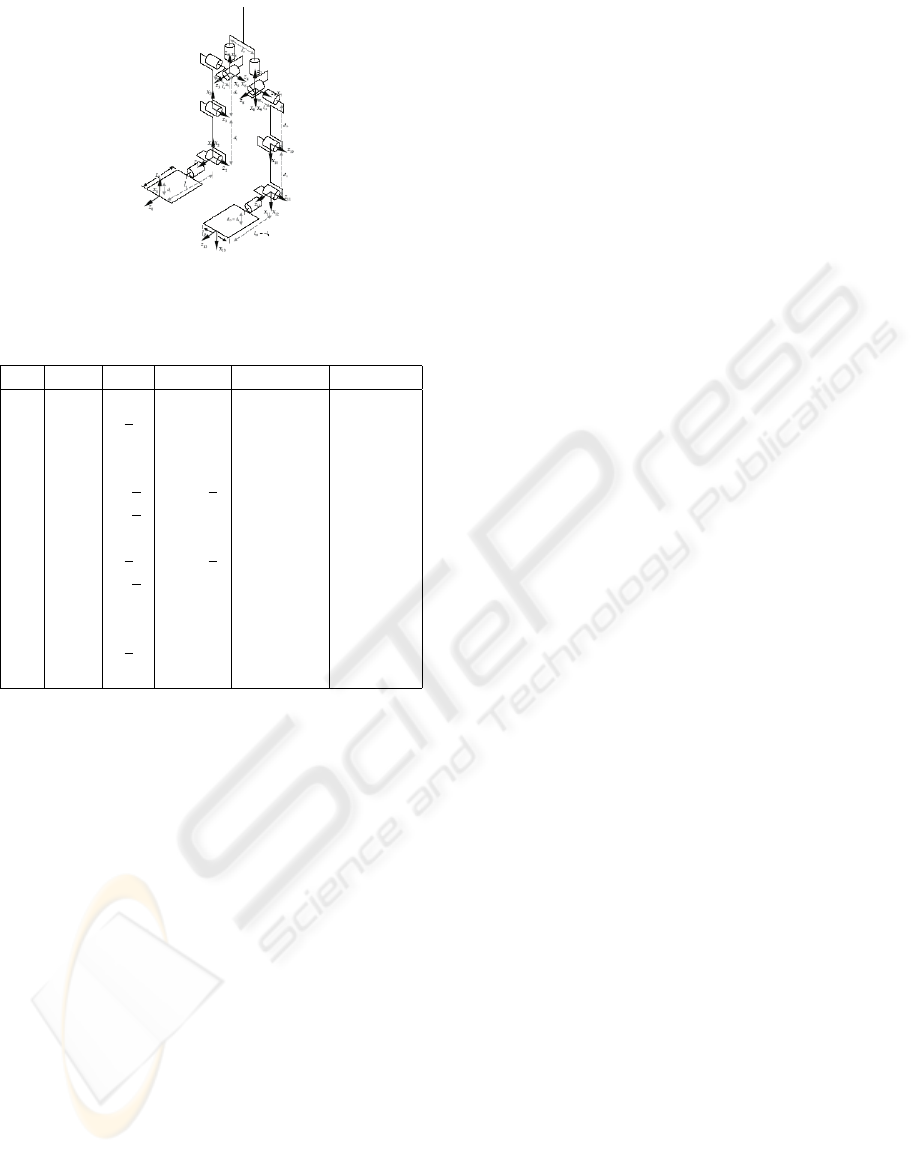

2.1 Biped Model

We considered an anthropomorphic biped robot with

thirteen rigid links connected by twelve motorized

joints to form a tree structure. It is composed of a

torso, which is not directly actuated, and two identi-

cal open chains called legs that are connected at the

hips. Each leg is composed of two massive links con-

nected by a joint called knee. The link at the extremity

of each leg is called foot which is connected at the leg

by a joint called ankle. Each revolute joint is assumed

to be independently actuated and ideal (frictionless).

The ankles of the biped robot consist of the pitch and

the roll axes, the knees consist of the pitch axis and

the hips consist of the roll, pitch and yaw axes to con-

stitute a biped walking system of two 2-DoF ankles,

two 1-DoF knees and two 3-DoF hips as shown in

figure 1. The action to walk associates single support

phases separated by impacts with full contact between

the sole of the feet and the ground, so that a model in

single support, a model in double support and an im-

pact model are derived.

