MECHANICAL PERFORMANCE OF A MANIPULATOR IN

VIRTUAL REALITY SYSTEMS

Jose San Martin

Department of Computers Architecture, Universidad Rey Juan Carlos, Madrid, Spain

Gracian Trivino

Department of Photonic Technology, Universidad Politecnica, Madrid, Spain

Keywords: Virtual reality, Haptic interface, Manipulability, Mechanical Performance.

Abstract: Frequently, the human interface of a virtual reality system includes a 3D manipulator. In order to optimize

the use of this device, the designer must take into account its mechanical characteristics. An obvious design

criterion consists of maximizing the coincidence between the application 3D space and the physical volume

where the manipulator provides its maximum performance. This paper explains in detail the analysis of

manipulability for the PHANToM OMNi haptic device including the study of the manipulability

distribution into its real workspace boundaries. As result of this study we will define a measure of the

quality of the device placement inside the virtual reality system platform. We apply this measure for

designing the mechanical configuration of a simulator for Minimally Invasive Arthroscopic Surgery.

1 INTRODUCTION

1.1 Object of Study

At the moment of evaluating the performance of a

mechanical manipulator, one of the elements to

consider is its capability for reaching and moving

around the different points belonging to the

workspace. Depending on the application

requirements and on the device features it will allow

the transmission of movement and force with major

or minor difficulty up to the end of the kinematics

chain. These characteristics are associated with the

concept of manipulability that this work describes

thoroughly in section 4.

We use the PHANToM OMNi of SensAble

Technologies, that is a well known haptic device

(SensAble Technologies, 2004), to describe and

demonstrate the contributions of this work.

1.2 Defining Workspaces

We introduce three definitions relative to the device

working area:

(a) Nominal Workspace (NW). This is the

volume in which the manufacturer guarantees the

specified force feedback and precision. For the

OMNi device it is a rectangular prism of dimensions

160 W x 120 H x 70 D mm.

(b) Real Workspace (RW). This is the volume

that we can reach with the End Effector. Note that

RW includes a marginal zone where performance of

the device can be unacceptable for some

applications.

(c) Effective Workspace (EW). It is the volume

of the application, so it is different in each system.

For instance it is the working space used by a

surgeon inside of a knee in a simulation of

Minimally Invasive Surgery. In this paper we will

show the relevancy of the shape and size of the EW

for the aim of obtaining a good device performance.

1.3 PHANTOM OMNi Device

Figure 1 identifies the main mechanical components

of the OMNi device: Element A (Head) turns around

Y axis (yaw), defining angle θ

1

. Element B (Crank)

turns around X axis (pitch), defining angle θ

2

.

Element C (Connecting Rod) turns around X’

relative axis (pitch), defining angle θ

3

. Elements D

235

San Martin J. and Trivino G. (2007).

MECHANICAL PERFORMANCE OF A MANIPULATOR IN VIRTUAL REALITY SYSTEMS.

In Proceedings of the Second International Conference on Computer Graphics Theory and Applications - AS/IE, pages 235-240

DOI: 10.5220/0002073302350240

Copyright

c

SciTePress

(Wrist), E (Fork) and F (Stylus) turn around

orthogonal axes located at the End Effector and are

the Gimbal angles.

Figure 1: Different Components of the OMNi device.

Coordinate System (CS) XYZ in the origin. Arms

l

1

=129mm and l

2

=133 mm.

As far as we are interested in study the

movement of the point where force feedback is

applied, we will not consider the three gimbal

elements (D, E and F).

Table 1: Relative values of θ

3

depending on θ

2

(value of

the angles in degrees).

θ

2

θ

3 minimum

θ

3 maximum

0 -20 65

15 -15 90

30 -9 105

40 0 110

50 10 112

60 20 113

80 40 114

90 50 114

105 60 110

For this device, values of θ

1

range from -50º to

55º and values of θ

2

range from 0º to 105º. Note that

there is kinematics cylindrical symmetry for θ

1

values. Due to the Omni mechanical design, range of

θ

3

is not constant and depends on the value of θ

2

and

on the angle inter-arms (l

1

-l

2

). Table 1 shows the

correspondence between these angles.

2 KINEMATICS

References (Cavusoglu, Feygin and Tendick, 2002)

and (Rodriguez and Basañez, 2005) describe a

similar kinematics analysis of a former PHANToM

haptic device version.

