SCADA WEB

Remote Supervision and Maintenance of Industrial Processes

José Ramón Janeiro, Eduardo J. Moya, David García, Oscar Calvo and Clemente Cárdenas

Fundación CARTIF, Parque Tecnológico de Boecillo. Parcela 205. 47151 Boecillo, Valladolid, Spain

Keywords: Remote Supervision, Control, Maintenance, Industrial Process, PLC, OPC, OPC-DA, SCADA, Web,

Internet, Java, GSM, GPRS, SMTP, PLC.

Abstract: This article explains a SCADA System called SCADA Web developed by CARTIF Foundation. This

SCADA System makes possible remote monitoring and control from the process controlled by PLC using

Web Technology. SCADA Web has been developed on platform Java EE and provides visualization and

control signals, trend charts, alarms, historical data and alarm reports.

1 INTRODUCTION

Internet, together with the use of technologies such

as GMS/GPRS/UMTS (International Engineering

Consortium), provides communication mechanisms

with a great number of possibilities (GeneraLynx).

These technologies are present more and more in the

industry.

Nowadays, a large extent of automation

in

dustrial solutions demand maintenance and

supervision systems because of the high complexity

and the need of managing a large volume of data.

Computers are the main support for supervision

and m

aintenance systems due to the high

performances and informations that they can

process.

The main reasons to develop a SCADA Web

(Janei

ro, J. R., 2006) have been the growing use of

the supervision and maintenance system on

computers and the features that support the

technologies GSM/GPRS/UMTS and Internet.

This paper is organized as follows. In Section 2

the characteri

stics that a remote supervision and

maintenance system have to support are presented.

The SCADA Web Application arquitecture

necessa

ry to supervise a process in a remote way is

presented in Section 3.

In Section 4 the main features and an operation

m

anual of the SCADA Web Application is

presented.

Conclusions and open issues for future research

are

discussed in Section 5.

2 REMOTE SUPERVISION AND

MAINTENANCE OF

INDUSTRIAL PROCESSES

Nowadays, more and more systems are being

supervised in a remote manner in order to keep the

process running in a correct state. The most

important applications to be carried out are

maintenance actions, although this depends on the

nature of the process.

The traditional arquitecture of these systems in

relatio

n to remote supervision is composed by a

Web Server that, after a correct authentication,

allows access to remote supervision services of an

industrial process. The supervision systems have to

fulfill the next requirements:

It

is only necessary one computer and an

Internet connection to supervise the system

There is not need of special soft

ware

installation in the remote computer, except for

some specific plug in.

In

dependence of the remote computer operative

system.

The acces

s to applications must be controlled to

avoid risks, due the that these remote

supervision tasks can be accessible through a

network like internet.

Be carefu

l with the exchange between remote

computer and the process due to security

problems. One possible solution is the use of

safe communication protocols like HTTPS.

220

Ramón Janeiro J., J. Moya E., García D., Calvo O. and Cárdenas C. (2007).

SCADA WEB - Remote Supervision and Maintenance of Industrial Processes.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 220-225

DOI: 10.5220/0001647702200225

Copyright

c

SciTePress

Maintenance systems send alarms or warning by

means of SMS and e-mail. These methods supply an

efficient notification reducing failure correction

times and therefore reducing process costs.

3 SCADA WEB ARCHITECTURE

The acronym of SCADA Web Application comes

from SCADA (Supervisory Control And Data

Acquisition) and WEB (World Wide Web). This

application makes remote supervision and

maintenance of any industrial process possible. The

above-mentioned process can be controlled by

PLC´s of different brands by means of a web

browser, an e-mail client and a mobile.

This application offers a number of features

beyond the usual characteristics of a simple SCADA

system. It contains elements focused towards

industrial process maintenance like SMS messaging

(Short Message Service) using technology

GSM/GPRS (Global System for Mobile

Communications /General Packet Radio Service)

and e-mails.

