FORWARD KINEMATICS AND GEOMETRIC CONTROL OF A

MEDICAL ROBOT

Application to Dental Implantation

Richard Chaumont, Eric Vasselin and Dimitri Lefebvre

GREAH of LE HAVRE University, 25 rue Philippe LEBON. 76058 LE HAVRE Cede, France

Keywords: Surgical robotics, geometric modelling, inverse geometric modelling, dynamic modelling, non linear

system, identification.

Abstract: Recently, robotics has found a new field of research in surgery in which it is used as an assistant of the

surgeon in order to promote less traumatic surgery and minimal incision of soft tissue. In accordance with

the requirements of dental surgeons, we offer a robotic system dedicated to dental implants. A dental

implant is a mechanical device fixed into the patient’s jaw. It is used to replace a single tooth or a set of

missing teeth. Fitting the implant is a difficult operation that requires great accuracy. This work concerns

the prototype of a medical robot. Forward and inverse kinematics as dynamics are considered in order to

drive a control algorithm which is as accurate and safe as possible.

1 INTRODUCTION

Computer-assisted dental implantology is a

multidisciplinary and complex topic that includes

medical imagery, robotics and computer vision

(Langlotz, & al, 2000 ; Nikou & al, 2000). The

fitting of a dental implant is currently the only

technique suitable to permanently restore the teeth.

For this purpose, specific surgery has been recently

developed. Such operations require great accuracy.

Moreover, the spread of this type of surgery justifies

the extension and use of new techniques (Taylor,

1994). This research and development work focuses

on the medical robotics applied to dental

implantology. The main contributions of this article

are to discuss the forward kinematics and kinematics

uncertainties, and also to provide a geometric

control for the orientation of the drill.

2 MEDICAL ROBOTICS

For the last twenty years, new technologies have

been used to improve surgical operations so that

medical research and engineering improvements are

closely linked today. On one hand, data processing,

computer vision and medical imaging are used in an

intensive way in operation rooms. On the other

hand, the three principles of robotics-perception,

reasoning and action - have been adapted for

medical and surgery issues (Lavallee & al, 1995).

The main goal is to bring together the fundamental

principles of robotics and computer vision in order

to assist the surgeon in daily therapeutic operations.

The aims of medical robotics are to provide less

traumatic investigation systems, to provide

simulation tools, and, finally, to provide tools that

are easier and more flexible to use.

The aim of dental implantology is to use bones

and implants in order to provide prosthetic support.

The main advantage in comparison with a

conventional prosthesis is that dental implantology

doesn't mutilate healthy teeth. At the time tooth

extraction is completed, the fitting of a dental

implant allows the consolidation of the prostheses.

The main difficulty is to place the implants

correctly. That is the reason why conventional

prosthesis is still prefered to dental implantology in

many cases.

Dental implants guarantee the patient better

comfort but can also reduce overall cost owing to

their longevity and lack of inherent complications in

comparison with classic prostheses. For difficult

cases (completely toothless patients, weak density

bones, multiple implants, etc), dental surgeons are

confronted with a complex operation. Over the

years, the main difficulty concerned the integration

of the bone-implant.

This problem has been solved by technical

improvements and surgical advances (equipment,

implant shapes, surgical protocol, etc). According to

110

Chaumont R., Vasselin E. and Lefebvre D. (2007).

FORWARD KINEMATICS AND GEOMETRIC CONTROL OF A MEDICAL ROBOT - Application to Dental Implantation.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 110-115

DOI: 10.5220/0001652501100115

Copyright

c

SciTePress

the opinion of many clinicians, the difficulty is

henceforth to improve fitting techniques. The

position and orientation of implants must take into

account biomechanical and anatomical constraints

(Dutreuil, 2001) involving three main criteria:

mastication, phonetics and aesthetics. In particular,

the problems to be solved are :

• How to adjust the implant position in the

correct axis.

• How to optimize the relative position of

two adjacent implants.

• How to optimize the implant position

according to the bone density.

• How to conduct minimal incision of soft

tissue.

Our answer to these questions is image guided

surgery (Etienne & al, 2000). This solution uses an

optical navigation system with absolute positioning

in order to obtain position and orientation of the

surgeon's tool in real time with respect to the

patient’s movements. The operation is planned on

the basis of scanner data or x-ray images for simple

clinical cases.