2.2 Geometric Description of the Biped

To define the geometric structure of the biped walk-

ing system we assume that the link 0 (stance foot)

is the base of the biped robot while link 12 (swing

foot) is the terminal link. Therefore we have a sim-

ple open loop robot which geometric structure can be

described using the notation of Khalil and Kleinfinger

(Khalil and Dombre, 2002). The definition of the link

frames is given in figure 1 and the corresponding ge-

ometric parameters are given in Table I. The frame R

0

coordinates, which is fixed to the tip of the right foot

(determined by the width l

p

and the length L

p

), is de-

fined such that the axis z

0

is along the axis of frontal

joint ankle. The frame R

13

is fixed to the tip of the left

foot in the same way that R

0

.

2.3 Dynamic Model in Single Support

Phase

During the single support phase the stance foot is as-

sumed to remain in flat contact on the ground, i.e.,

no sliding motion, no take-off, no rotation. Therefore

the dynamics of the biped is equivalent to an 12 DoF

manipulator robot. Let q ∈ R

12

be the generalized co-

ordinates, where q

1

,...,q

12

denote the relative angles

of the joints, ˙q ∈ R

12

and ¨q ∈ R

12

are the velocity

MODELING AND OPTIMAL TRAJECTORY PLANNING OF A BIPED ROBOT USING NEWTON-EULER

FORMULATION

77

Figure 1: The multi-body model and link frames of the

biped robot.

Table 1: Geometric parameters of the biped.

j a( j) α

j

θ

j

r

j

d

j

1 0 0 q

1

l

1

d

1

2 1

π

2

q

2

0 0

3 2 0 q

3

0 d

3

4 3 0 q

4

l

4

d

4

5 4 −

π

2

q

5

−

π

2

0 0

6 5 −

π

2

q

6

0 0

7 6 0 q

7

0 d

7

8 7

π

2

q

8

−

π

2

0 0

9 8 −

π

2

q

9

0 0

10 9 0 q

10

l

10

= l

4

d

10

= d

4

11 10 0 q

11

0 d

11

= d

3

12 11

π

2

q

12

0 0

13 12 0 q

13

l

13

= −l

1

d

13

= d

1

and acceleration vectors respectively. The dynamic

model is computed using the Newton-Euler method

(see (Khalil and Dombre, 2002)) represented by the

following relation

Γ = f(q, ˙q, ¨q,F

t

) (1)

where Γ ∈ R

12

is the joint torques vector and F

t

is

the external wrench (forces and torques), exerted by

the swing foot on the ground. In single support phase

F

t

= 0 and in double support phase F

t

6= 0.

In order to denote the dynamic model under the

Lagrange form

Γ = D

s

(q) ¨q+ H

s

(2)

with

H

s

= (C

s

(q, ˙q) + G

s

(q)) (3)

the equation (1) is used. In such calculation the ma-

trix D

s

and the vector H

s

are needed. C

s

∈ R

12

repre-

sents the Coriolis and centrifugal forces and G

s

∈ R

12

is the vector of gravity.

The matrix D

s

is calculated by the algorithm

of Newton-Euler, by noting from the relation (1),

(M.W.Walker and D.E.Orin, 1982), that the i

th

col-

umn is equal to Γ if

˙q = 0,g = 0, ¨q = e

i

,F

t

= 0

e

i

∈ R

12×1

is the unit vector, whose elements are zero

except the i

th

element which is equal to 1.

The calculation of the vector H

s

is obtained in the

same way that D

s

considering that H

s

= Γ if ¨q = 0.

Therefore, the dynamic model under the Lagrange

form is denoted by the following matrix equations

Γ = D

s

(q) ¨q+ H

s

(q, ˙q)

where D

s

∈ R

12×12

is the symmetric definite positive

inertia matrix.

To take easily into account the effect of the reac-

tion force on the stance foot, it is interesting to add 6

coordinates to describe the situation of the stance foot.

Newton variables are used for this link, thus its veloc-

ity is described by the linear velocity of frame R

0

: V

0

and angular velocity ω

0

. Since the stance foot is as-

sumed to remain in flat contact, the resultant ground

reaction force/moment F

R

and M

R

are computed by

using the Newton-Euler algorithm. ω

0

= 0,

˙

ω

0

= 0

and

˙

V

0

= −g are the initial conditions of the Newton-

Euler algorithm to take into account the effect of grav-

ity. So, the equation (2) becomes

D(X)

˙

V +C(V,q) + G(X) = D

Γ

Γ+ D

R

R

F

R

(4)

where X = [X

0

,α

0

,q]

T

∈ R

18

, X

0

and α

0

is the posi-

tion and the orientation variables of frame R

0

, V =

[

0

V

0

,

0

ω

0

, ˙q]

T

∈ R

18

and

˙

V = [

0

˙

V

0

,

0

˙

ω

0

, ¨q]

T

∈ R

18

.

