MODELING AND CONTROL OF AN EXPERIMENTAL SWITCHED

MANUFACTURING SYSTEM

Michael Canu, Dominique Morel and Naly Rakoto-Ravalontsalama*

Ecole des Mines de Nantes (*and IRCCyN)

4 rue Alfred Kastler, 44307 Nantes Cedex 03, France

Keywords:

Manufacturing Systems.

Abstract:

The notion of switched discrete event systems (DES) has been introduced recently. This is a class of DES

where each automaton is the composition of two basic automata, but with different composition operators.

A switching occurs when there is a change of the composition operator, but keeping the same two basic au-

tomata. A mode behavior is defined as the active DES behavior for a given composition operator. Composition

operators are supposed to change more than once so that each mode is visited more than once. In this paper

we study the modeling and control of an experimental manufacturing system as an example of switched DES.

1 INTRODUCTION

Supervisory control initiated by Ramadge and Won-

ham (Ramadge and Wonham, 1987) provides a sys-

tematic approach for the control of discrete event sys-

tem (DES) plant. Most of the properties of a given

composed system depend on the composition oper-

ator. The modular approach reflects the underlying

physical properties of complex systems such as man-

ufacturing systems.

The most common composition operators used in

supervisory control theory are the product and the par-

allel composition (Cassandras and Lafortune, 1999),

(Wonham, 2004). However many different types of

composition operators have been defined, e.g., the pri-

oritized synchronous composition (0), the biased syn-

chronous composition (Lafortune and Chen, 1990),

see (Wenck and Richter, 2004) for a review of most

of the composition operators. Multi-Agent composi-

tion operator (Romanovski and Caines, 2002), (Ro-

manovski and Caines, 2006) is another kind of opera-

tor, which differs from the synchronous product in the

aspects of simultaneity and synchronization.

Related work concerns a) fault diagnosis for DES

(the readers are referred to (Jensen, 2003) for a com-

prehensive survey), b) mode-automata for reactive

system programming, introduced in (Maraninchi and

Remond, 1998), c) supervisory uniqueness for oper-

ating mode systems studied in (Kamach et al., 2005)

where the authors propose a multi-model approach to

DES, and finally d) sensor failure tolerant supervisory

control proposed in (Rohloff, 2005) where different

automata are used to model the system observation

behavior in the various modes of operations.

This paper studies the application of switched

DES methodology to an Experimental Manufacturing

Cell. This cell is composed of two robotized work-

stations connected to a central conveyor belt. Re-

cently, three new semi-automated workstations have

been added in order to increase the flexibility aspects

of the cell. This flexibility allows the designer to

study different mode behaviors of the experimental

cell.

The paper is organized as follows. In Section 2,

the notation and preliminaries are given. The notion

of switched DES is recalled in Section 3. In Section

4, the controllability property is studied. Finally the

experimental cell behavior is described in Section 5.

484

Canu M., Morel D. and Rakoto-Ravalontsalama N. (2007).

MODELING AND CONTROL OF AN EXPERIMENTAL SWITCHED MANUFACTURING SYSTEM.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 484-488

DOI: 10.5220/0001637204840488

Copyright

c

SciTePress

2 NOTATION AND

PRELIMINARIES

Let the discrete event system plant be modeled by a

finite state automaton (Hopcroft and Ullman, 1979)

G = (Q, Σ, δ, q

0

, Q

m

)

where Q is the finite set of states, Σ is the finite set

of events associated with the transitions in G, δ : Q×

Σ → Q is the partial transition function, q

0

is the initial

state and Q

m

⊆ Q is the set of marked states.

Let Σ

∗

be the set of all finite strings of elements in

Σ including the empty string ε. The function δ can be

generalized to δ : Σ

∗

× Q → Q. The notation δ(s, q)!

for any s ∈ Σ

∗

and q ∈ Q denotes that δ(s, q) is defined.