Using OPC-DA(OPC-Foundation) protocol

(OLE for Process Control-Data Access) based on

OLE/COM/DCOM (Object Linking and

Embedding/Component Object Model/Distributed

Component Object Model) it is possible to access

the variables.

In order to avoid the use of DCOM technology

due to problems with the firewalls (OPC

Programmers’ Connection), we have developed an

application called OPC gateway to supervise the

process without limiting the structures of control.

This application uses OPC-DA implementation in

its interface “Automation” allowing the SCADA

Web Application to access the variables by means of

strings UNICODE based on Sockets. Although the

OPC gateway application support DCOM, it is

expected to be installed in the same computer where

the OPC-DA server is located so that it is only

necessary to use COM technology.

The use of OPC-XDA(OPC Foundation) (OLE

For Process Control- XML Data Access) instead of

OPC-DA was ruled out because of the generally

scarce in utilization of this protocol by PLC´s

manufacturers. Even so, it is desirable that the

application supports both protocols in future

versions.

In fact, the SCADA Web Application is a Web

application developed using the platform Java EE

(Java Enterprise Edition) (Sun Microsystems).

Apache Tomcat (The Apache Software

Foundation) has been the server used. SCADA Web

Application is based on the next technologies: JSP,

Servlet, Applet, Beans, JDBC, JavaMail, JAF and

JAXB. The use of these technologies leads to a high

development cost of the application, a null or low

acquisition cost and high flexibilility and scalability

compared, for example, to commercial SCADA.

Figure 1: SCADA Web Application Structure.

The configuration parameters of SCADA Web

Application are inserted in an XML file called

scadaweb.xml. This file has to keep the xml schema

which is defined in the file scadaweb.xsd The use of

an XML file to configure the application allows a

high degree of flexibility and scalability in the

parameters configuration, as well as a simplification

of the configuration process to the user.

Thanks to JAXB (Java Architecture for XML

Binding) the schema XML is mapped to JAVA

classes providing a simple way to access the

configuration file scadaweb.xml. The SCADA Web

Application is divided in two modules called

Supervision and Maintenace modules. Next, these

modules will be explained.

3.1 Supervision Module

This module has the typical characteristics of a

comercial SCADA. An industrial process can be

remotely supervised via WEB thanks to this module.

Although this module was designed for remote

supervision via WEB, it can be used for local

supervision of a process. Furthermore, thanks to its

generic design, it’s possible to supervise the process

using informatics nets so complex as desired (LAN,

Internet, Routers, ...).

The Supervision Module of SCADA Web

Application is a multiuser system that lets to several

SCADA WEB - Remote Supervision and Maintenance of Industrial Processes

221

remote users supervise the same process at the same

time.

This module is based on a client-server

architecture (Applet-Servet/JSP) which allows to

distribute the computacional load of the application

between Tomcat Apache server and remote

machines.

An Applet is an application, written on Java,

which is executed on a Web browser. Using an

applet allows us to have a more complete interface

from the point of view of the client.

A Servlet is a Java class that is carried out on an

application server in order to answer clients

requests. The clients are Applet´s in the case of

SCADA Web.

A page JSP is a file that combines HTML targets

with script targets which belong to Java Server

Pages specification. The page JSP has a similar

aspect to HTML targets, but they are changed in

Servlet in order to compile and generate the

appropriated class files. The resulting file from the

transformation of page JSP is a combination of

HTML code cointained in JSP page and dynamic

content which is especified by JSP specification

targets. The exchange of information between

Applet and Servlet is carried out by HTTP

tunneling, in other words, transmitting binary

information using HTTP protocol.

Due to security obsession this protocol is usually

the only possible method of information

transmission.

3.2 Maintenance Module

This module is executed as a daemon checking

permanently that alarms have been configured to

take place. Alarm notification is carried out by

maintenance workers using two diferent methods

depending on configuration.

The first method consist of an alarm notification

using GSM/GPRS technology by SMS. It is

necessary that the computer where SCADA Web

application is installed, is connected to a

GSM/GPRS modem, normally through a serial port.

