SLIDING MODE CONTROL FOR HAMMERSTEIN MODEL BASED

ON MPC

Zhiyu Xi and Tim Hesketh

School of Electrical Engineering & Telecommunications

University of New South Wales

Australia

Keywords:

Sliding mode, reaching control, equivalent control, MPC, Hammerstein model, nonlinearity.

Abstract:

This paper addresses discrete sliding mode control of nonlinear systems. The nonlinear system is identified

as a Hammerstein model firstly to isolate the nonlinearity from the sliding surface design. An MPC law

is employed to design the sliding surface. Then Utkins method of equivalent control is used. The method

illustrates the effect of the nonlinearity on reaching control. The ball and beam system is adopted as an

example. Simulation and on-line results are provided.

1 INTRODUCTION

Variable structure systems (VSS) have been exten-

sively used for control of dynamic industrial pro-

cesses. The essence of variable structure control

(VSC) (Raymond et al., 1988) is to use a high

speed switching control scheme to drive the nonlin-

ear plant’s state trajectory onto a specified and user

chosen surface in the state space which is commonly

called the sliding surface or switching surface, and

then to keep the plant’s state trajectory moving along

this surface. The surface is chosen to produce spec-

ified dynamic behaviour. Once the state trajectory

intercepts the sliding surface, it remains on the sur-

face for all subsequent time, sliding along the sur-

face, leading to the term “sliding mode”. Sliding

mode controller design comprises two stages. The

first is the design of sliding surface, while the second

forces the state to approach the sliding surface from

any other region of the state space, and remain on it.

The ball and beam system is a widely used lab-

oratory process. It reflects typical control problems

which include a double integrating factor, nonlinear-

ity, time delay and noise. In the ball and beam sys-

tem, a conductive ball lies on the beam comprised

of two parallel rods, and is free to roll along the

beam. A resistive strip, with impedance proportional

to length, covers one of the rods. The other rod is con-

ductive. The position of the ball can be determined

by introducing a small current through the rods and

measuring the resulting voltage, which varies with

impedance as the ball moves. One end of the beam

is fixed and the other is mounted on the output shaft

of a DC servo motor so the beam is tilted as the motor

shaft rotates. The control task is to regulate the posi-

tion of the ball by altering the angular shaft position

of the DC motor.

Design from an identified model has potential ad-

vantages in nonlinear control for the ball and beam,

and more generally. It relies on mathematical tools

and algorithms that build dynamical models from

measured data. Relatively simple structures of non-

linearity may be used to describe complex nonlinear

systems or ones for which models are difficult to de-

rive. In this paper, discrete sliding mode control of a

system described by a Hammerstein model will be ad-

dressed. This provides a simple method to deal with

nonlinear systems using VSC. The ball and beam sys-

tem will be used as an example to illustrate the design

procedure.

The control of a Hammerstein model has been ad-

dressed in the past by several authors (cite15,cite16).

Satisfying performance has been derived. In (Hwang

and Hsu), Hwang and Hsu talked about nonlinear con-

trol profile based on Hammerstein model in case of

model uncertainty. They also introduced an inverse

block into the system. Meanwhile, they spent a lot

effort on designing an observer.

232

Xi Z. and Hesketh T. (2007).