D ∈ R

18×18

is the symmetric definite positive iner-

tia matrix, C ∈ R

18

represents the Coriolis and cen-

trifugal forces, G ∈ R

18

is the vector of gravity.

R

F

R

= [F

R

,M

R

]

T

∈ R

6

is the ground reaction forces

on the stance foot, calculated by the Newton-Euler al-

gorithm, D

Γ

= [0

6×12

| I

12×12

]

T

∈ R

18×12

and D

R

=

[I

6×6

| 0

12×6

]

T

∈ R

6×18

are constant matrices com-

posed of 1 and 0.

In the optimization process, the torques and force

are calculated with the Newton-Euler algorithm and

not with the equation (4). The Newton-Euler is much

more efficient from the computation point of view,

(Khalil and Dombre, 2002).

2.4 Dynamic Model in Double Support

Phase

In double support phase, only the forces and moments

of interaction of the left foot with the ground have to

be added. Then, the model (4) becomes

D(X)

˙

V +C(V,q) + G(X) + D

f

R

f

= D

Γ

Γ+ D

R

R

F

R

(5)

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

78

where R

f

∈ R

6

represents the vector of forces F

12

and

moments M

12

exerted by the left foot on the ground.

This wrench is naturally expressed in frame R

12

:

12

F

12

,

12

M

12

. The virtual work δW

12

of this wrench is :

δW

12

=

12

F

T12

12

d

12

+

12

M

12

12

δ

12

(6)

where

12

d

12

represents an infinitesimal virtual dis-

placement of the link 12 and

12

δ

12

represents an in-

finitesimal virtual angular displacement. The relation

between these virtual displacements,

12

d

12

and

12

δ

12

,

and the virtual joints displacement δq

12

are the same

that between the velocities

12

V

12

,

12

ω

12

and ˙q

12

.

Usually the velocities of link 12 can be expressed

as

V

12

w

12

=

V

0

+ w

0

×

0

P

12

w

12

+ J

12

˙q (7)

where

0

P

12

is the vector linking the origin of frame R

0

and the origin of frame R

12

expressed in frame R

0

, J

12

∈ R

6×12

is the Jacobian matrix of the robot, J

12

˙q rep-

resents the effect of the joint velocities on the Carte-

sian velocity of link 12. The velocities V

12

and w

12

must be expressed in frame R

12

, thus we write (7):

12

V

12

12

w

12

=

12

A

0

−

12

A

0

0

ˆ

P

12

0

3×3

12

A

0

0

V

0

0

w

0

+

12

J

12

˙q

(8)

where

12

A

0

∈ R

3×3

is the rotation matrix, which de-

fines the orientation of frame R

0

with respect to frame

R

12

. Term

0

ˆ

P

12

is the skew-symmetric matrix of the

vector product associated with vector

0

P

12

.

0

ˆ

P

12

=

0 −P

z

P

y

P

z

0 −P

x

−P

y

P

x

0

Defining matrix D

f

∈ R

18×6

as the concatenation

of two matrices such that D

f

= [T |

12

J

12

]

T

, where

12

J

12

∈ R

6×12

is the Jacobian matrix of the robot and

T ∈ R

6×6

equals

T =

12

A

0

−

12

A

0

0

ˆ

P

12

0

3×3

12

A

0

(9)

Then, the linear and angular velocities of the swing

foot in frame R

12

is :

12

V

12

12

w

12

= D

T

f

V (10)

Then D

f

can be defined by applying the virtual prin-

ciple on the second leg. However in order to com-

pute the matrix D

f

, it is necessary, either to calculate

the matrix

12

J

12

jacobian by a traditional method, by

taking into account the equation (9), or to calculate

this matrix by the algorithm of Newton-Euler, by not-

ing from relation (5) that the i

th

column is equal to

D

Γ

Γ+ D

R

R

F

R

if

˙

V = 0,V = 0,g = 0 and R

f

= e

i

e

i

∈ R

6×1

is the unit vector, whose elements are zero

except the i

th

element which is equal to 1.

2.5 Impact Equations for Instantaneous

Double Support

When the swing foot touches the ground, an impact

exists. In reality many possibilities can appear for an

impact (partial contact with the sole on the ground,

elastic deformations of the bodies and the ground).