Communication between modem and SCADA Web

is made by standard AT commands. The library

command used to operate the computer ports is one

from the RXTX organization (RXTX Serial and

parallel I/O libraries supporting Sun’s CommAPI).

The second method consist of alarm notification

using e-mails. A SMTP server which is configurable

in SCADA Web Application is used. In this case the

library used is JavaMail from Sun Microsystems.

4 SCADA WEB

SCADA Web Application is executed within

applications servers. This application allows an

interaction between user and process by means of

three interfaces, HTTP, GSM/GPRS and e-mails.

The first interface, HTTP, makes it possible to

supervise the process in a remote manner from a

web browser.

The interface GSM/GPRS is oriented to offer an

instantaneous warning procedure reducing failure

correction times and the costs of industrial

processes.

Finally, the e-mail interface carries out the same

functions that GSM/GPRS interface, although it

allows to send more information. The main reason is

to provide redundant alarm warning procedures, so

that the user is notified as soon as possible. E-mail,

unlike GSM/GPRS, is used to notify less critical

alarms. The HTTP interface has been grouped inside

what has been called Supervision Module, while

GSM/GPRS interface and e-mails are in

Maintenance. Next, these modules are explained.

4.1 SCADA Web Configuration

As in other software applications, the configuration

of SCADA Web Application is done by an XML file

according to XML Schema called scadaweb.xsd.

This configuration file has four blocks well

differentiated: Parameters, Maintenance, Protocols,

and Users.

The reading frecuency of PLC´s variables in

“Paramaters Block” is normally about half a second.

The update frequency of the different databases of

the supervisory system is also configurated These

are called reports or historical data.

Inside the “Maintenance Block” the neccesary

basic parameters required by the above-mentionated

block are configurated. There are two sections in this

block: SMS and E-MAIL. In SMS Section the port

is configurated. It contains the modem GSM/GPRS

the PIN, the SMS Server phone and the alarms to

detect besides text message and the phone where it

will be sent.

The SMTP server (address and port), the sender

address, alarms to detect together with the content

and message addressee are configurated in E-MAIL

Section.

In Protocol Block the available protocols, in this

case OPC-DA, are added together with the adress

and port of OPC-DA server.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

222

In Users Block passwords, usernames and access

permission to the different parts of the program are

configurated.

4.2 Supervision Module

The necessary requirements to access SCADA Web

application are Internet connection and a computer.