Let L(G) ⊆ Σ

∗

be the language generated by G, that

is,

L(G) = {s ∈ Σ

∗

|δ(s, q

0

)!}

Let K ⊆ Σ

∗

be a language. The set of all prefixes of

strings in K is denoted by

K with K = {s ∈ Σ

∗

|∃ t ∈

Σ

∗

;st ∈ K}. A language K is said to be prefix closed

if K = K. The event set Σ is decomposed into two

subsets Σ

c

and Σ

uc

of controllable and uncontrollable

events, respectively, where Σ

c

∩Σ

uc

=

/

0. A controller,

called a supervisor, controls the plant by dynamically

disabling some of the controllable events. A closed

language K ⊆ L(G) is said to be controllable with re-

spect to L(G) and Σ

uc

if (Ramadge, 1987)

KΣ

uc

∩ L(G) ⊆ K.

In the supervisory control theory, composition

means synchronization of finite state automata. The

basis for the definition of all the composition op-

erators are G

a

= (Q

a

, Σ

a

, δ

a

, q

0a

, Q

ma

) and G

b

=

(Q

b

, Σ

b

, δ

b

, q

0b

, Q

mb

) with disjoint state sets Q

a

∩

Q

b

=

/

0 but generally overlapping event sets. The

result of any composition is an automaton G

i

=

G

a

||

op

i

G

b

= (Q, Σ, δ, q

0

, Q

m

) with the state Q = Q

a

×

Q

b

, the event set Σ = Σ

a

∪ Σ

b

and initial state x

0

=

x

0a

, x

0b

, where op

i

is a composition operator. Each

operator is defined by a distinct transition function

with σ ∈ Σ a single event and q ∈ Q a state.

Among the different types of composition opera-

tors, we recall here the biased synchronous composi-

tion (BSC) and the strict product composition (SPC).

Definition 1 (Lafortune and Chen, 1990) The Bi-

ased Synchronous Composition (BSC) is defined as

follows. The automaton G

a

is called the master and

G

b

is called the follower.

δ(q, σ) =

δ

a

(q

a

, σ) × δ

b

(q

b

, σ) if δ

a

(q

a

, σ)!∧ δ

b

(q

b

, σ)!

δ

a

(q

a

, σ) × {q

b

} if δ

a

(q

a

, σ)!∧ ¬δ

b

(q

b

, σ)!

/

0 otherwise.

Definition 2 The strict product composition (SPC)

is defined as follows.

δ(q, σ) =

δ

a

(q

a

, σ) × δ

b

(q

b

, σ) if δ

a

(q

a

, σ)!∧ δ

b

(q

b

, σ)!

/

0 otherwise.

These two composition operators will be taken as

example in the next sections.

3 SWITCHED DES

The basic idea is the following. Without loss of gen-

erality we consider two automata G

a

and G

b

as de-

fined above. Let G

i

be the composed automaton from

G

a

and G

b

with operator op

i

, that is G

i

= G

a

||

op

i

G

b

.