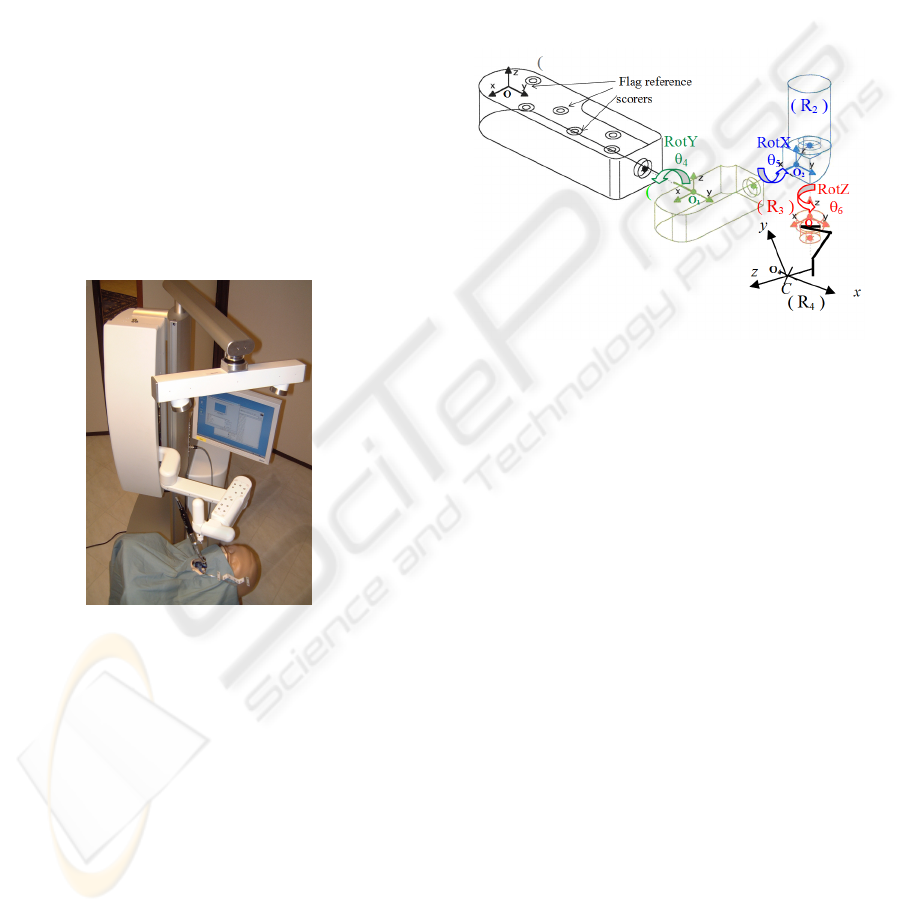

Figure 1: Navigation system.

The technique consists in initializing the

superimposing of patient data and data derived form

a set of specific points attached to the patient’s jaw

(Granger, 2003). The patient’s jaw is then analyzed

in real time by the navigation system. The Dental

View navigation machine guides the surgeon via the

image during the operative phase.

However, clinical tests show that supplementary

assistance is necessary to help the surgeon during

the drilling phase in order to fulfil precision

requirements. For this purpose, we developed a

surgical robot which controls orientation during the

drilling phase.

Our robot is a semi-active mechanical device. It

has a passive arm and a motorized wrist with three

degrees of freedom (dof) that are not convergent (i.e.

not a spherical wrist). The basis is passive, that is to

say it is not motorized and can be manipulated by

the surgeon like an instrument. The aim of the

controller is to guide the surgeon so that it will

respect the scheduled orientation.