In this study the Coordinate System Origin

(CSO) is the center of the element A.

2.1 Forward Kinematics

It is the expression of the End Effector position in

Cartesian coordinates in function of the angles of the

joints θ

i

:

()

321

,,),,(

θ

θ

θ

Fzyx

=

From the geometrical relations between the

elements in figure 2, adding sequentially the

transformations T01, T02 and T03, we obtain the

transformation matrix T04 from CSO to the End

Effector position:

⎟

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎜

⎝

⎛

+−−

+−

+−

1000

)sin()cos()cos()cos()cos()cos()sin()cos()sin(

)sin()cos()sin()cos(0

)sin()sin()sin()cos()sin()cos()sin()sin()cos(

31221131311

213233

31212113311

θθθθθθθθθ

θθθθ

θθθθθθθθθ

ll

ll

ll

Where the sub-matrix R04, is the system rotation

matrix:

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎝

⎛

−−

−

=

)

3

cos()

1

cos()

3

sin()

1

cos()

1

sin(

)

3

sin()

3

cos(0

)

1

sin()

3

cos()

3

sin()

1

sin()

1

cos(

04

θθθθθ

θθ

θθθθθ

R

And the coordinates of the End Effector referred

to CSO are the last column of T04.

x=

13221

sin)sincos(

θθθ

ll +

y=

3221

cossin

θ

θ

ll

−

z=

13221

cos)sincos(

θ

θ

θ

ll

+

2.2 Inverse Kinematics

It consists of the expression for the angles θ

i

of each

joint in function of the End Effector position

Cartesian coordinates:

()

zyxI ,,),,(

321

=

θ

θ

θ

Almost directly and using the cosine theorem we

obtain:

θ

1

=

)arctan(

z

x

−

;

θ

2

=

)arctan(

H

y

+ )

2

arccos(

1

2

2

2

1

2

Ll

llL −+

θ

3

= )

sin

cos

arctan(

21

21

yl

lH

−

−

θ

θ

3 JACOBIAN CALCULATION

Given a function F: R

n

→ R

m

with m components y

1

to y

m

each of them with n independent variables x

1

to x

n

, the Jacobian consists of the matrix of partial

derivatives of y

i

respect of each one of the x

i

.

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

236

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎝

⎛

∂

∂

∂

∂

∂

∂

∂

∂

=

n

x

m

y

x

m

y

n

x

y

x

y

J

...

1

.....

1

...

1

1

The upper half of the Jacobian represents the

relation that exists between the linear velocities of

the End Effector with the angular velocity of the

joints:

V=Ju · dθ/dt

The lower half represents the relation between

the angular velocity of the End Effector with the

angular velocity of the joints:

ω = J

l

· dθ/dt

In the case of the OMNi, upper half of the J has

the dimensions (3xn) where n is the number of

degrees of freedom. For this device the Jacobian is:

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎝

⎛

−

−−

−

+

=

00)sin(

00)cos(

100

)sin(0

0)cos(0

00)sin()cos(

3

3

2321

321

3221

θ

θ

θθ

θθ

θθ

ll

l

ll

J

4 MANIPULABILITY

Manipulability is the skill in transmitting movement

and applying forces in arbitrary directions (Park and

Kim, 1998). We can also say that the manipulability

of a device indicates its ability to move freely in all

the directions in the workspace (Murray, Li and

Sastry, 1994). Another definition is that

manipulability is the efficiency with which a

manipulator transmits force and velocity to its End

Effector (Staffetti, Bruyninckx and De Schutter,

2002).

4.1 Calculation of Manipulability Map

The manipulability of a device was conceptually

defined by (Salisbury and Craig, 1982) and the first

formulation that allowed a mathematical simple

quantification was brought up by (Yoshikawa,

1985).

A widely used algebraic definition of

manipulability is the one by (Yoshikawa, 1990).

,)Ju'*(Judet =

μ

Where Ju is the upper part of the Jacobian and

Ju’ is its transposed one. Others authors propose

different formulations for the Manipulability. For

example (Cavusoglu, Feygin and Tendick, 2002)

(Tavakoli, Patel and Moallem, 2004) make use of:

μ = σ

min

(J

u

)/σ

max

(J

u

) (1)

Where σ

min

and σ

max

are the minimum and the

maximum of the singular values of J

u

.