After previously stated requirements are fulfilled

it is necessary to open a web browser window and to

connect to the server where the SCADA Web

application is installed. A similar window is showed

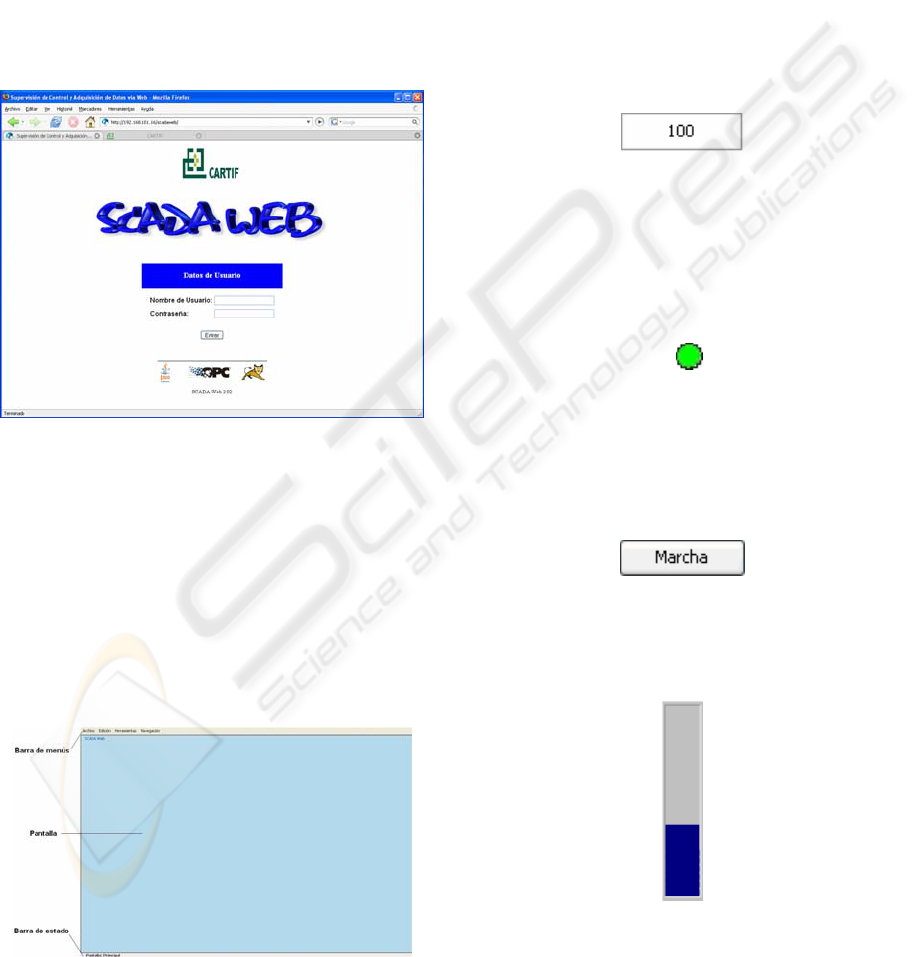

in Figure 2.

Figure 2: Initial Window of SCADA Web.

In this window it is neccesary to authenticate in

order to access to the application. After a correct

authentication, it is possible to access the

applications: “Builder” and “Viewfinder”.

The “Builder Application” is going to allow the

creation of a series of windows with components

thanks to a high level graphic interface with the user.

Linking ones with the others it is possible to

build a SCADA system of a specific installation.

In the figure 3 an image of “Builder Application

is showed”.

Figure 3: SCADA Web Application: “Constructor”.

The application allows to add windows so that a

SCADA system can be built with so many windows

as desired. Each window can be associated to a

wallpaper.

Hereafter the available components of the

application will be explained. Every component has

a properties dialogue box associated that allows to

realize its configuration.

Some of the components that can be added

(Besides of labels, rectangles and image

components) are:

Text Field displays analog and digital

variables.

Figure 4: Text Field Component.

LED can be associated with one or more digital

variables. This element makes it possible, by

means of colors, to show the state of the

variables. A typical example is failure-non

failure state monitoring and on/off motor state

Figure 5: LED Component.

Button is used to control digital or analog

variables. When the button is pressed,

depressed or is pressed during a time period,

the variable changes of value.

Figure 6: Button Component.

Vertical Bar Graph simulates a level and it is

associated with analog and digital variables.

Figure 7: Vertical Bar Graph.