SLIDING MODE CONTROL FOR HAMMERSTEIN MODEL BASED ON MPC.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 232-237

DOI: 10.5220/0001639402320237

Copyright

c

SciTePress

2 HAMMERSTEIN MODEL

Hammerstein models are amongst those most com-

monly used for nonlinear identification. They are ca-

pable of providing simple nonlinear models for a wide

range of engineering problems. The model is charac-

terized by a static nonlinearity followed by a linear

time invariant (LTI) block. A typical Hammerstein

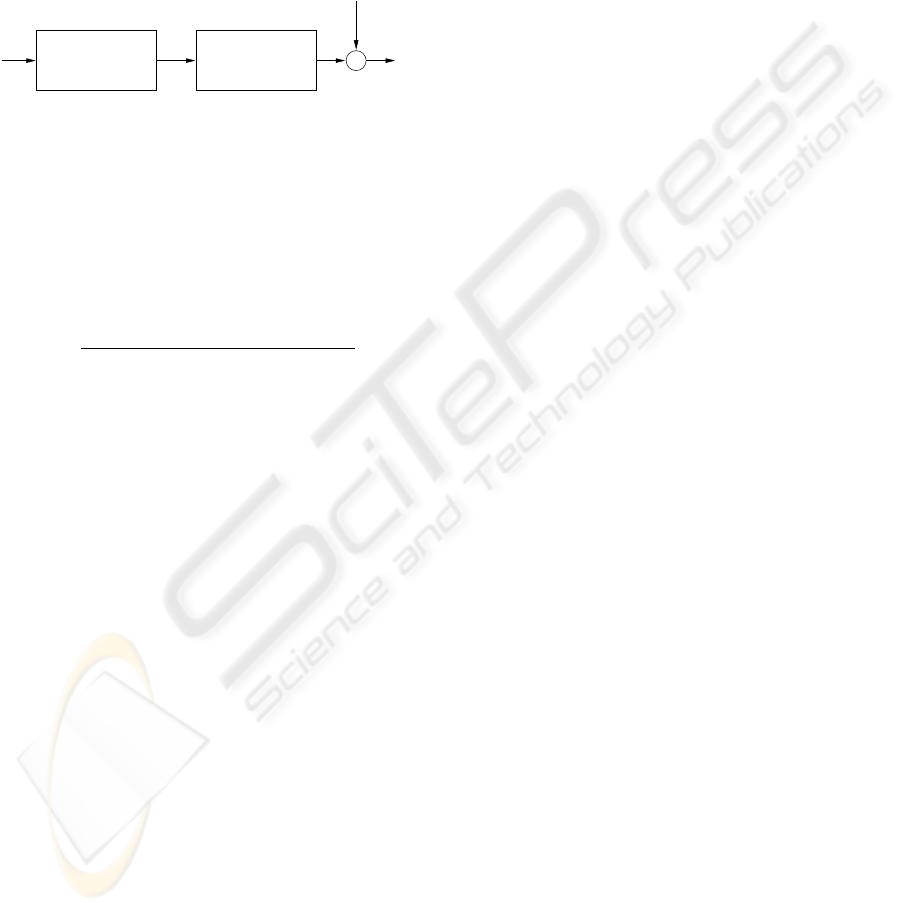

model for a process is shown in Figure 1:

n

u x +

+

y

Nonlinear

Static

Linear

Dynamic

Figure 1: Typical Hammerstein model.

y(t) = Tx(t) + n(t) (1)

x(t) = f(u(t)) (2)

where x(t) and y(t) are the inputs and outputs respec-

tively, n(t) is additive noise, f is the nonlinear map-

ping, T is the transfer function of linear part which

can be written as

T =

b

0

+ b

1

q

−1

+ b

2

q

−2

+ ··· + b

m

q

−m

1+ a

1

q

−1

+ a

2

q

−2

+ ··· + a

n

q

−n

with q

−1

representing the unit delay operator.

In this way, the nonlinearity of system is separated

from the linear block. This leads to the possibility of

ignoring the nonlinearity during key steps in the con-

troller design. Also, the nonlinear block in the Ham-

merstein model is a polynomial, which is a relatively

simple form. This reduces problems introduced by

complex nonlinearities such as exponentials and si-

nusoids.

3 DISCRETE SLIDING MODE

CONTROL DESIGN

3.1 Sliding Surface Design

Suppose the state space model of the above Hammer-

stein model is:

z(t) = Az(t − 1) + Bx(t) (3)

y(t) = Cz(t) + ¯n(t) (4)

where x(t) = f(u(t)).

Performing a similarity transformation defined by

an orthogonal matrix P:

z

l

= Pz = [z

1

: z

2

]

T

, A

l

= PAP

T

, B

l

= PB =

0

B

2

,

(5)

where z

1

does not have direct dependence on the in-

put nonlinearity. Sliding surface design may be un-

dertaken considering only z

1

, treating z

2

as an “input”

to the partitioned equations. In this way, the nonlin-

earity may be ignored while determining the sliding

surface, which is linear.