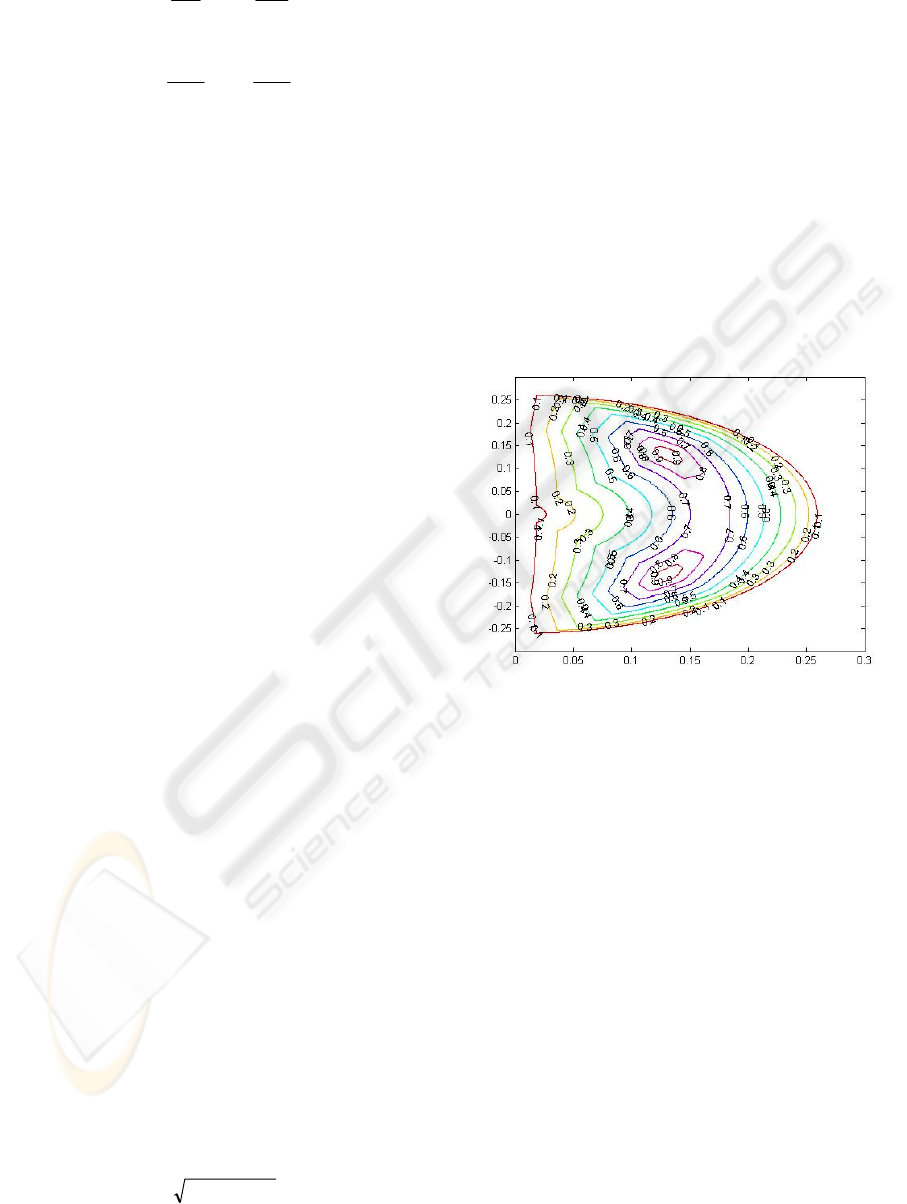

4.2 Map of Manipulability

Figure 2 shows the map of curves of iso-

manipulability in the plane X=0 (θ

1=

0) calculated by

(1). Because the Jacobian does not depend on θ

1

, the

manipulability is equal for any plane defined by a

value of θ

1

.

Figure 2: Iso-manipulability curves map for plane X=0.

Axis values in meters. Curves contain values of µ.