In the same way let G

j

be the composed automaton

from the same G

a

and G

b

but with operator op

j

, that

is G

j

= G

a

||

op

j

G

b

, as it is depicted in Figure 2 and

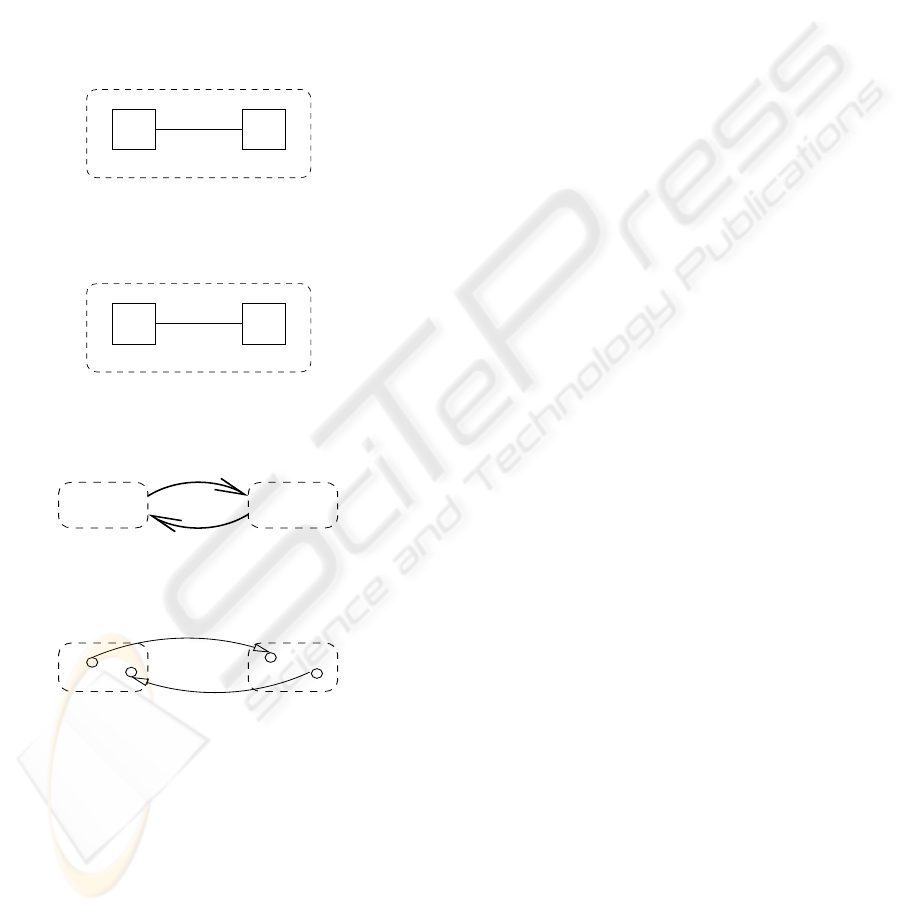

Figure 3.