To simplify our study this impact is assumed to be in-

stantaneous and inelastic with complete surface of the

foot sol touching the ground. This means that the ve-

locity of the swing foot touching the ground is zero

after its impact. We assume that the ground reaction

at the instant of impact is described by a Dirac delta-

function with intensity I

R

f

. Assuming that the previ-

ous stance foot is motionless before the impact and

does not remains on the ground after the impact the

dynamic model during the impact is (see (Formal’sky,

1982) and (M. Sakaguchi and Koizumi, 1995))

D(X)∆V = −D

f

I

R

f

(11)

D

T

f

V

+

= 0 (12)

0

V

−

0

0

w

−

0

=

0

3×1

0

3×1

(13)

where ∆V = (V

+

− V

−

) is the change of velocity

caused by the impact and V

+

(respectively V

−

) de-

note the linear and angular velocity of the stance foot

and also the joint velocities of the biped after (respec-

tively before) the impact. These equations form a sys-

tem of linear equations which solution allows to know

the impulse forces and the velocity after the impact,

thus they can be applied to the biped walking system.

3 DEFINITION OF THE

WALKING CYCLE

Because biped walking is a periodical phenomenon

our objective is to design a cyclic biped gait. A com-

plete walking cycle is composed of two phases: a sin-

gle support phase and a double support phase which is

modeled through passive impact equations. The sin-

gle support phase begins with one foot which stays

on the ground while the other foot swings from the

rear to the front. We shall assume that the double sup-

port phase is instantaneous, this means that when the

swing leg touches the ground the stance leg takes off.

There are two facets to be considered for this prob-

lem. The definition of reference trajectories and the

method to determine a particular solution of it. This

section is devoted to the definition of reference tra-

jectories. The optimal process to choose the best so-

lution of parameters, allowing a symmetric half step,

MODELING AND OPTIMAL TRAJECTORY PLANNING OF A BIPED ROBOT USING NEWTON-EULER

FORMULATION

79

from the point of view of a given criterion will be de-

scribed in the next section.

3.1 Cyclic Walking Trajectory

Since the initial configuration is a double support con-

figuration, the both feet are on the ground, the twelve

joint coordinates are not independent. Because the

absolute frame is attached to the right foot we define

the situation of the left foot by (y

l f

,z

l f

,φ

l f

) and the

situation of the middle of the hips (x

h

,y

h

,z

h

,θ

h

), both

expressed in R

0

frame. (y

l f

,z

l f

) is the coordinate, in

the horizontal plane, of the left foot position, φ

l f

de-

notes the left foot yawing motion, (x

h

,y

h

,z

h

) is the

hip position and θ

h

defines the hip pitching motion.

The values of the joint variables are solution of the

inverse kinematics problem for a leg, which may also

be considered as a 6-link manipulator. The problem

is solved with a symbolic software, (SYMORO+, see

(Khalil and Dombre, 2002)).

In order to deduce the final configuration, we im-

pose a symmetric role of the two legs, therefore from

the initial configuration, the final configuration is de-

duced as:

q

f

DS

= Eq

i

DS

(14)

where E ∈ R

12×12

is an inverted diagonal matrix

which describes the legs’ exchange.

Taking into account the impulsive impact (11)-

(13), we can compute the velocity after the impact.

Therefore, the velocity after the impact, ˙q

+

, can be

calculated when the velocity before the impact, ˙q

−

, is

known. The use of the defined matrix E allows us to

calculate the initial velocity for the current half step

as:

˙q

i

= E ˙q

+

. (15)

By this way the conditions of cyclic motion are satis-

fied.

3.2 Constraints

In order to insure that the trajectory is possible, many

constraints have to be considered.

3.2.1 Magnitude Constraints on Position and

Torque

• Each actuator has physical limits such that

|

Γ

i

|

− Γ

i,max

≤ 0, for i = 1, ..., 12 (16)

where Γ

i,max

denotes the maximum value for each

actuator.

|

˙q

i

|

− ˙q

i,max

≤ 0, for i = 1, ..., 12 (17)

where ˙q

i,max

denotes the maximum velocity for

each actuator.

• The upper and lower bounds of joints for the con-

figurations during the motion are:

q

i,min

≤ q

i

≤ q

i,max

, for i = 1, ..., 12 (18)

q

i,min

and q

i,max

stands respectively for the mini-

mum and maximum joint limits.

3.2.2 Geometrical Constraints in Double

Support Phase

• The distance d(hip, foot) between the foot in

contact with the ground and the hip must remain

within a maximal value, i.e.,

d(hip, foot) ≤ l

hip

. (19)

This condition must hold for initial and final con-

figurations of the double support.

• In order to avoid the internal collision of both feet

through the lateral axis the heel and the toe of the

left foot must satisfy

y

heel

≤ −a and y

toe

≤ −a (20)

with a >

l

p

2

and and l

p

is the width of right foot.

