A KALMAN FILTERING APPROACH TO ESTIMATE CLAMP

FORCE IN BRAKE-BY-WIRE SYSTEMS

Stephen Saric and Alireza Bab-Hadiashar

Faculty of Engineering and Industrial Sciences, Swinburne University of Technology, John Street, Hawthorn, Australia

Keywords: Brake-by-wire, sensor fusion, dynamic stiffness, torque balance, optimisation.

Abstract: Removing a clamp force sensor from brake-by-wire (BBW) system designs has been driven by the need to

reduce costs and design complexities. In this paper an improved method is presented to estimate clamp force

using other sensory information. The proposed estimator is based on the Kalman filter where the actuator

resolver is used in a dynamic stiffness model and the actuator current sensors as well as the resolver are

used to give measurement updates in a torque balance model. Experimental results show that the estimator

can handle highly dynamic braking scenarios making it suitable for possible use in anti-lock braking system

(ABS) controls. A comparison is made with a previous attempt to estimate clamp force in BBW systems

and it is shown that the proposed estimator improves the root mean square error (RMSE) of estimation. A

training strategy is explained to ensure that the estimator can adequately adapt to parameter variations

associated with wear. This paper finally discusses reliability issues associated with the developed clamp

force estimator.

1 INTRODUCTION

Drive-by-wire (DBW) technologies are being

currently developed and introduced into the

automotive industry. One advantage of such

technologies is to produce intelligent vehicle control

systems that improve performance by benefiting

from the integration of electronic systems (Schenk et

al. 1995). The subject technology of interest in this

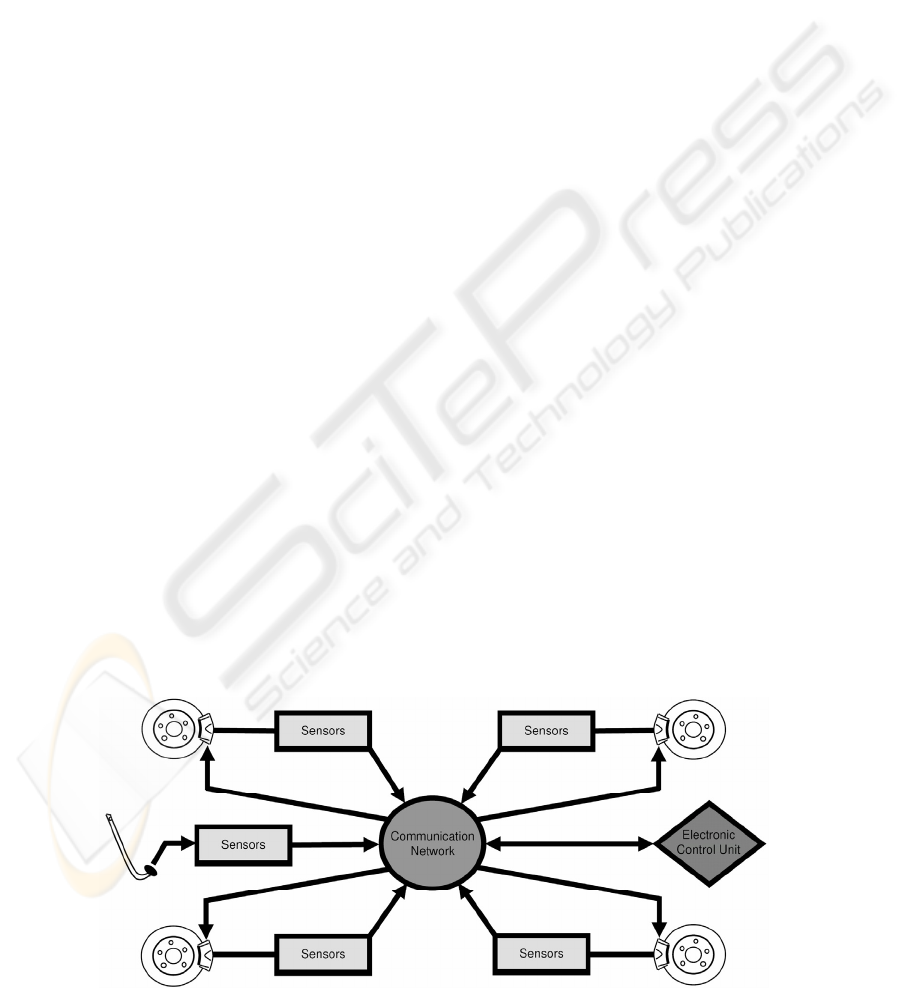

paper is BBW systems for disk brakes. Figure 1

shows a schematic diagram of a BBW system as

given by Saric et. al. (2007). A pedal feel emulator

provides the human-machine interface in a BBW

system. This pedal is fitted with sensors whose

outputs are processed by an electronic control unit

which then controls the actuators.

An electric motor that is coupled to reduction

gearing is the general setup used for an electro-

mechanical brake (EMB) actuator. The motor is

normally of a permanent magnet brushless DC type

for the reasons of compactness and enhanced

commutation efficiency. A planetary gear-set

connected to a ball-screw are generally the

components used in the reduction gearing.