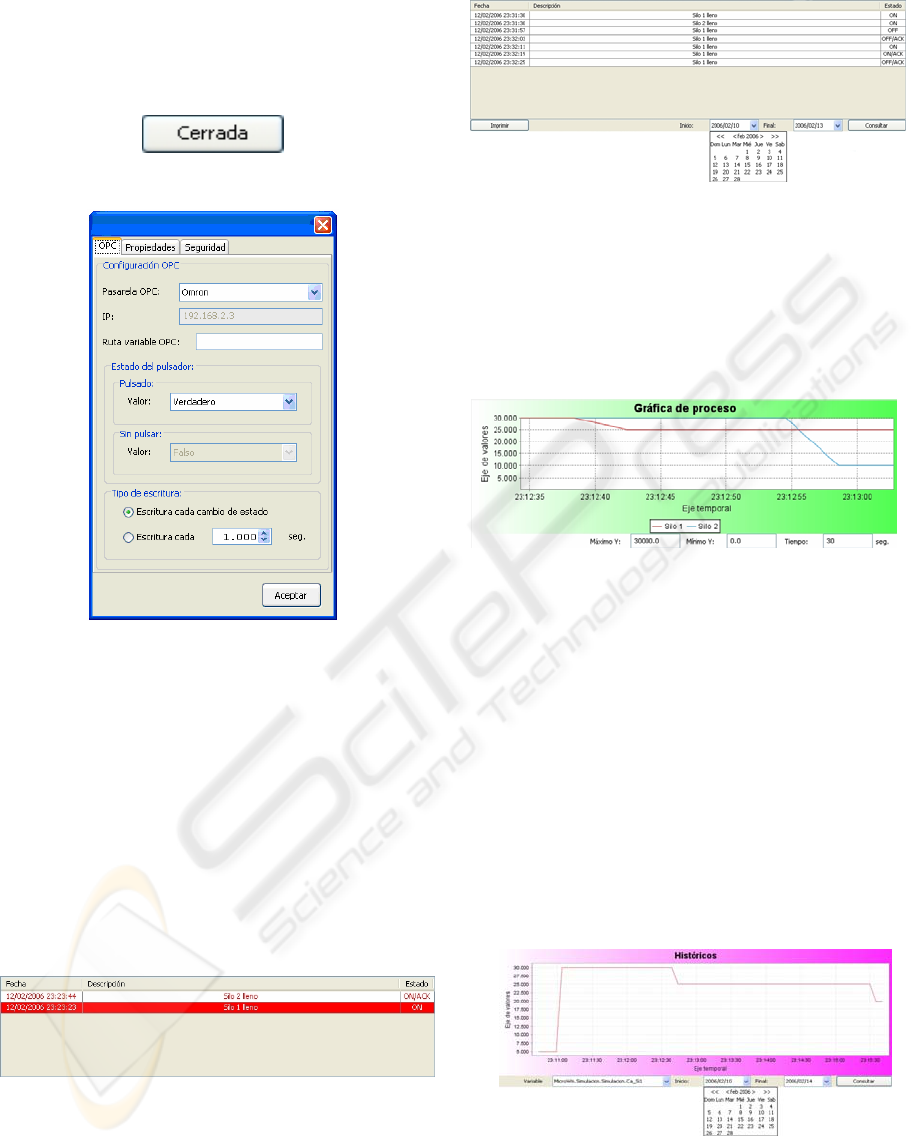

Toggle allows to supervise digital variables.

The monitoring of variables is carried out by

the state (pressed/depressed) in which the

SCADA WEB - Remote Supervision and Maintenance of Industrial Processes

223

toggle can be found. When the user presses,

the toggle the variable value is modified. In

Figure 9 the dialogue window to configure the

component is depicted.

Figure 8: Toggle Component.

Figure 9: Dialogue window of a toggle.

Alarms. In the SCADA Web Application it is

also allowed to configure alarms. It is possible the

monitoring and recognition of alarms. Alarms are

administered in the server. Because of this, the

consistency of all alarms by users can be saved. In

this way we can supervise remotly and

simultaneously the process.

Moreover, in order to avoid lacking firmness in

relation to dates, every happened event is registered

according to server time. All these events are

registered in a database to a subsequent consultation.

In Figure 10 the alarms component is showed.

Figure 10: Alarms Component.

Alarm Reports. Alarms are registered in a

database which can be looked up using the “Report

Component”. The generated reports can be printed.

Figure 11: Reports Component.

Trend Charts. Besides monitoring process

variables using controls explained before is possible

to obtain the trend of these variables by graphics

using their corresponding component. Their value

can be also scaled as it is showed in the Figure

12(JFree.org).

Figure 12: Graphics Component.

Historical Data In this last component the data

to register in a database are configurated. Later,

during the process supervision it will be possible to

do consultations of these data by graphics or

accessing directly to the database to obtain the real

value. An example is depicted in Figure 13

(JFree.org).