3 FORWARD KINEMATICS

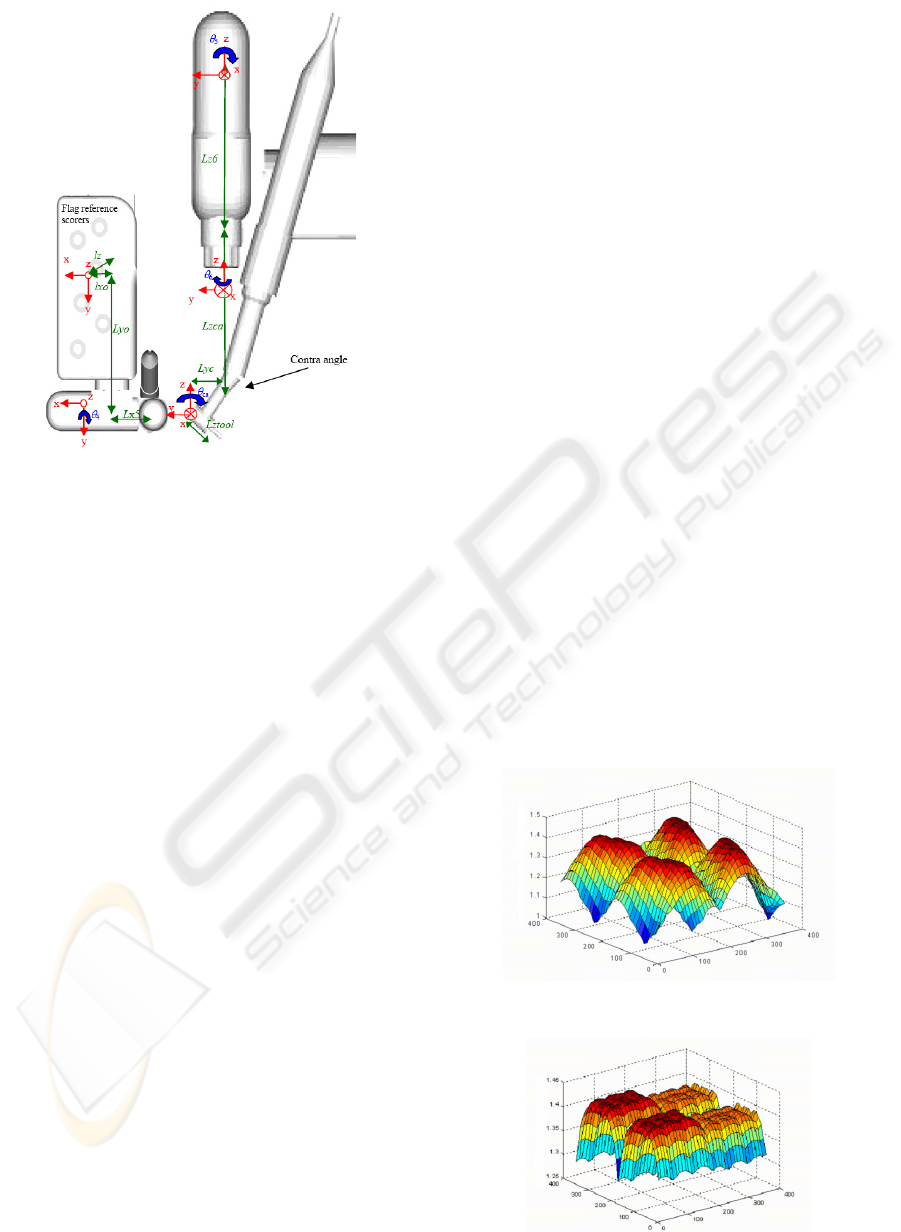

Drill orientation is characterized by 3 dof RotY,

RotX and RotZ and depends also on contra angle ca

(Fig. 3). The structure is represented in Fig.2.

Figure 2: Robot axis.

3.1 Notations

We use homogeneous transformations to describe

position and orientation from one link to another.

Let us consider the matrix M :

R

T

M

PQ

⎡

⎤

=

⎢

⎥

⎣

⎦

(1)

with P = [0 0 0], Q = [1] is a homothetic coefficient

equal to 1 (orthogonal transformation); R is a

orthogonal rotation matrix; and T is a translation

matrix.

For simplicity, calculations are not given in

detail. Notations will be represented above Fig.3.

Lxo, Lyo, Lzo : distance x, y, z between computer

vision coordinate frame and 4

th

joint coordinate

frame.

Lx5, Lz6 : distance x, z between 4

th

joint and 5

th

joint.

Lyca, Lzca : distance y, z between 5

th

joint and

effector.

Lztool : drill length.

θ

4

, θ

5

, θ

6

: wrist joint variables.

Ca: contra angle.

ε

i

: orthogonal uncertainty between joints.

l

i

: length uncertainty between links.

FORWARD KINEMATICS AND GEOMETRIC CONTROL OF A MEDICAL ROBOT - Application to Dental

Implantation

111

Figure 3: Robot parameters and axes.

3.2 Kinematic Uncertainties

First, we are going to determine the effector position

in the ideal case, without considering uncertainties

related to length and orthogonality links. We use

homogeneous transformations to change the

coordinate frame attached to a joint to the coordinate

frame attached to the next one. We obtain 6 matrices

that change the coordinate frames according to (2) :