Figure 1: BBW System.

249

Saric S. and Bab-Hadiashar A. (2007).

A KALMAN FILTERING APPROACH TO ESTIMATE CLAMP FORCE IN BRAKE-BY-WIRE SYSTEMS.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 249-255

DOI: 10.5220/0001643802490255

Copyright

c

SciTePress

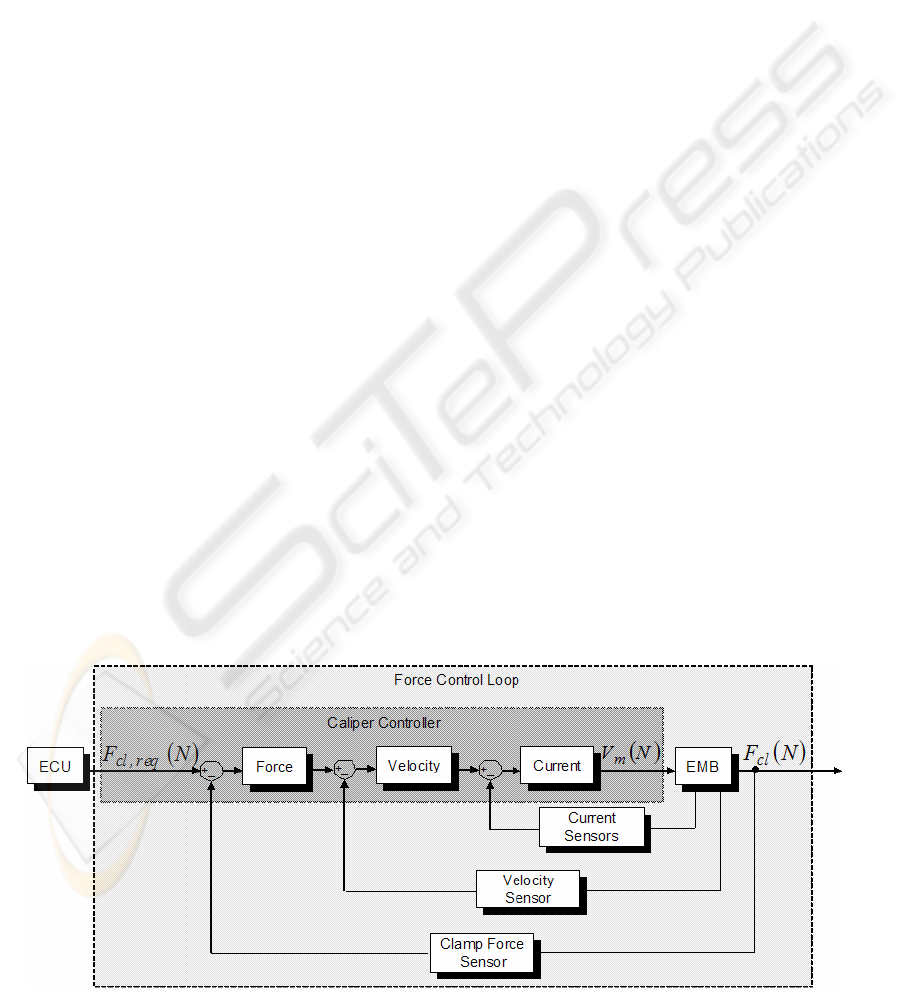

To control EMB caliper clamping force, a clamp

force sensor is typically used to close the control

loop. A standard motion control architecture

(cascaded position, velocity and current control

loops) which is slightly altered can be used to

control an EMB. Line et al. (2004) exchange the

position control loop for a force control loop for

EMB control purposes. This architecture is shown in

figure 2 as given by Hoseinnezhad et. al. (2006).

The control system depicted in figure 2 requires the

use of a displacement sensor, normally a resolver,

and three motor current sensors for a three phase

brushless DC motor.

The adequate implementation of a clamp force

sensor in an EMB system can be a difficult thing to

achieve. If a clamp force sensor is placed near to a

brake pad, it must then be able to mechanically

withstand the high temperatures (up to 800

O

C) it

will be subject to. Also temperature drifts may need

to be compensated for. By embedding a clamp force

sensor deep within a caliper, i.e. at the near end of

the ball-screw this situation can be avoided.

However due to the effects of friction between the

embedded clamp force sensor location and an inner

pad, a hysteresis effect results which prevents a true

clamp force to be sensed. A clamp force sensor is a

costly item in an EMB caliper. This is due to a high

supplier cost and increased production expenses due

to its inclusion. These high production costs result

from online calibration for each individual sensor

because of performance variability from one unit to

another, as well as difficult assembly procedures due

to the small tolerances being dealt with.

The elimination of a clamp force sensor from

EMB designs is highly desirable because of the cost

issues and engineering challenges involved with its

use. A way to eliminate this component may be

realized via a sensor fusion approach, that is, to

estimate clamp force using remaining EMB system

sensors.

The introduction given here is followed by a

developmental background that briefly explains

previous works completed on estimating clamp force

in EMB systems. A description of the developmental

steps taken to attain our new clamp force estimator

is then provided, followed by describing the test rig

which we have employed. Validation results are

given which then finally leads to conclusive

remarks.