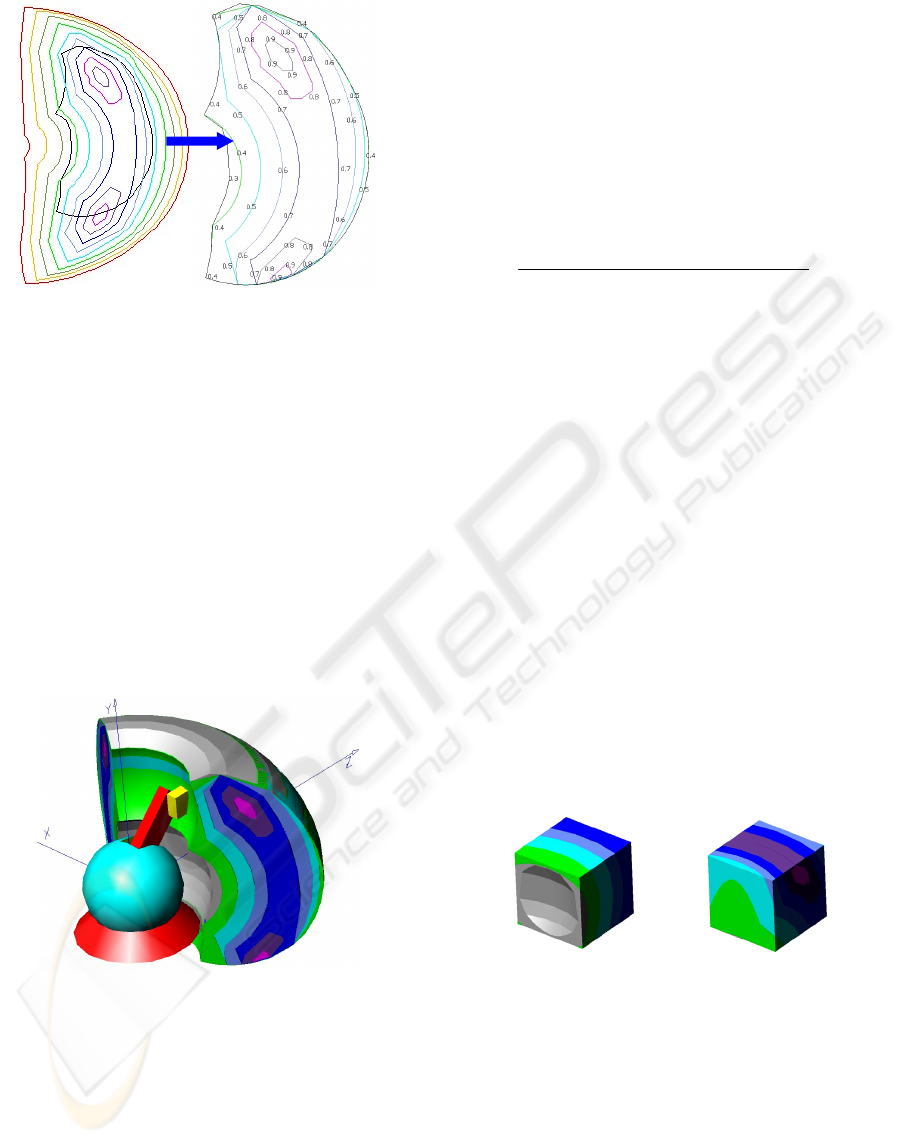

4.3 Real Workspace

According to the θ

1

, θ

2

and

θ

3

ranges in table 1 we

can describe the maximum area that End Effector

can reach in the plane YZ. The real workspace-RW

is defined by this curve. This evolving curve is

projected on the map of manipulability and so we

can extract the portion of the map that the End

Effector can really reach (fig. 3).

MECHANICAL PERFORMANCE OF A MANIPULATOR IN VIRTUAL REALITY SYSTEMS

237

Figure 3: Projection of the real workspace on the

manipulability map and Subspace of manipulability

defined for the real workspace.

Note that, in the Omni device, the best values of

manipulability are included in the real working area.

5 3D MAP OF MANIPULABILITY

Integrating the 2D surfaces of iso-manipulability we

can generate volumes containing points with equal

value of µ. Figure 4 shows the 3D Map of

Manipulability associated to the PHANToM OMNi

device. It will be useful to the designer of a new

virtual reality system to consider this volume as a

virtual part of the OMNi.

Figure 4: Scheme of the 3D Map of Manipulability for the

OMNi.

6 VOLUMETRIC AVERAGE

MANIPULABILITY

This section concerns with the study of how to

situate the OMNi in the system mechanical platform

to obtain its maximum performance.