Besides, is necessary to configure users that

could use this SCADA system and the permission

level of each one. Due to this and to the fact that

each component has a permission level associated is

possible to control the access as well as to adapt the

SCADA system according to permission level of the

authenticated user.

Figure 13: Historical Component.

After having built the SCADA system of a

particular installation, then it will be possible to keep

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

224

in a local hard disk or in the server. In the last

instance it is possible to do a remote supervision of

the process if you have a computer and internet

connection.

“Viewfinder Application” makes it possible to

carry out the SCADA system created with the

“Builder Application”. In order to configurate these

configurations it is necessary to open them and after

a correct authentication the variable update

frequency will be fixed.

The configuration of update variable frequency

make it possible to adapt the refresh time to the

necessities of the person that wants to supervise the

system. A clear example happens in industry when

the system goes to be supervised simultaneously by

workers in the monitoring process and quality

control.

4.3 Maintenance Module

This module sends alarms of the industrial process

by SMS messages and e-mails. The complete

configuration is done by XML configuration file.

Thanks to this module the alarm notification time

generated is decreased and the costs in the industrial

process associated with alarms are reduced.

Furthermore, all alarm events and e-mail and SMS

messages associated are registrated in SMS and e-

mail databases.

Figure 14: An alarm e-mail.

5 CONCLUSIONS

A system SCADA for remote monitoring and

control of procceses is suggested. This SCADA Web

Application consists of a sub-application called

“Builder” that allows to make SCADA systems for

an industrial plant and a sub-application

“Viewfinder” whose function is supervise an

industrial process based on SCADA systems built by

the “Builder”.

The process variables of an industrial plant

controlled by different PLC´s brands can be

remotely supervised by this application. It is only

necessary to have a computer and Internet

connection. The SCADA system can also represent

by graphics the current evolution of process

variables and the configuration of alarms to warn

when a failure takes place. Besides, these alarms are

registered and can be recognized by user.

There is a possibility of printing and the

monitoring reports by SCADA system of industrial

plant.

The SCADA system allows to create historical

data in order to a later consulting in a visual way.

In the SCADA permission levels to adapt the

posibilites of supervision tasks to worker

permission level who supervises the installation are

configurated.

Finally, it shoud be remarked that thanks to use

an object orientation programming language and an

organization of application in components it is

possible easily add new elements in this application.

ACKNOWLEDGEMENTS

This work was supported in part by “Programa de

Fomento de la Investigación Técnica para los

Centros Tecnológicos”, (PROFIT grant FIT 330220-

2005-138 ) from the Spanish Education and Culture

Ministry.

REFERENCES

International Engineering Consortium. Global System for

Mobile Communication, <http://www.iec.org/online/tu

torials/gsm/> (last accessed on January 10, 2007)

Janeiro, J. R., 2006. Supervisión remota de procesos

industriales controlados por Autómatas Programables,

University of Valladolid. Spain, 1

nd

edition.

JFree.org. JFreeChart, <

http://www.jfree.org/jfrechart/>

(last accessed on January 10, 2007)

OPC Foundation. Specifications,http://ww.opcfoundati

on.org (last accessed on January 10, 2007)

OPC Programmers' Connection. OLE for Process Control,

http://ethernet.industrial-networking.com/ieb/article

display.asp?id=21 (last accessed on January 10, 2007)

RXTX. Serial and parallel I/O libraries supporting Sun's

CommAPI, <http://ww.rxtx.org> (last accessed on

January 10, 2007)

Sun Microsystems. Java Enterprise Edition, <http://java

.sun.com/javaee/> (last accessed on January 10, 2007)

The Apache Software Foundation. Apache Tomcat,

<http://tomcat.apache.org> (last accessed on January

10, 2007)

GeneraLynx. Remote supervision and control by WAP,

<

www.euroines.com/down/DemoDoc/WapScada%20

DD.pdf> (last accessed on January 10, 2007)

SCADA WEB - Remote Supervision and Maintenance of Industrial Processes

225