3.2.3 Walking Constraints

• During the single support phase to avoid colli-

sions of the swing leg with the stance leg or with

the ground, constraints on the positions of the four

corners of the wing foot are defined.

• We must take into account the constraints on the

ground reaction R

F

R

= [R

F

Rx

,R

F

Ry

,R

F

Rz

]

T

for the

stance foot in single support phase as well as im-

pulsive forces I

R

f

= [I

R

fx

,I

R

fy

,I

R

fz

]

T

on the foot

touching the ground in instantaneous double sup-

port phase. The ground reaction and impulsive

forces must be inside a friction cone defined by

the friction coefficient µ. This is equivalent to

write

q

R

2

F

Ry

+ R

2

F

Rz

≤ µR

F

Rx

(21)

q

I

2

R

fy

+ I

2

R

fz

≤ µI

R

fx

(22)

The ground reaction forces and the impulsive

forces at the contact can only push the ground but

may not pull from ground, then the condition of

no take off is deduced:

R

f

x

≥ 0 (23)

I

R

fx

≥ 0. (24)

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

80

• In order to maintain the balance in dynamic walk-

ing, the ZMP ≡ CoP, (Zero Moment Point equiv-

alent to the Center of Pressure, see (Vukobratovic

and Stepanenko, 1972), point must be within the

support polygon, i.e., the distance from CoP to

support polygon is negative

d(CoP, SP) ≤ 0, (25)

where SP denotes the support polygon determined

by the width l

p

and the length L

p

of the feet.

4 PARAMETRIC OPTIMIZATION

4.1 The Cubic Spline

To describe the joint motion by a finite set of parame-

ters we choose to use for each joint a piecewise func-

tion of the form

q

i

= ϕ

i

(t) =

ϕ

i1

(t) i f t

0

≤ t ≤ t

1

ϕ

i2

(t) i f t

1

≤ t ≤ t

2

.

.

.

ϕ

in

(t) i f t

n−1

≤ t ≤ t

n

i = 1,...12

where ϕ

k

(t) are polynomials of third-order such that

ϕ

ik

(a

ik

,t) =

3

∑

j=0

a

ik j

(t −t

k−1

)

j

, k = 1,...,n ∀t ∈ [t

0

,t

n

]

(26)

where a

ik j

are calculated such that the position,

velocity and acceleration are always continuous in

t

0

,t

1

,...t

n

. We used n = 3, thus the motion is defined

by a specified initial configuration, a final configura-

tion in double support and two intermediate configu-

rations in single support taking into account the initial

and final velocity as boundary conditions.

4.2 Optimization Parameters

A parametric optimization problem has to be solved

to design a cyclic bipedal gait with successive single

and double support phases. This problem depends on

parameters to prescribe the two intermediate configu-

rations, q

int1

and q

int2

, and the final velocity ˙q

f

in the

single support phase. Taking into account the condi-

tions (14) and (15) the minimal number of parameters

necessary to define the joint motion are:

1. Twenty-four parameters are needed to define the

two intermediate configurations in single support

phase, twelve parameters for the first intermediate

configuration q

i,int1

and twelve parameters for the

second intermediate configuration, q

i,int2

for i =

1,...,12.

2. The velocity before the impact is also prescribed

by twelve parameters, ˙q

−

i

(i = 1, ...12).

3. The left foot yawing motion denoted by φ

l f

and its

position (y

l f

,z

l f

) in the horizontal plane as well as

the situation of the middle of the hips defined by

(x

h

,y

h

,z

h

,θ

h

) in double support phase are chosen

as parameters.

Let us remark that to define the initial and final

configurations in double support nine parameters are

required however we define these configurations with

only seven parameters. The two others parameters,

orientation of the middle of the hips in frontal and

transverse plane, are fixed to zero. The duration of a

half step, T

s

, is fixed arbitrarily.

4.3 Criterion

In the optimization process we consider, as criterion

J

Γ

, the integral of the norm of the torque divided by

the half step length. In other words we are minimizing

a quantity proportional to the energy required for a

motion

J

Γ

=

1

d

T

s

0

Γ

T

Γdt (27)

where T

s

is the time of the half step. This general form

of minimal energy performance represents the losses

by Joule effects to cover distance d.