100

010

1

001

000 1

Lxo

Lyo

A

Lzo

⎛⎞

⎜⎟

⎜⎟

=

⎜⎟

⎜⎟

⎝⎠

cos 0 sin 0

44

0100

2

sin 0 cos 0

44

0001

A

θθ

θθ

⎛⎞

⎜⎟

⎜⎟

=

⎜⎟

−

⎜⎟

⎝⎠

10 0 5

0cos sin 0

55

3

0sin cos 0

55

00 0 1

Lx

A

θθ

θθ

⎛

⎞

⎜

⎟

−

⎜

⎟

=

⎜

⎟

⎜

⎟

⎝

⎠

cos si n 0 0

66

sin cos 0 0

66

4

0016

0001

A

Lz

θθ

θθ

−

⎛

⎞

⎜

⎟

⎜

⎟

=

⎜

⎟

⎜

⎟

⎝

⎠

10 0 0

0 c os( ) si n( ) 0

5

0sin() cos() 0

00 0 1

ca ca

A

ca ca

⎛

⎞

⎜

⎟

−

⎜

⎟

=

⎜

⎟

⎜

⎟

⎝

⎠

100 0

010

6

001

000 1

Lyca

A

Lzca

⎛⎞

⎜⎟

⎜⎟

=

⎜⎟

⎜⎟

⎝⎠

(2)

Ideal position in flag coordinate frame results

from the preceding matrices :

0 123456 4

() ()

ideal

VRAAAAAAVR=××××××

(3)

with V(R

4

) = [0 0 1 0]

T

to get effector orientation for

the “z” axis and V(R

4

) = [0 0 0 1]

T

to get effector

position.

⎟

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎜

⎝

⎛

±

±

±

=

1000

100

010

001

'

1

zo

yo

xo

lLzo

lLyo

lLxo

A

10 0 0cos 0sin0cos sin 00

44 22

0 cos sin 0 0 1 0 0 sin cos 0 0

11 22

'

2

0sin cos 0 sin 0cos 0 0 0 10

11 4 4

00 0 1 0001 0 0 01

A

θθ εε

εε εε

εε θ θ

±−±

⎛⎞⎛⎞⎛ ⎞

⎜⎟⎜⎟⎜ ⎟

±−± ± ±

⎜⎟⎜⎟⎜ ⎟

=××

⎜⎟⎜⎟⎜ ⎟

±± −

⎜⎟⎜⎟⎜ ⎟

⎝⎠⎝⎠⎝ ⎠

1 0 0 5 cos 0 sin 0 cos sin 0 0

53 3 44

0 cos sin 0 0 1 0 0 sin cos 0 0

55 4 4

'

3

0 sin cos 0 sin 0 cos 0 0 0 1 0

55 3 3

00 0 1 0 0 0 1 0 0 01

Lx l

x

A

εε εε

θθ ε ε

θθ ε ε

±± ± ±−±

⎛⎞⎛⎞⎛⎞

⎜⎟⎜⎟⎜⎟

−±±

⎜⎟⎜⎟⎜⎟

=××

⎜⎟⎜⎟⎜⎟

−± ±

⎜⎟⎜⎟⎜⎟

⎝⎠⎝⎠⎝⎠

10 0 0cos 0sin 0cos sin0 0

6666

0cos sin 0 0100sincos00

55 66

'

4

0 sin cos 0 sin 0 cos 0 0 0 1 6

55 6 6 6

00 0 1 0 001 0 00 1

A

Lz l

z

εεθθ

εε θθ

εε ε ε

±± −

⎛⎞⎛⎞⎛ ⎞

⎜⎟⎜⎟⎜ ⎟

±−±

⎜⎟⎜⎟⎜ ⎟

=××

⎜⎟⎜⎟⎜ ⎟

±± −± ± ±

⎜⎟⎜⎟⎜ ⎟

⎝⎠⎝⎠⎝ ⎠

100 0

010

'

5

001

000 1

Lyca l

yca

A

Lzca l

z

ca

⎛⎞

⎜⎟

±

⎜⎟

=

⎜⎟

±

⎜⎟

⎜⎟

⎝⎠

1 0 0 0 cos 0 sin 0 cos sin 0 0

55 66

0 cos( ) sin( ) 0 0 1 0 0 sin cos 0 0

'

66

6

0sin() cos() 0 sin 0cos 0 0 0 10

55

00 01 0001 0 001

ca ca

A

ca ca

εε εε

εε

εε

⎛⎞⎛⎞⎛⎞

±± ±−±

⎜⎟⎜⎟⎜⎟

−±±

⎜⎟⎜⎟⎜⎟

=××

⎜⎟⎜⎟⎜⎟

−± ±

⎜⎟⎜⎟⎜⎟

⎜⎟⎜⎟⎜⎟

⎝⎠⎝⎠⎝⎠

(4)

We will model actual position and orientation of

the effector by considering uncertainties relating to

link length (maximum tolerance of 0.1 mm) and also

of frame orthogonal uncertainties (maximum

tolerance 0.1 degree). Because of digital encoder

resolution (200 000 points per revolution) and of

gear reduction encoders uncertainties are negligible.