2 BBW CLAMP FORCE

ESTIMATION REVIEW

Developed torque in an EMB caliper can be

determined from motor current sensors which are

part of all EMB designs. A simplified model says

that the torque induced by a permanent magnet DC

motor is linearly related to the current passing

through the field coil, that is:

T

m

= K

m

I

m

(1)

where T

m

, I

m and

K

m

are the motor torque, the field

current and the motor torque constant respectively.

The latter term is a constant that is experimentally

determined. For a brushless permanent magnet DC

motor the current (I

m

) is the quadrature component

of the resultant current space vector as found from

the individual phases (Krishnan 2001, p. 527). Since

the motor torque input in an EMB caliper causes a

clamping force, it is apparent that a relationship

must exist between these two variables. To

determine an induced clamp force in an EMB caliper

using motor current information, a torque balance

Figure 2: EMB system control architecture.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

250

can be solved as follows:

T

m

= T

a

+ T

i

+ T

f

I

m

K

m

= γ

tot

F

cl

+ J

tot

d

2

θ

m

/dt

2

+ T

f

F

cl

= (I

m

K

m

- J

tot

d

2

θ

m

/dt

2

- T

f

) / γ

tot

. (2)

The torque balance says that the torque developed

by the motor (T

m

) equals the torque required to

provide clamping force (T

a

), to meet the necessary

inertial demands (T

i

) and to overcome frictional

resistance (T

f

). By combining the load ratios from a

series connected planetary gear-set and ball-screw, it

can be found that this value (γ

tot

) acts as a gain

relating the application torque (T

a

) to the clamp

force (F

cl

). The entire caliper inertia (J

tot

) is lumped

and involves both rotational and translational

motions. This value is usually attained using

empirical data where an energy balance, over a stage

of motor acceleration, is formulated to find the

lumped inertia (J

tot

).

Equation (2) shows that the frictional torque (T

f

)

term is undefined. The reason for this is that as

Olsson et al. (1998, p. 176) explain, using theoretical

friction models for practical purposes is difficult to

achieve in a satisfactory manner. To overcome this

problem, theoretical friction models should be

merged with experimentally established phenomena

unique to a particular system. Friction models of any

sort tend to be avoided in trying to estimate clamp

force in an EMB caliper because of the problems in

trying to account for wear in the reduction gearing.

This subject will be continued in later discussion.

A clamp force estimation algorithm was

developed by Schwarz et al. (1999) for use on an

EMB caliper designed for a disk brake. Equation (2)

was involved in part within their algorithm. By

employing a differing technique they avoid the need

for using a friction model which is explained in

more detail as follows. A low amplitude high

frequency sinusoid is superimposed on the otherwise

normal angular motion from the motor. This forces

the motor to pass the same angular position in a

finite length of time between a clamping and

releasing action. At both these instants the

application of (2) yields:

T

m,cl

= γ

tot

F

cl

+ J

tot

d

2

θ

m,cl

/dt

2

+ T

f

(3)

T

m,rl

= γ

tot

F

cl

+ J

tot

d

2

θ

m,rl

/dt

2

- T

f

(4)

where the subscripts cl and rl indicate clamping and

releasing respectively. The friction terms in (3) and

(4) have approximately the same magnitudes but

opposite signs due to the change in course of motor

travel. Adding (3) and (4) cancels out the friction

terms and after some manipulation the following

equation to estimate clamp force (F

cl

*

) can be found:

F

cl

*

= (T

m,cl

+ T

m,rl

- J

tot

d

(θ

m,cl

+ θ

m,rl

) /dt

2

) /(2γ

tot

).

(5)