4.4 Optimization Algorithm

Generally, many values of parameters can give a pe-

riodic bipedal gait satisfying constraints (17)-(24). A

parametric optimization process, which objective is

to minimize J

Γ

under nonlinear constraints, is used to

find a particular nominal motion. This optimization

process can be formally stated as

minimize J

Γ

(p)

subject to g

i

(p) ≤ 0 i = 1,2,...,l

(28)

where p is the vector of parameters, J

Γ

(p) is the cri-

terion to minimize with l constraints g

i

(p) ≤ 0 to sat-

isfy. This constraints are given in section 3.2. The

nonlinear constrained problem is solved using the

Matlab function fmincon. This optimization function

provide an optimization algorithm based on the Se-

quential Quadratic Programming (SQP). Therefore,

this nonlinear optimization problem with forty-three

variables: twenty-four for the two intermediate con-

figurations in single support, twelve for the velocity

before the impact and seven to solve the inverse kine-

matics problem, subject to the constraints given by

(17)-(24), is solved numerically.

MODELING AND OPTIMAL TRAJECTORY PLANNING OF A BIPED ROBOT USING NEWTON-EULER

FORMULATION

81

Table 2: Parameters of SPEJBL.

Physical Parameters Mass (kg) Length (m)

Torso 0.3967 d

7

= 0.140

Right Leg

Hip 0.2604 linked to torso

Thigh 0.1224 d

4

= 0.120

Shin 0.0558 d

3

= 0.120

Ankle 0.1278 d

1

= 0.042

Foot 0.3045 L

p

= 0.178

5 SIMULATION RESULTS

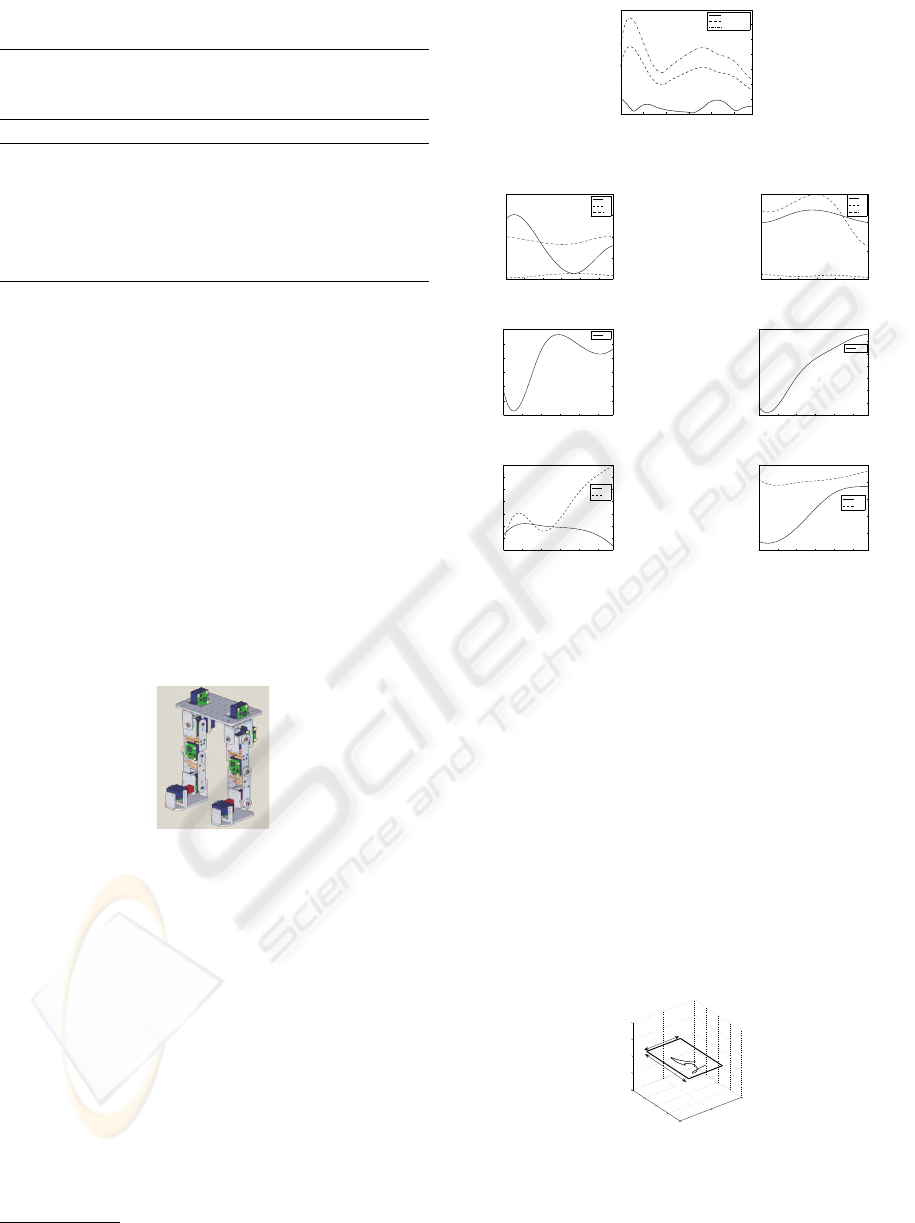

To validate our proposed method, we present the re-

sults of an optimal motion for the biped shown in fig-

ure 2. The desired trajectory was obtained by the op-

timization process presented in Section IV, with the

minimization of the criterion (27) satisfying the con-

straints given by (17)-(24). The figure 4 shows the

evolution of the optimal motion for a half step with

duration, of a single support, which is equal to 0.58

s. For the simulation, we use the physical parameters

of the SPEJBL

1

. The physical parameters of SPEJBL

are collected in Table 2. Figure 2 shows the photo

of SPEJBL and also the dimensional design drawn by

VariCAD software.

Figure 2: Dimensional drawing of SPEJBL.

The results shown have been obtained with T

s

=

0.58 s. The optimal motion is such that the step length

is 0.366 m and the optimal velocity is 0.6323 m/s.

These values are results of the optimization process.

The normal components of the ground reactions,

in function of time, of the stance foot during one half

step in single support are presented in figure 3. The

average vertical reaction force is 20 N, which is co-

herent with the weight of the robot which the mass

equals 2.1385 Kg. The chosen friction coefficient is

0.7.

The figure 4 shows the evolutions of joint vari-

ables q

i

(t) i = 1, ..., 12, defined by the third-order