DES 1

DES 2

DES n

switch

Supervisor

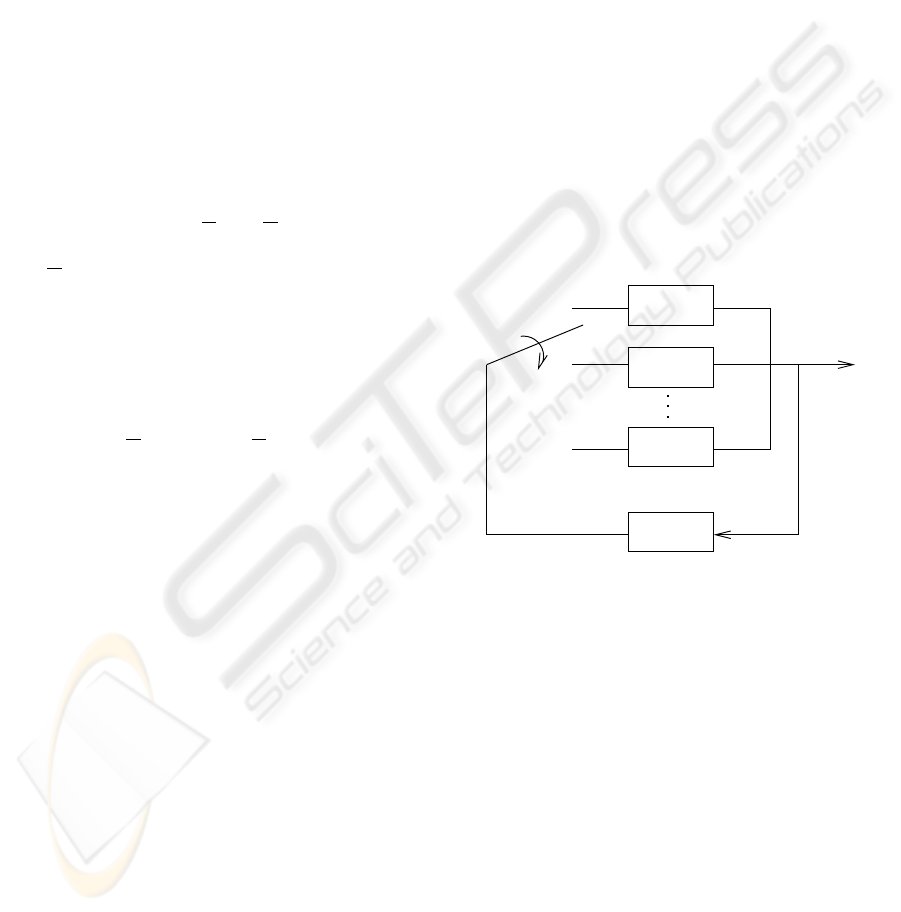

Figure 1: Switched DES.

Definition 3 Equivalent states.

The states (q

a

, q

b

)

i

of automaton G

i

and (q

c

, q

d

)

j

of

automaton G

j

are said to be equivalent (q

a

, q

b

)

i

≡

(q

c

, q

d

)

j

if they result from the composition of the

same pair of states but with different composition op-

erators (q

a

= q

c

and q

b

= q

d

).

Assumptions. Given two automata G

i

and G

j

,

switching between automaton G

i

and automaton G

j

is possible if the following assumptions hold.

1. G

i

and G

j

have at least two equivalent states

2. Switching between G

i

and G

j

is performed

through their equivalent states.

3. Switching from G

i

to G

j

has zero duration, as well

as from G

j

to G

i

.

MODELING AND CONTROL OF AN EXPERIMENTAL SWITCHED MANUFACTURING SYSTEM

485

Definition 4 (Rakoto, 2006b) Switched DES.

A switched discrete event system is defined as fol-

lows.

L

switched

(G) = L(G

i

), i ∈ I = {1, . . . , n} (1)

where G

i

is the model of DES

i

, and I is an index set.

In this special case, G

i

= G

a

||

op

i

G

b

.

We can see in Figure 2 and Figure 3 the automa-

ton G

1

and G

2

, respectively. Then automata G

1

and

G

2

can switch between them, as it is shown in Fig-

ure 4. Actually, the switching are made through the

equivalent states of G

1

and G

2

, see Figure 5.

G1 = Ga ||_op1 Gb

Ga Gb

Figure 2: Automaton G

1

.

Ga Gb

G2 = Ga ||_op2 Gb

Figure 3: Automaton G

2

.

G1 G2

Figure 4: Switched automaton.

G1

G2

Figure 5: Automata switching through equivalent states.

We give here below some examples of switched

DES:

• Manufacturing systems where the operating

modes are changing (e.g. from normal mode to

degenerated mode)

• Discrete event systems after an emergency signal

(from normal to safety mode)

• Complex systems changing from normal mode to

recovery mode (or from safety mode to normal

mode).

We can distinguish, like for the switched

continuous-time systems, the notion of autonomous

switching where no external action is performed and

the notion of controlled switching, where the switch-

ing is forced. The notion of switched DES has been

adapted from the switched continuous-time systems.

For a survey of switched continuous-time systems,

one can refer to (Liberzon and Morse, 1999) and the

references therein.

On one hand DES and continuous-time systems

share the notion of controllability (but each domain

has its own definition). On the other hand, stabil-

ity analysis in continuous-time systems cannot be

adapted to DES (even though some work exist on the

stability of DES (Passino et al., 1994), (Passino and

Burgess, 1998) and the references therein). Thus the

notion of stability analysis has been changed to non-

blocking analysis. Before defining the problems, we

need to define the notion of switching sequence. A

switching sequence is defined to be the successive

active automata when the successive switchings oc-

cur. The following problems have been defined in

(Rakoto, 2006b)

• Problem A. Find conditions that guarantee that the

switched DES (1) is controllable with respect to

the Language L(G) and with respect to all the un-

controllable events, for any switching sequence.