Moreover, we only consider uncertainties that

concern the robot wrist (the arm is a passive

mechanical structure). For every dof two uncertainty

matrices are added according to the axes that are not

articulated. Equation (4) is obtained as a

consequence.

Actual effector position is given by (5):

0 123456 4

() ' ' ' ' ' ' ()

actual

VRAAAAAAVR

=

××××××

(5)

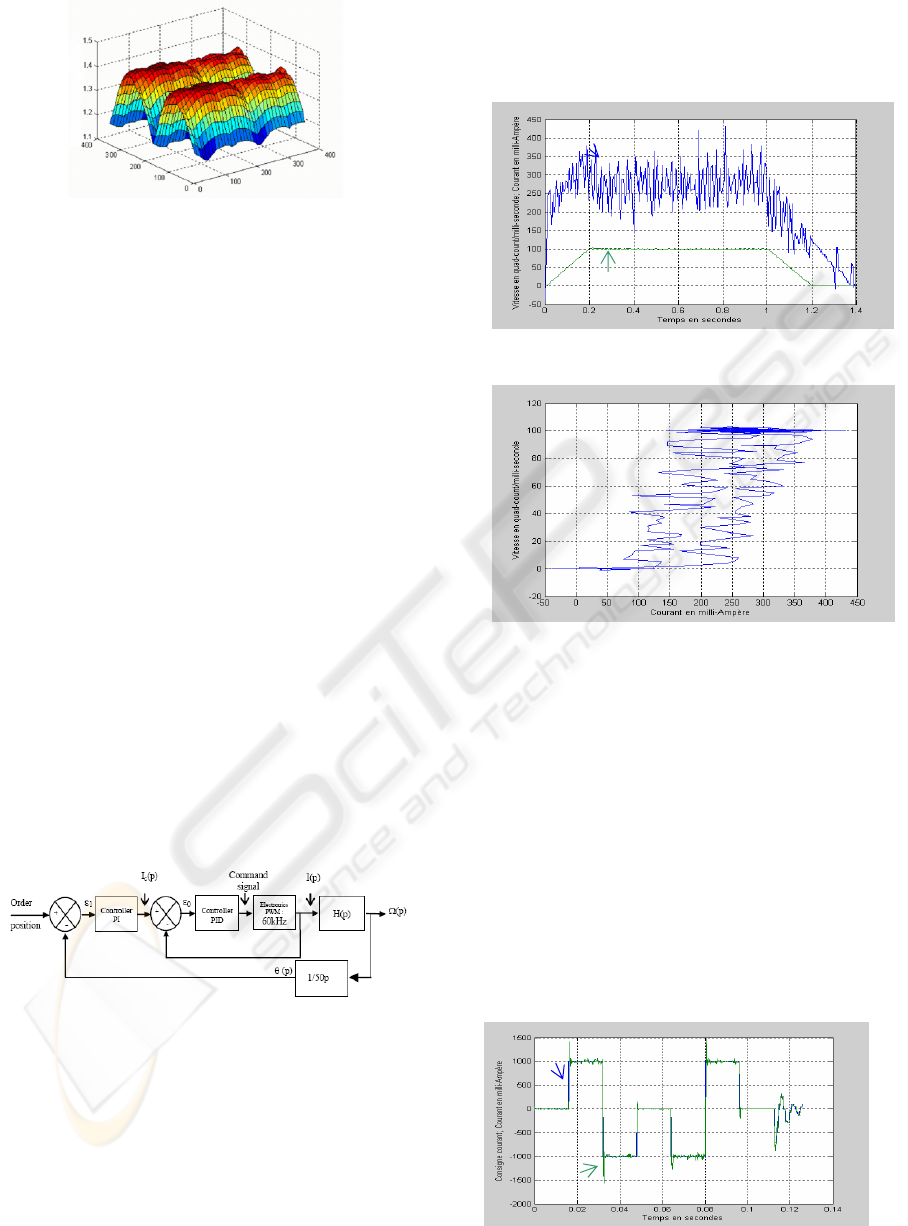

Figure 4: Magnitude of error function for θ

4

and θ

5

.

Figure 5: Magnitude of error function for θ

4

and θ

6

.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

112

Figure 6: Magnitude of error function for θ

5

and θ

6

.