The partitioned state equations corresponding to

(3) and (4) may now be expressed in the following

way:

z

l1

(t +1) = A

l11

z

l1

(t) + A

l12

z

l2

(t) (6)

z

l2

(t +1) = A

l21

z

l1

(t) + A

l22

z

l2

(t) + B

l2

x(t).(7)

Suppose

sz

l

(t) = [

s

1

s

2

··· s

v

]z

l

(t) = w

1

z

l1

(t)+w

2

z

l2

(t)

in which v is the dimension of the corresponding state

vector, and s is the sliding surface, then the sliding

condition is

w

1

z

l1

(t) + w

2

z

l2

(t) = 0,

which yields

z

l2

(t) = −w

−1

2

w

1

z

l1

(t). (8)

Substitute (8) into (6) then we have,

z

l1

(t + 1) = A

l11

z

l1

(t) − A

l12

w

−1

2

w

1

z

l1

(t) (9)

= (A

l11

− A

l12

w

−1

2

w

1

)z

l1

(t). (10)

Any standard design algorithm which produces a

linear state feedback controller for a linear dynamic

system can be used to determine (A

l11

− A

l12

w

−1

2

w

1

)

and achieve desired performance through selection

of sliding mode dynamics (Spurgeon, 1992). Pole

placement is an obvious way of assigning closed

loop eigenvalues, but for systems of higher order the

method has attendant difficulties.

MPC is a widely-used method for calculating

closed-loop feedback controller gains. It is suitable

for systems with high order. It is employed to de-

termine the sliding surface in this paper. Consider-

ing z

l1

(t + 1) = A

l11

z

l1

(t) + A

l12

z

l2

(t), z

l2

(t) can be

viewed as the input to a new system the state vector

of which is z

l1

(t). An MPC criterion minimizes the

cost function which is defined to be:

J =M

⊤

t+1

M

t+1

+λU

⊤

t

U

t

. (11)

where

M

t+1

=

z

l1

(t +1)

z

l1

(t +2)

···

z

l1

(t + N)

,U

t

=

z

l2

(t)

z

l2

(t +1)

···

z

l2

(t +N − 1)

.

The goal is to fix the relationship between z

l2

(t) and

z

l1

(t) to prescribe desirable performance for the nom-

inal sliding mode dynamics. The controller gain de-

rived is:

z

l2

(t) = −kz

l1

(t) (12)

SLIDING MODE CONTROL FOR HAMMERSTEIN MODEL BASED ON MPC

233

which means that

σ(z

l

(t)) =

h

k

.

.

. I

i

z

l

(t) (13)

Note that inversion of the similarity transforma-

tion (using P) is needed to recover z(t) from z

l

(t).

Then sz(t) is the sliding surface.

3.2 Sliding Mode Controller Design

The reaching law still applies for discrete systems.

However, the state trajectory may overshoot the slid-

ing surface repeatedly, so that true sliding does not

occur. The switching manifold of a discrete VSC sys-

tem is called an ideal switching manifold because in

all practical situations, switching seldom occurs on

it. The size of each successive overshoot is non-

increasing and the trajectory stays within a specified

band which is called a

quasi-sliding mode

(QSM).

The specified band is called

quasi-sliding mode band

(QSMB) (Gao et al., 1995) and is defined by

{

x | −∆ < s(x) < ∆

}

(14)

where 2∆ is the width of the band.

Consider the single input linear system with

switching manifold s, a common type of sliding mode

controller is:

u(t) = u

eq

(t) + u

2

(t) (15)

where u

eq

(t) represents the equivalent control which

ensures sliding and u

2

(t) drives the state onto the slid-

ing surface, (termed reaching control).

According to the definition of sliding mode, we

have

σ(t +1) = sz(t+1) = sAz(t)+sBu

eq

(t) = σ(t). (16)

and

σ(t) = 0.

From the above, the equivalent control can be de-

scribed as follows:

u

eq

(t) = −(sB)

−1

sAz(t). (17)

Then let us consider the reaching control law. For

continuous SMC problem, a simple Lyapunov func-

tion V(σ(z)) = 0.5σ

T

(z)σ(z) is considered. The cor-

responding reaching condition is

∂V

∂t

= σ

T

·

σ < 0. (18)

In discrete system design, the equivalent form of this

condition is

[σ(t + 1) − σ(t)]σ(t) < 0. (19)

Substitute (3), (4), (15) and (17) into (19) then:

[σ(t + 1) − σ(t)]σ(t) = (sAz(t) + sBu(t) − sz(t))sz(t)

= ((sB)((sB)

−1

sAz(t)

+u(t)) − sz(t))sz(t)

= (sB(u(t) − u

eq

(t))

−sz(t))sz(t).