• Problem B. Identify the classes of switching se-

quences for which the switched DES (1) is con-

trollable with respect to the Language L(G) and

with respect to all the uncontrollable events.

• Problem C. Find conditions that guarantee that the

switched DES (1) is nonblocking.

• Problem D. Identify the classes of switching se-

quences for which the switched DES (1) is non-

blocking.

We can note that discretization of a switched continu-

ous system (see e.g., (Rakoto, 2001) may be a solution

to the adaptation to the DES context.

4 CONTROLLABILITY OF

SWITCHED DES

In this section we address a specific problem related

to the controllability of a switched DES (1).

Problem 1. Given a switched automaton

L

switched

= L(G) = L(G

i

), i ∈ I = {1, 2} where

G

1

= G

a

||

op

1

G

b

= G

a

||

BSC

G

b

and G

2

= G

a

||

op

2

G

b

=

G

a

||

SPC

G

b

, find the conditions that guarantee the con-

trollability of the switched DES L

switched

= L(G).

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

486

ws5_conveyor

Robot_2

Robot_9 Robot_1

ws1_conveyor

ws3_conveyor ws2_conveyor ws4_conveyor

EMN Experimental Manufacturing Cell

(Assembly of DUPLO blocks)

Workstation_1Load-Unload_Station

Central Conveyor Belt (CCB)