The EW is a 3D volume that must be situated

inside the 3D map of Manipulability. The

intersection from both solids determines different

values of µ in EW indicated by different sub

volumes vi (different colors in figure 4). The total

volume V

T

is:

n

n

i

iT

vvvvV +++==

∑

...

21

We define Volumetric Average Manipulability

as:

V

) v·µ v·µ v·µ v· (µ

µ

T

nn332211

v

………+++

=

(2)

Where µ

i

is the Manipulability in each v

i

.

This measure is useful to do a quantitative

comparison between different possible mechanical

configurations of a system using manipulators.

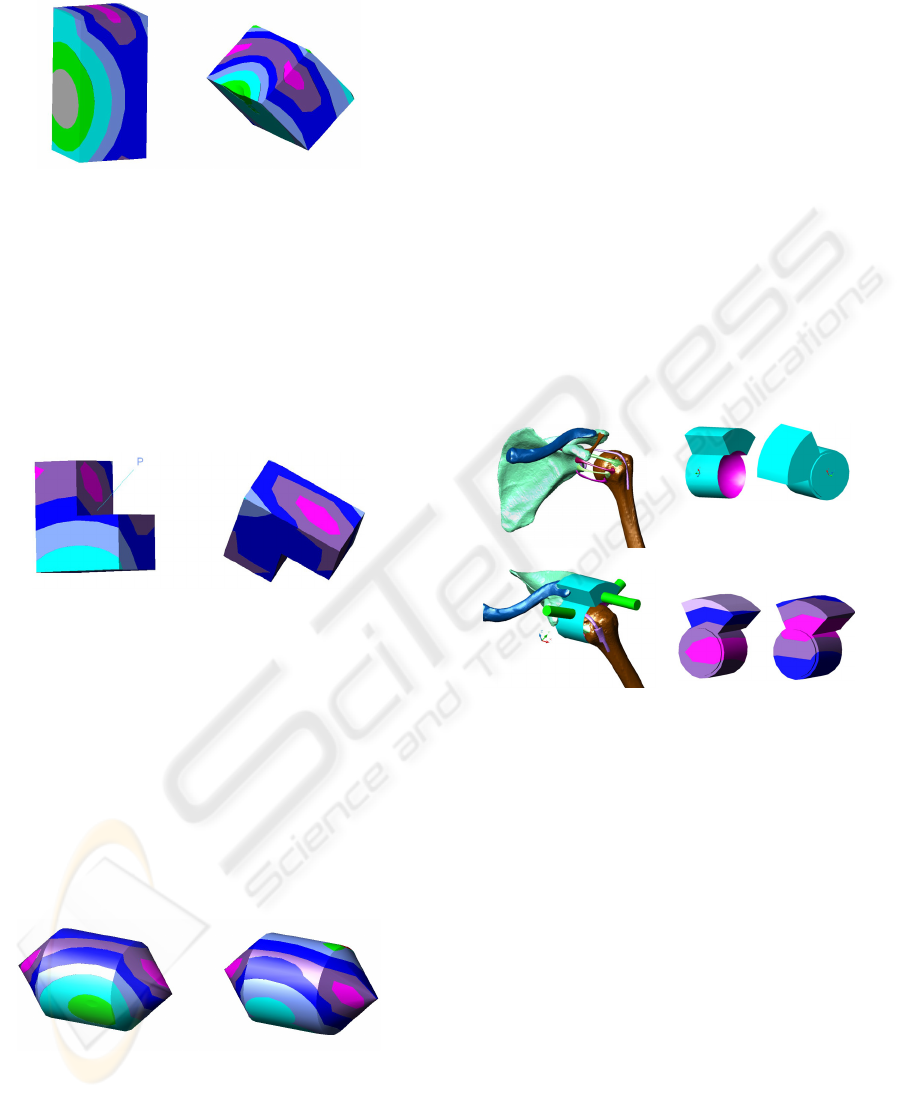

7 THEORETICAL EXAMPLES

We have designed four tests, each one with two

options for placing the Effective Workspace, in

order to verify the usability of the Volumetric

Average Manipulability µ

v

.

Test A. EW is a cube of L=100mm:

Case A1. We place the center of gravity (CG) at

150 mm from the origin along the axis Z. After

calculation, formula (2) produces: µ

v

=0.5411.