From (4) and (5), we know the ideal position and

orientation of the wrist as well as its actual position

and orientation which take kinematic uncertainties

into account. Therefore, we can obtain the position

and orientation errors :

000

() () ()

actual ideal

E

RV RV R=−

(6)

Figs. 4 to 6 represent the maximal uncertainty

magnitude (millimeter) generated by mechanical and

assembly tolerances. One observes that :

• Uncertainty magnitude is always superior

to 1 millimeter,

• Uncertainty magnitude can reach 1.4

millimeters for particular link positions.

In order to fulfil precision requirements

uncertainties must be lower than 1 millimeter.

Therefore, it is necessary to calibrate the robot wrist.

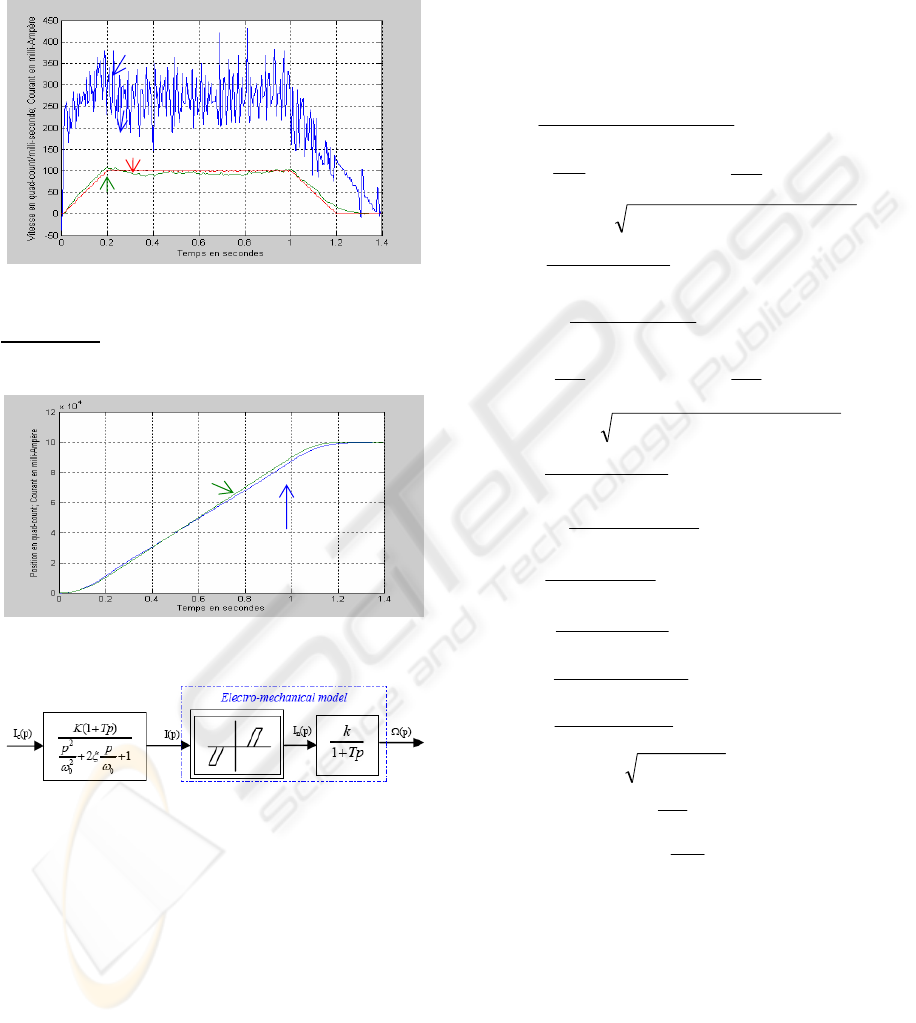

4 DYNAMICS

In this section we will propose a dynamic model for

the axis of the robot. The axis control architecture is

presented in Fig.7. Technical caracteristics of the

electromechanical and electronic devices can be

found in (Chaumont & al, 2006).

Figure 7: Axis control structure.

4.1 Identification of Electromechanical

Device

Closed loop identification for electromechanical

device is proposed in this section (Richalet, 1998).

System output is the velocity and system input is the

current. The robot axis has been placed so that

inertia moment can be considered as constant

whatever the orientation.

The time response (Fig. 8) presents a

dissymmetry between the current generating the

acceleration in comparison with the current

generating the deceleration.

Figure 8: Protocol signature.

Figure 9: Hysteresis system.

The process is non linear. Fig. 9 represents

input/output signature with a dead zone and a

histereses. The electromechanical transfer function

is represented in Fig.13.

4.2 Identification of Electronic Device

Electronic device input is the desired current and

output is the actual current. It represents the

electronic system part that is composed of the PWM

and its controller.