semi-automated

Workstation_3

Pallet

Transfer System

Workstation_2

Workstation_4

semi-automated

Workstation_5

semi-automated

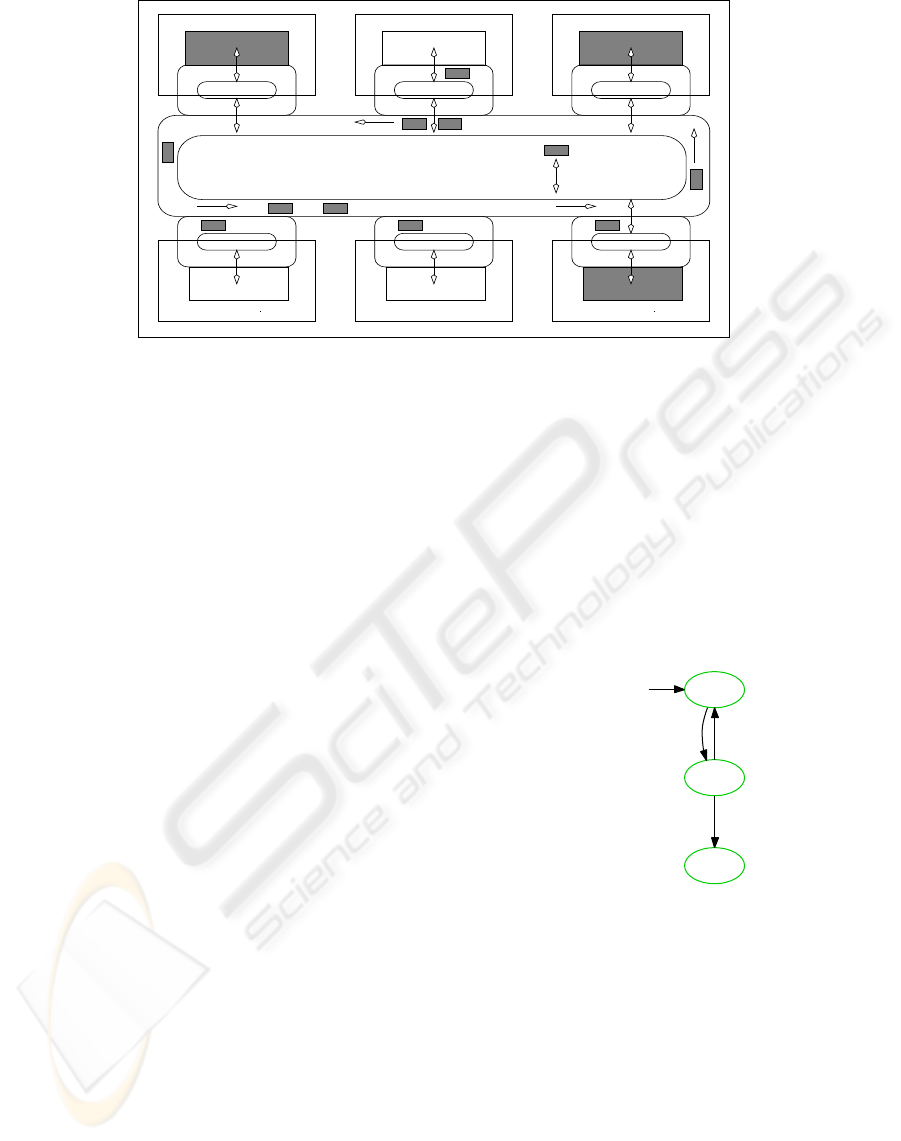

Figure 6: Experimental Manufacturing Cell.

Theorem 1 Given a switched automaton L

switched

=

L(G) = L(G

i

), i ∈ I = {1, 2} where G

1

= G

a

||

BSC

G

b

and G

2

= G

a

||

SPC

G

b

, the switched automaton L(G) =

L(G

i

) is controllable with respect to both L(G

1

) and

L(G

2

) and with respect to Σ

u

c if

1. K

a

, K

b

, L(G

2

) are pairwise non conflicting

2. K

b

, L(G

a

) are non conflicting

3. K

b

is controllable w.r.t. L(G

a

)

Proof. The proof can be found in (Rakoto, 2006b). It

is based on four propositions that have been given in

(Wenck and Richter, 2004).

5 EXPERIMENTAL

MANUFACTURING CELL

An automated manufacturing system generally con-

sists of a number of interconnected material process-

ing stations capable of processing a wide variety of

part types, a material transport system, a communica-

tion system for integrating all aspects of manufactur-

ing and a supervisory control system. The experimen-

tal manufacturing cell is composed of the following

components (Chen et al., 2004): a) a central conveyor

belt, b) two robotized workstations, with a station

conveyor each, c) a transfer system between the cen-

tral conveyor belt and the station conveyor, d) another

transfer system between the station conveyor and the

corresponding robot, and e) a load-unload robotized

worksation.

Recently, three semi-automated workstations have

been added to increase the flexibility aspects of the

cell. Indeed, each semi-automated workstation can

perform either manual or automated tasks. The ex-

perimental manufacturing cell is depicted in Figure 6.

Behavioral specifications of such an automated

manufacturing system include: a) logic-based spec-

ifications (e.g. safety, error recovery, the sequenc-

ing of operations, part routing and production vol-

ume requirement), b) temporal production specifica-

tion: production times, and c) utility optimality spec-

ification: e.g. costs.