= (sBu

2

(t) − sz(t))sz(t).

u

2

(t) should be selected to ensure that:

sBu

2

(t) < sz(t) when sz(t) > 0 (20)

sBu

2

(t) > sz(t) when sz(t) < 0. (21)

As mentioned before, in a discrete sliding mode

control system, the switching manifold is actually an

ideal one. To eliminate the overshoot, the reaching

law should be modified. Once the state trajectory en-

ters a specified band around the manifold, the reach-

ing control action ceases and only sliding control ap-

plies. The goal is to keep the state trajectory within

the specified band.

The modified reaching control law is:

sBu

2

(t) < sz(t) when sz(t) > ∆ (22)

sBu

2

(t) > sz(t) when sz(t) < −∆. (23)

Considering equations (18)-(21) and absolute val-

ues of σ(t + 1) and σ(t), if

k

σ(t + 1)

k

<

k

σ(t)

k

, (24)

it can be concluded that the state trajectory is towards

the sliding surface. On the contrary, if

k

σ(t + 1)

k

>

k

σ(t)

k

, (25)

the trajectory is away from the sliding surface.

Note that (24) is equivalent to

k

sBu

2

(t)

k

<

k

σ(t)

k

, (26)

and (25) is equivalent to

k

sBu

2

(t)

k

>

k

σ(t)

k

. (27)

The conclusion may be drawn that while the tra-

jectory is outside the (ε =

k

sBu

2

(t)

k

), the trajectory

will approach the surface. While the state is within

this specified neighborhood, it moves in the direction

of leaving the surface (Hui and Zak, 1999). Thus

u

2

(t) has to be carefully chosen because the value of

ε =

k

sBu

2

(t)

k

is the crucial factor which determines

the radius attraction around the sliding surface.