Case A2. We place it in the neighborhood of the

optimal manipulability values zone, CG at position

XYZ (-10, 94, 151) mm. After calculation it

produces: µ

v

= 0.7103 sensitively higher.

Figure 5 shows the intersections of the EW with

the solid of manipulability. Cases A1 and A2.

Figure 5: Intersection of the workspaces with the solid of

manipulability.Test A.

Test B. EW is a rectangular squared-base prism

of side L=100mm and height H=200mm:

Case B1. CG of the prism at (-10, 14, 151). The

Manipulability obtained is µ

v

=0.6422 (fig. 6).

Case B2. We situate it, lying down on a plane

parallel to the XZ, fitting in the ideal zone of

manipulability. First we translate GC of the prism at

(5, 92, 161) and a turning of 45 º with regard to an

axis parallel to the Z axis that crosses the CG. The

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

238

value obtained is µ

v

=0.7353 (fig. 6). Note that this

high value has been obtained by inclining the OMNi.

Figure 6: Intersection of the EW with the solid of

manipulability. Test B.

Test C. EW is an L-shaped solid of side

L=50mm + rectangular prism of square base of side

L=50mm and height H=100mm:

Here, not only it is need to align the EW with the

optimal zone of the manipulability map, but also to

modify the orientation. For the case C1 it has been

obtained a value of µ

v

=0.7730 (fig. 7). In the second

case C2 by means of two turning, we get a value of

µ

v

=0.8336 (fig. 11).

Figure 7: Intersection of the EW with the solid of

manipulability. Test C.

Test D. EW is a solid of revolution axis Y (D:

100 mm): cylinder (H: 90 mm) with a cone (H:

50mm) in each of the bases and a hollow in its

interior.

Case D1. Turn of -90º around axis Z. We move

the CG from CSO at position XYZ (21, 107, 148).

After calculation it produces: µ

v

=0.7618 (fig. 8).

Case D2. Turn of -90º around axis Z. We move

the CG from CSO at position XYZ (-14, 114, 163)

avoiding the hollow of the solid. After calculation it

produces: µ

v

=0.7829 (fig. 8).

Figure 8: Intersection of the EW with the solid of

manipulability. Test D.

This Test D simulates a more complex and not

homogeneous EW, similar to a cavity in a virtual

surgical simulation, being the hollow an unreachable

space, for example a bone, where we are not

interested in optimizing µ.

8 DESIGN OF AN APPLICATION

This section describes a real application of the ideas

developed above. It consists of the positioning of the

OMNi device when used as a component of a

simulator for training in Minimally Invasive

Arthroscopic Surgery (Bayona, Garcia, Mendoza

and Fernandez, 2006), (GMV, 2006). This study is

centered in a virtual model of the human left

shoulder.

Figure 9-1 shows an anatomical model of this

joint where the subacromial capsule has been

suppressed. In this case the EW has two spaces quite

differenced that we name EW-glenohumeral and

EW-subacromial.

1. Anatomical model

2. Two views of EW

3. Shoulder view plus

EW. Portals in green.

4. Results of study of µ

v

cases 1 and 2.

Figure 9: Study of µ

v

in a real implementation.

EW-glenohumeral is the domain of surgeries

such as acromioplasty and it has been modeled using

two cylinders and a spherical hollow. EW-

subacromial is the domain of surgeries such as

arthroscopic labrum fixation and it has been

modeled using a pipe sector. Nevertheless there are

operations, as the diagnostic arthroscopy, which

cover both spaces (Giacomo and Constantini, 2004).

Figure 9-2 shows two views of the whole EW.

Figure 9-3 shows this EW in its placement into

the anatomical model. Note that portals for surgical

instrumentation access (green colored in the figure)

are not included in the µ

v

study because that space

has not meaningful value. Also here, two cases have

been considered (fig. 9-4):

Case 1. EW situated matching the CG of EW-

glenohumeral with the maximum manipulability

zone; position XYZ (85, 118, 148). The aim of this

MECHANICAL PERFORMANCE OF A MANIPULATOR IN VIRTUAL REALITY SYSTEMS

239

approach is obtaining optimal manipulability values

in EW-glenohumeral. After calculation it produces:

µ

v

=0.8073 in the whole of EW. Analyzing them

separately, we obtain µ

v

=0.8873 for EW-

glenohumeral and µ

v

=0.7194 for EW-subacromial.