Passing the same motor angle via sinusoidal

differing becomes a harder and harder task to

achieve as the clamp force application rate is

increased. Also the requirement of reversing

direction in a short period of time during increased

clamp force application rates will most likely

challenge the dynamic control ability of the EMB

system. A means to cope with these problems is

proposed by Schwarz et al. (1999). The

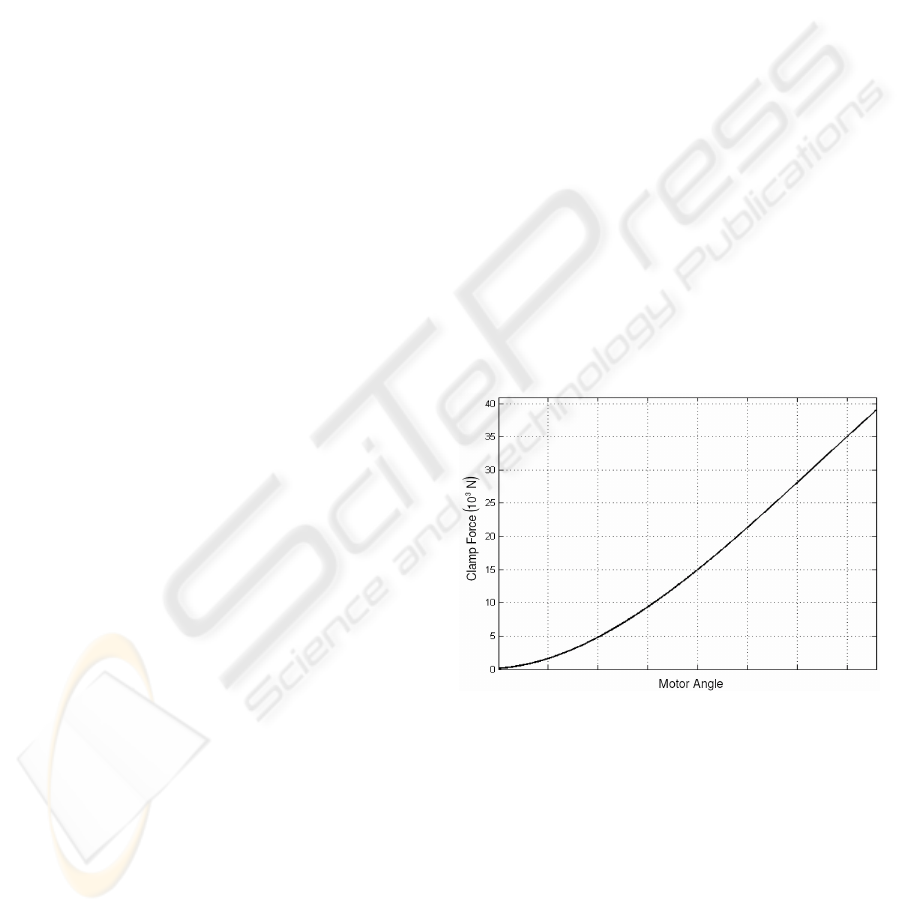

characteristic curve of an EMB caliper is a

relationship between motor angle and applied clamp

force where the former is varied in a pseudo-static

fashion. Figure 3 displays this curve for an EMB

caliper as given by Hoseinnezhad et. al. (2006).

Schwarz et al. (1999) put forward the use of a

caliper characteristic curve to provide feedback

control of applied clamp force. When the

opportunity to use (5) arises, it is done so with the

intentions of adapting the parameters in the

characteristic curve due to pad wear.

Figure 3: Characteristic curve for an EMB Caliper.