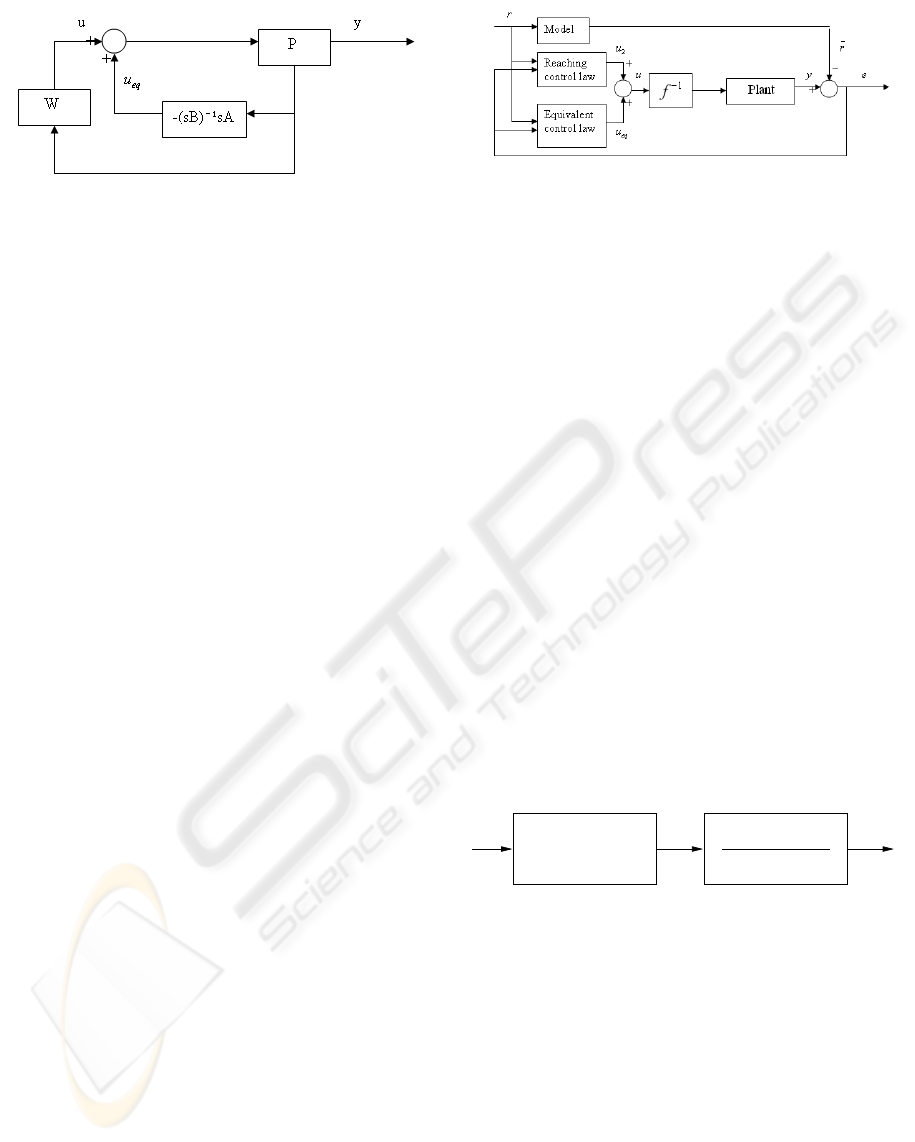

Figure 2. shows the structure of closed loop slid-

ing mode control system: where P is the plant and W

represents the reaching controller.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

234

Figure 2: Structure of closed loop sliding mode control sys-

tem.

3.3 Sliding Mode Control for a

Hammerstein Model

In a Hammerstein model, the nonlinearity has been

separated from the linear block already. The nonlinear

mapping f is a smooth polynomial with respect to its

input, hence it is invertible. Thus in the controller

design stage, the nonlinearity can be ignored and the

controller is only designed based on the linear block

and afterwards, the control signal is filtered through

an inverse of the nonlinearity before being sent to the

plant. This may not be necessary if the nonlinearity is

taken into account in the Lyapunov function used for

determination of the reaching control.

As far as the description of the linear block is con-

cerned, a non-minimal state space model is employed

(refer to (Xi and Hesketh) for details of derivation of

non-minimal state space models). The motivation for

this is that in a non-minimal state space model, the er-

ror signal sequence is contained in state vector (the er-

ror signal being the difference between the plant out-

put and the desired trajectory). Sliding mode control

results in a regulator, where the state variables will

be constrained to move along the sliding surface and

eventually reach and stay at zero. Thus the error sig-

nal will be regulated to approach zero and stay there

if the sliding mode control is based on a non-minimal

state space model. This is the aim of tracking con-

trol. Figure 3. shows the structure of such a control

system.

In the figure, r represents the set point and e is

the difference between filtered set point and the out-

put of plant (Xi and Hesketh). For our example, the

“filter” is selected simply as q

−1

. Here both equiva-

lent and reaching controller are related to the tracking

error and the set point. The control action force the

states to reach the sliding manifold and move along it.

This action continues until the plant output is equal to

the filtered set point, which is equivalent to the error

signal being zero. Then the states will be kept at the

Figure 3: Structure of sliding mode control system based on

Hammerstein model.

origin and the system achieves steady state.

4 EXAMPLE AND SIMULATION

RESULTS

4.1 Identification of Ball and Beam

Deriving an approximate model of the ball and beam

system involves determining the transfer function be-

tween the input signal (the shaft angle of the mo-

tor) and the output signal (the position of the ball).

In an identification experiment, a pseudo-random se-

quence is applied to the input signal, and both in-

put and output signals are sampled (For the ball and

beam the sampling interval selected was 1 second).

Here Captain Toolbox which is written for Matlab is

used to realize the identification ((Young et al., 2001),

http://www.es.lancs.ac.uk/cres/captain/). The result

of the Hammerstein model identification is:

y(t) = 0.962y(t −1)+0.396u(t − 1) − 0.036u

2

(t − 1)

u x

y

0.396u(t)−0.036u (t)

2

q

−1

1−0.962q

−1

Figure 4: Identification result of Hammerstein model.

The resultant non-minimal state space model of

the linear block is:

z(t) = Az(t − 1) + B∆x+ Q∆r(t) (28)

y(t) = Cz(t) (29)

where

A =

1.962 −0.962 −1 0.962

1 0 0 0

0 0 0 0

0 0 1 0

, B =

1

0

0

0

,

C =

1 0 0 0

, Q =

0

0

1

0

, z(t) =

e

eq

−1

∆r

∆rq

−1

.

SLIDING MODE CONTROL FOR HAMMERSTEIN MODEL BASED ON MPC

235

Suitable differencing is undertaken to introduce

∆ = 1 − q

−1

. Note the way in which the setpoint

is introduced within the state vector. This results in

feedforward action, achieved with the sliding mode

control.