Identification is achieved in closed loop. A

survey of electronic control shows us that the

transfer function is a second order overshoot with a

stable zero.

Figure 10: Protocol signature.

Courant

(

mA

)

Speed (quarter-count/ms)

Consi

g

nes en courant

(

mA

)

Courant (mA)

FORWARD KINEMATICS AND GEOMETRIC CONTROL OF A MEDICAL ROBOT - Application to Dental

Implantation

113

4.3 Discussion

The model is validated with the same desired

current. Results obtained with the model and with

the system are compared according to velocity

kinetics (Fig. 11) and position (Fig. 12).

Figure 11: Velocity response.

Parameters

ω

0

= 730.97; ξ = 0.4258; K = 0.9955; k = 0.5969 ; T = 0.539

Histereses size: 75 mA Dead zone size: 115 mA.

Figure 12: Position response.

Figure 13: Axis module.

5 CONTROL DESIGN

Forward kinematics is given by equation (2). This

model shows how to determine the effector’s

position and orientation in terms of the joint

variables with a function “f”. Inverse kinematics is

concerned with the problem of finding the joint

variables in terms of effector’s position and

orientation. Our aim is to control the orientation of

the effector. The function “f” corresponds therefore

to V

ideal

(R

0

) expressed by equation (3) with V(R

4

) =

[0 0 1 0]

T

(uncertainties are not considered for

control design).

Matrix V

ideal

(R

0

) leads to equations (7) to (9) :

Vx

0

=sin(ca).cos(θ

4

).sin(θ

6

)–sin(ca).sin(θ

4

).

sin(θ

5

).cos(θ

6

)+sin(θ

4

).cos(θ

5

).cos(ca) (7)

Vy

0

= – cos(θ

5

).cos(θ

6

).sin(ca) – sin(θ

5

).cos(ca) (8)

Vz

0

= –sin(ca).sin(θ

4

).sin(θ

6

) –.cos(θ

4

).sin(θ

5

).

cos(θ

6

) + cos(θ

4

).cos(θ

5

).cos(ca) (9)

From equations (7), (8) and (9), expressions θ

4

,

θ

5

and θ

6

are determined.

)sin(

).sin().cos(

asin

0404

6

ca

VzVx

θ

θ

θ

−

=

,

66

θ

π

θ

−=

a

(10)

1

0

5

1

acos a

yV

+

⎟

⎠

⎞

⎜

⎝

⎛

=

ρ

θ

,

1

0

5 .2acos

1

a

yV

a +

⎟

⎠

⎞

⎜

⎝

⎛

−=

ρ

θ

(11)

with :

()

)(cos)sin().cos(

2

2

61

caca +=

θρ

π

θ

+

⎟

⎠

⎞

⎜

⎝

⎛

=

)sin().cos(

)cos(

atan

6

1

ca

ca

a

if -cos(θ

6

).sin(ca) < 0

or

⎟

⎠

⎞

⎜

⎝

⎛

=

)sin().cos(

)cos(

atan

6

1

ca

ca

a

θ

if -cos(θ

6

).sin(ca) > 0

2

2

0

5

acos a

yV

b +

⎟

⎠

⎞

⎜

⎝

⎛

=

ρ

θ

,

2

2

0

5 .2acos a

yV

c +

⎟

⎠

⎞

⎜

⎝

⎛

−=

ρ

θ

(12)

with :

()

)(cos)sin().cos(

2

2

62

caca

a

+=

θρ

π

θ

+

⎟

⎠

⎞

⎜

⎝

⎛

=

)sin().cos(

)cos(

atan

6

2

ca

ca

a

a

if -cos(θ

6a

).sin(ca) < 0

or

⎟

⎠

⎞

⎜

⎝

⎛

=

)sin().cos(

)cos(

atan

6

2

ca

ca

a

a

θ

if -cos(θ

6a

).sin(ca) >0

b

ca

+=

σ

θ

θ

)sin().sin(

acos

6

4

b

ca

aa .2

)sin().sin(

cos

6

4

+−=

σ

θ

θ

b

ca

a

a

b

+=

σ

θ

θ

)sin().sin(

cos

6

4

b

ca

a

a

c

.2

)sin().sin(

cos

6

4

+−=

σ

θ

θ

(13)

with :

2

0

2

0

VzVx +=

σ

(

)

π

−−=

0

0

atan

Vx

Vz

b

if Vx

0

< 0

(

)

0

0

atan

Vx

Vz

b −=

if Vx

0

> 0

Equations (10) to (13) show that angle θ

6

depends on

θ

4

, that angles θ

4

and θ

5

depend on θ

6

. A robot is

"resolvable" if a unique solution exists for equation

θ = f

-1

(x). Our study suggest that our medical

robot’s wrist is not resolvable.