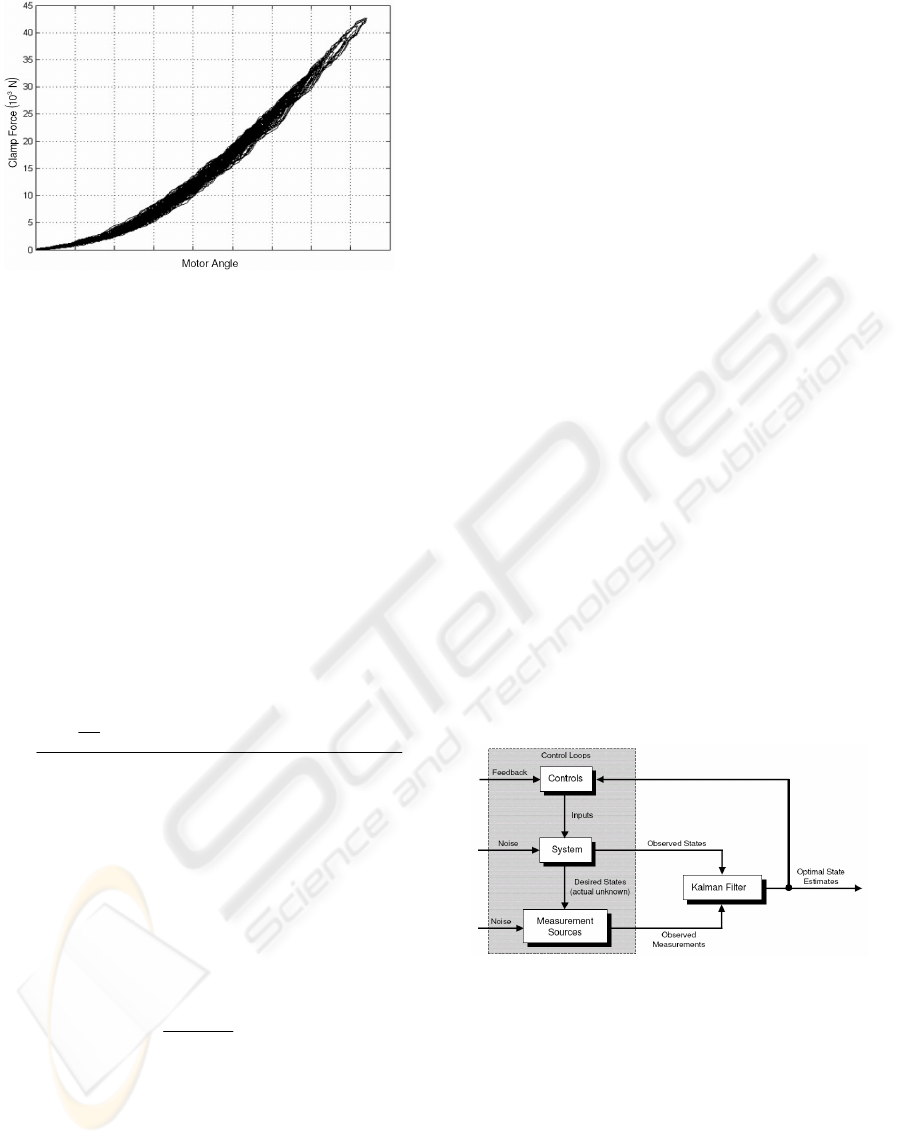

As provided by Hoseinnezhad et al. (2006),

figure 4 displays clamp force versus motor angle for

a highly dynamic situation where the motor angle is

varied in a uniform random fashion with a sample

time of 100 ms. It is clear that considerable dynamic

exists within the system and that the use of a

characteristic curve for clamp force estimation

purposes has its limitations for highly dynamic

scenarios. The cause of this dynamic is attributed to

viscoelastic effects exhibited mainly by the caliper

bridge. Hoseinnezhad et al. (2006) developed a

dynamic stiffness model to handle such viscoelastic

A KALMAN FILTERING APPROACH TO ESTIMATE CLAMP FORCE IN BRAKE-BY-WIRE SYSTEMS

251

Figure 4: Clamp force versus motor angle for highly

dynamic case.

effects. This model is given as follows in discrete

time notation:

1)-(α+)(θα+)(θα+)(θα=)(

01

2

2

3

3

kFkkkkF

*

cl

mmm

*

cl

(6)

where α

4

, α

3

, α

2

, α

1

and α

0

are experimentally

determined constants and θ

m

is the motor angle.

Saric et al. (2006, 2007) uses (6) as well as a

second model to estimate clamp force in a fusion

algorithm which optimizes the RMSE of estimation.

The second model is based on the torque balance

approach where a dynamic Coulomb friction model

is used which is dependent on clamp force and is

shown below in discrete time notations:

.

kk

kkAkkk

t

J

kT

kF

mmktot

mmkmmm

s

tot

m

*

cl

1))(θ)(sgn(θμ+γ

1))(θ)(sgn(θ2))(θ+1)(2θ)((θ)(

=)(

2

--

-------

(7)

where t

s

, μ and A are the sampling time, the

coefficient of Coulomb friction and an offset friction

term respectively. The two models given by (6) and

(7) are fused together by Saric et al. (2006, 2007)

using a maximum likelihood estimator to give an

optimized estimate of clamp force which is as

follows:

(8)))(-)((

σ+σ

σ

+)(=)(

22

2

kFkFkFkF

ˆ

*

ds

*

tb

tbds

ds

*

ds

cl

where σ is the standard deviation and the subscripts

ds and tb indicate dynamic stiffness and torque

balance respectively. Gaussian noises were assumed

in the derivation of (8). After having adapted

parameters, as detailed by Saric et. al. (2007) and

described previously, an improvement in the RMSE

of approximately 10% is obtained as a result of

fusing via (8). Parameters are adapted in (6) due to

stiffness variations because of pad wear, and in (7)

because of frictional variations in the caliper

reduction gearing.

The fusion algorithm used by Saric et al. (2006,

2007) does not have a recursive nature. Therefore

the use of a Kalman filter will further improve

estimation accuracy (Kalman 1960, p. 35; Sorenson

1970, p. 63). In this paper we present the use of a

Kalman filter to estimate clamp force. The ensuing

section details how we setup the Kalman filter for

clamp force estimation purposes in a BBW system.