4.2 Controller Design and Simulation

This system is typically unobservable. Performing of

observable/unobservable decomposition prevents sin-

gularity occurrence later. The system model becomes:

−

z(t) =

−

A

−

z(t − 1) + B∆

−

x(t − 1) + Q

ob

∆r(t)(30)

−

y(t) =

−

C

−

z(t) (31)

where the transformation matrix is T and

−

A =

0 0.5698 0.4188 0.7071

0 0.3374 0.2480 −0.4188

0 −0.4591 −0.3374 0.5698

0 0 −1.6885 1.962

,

−

B =

0

0

0

1

,

−

C =

0 0 0 1

.

Extracting the observable part we have:

z

ob

(t) = A

ob

z

ob

(t −1) + B

ob

∆u

ob

(t −1) (32)

y

ob

(t) = C

ob

z

ob

(t) (33)

where

A

ob

=

0.3374 0.2480 −0.4188

−0.4591 −0.3374 0.5698

0 −1.6885 1.962

, B

ob

=

0

0

1

.

In this case, the requirement of equation (5) has al-

ready been satisfied so that no further transformation

P is needed. Then

A

ob11

=

0.3374 0.248

−0.4591 −0.3374

, A

ob12

=

−0.4188

0.5698

,

A

ob21

=

0 −1.6885

, A

ob22

= [1.962]

The result of optimization is

k

1

k

2

.

Note that an inversion of the observ-

able/unobservable decomposition is to be performed

to recover the state vector z

ob

(t) = Tz(t) after sliding

surface design,

σ(z

ob

(t)) =

k

1

k

2

1

z

ob

(t) (34a)

σ(z(t)) =

k

1

k

2

1

Tz(t) = sz(t).(34b)

In this case, u

2

(t) is chosen to be −αsgn(σ(x(t))).