S0.S0

S1.S1

a g

S2.S0

!b

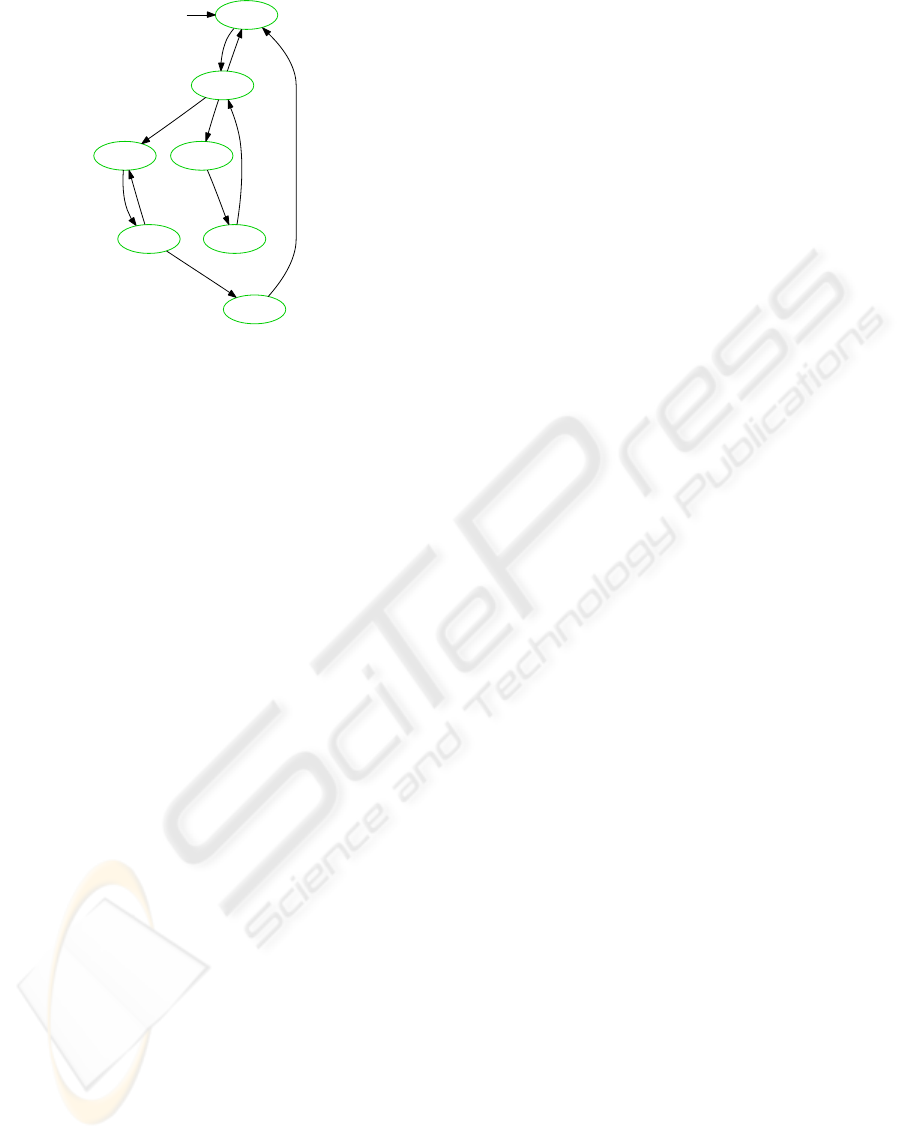

Figure 7: Composed Automaton.

The results were obtained using the tool Suprem-

ica (Akesson et al, 2006). Only two types of composi-

tion product were used. However this can be extended

to different types of composition products.

6 CONCLUSIONS

This paper studies the application of the switched

DES methodology, introduced previously to an Ex-

perimental Manufacturing Cell. The different mode

behaviors were possible to obtain thanks to the re-

MODELING AND CONTROL OF AN EXPERIMENTAL SWITCHED MANUFACTURING SYSTEM

487

S0.S0.S0

S1.S1.S1

a

S0.S1.S0

aS0.S2.S0

S1.S2.S1

a

g

!b

S2.S1.S2

d

!b

g

S2.S2.S2

d

r

r

Figure 8: Composed Automaton (with priority).

cently added semi-automated workstations. These

latter increased the flexibility of the system, and it

allows the designer to apply the switched DES ap-

proach. Future work will be focused on a) obtain-

ing more different mode behaviors for controllability,

and b) study nonblocking properties in some specific

cases.

ACKNOWLEDGEMENTS

This work was supported in part by the French

2000-2006 ”Contrat Etat-R

´

egion CER STIC 9, N.

18036: Optimisation des processus industriels”

Nantes, France.

REFERENCES

K. Akesson, M. Fabian, H. Flordal, and R. Malik. ”Suprem-

ica - An integrated environment for verification, syn-

thesis and simulation of discrete event systems,”

Proc. of 2006 Workshop of Discrete Event Sys-

tems (WODES’06), July 2006, Ann Arbor, Michigan,

USA.