3 KALMAN FILTER SETUP

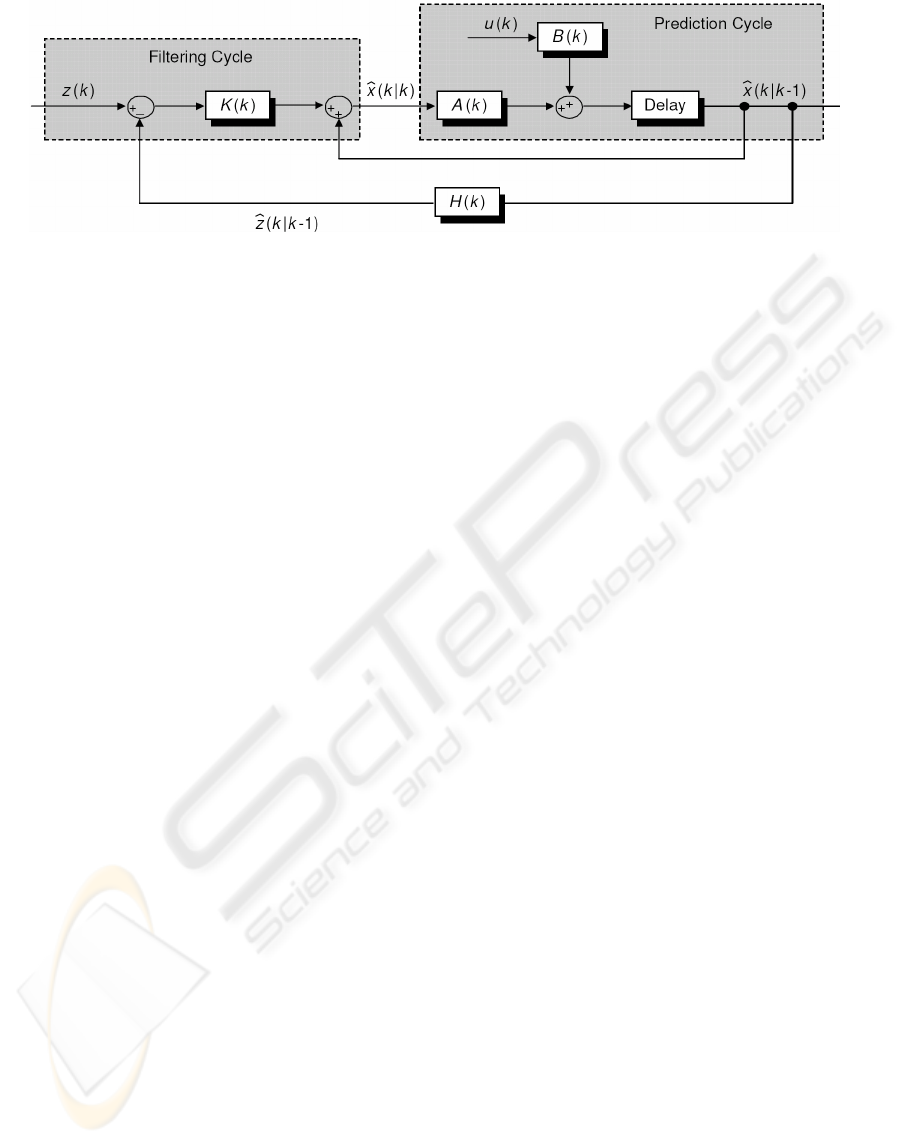

A Kalman filter is a linear, recursive, discrete time

estimation algorithm. It is maximum likelihood in

nature in that the RMSE’s are minimized. A Kalman

filter is implemented widely in control systems to

give improved system state estimates. Figure 5

shows a block diagram representation of a Kalman

filter in a control system. The use of a Kalman filter

is advantageous because of noise influences

(Gaussian) which render the true system states

unknown. A Kalman filter uses system dynamics as

well as other measurement sources to estimate

states. Typically the later is attained from direct

sensory measurements. The noises which affect both

kinds of estimates the Kalman filter receives, view

figure 5, are required to be uncorrelated.

Figure 5: Typical Kalman filter application.

In the case where the system dynamics and/or

measurement dynamics (which acts on the system

dynamic estimates) is non-linear, an Extended

Kalman filter (EKF) can be used which performs a

linearization procedure. This is not necessary for our

purposes due to the linear nature of the

circumstances. Figure 6 shows a block diagram

representation of a Kalman filter where:

x - is the system state vector

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

252

Figure 6: Block diagram representation of a Kalman filter.

u - is the control inputs

z - is the observation vector

K - is the filter gain

A - is the coefficient matrix of the system

B - is the driving matrix

H - is the measurement matrix.

The hat (^) scripts in figure 6 denote the criteria

of trying to minimize the RMSE of estimation. The

discrete time notation used in figure 6, k|k-1,

indicates that the estimate at k was determined given

knowledge at k-1. The filter gain is defined as

follows:

K(k) = P(k|k-1)H

T

(k)(H(k)P(k|k-1)H

T

(k) + R)

-1

(9)

where,

P - is the covariance matrix of state estimates

R - is the measurement noise covariance

matrix.

The matrices (P(k|k-1)) and (P(k|k)) for a Kalman

filter are given below as:

P(k|k-1) = A(k)P(k-1|k-1)A(k)

T

+ Q (10)

P(k|k) = (I - K(k)H(k))P(k|k-1) (11)

where,

Q - is the system noise covariance matrix

I - is the identity matrix.

It should be noted that the system noise covariance

(Q) and measurement noise covariance (R) matrices

may be time-variant, however we assume them here

to be constant. As shown in figure 6, a Kalman filter

of any type involves the recursive application of

prediction and filtering cycles. Brown and Hwang

(1992) give a complete derivation of the Kalman

filter algorithm.

To employ a Kalman filter for clamp force

estimation in a BBW system, we firstly use (6) as

our state space system equation. The constant α

0

from (6) is taken to be equal to A(k) from figure 6.

Note that typical matrix notations were not required

due to the unit state space dimension of (6). The

clamp force in (6) is non-linearly proportional to the

motor angle input. This non-linearity does not

require the use of an EKF because it is not state

dependent. To integrate this non-linearity within the

Kalman filtering algorithm given in figure 6 we

apply the following equality:

)(θα+)(θα+)(θα= )()(

1

2

2

3

3

kkkkukB

mmm

(12)

We take the equivalent of

)|( 1-kkx

from figure 6 to

be directly equal to

)|( 1-kk z

ˆ

, that is:

(13)11 ).|(=)|( -kkF-kkz

ˆ

cl

For this situation H(k) is taken to have a constant

unit value. We use (7) as our source for

measurement updates which is equivalent to z(k)

from figure 6. Saric et al. (2007) found that the

RMSE’s associated with (6) and (7), after having

adapted parameters, were 0.35 and 0.61 kN

respectively. These values squared are used for

assumed constant system (Q) and measurement (R)

error variances (the typical term covariance has not

been used since (6) has a unit state space

dimension).