spline function presented in Section III, in the single

1

SPEJBL is a biped robot designed in the Department of

Control Engineering of the Technical University in Prague.

0 0.1 0.2 0.3 0.4 0.5

0

5

10

15

20

25

30

35

Time [s]

Ground reaction force [N]

√(FRy

2

+FRz

2

)

µFRx

FRx

Figure 3: Normal components in the stance foot.

0 0.1 0.2 0.3 0.4 0.5

−100

−50

0

50

100

Time [s]

Position [°]

q4

q5

q6

Right hip joint positions

0 0.1 0.2 0.3 0.4 0.5

−100

−50

0

50

Time [s]

Position [°]

q7

q8

q9

Left hip joint positions

0 0.1 0.2 0.3 0.4 0.5

−60

−50

−40

−30

−20

−10

0

Time [s]

Position [°]

q3

Right knee joint position

0 0.1 0.2 0.3 0.4 0.5

10

15

20

25

30

35

40

45

Time [s]

Position [°]

q10

Left knee joint position

0 0.1 0.2 0.3 0.4 0.5

0

5

10

15

20

25

30

35

Time [s]

Position [°]

q1

q2

Right ankle joint positions

0 0.1 0.2 0.3 0.4 0.5

−40

−30

−20

−10

0

10

Time [s]

Position [°]

q11

q12

Right ankle joint positions

Figure 4: Evolution of joint positions.

support phase during one half step. Let us remark that

the evolution of each joint variable depends on the

boundary conditions ( ˙q

i,ini

, ˙q

i, fin

for i = 1,...,12 ) and

also on the intermediate configurations (q

i,int1

, q

i,int2

for i = 1,...,12 ) whose values are computed in the

optimal process.

The figure 5 shows the CoP trajectory which is al-

ways inside the support polygon determined by l

p

=

0.11 m and L

p

= 0.17 m., that is, the robot maintains

the balance during the motion. Because the minimal

distance between of CoP and the boundary of the foot

is large, smaller foot is acceptable for this cyclic mo-

tion.

−0.1

0

0.1

−0.2

−0.15

−0.1

−0.05

0

−1

−0.5

0

0.5

1

X−axis

Y−axis

Z−axis

L

P

P

l

Figure 5: The evolution of CoP trajectory.

For a set of motion velocities, the evolution of J

Γ

criterion is presented in figure 6. With respect to the

evolution of J

Γ

we can conclude that the biped robot

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

82

0.5 0.55 0.6 0.65 0.7 0.75

5

5.2

5.4

5.6

5.8

6

6.2

6.4

6.6

6.8

Velocity [m/s]

J [N2.m.s]

Figure 6: J

Γ

in function of several motion velocities for the

biped.

consumes more energy for low velocities to generate

one half step. Due to the limitations of the joint ve-

locities we could not obtain superior values to 0.73

m/s. The energy consumption increases probably

for higher velocity (see (Chevallereau. and Aoustin,

2001)). The robot has been designed to be able to

walk slowly, this walk require large torque and small

joint velocities. Its design is also based on large feet

in order to be able to use static walking, as a conse-

quence the feet are heavy and bulky, thus the resulting

optimal motion is close to the motion of a human with

snowshoes.