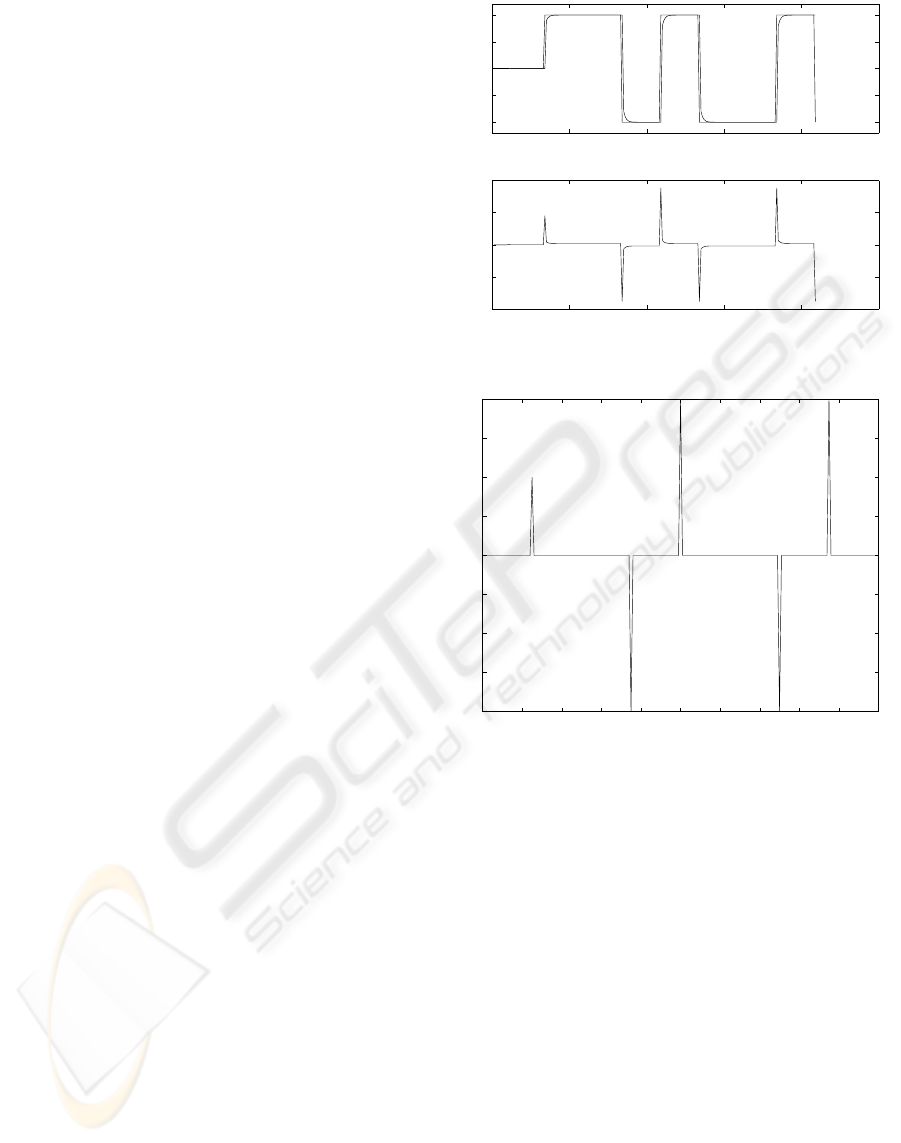

Figure 5. shows the performance of the above sliding

0 50 100 150 200 250

−1

−0.5

0

0.5

1

y and rbar

0 50 100 150 200 250

−2

−1

0

1

2

u

Figure 5: Performance with a linear model.

0 20 40 60 80 100 120 140 160 180 200

−0.2

−0.15

−0.1

−0.05

0

0.05

0.1

0.15

0.2

Figure 6: σ(t) defined in equation (13).

mode design. The figure shows simulation results, but

on-line control is similar.

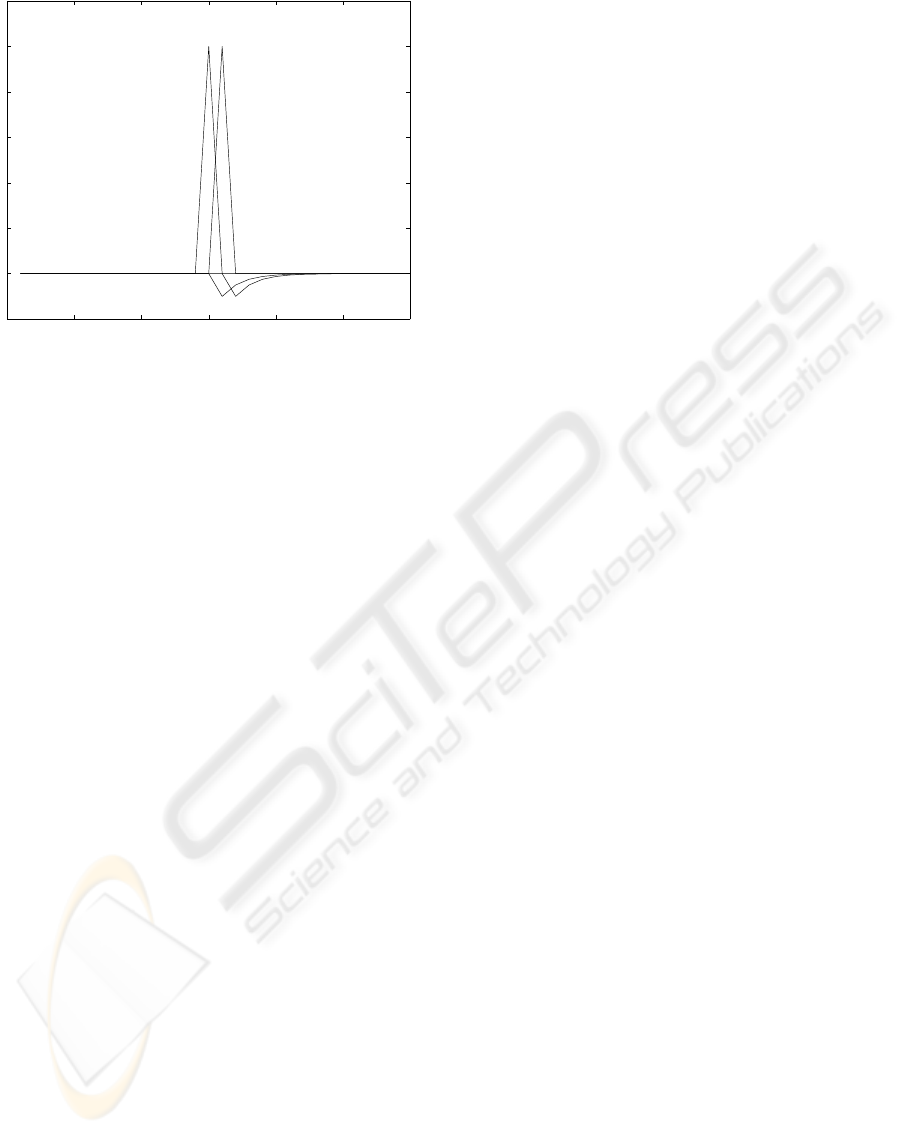

Figure 6. shows the values of σ(t) And Figure 7.

shows the state trajectory:

It is shown that the system follows the ideal trajec-

tory. The switching law works while sliding condition

is not met. Equivalent control regulates the state to

move along the sliding surface until the equilibrium

point is achieved.