5.1 Reachable Workspace

Analysis of the resulting equations shows that the

determination of the desired current according to a

given set of joint variables θ

4

, θ

5

and θ

6

is difficult.

Courant order (mA)

Process speed (quarter-count/ms)

Model speed (quarter-count/ms)

Position(quater-count)

Consigne position (quater-count)

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

114

Indeed, a given orientation has several solutions for

joint variables. Fig. 14 illustrates these points by

defining the reachable workspace. The method we

propose consists in considering θ

4

as a constant

parameter in order to work out joint variables θ

5

and

θ

6

according to θ

4

. The choice of θ

4

is motivated by

optimization method.

Figure 14: Reachable workspace.

5.2 Control Strategy

The controller must satisfy real time requirements.

The sampling frequency is 20 Hz. Moreover, several

applications such as artificial vision and data

processing take place simultaneously. The controller

inputs are :

• Data from artificial vision and image

superimposition,

• Desired drill orientation,

• Actual angular values returned by digital

encoders.

The algorithm determines the values of V

xo

, V

yo

,

and V

zo

that are vector components in the flag

reference scorers of the robot. It determines θ

5

and

θ

6

with respect to θ

4

and verifies that solutions are in

the reachable workspace. If solutions are outside the

reachable workspace, the algorithm increments θ

4

with 1° and recalculates θ

5

and θ

6

. Incrementation is

repeated until a solution is found in the reachable

workspace.

6 FURTHER WORKS

The protocol used for identification will be applied

in a generic way on the other axes in order to obtain

a dynamic model of the robot. As a consequence, we

will be able to simulate the robot’s dynamic

behaviour and to develop safe and efficient control

design. On the other hand, our work will concern the

following points :

• Accuracy, wrist calibration,

• Study of position / orientation decoupling,

• Trajectory planning, ergonomics.

This medical robot is an invasive and semi-active

system. Therefore, an exhaustive study on reliability

will also be necessary (Dombre, 2001) before

starting clinical simulations and experimentations.

ACKNOWLEDGEMENTS

Authors thank the Doctor DERYCKE, a dental

surgeon specialized in implantology, CHIEF

EXECUTIVE OFFICER of DENTAL VIEW.

REFERENCES

Langlotz F, Berlemann U, Ganz R, Nolte LP., 2000.

Computer-Assisted Periacetabular Osteotomy. Oper.

Techniques in Orthop, vol 10, N° 1, pp. 14-19

Nikou C, Di Gioia A, Blackwell M, Jaramaz B, Kanade

T., 2000. Augmented Reality Imaging Technology for

Orthopaedic Surgery. Oper. Techniques in Orthop, vol

10, N° 1, pp. 82-86.

Taylor R.,1994. An Image Directed Robotic System for

Precise Orthopaedic Surgery. IEEE Trans Robot, 10,

pp. 261-275.

Lavallee S, Sautot P, Traccaz J, P. Cinquin P, Merloz P.,

1995. Computer Assisted Spine Surgery : a technique

for accurate transpedicular screw fixation using CT

data and a 3D optical localizer. Journal of Image

Guided Surgery.

Dutreuil J., 2001. Modélisation 3D et robotique médicale

pour la chirurgie. Thèse, Ecole des Mines de Paris.

Etienne D, Stankoff A, Pennnec X, Granger S, Lacan A,

Derycke R., 2000. A new approach for dental implant

aided surgery. The 4

th

Congresso Panamericano de

Periodontologia, Santiago, Chili.

Granger S., 2003. Une approche statistique multi-échelle

au recalage rigide de surfaces : Application à

l’implantologie dentaire. Thèse, Ecole des Mines de

Paris.

Chaumont R, Vasselin E, Gorka M, Lefebvre D., 2005.

Robot médical pour l’implantologie dentaire :

identification d’un axe, JNRR05. Guidel, pp 304-305.

Richalet J., 1998. Pratique de l’identification. Ed. Hermes.

Dombre E., 2001. Intrinsically safe active robotic systems

for medical applications. 1st IARP/IEEE-RAS Joint

Workshop on Technical Challenge for Dependable

Robots in Human Environments, Seoul, Korea.

A

B

C

FORWARD KINEMATICS AND GEOMETRIC CONTROL OF A MEDICAL ROBOT - Application to Dental

Implantation

115