6 CONCLUSION

Optimal joint reference trajectories for the walking of

a 3D biped are found. A methodology to design such

optimal trajectories is developed. This tool is useful

to test a robot design or for the control of the robot. In

order to use classical optimization technique, the opti-

mal trajectory is described by a set of parameters: we

choose to define the evolution of the actuated relative

angle as spline functions. A cyclic solution is desired.

Thus the number of the optimization variables is re-

duced by taking into account explicitly of the cyclic

condition. Some inequality constraints such as the

limits on torque and velocity, the condition of no slid-

ing during motion and impact, some limits on the mo-

tion of the free leg are taken into account. Optimal

motion for a given duration of the step have been ob-

tained, the step length and the advance velocity are the

result of the optimization process. The result obtained

are realistic with respect to the size of the robot under

study. Optimal motion for a given motion velocity

can also be studied, in this case the motion velocity is

consider as a constraint. The proposed method to de-

fine optimal motion will be tested on other prototype

with dimension closer to human.

REFERENCES

Beletskii, V. V. and Chudinov, P. S. (1977). Parametric

optimization in the problem of bipedal locomotion.

Izv. An SSSR. Mekhanika Tverdogo Tela [Mechanics

of Solids], (1):25–35.

Bessonnet, G., Chesse, S., andSardin, P. (2002). Generating

optimal gait of a human-sized biped robot. In Proc.

of the fifth International Conference on Climbing and

Walking Robots, pages 717–724.

Channon, P. H., Hopkins, S. H., and Pham, D. T. (1992).

Derivation of optimal walking motions for a bipedal

walking robot. Robotica, 2(165–172).

Chevallereau., C. and Aoustin, Y. (2001). Optimal refer-

ence trajectories for walking and running of a biped.

Robotica, 19(5):557–569.

Formal’sky, A. (1982). Locomotion of Anthropomorphic

Mechanisms. Nauka, Moscow [In Russian].

Grishin, A. A., Formal’sky, A. M., Lensky, A. V., and Zhit-

omirsky, S. V. (1994). Dynamic walking of a vehicle

with two telescopic legs controlled by two drives. Int.

J. of Robotics Research, 13(2):137–147.

Khalil, W. and Dombre, E. (2002). Modeling, identification

and control of robots. Hermes Sciences Europe.

L. Hu, C. Z. and Sun, Z. (2006). Biped gait optimization us-

ing spline function based probability model. in Proc.

of the IEEE Conference on Robotics and Automation,

pages 830–835.

M. Sakaguchi, J. Furushu, A. S. and Koizumi, E. (1995).

A realization of bunce gait in a quadruped robot with

articular-joint-type legs. Proc. of the IEEE Conference

on Robotics and Automation, pages 697–702.

Miossec, S. and Aoustin, Y. (2006). Dynamical synthesis of

a walking cyclic gait for a biped with point feet. Spe-

cial issue of lecture Notes in Control and information

Sciences, Ed. Morari, Springer-Verlag.

M.W.Walker and D.E.Orin (1982). Efficient dynamic com-

puter simulation of robotics mechanism. Trans. of

ASME, J. of Dynamic Systems, Measurement and

Control, 104:205–211.

Rostami, M. and Besonnet, G. (1998). Impactless sag-

ital gait of a biped robot during the single support

phase. In Proceedings of International Conference on

Robotics and Automation, pages 1385–1391.

Roussel, L., de Wit, C. C., and Goswami, A. (2003). Gener-

ation of energy optimal complete gait cycles for biped.

In Proc. of the IEEE Conf. on Robotics and Automa-

tion, pages 2036–2042.

Saidouni, T. and Bessonnet, G. (2003). Generating globally

optimised saggital gait cycles of a biped robot. Robot-

ica, 21(2):199–210.

Vukobratovic, M. and Stepanenko, Y. (1972). On the stabil-

ity of anthropomorphic systems. Mathematical Bio-

sciences, 15:1–37.

Zonfrilli, F., Oriolo, M., and Nardi, T. (2002). A biped loco-

motion strategy for the quadruped robot sony ers-210.

In Proc. of the IEEE Conf. on Robotics and Automa-

tion, pages 2768–2774.

MODELING AND OPTIMAL TRAJECTORY PLANNING OF A BIPED ROBOT USING NEWTON-EULER

FORMULATION

83