5 CONCLUSION

In this paper, discrete sliding mode control is applied

to a Hammerstein model which results from nonlinear

system identification. The nonlinearity is separated

during the sliding surface design, so that the switch-

ing surface is actually a linear one. The surface is

derived by an MPC approach. The nonlinearity is re-

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

236

0 5 10 15 20 25 30

−0.2

0

0.2

0.4

0.6

0.8

1

1.2

Figure 7: State variables.

considered in design of the reaching control. The ball

and beam system is used as an example and simula-

tion results show satisfying performance.

REFERENCES

Bitmead, R. R., Gevers, M., and Wertz, V., 1990,

Adaptive

Optimal Control: The Thinking man’ s GPC (Prentice

Hall)

.

Clarke, D. W., Mohtadi, C., and Tuffs, P. S., 1987,

General-

ized Predictive Control– Part I. The Basic Algorithm

,

Automatica, 23, 137- 148;

Clarke, D. W., Mohtadi, C., and Tuffs, P. S., 1987,

General-

ized Predictive Control–Part II. Extensions and Inter-

pretations

, Automatica, 23, 149-160

C. James Taylor, Arun Chotai and Peter C. Young, 2000,

State space control system design based on non-

minimal state-variable feedback: further generaliza-

tion and unification results

, International Journal of

Control, 2000, Vol. 73, No. 14, 1329- 1345

Raymond, A DeCarlo, Stanislaw H. Zak, Gregory

P.Matthews,

Variable Structure Control of Nonlinear

Multivariable Systems: A Tutorial

, Proceedings of

The IEEE, Vol. 76, No. 3, March 1988

S. K. Spurgeon,

Temperature Control of Industrial Process

using a Variable Structure Design Philosophy

, Trans

Inst MC Vol. 14, No. 5, 1992

Stefen Hui, Stanislaw H. Zak,

On discrete-time variable

structure sliding mode control

, Systems & Control

Letters 38 (1999) 283-288

Weibong Gao, Yufu Wang, Abdollah Homaifa,

Discrete-

Time Variable Structure Control Systems

, IEEE

Transactions on Industrial Electronics, Vol. 42, No.2,

April 1995

Jozef Voros,

System Identification of Discontinuous Ham-

merstein Systems,

Automatica Vol.33.No.6. pp. 1141-

1146, 1997

F. Giri, F. Z. Chaoui, Y. Rochdi,

Parameter identification of

a class of Hammerstein plants

, Automatica, 37 (2001)

749-756

Xinghuo Yu and Guanrong Chen,

Discretization Behav-

iors of Equivalent Control Based Sliding-Mode Con-

trol Systems

, IEEE Transaction On Automatic Con-

trol, Vol. 48, No. 9, September 2003

Xinghuo Yu, Shuanghe Yu,

Discrete Sliding Mode Control

Design With Invariant Sliding Sectors

, Transaction of

the ASME, Vol. 122, Page776-782, December 2000.

Zhiyu Xi, Tim Hesketh,

MPC With a NMSS Model

, The

Sixth International Conference on Control and Au-

tomation.

Peter C. Young, Paul McKenna, John Brunn,

Identification

of Nonlinear Stochastic Systems by State Dependent

Parameter Estimation

, International Journal of Con-

trol, 2001, Vol. 74, No. 18, 1837-1857

C. L. Hwang and J. C. Hsu,

Nonlinear control design for a

Hammerstein model system

, IEE Procedings, Control

Theory and Applications, Vol 142, Issue 4, p.p 277-

285

Zi Ma, Arthur Jutan, Vladimir B. Bajic,

Nonlinear self-

tuning controller for Hammerstein plants with appli-

cation to a pressure tank

. Int. J. Comput. Syst. Signal,

1(2), 221-230, 2000

SLIDING MODE CONTROL FOR HAMMERSTEIN MODEL BASED ON MPC

237