With the Kalman concept to estimate clamp

force in BBW systems defined, the next section

briefly describes the test rig required to obtain

necessary data for analysis and subsequent

validation purposes.

A KALMAN FILTERING APPROACH TO ESTIMATE CLAMP FORCE IN BRAKE-BY-WIRE SYSTEMS

253

4 EXPERIMENTAL

ENVIRONMENT

A test rig was setup for use on a prototype EMB

caliper. An external servo motor was used to provide

actuation by coupling it to the caliper internal

reduction gearing as shown in figure 7. The external

motor is of the permanent magnet brushless type,

with ratings of 55.5 N.m and 5, 000 rpm and ensures

that maximum clamp forces can be achieved. To

interface with this motor, the RS232 protocol was

utilized. MATLAB’s Simulink package along with

the xPC block-set provided a real time operating

system that was implemented to control the external

Figure 7: Test rig using a brushless permanent magnet

external servo motor.

1. host PC

2. target PC

3. brushless permanent magnet external servo

motor

4. external torque sensor

5. EMB caliper

6. external clamp force sensor

7. National Instruments brake-out boxes

8. low pass filter/amplifier for external clamp

force sensor

9. DC power supply

10. ethernet hub

motor angle. The external motor is controlled by

PID controllers within a standard motion control

architecture; cascaded position, velocity and current

control loops as illustrated in figure 8. Sensory

information are logged by uploading the signal data

to the host PC from the target PC, marked 1 and 2

respectively in figure 7. The logged data is stamped

at 100 μs time-step intervals. Both the host and

target PC’s have Pentium 4 processors operating at

2.4 GHz. To measure the caliper motor angle, an

encoder output is taken from the 1:1 coupled

external servo motor. The resolution of this encoder

output provides 8, 192 counts per revolution. An

external torque sensor is used to sense torque input

to the EMB caliper. An external clamp force sensor

is used to measure the true load induced by the brake

pads.

Figure 8: Control scheme used for external servo motor.

For the reasons of clarity the external motor

angle and torque data from this test rig is considered

to be received from an EMB caliper itself since a

resolver and current sensors are available.

5 RESULTS AND DISCUSSIONS

After having adapted parameters in (6) and (7) as

detailed by Saric et. al. (2007) and described

previously, the Kalman filter setup given earlier for

clamp force estimation purposes in a BBW system

are applied to uniform random data. The uniform

random data involves varying the motor angle in a

uniform random manner with a sample time of 100

ms. We use the constant system (Q) error variance to

initialize the clamp force estimate error variance at

time equal to zero.

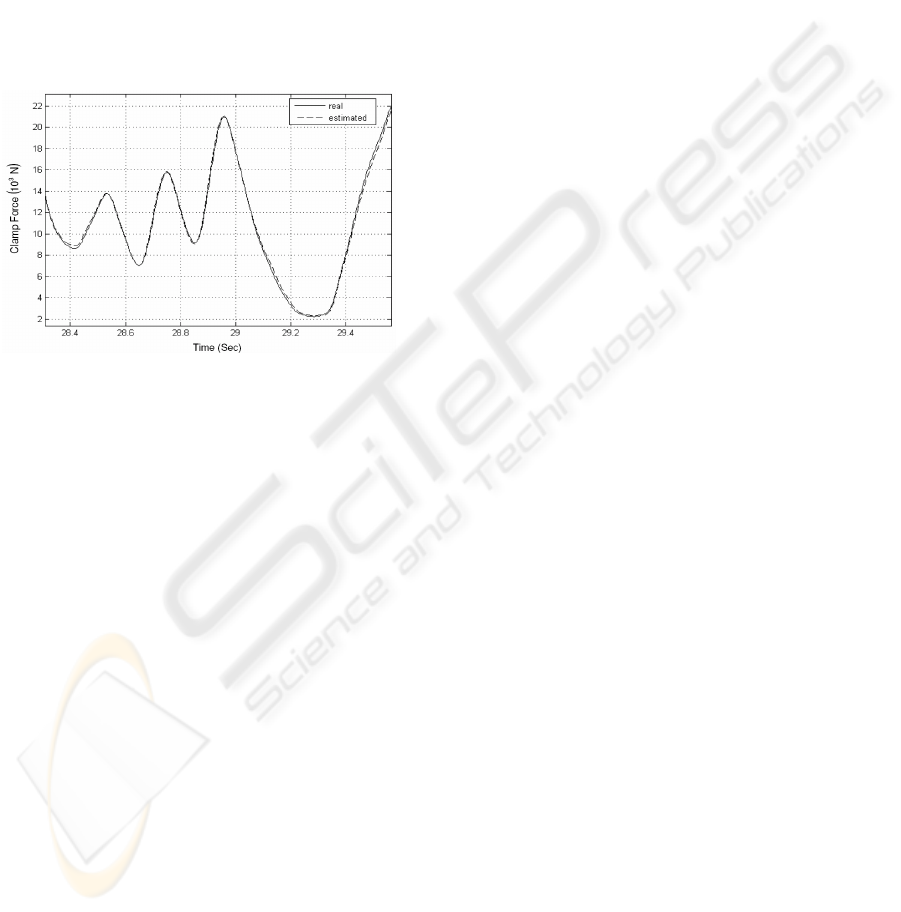

Figure 9 shows the performance of our new

method to estimate clamp force in a BBW system.