C.G. Cassandras and S. Lafortune. Introduction to Discrete

Event Systems. Boston, MA, USA: Kluwer Academic

Publishers, 1999.

X. Chen, D. Morel, and N. Rakoto-Ravalontsalama ”Multi-

Agent Based Supervisory Control of an Experimental

Manufacturing Cell”. Proc. of IFAC Symposium on

Large Scale Systems (LSS 2004) Osaka, Japan, July

26-28, 2004, pp. 391–394.

M. Heymann. ”Concurrency and discrete event control,”

In IEEE Control Systems Magazine, Vol. 10 N.4, pp.

103–112, 1990.

R.M. Jensen. ”DES Controller Synthesis and Fault Toler-

ant Control: A Survey of recent advances,” Technical

report TR-2003-40, Th IT University of Copenhagen,

Denmark, 2003.

J.E. Hopcroft and J.D. Ullman, ”Introduction to Automata

Theory, Languages, and Computation,” Addison-

Wesley, Reading, MA, USA, 1979.

O. Kamach, L. Pietrac, and E. Niel. ”Supervisory unique-

ness for operating mode systems,” Proc. of World

IFAC Congress 2005, Prague, Czech Republic, July

2005.

S. Lafortune and E. Chen. ”The infimal closed controllable

superlanguage and its application in supervisory con-

trol,” In IEEE Trans. on Automatic Control, vol.35,

N.4 pp. 398–405, 1990.

D. Liberzon and A.S. Morse. ”Basic problems in stability

and design of switched systems,” In IEEE Control

Systems Magazine, pp. 59–70, Oct. 1999.

F. Maraninchi and Y. Remond. ”Mode-Automata: About

modes and states for reactive systems” Proc. of Euro-

pean Symp. on Programming 1998, Lisbon, Portugal,

1998.

K.M. Passino, A.N. Michel, and P.J. Antsaklis. ”Lyapunov

stability of a class of discrete event systems,” In IEEE

Trans. on Automatic Control, vol.39, N.2 pp. 269–

279, Feb 1994.

K.M. Passino and K.L. Burgess. ”Stability Analysis of Dis-

crete Event Systems,” Wiley, New York, USA, 1998.

N. Rakoto-Ravalontsalama. ”Discrete approximation of

continuous and hybrid systems: Some consequences

to supervisory control,” Proc. of IFAC SSC 2001

(Symp. on System Structure and Control), Paper N.

123, Prague, Czech Republic, Aug. 2001.

N. Rakoto-Ravalontsalama. ”Supervisory control of

switched discrete event systems,” Proc. of Int. Sympo-

sium on MTNS 2006, July 24-28, 2006, Kyoto, Japan.

P.J. Ramadge and W.M. Wonham. ”Supervisory control of

a class of discrete-event processes,” In SIAM J. on

Control and Optimization, vol.25 N. 1, pp. 206–230,

1987.

K. Rohloff. ”Sensor failure tolerant supervisory control”

Proc. of the 44th IEEE Conf. on Decision and Control

and the European Control Conf. 2005, Seville, Spain,

pp. 3493–3498, December 2005.

I. Romanovski and P.E. Caines. ”On the supervisory con-

trol of multi-agent product systems” Proc. of the

41st IEEE Conf. on Decision and Control, Las Vegas,

Nevada USA, pp. 1181–1186, December 2002.

I. Romanovski and P.E. Caines. ”Multi-Agent product sys-

tems: Controllability and Non-blocking properties”

Accepted at WODES 2006, Ann Arbor, MI, USA, July

2006.

F. Wenck and J.H. Richter. ”A composition oriented per-

spective on controllability of large DES,” Proc. of

WODES 2004, Reims, France, pp. 271–276, 2004.

W.M. Wonham. Notes on Discrete Event Systems, Dept. of

ECE, University of Toronto, Toronto, Canada, 2004.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

488