This result shows that adaptation to ABS controls is

possible seeing as the actuation speeds are

comparable. A new RMSE of 0.29 kN results which

is an approximately 20 % improvement on the

RMSE from the dynamic stiffness model alone.

Saric et al. (2007) found that the use of a maximum

likelihood estimator with no recursive aspect, as

given by (8), gave a RMSE in clamp force

estimation of 0.32 kN where the same experimental

setup and control input was used as here. Therefore

we have demonstrated that the use of an Kalman

filter which has a recursive aspect, improves the

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

254

RMSE of clamp force estimation by approximately

10 % with regards to the methods used by Saric et.

al. (2007).

With in-service pad temperatures being able to

possibly reach 800

O

C, it has been found that the

stiffness of pads varies depending on the

temperature (Schwarz et. al. 1998). Stiffness is a

large component within the clamp force estimator

developed within this paper. The brake pad

temperature was kept constant using the static test

rig shown in figure 8, and hence temperature effects

on clamp force estimation under practical

circumstances should be investigated.

Figure 9: Uniform random data, 100 ms sample time, EKF

clamp force estimator validation.

6 CONCLUSIONS

This paper presents the use of a cost effective and

design friendly solution for an automotive BBW

actuator. The objective of making a clamp force

sensor a redundant component in an EMB system is

strongly encouraged by the results within this paper.

A dynamic stiffness model was used to estimate

clamp force which relied on the output from an

internal resolver. Based on a torque balance

approach, a second model was used to estimate

clamp force which relied on the use of internal

motor current sensors and an internal resolver. Wear

dependent parameters from both models were

adapted using an in-service method. The outputs

from the two independent models were fused using a

Kalman filter to give optimized estimates of clamp

force. The developed estimator has been shown via

experimental verification to be able to handle highly

dynamic braking situations. Also it has been shown

that the RMSE of estimation with regards to

previous attempts to estimate clamp force in BBW

systems has been improved upon. With continued

development the possible cost savings inherent with

attempting to make a clamp force sensor redundant

can be accomplished in future EMB designs.

ACKNOWLEDGEMENTS

The initiative formed by the centre of Research for

Advance By-Wire Technologies (RABiT) provided

a medium for which this collaborative work was

undertaken by Swinburne University of Technology

(SUT) and PGT. The authors of this paper would

like to thank the engineers from PGT for their kind

assistance.

REFERENCES

Brown, R.G., Hwang, P.Y.C., 1992. Introduction to

Random Signals and Applied Kalman Filtering, John

Wiley & Sons. United States, 2

nd

edition.

Hoseinnezhad, R., Saric, S., Bab-Hadiashar, H., 2006.

Estimation of Clamp Force in Brake-by-Wire

Systems: A Step-by-Step Identification Approach,

SAE Technical Paper Series, no. 061154.

Kalman, R.E., 1960.

A New Approach to Linear Filtering

and Prediction Problems, ASME Journal of Basic

Engineering, vol. 82, ser. D, pp. 35-45.

Krishnan, R., 2001. Electric Motor Drives, Prentice Hall,

New Jersey.

Line, C., Manzie, C., Good, M., 2004. Control of an

electromechanical brake for automotive brake-by-wire

systems with adapted motion control architecture, SAE

Technical Paper Series, no. 042050.

Olsson, H., Åström, K.J., Wit, CCd., Gäfvert, M.,

Lischinsky, P., 1998. Friction models and friction

compensation, European Journal of Control, vol. 4,

no. 3, pp. 176-195, 1998.

Saric, S., Bab-Hadiashar, A., Hoseinnezhad, R., 2007. A

Sensor Fusion Approach to Estimate Clamp Force in

Brake-by-Wire Systems, IEEE Transactions on

Vehicular Technologies, accepted for publication.

Saric, S., Bab-Hadiashar, A., Hoseinnezhad, R., 2006. A

Sensor Fusion Approach to Estimate Clamp Force in

Brake-by-Wire Systems, IEEE Vehicular

Technologies Conference, no. 27448.

Schenk, D.E., Wells, R.L., Miller, J.E., 1995. Intelligent

Braking for Current and Future Vehicles, SAE

Technical Paper Series, no. 950762.

Sorenson, H.W.,

1970. Least-squares estimation: from

Gauss to Kalman, IEEE Spectrum, vol. 7, pp. 63-68.

Schwarz, R., Isermann, R., Böhm, J., Nell, J., Rieth, P.,

1999. Clamping force estimation for a brake-by-wire

actuator, SAE Technical Paper Series, no. 990482.

Schwarz, R., Isermann, R., Böhm, J., Nell, J., Rieth, P.,

1998. Modelling and Control of an Electromechanical

Disk Brake, SAE Technical Paper Series, no. 980600.

A KALMAN FILTERING APPROACH TO ESTIMATE CLAMP FORCE IN BRAKE-BY-WIRE SYSTEMS

255