Case 2. CG of EW situated at maximum

manipulability zone, position XYZ (85, 118, 148).

The criterion is to obtain maximum average

manipulability values for all the EW. After

calculation it produces: µ

v

=0.8506 in the whole of

EW. Analyzing them separately, we obtain

µ

v

=0.8291 for EW-glenohumeral and µ

v

=0.8749 for

EW-subacromial.

9 CONCLUSIONS

A complete study about different workspaces to

distinguish in the environment of a haptic device has

been analyzed.

The need of establishing a criteria for helping the

mechanical design of a simulator of Minimally

Invasive Arthroscopic Surgery has lead us to

contribute in this field by creating a measure that we

have called Volumetric Average Manipulability (µ

v

).

A set of different configurations can be valued in

order to choose the best option. This new concept

will be able to help in the optimal design of a system

involving some haptic device.

The use of this measure has been demonstrated

in several cases of theoretical Effective Workspaces.

A study on the real case of a virtual human shoulder

joint involving the PHANToM OMNI haptic device

has been presented.

ACKNOWLEDGEMENTS

The authors are grateful to the Modeling and Virtual

Reality Group (GMRV) of the Rey Juan Carlos

University.

This work has been partially funded by the

Spanish Ministry of Education and Science (grant

TIC2003-08933-C02-01), Government of the

Community of Madrid (grant GR/SAL/0940/2004

and grant S-0505/DPI/0235).

REFERENCES

Bayona S., Garcia M., Mendoza C., Fernandez, J.M.,

Shoulder Arthroscopy Training System with Force

Feedback, pp. 71-76, International Conference on

Medical Information Visualisation-BioMedical

Visualisation (MedVis'06), 2006.

Cavusoglu, M. C., & Feygin, D. and Tendick F. A Critical

Study of the Mechanical and Electrical Properties of

the PHANToM Haptic Interface and Improvements for

High Performance Control. Teleoperators and Virtual

Environments, 11(6):555--568, 2002.

Di Giacomo, G. Costantini, A. Arthroscopic shoulder

surgery anatomy: Basic to advanced portal placement.

Operative Techniques in Sports Medicine, Volume

12, Issue 2, Pages 64-74 G, 2004.

GMV, Universidad Rey Juan Carlos, Universidad

Politecnica de Madrid, Hospital Severo Ochoa de

Leganes, Virtual Reality Arthroscopy Trainer.

Technological Innovation for improving minimally

invasive surgery skills, 2006.

http://www.insightmist.com/index_en.htm

Murray, R. M., Li, Z., & Sastry, S. S. (1994). A

mathematical introduction to robotic manipulation.

CRC Press, Inc. Boca Raton, FL.

Park, F., Kim, J., Manipulability of Closed Kinematic

Chains, in J. Mech. Des., Vol. 120, Dec. 1998.

Rodriguez, A., Basañez, L. (2005). Modelo cinematico de

la interface háptica PHANToM Premium 1.5/6DOF.

(Tech. Rep.). Universidad Politecnica de Cataluña.

Instituto de Organización y Control de Sistemas

Industriales.

Salisbury, J.K., and Craig, J. J., Articulated hands: force

control and kinematic issues, Int. J. Robotics

Research, Vol. 1 no. 1, 1982, pp. 4-17.

SensAble Technologies. PHANToM OMNi User’s Guide.

November 2004.

Staffetti, E., Bruyninckx, H. & De Schutter, J. 2002. On

the Invariance of Manipulability Indices. J. Lenarcic

and F. Thomas (eds.), Advances in Robot Kinematics,

Kluwer Academic Publishers: 57-66.

Tavakoli, M., Patel, R.V. and Moallem M. (2004) Design

Issues in a Haptics-Based Master-Slave System for

Minimally Invasive Surgery. In proceedings of the

2004 IEEE International Conference on Robotics and

Automation (ICRA '04), pp. 371-376, New Orleans,

LA.

Yoshikawa, T.; Manipulability and redundancy control of

robotic mechanisms, Robotics and Automation.

Proceedings of IEEE International Conference on,

Volume 2, Mar 1985 Page(s):1004 – 1009.

Yoshikawa, T.; Foundations of Robotics: Analysis and

Control. Cambridge, MA: MIT Press, 1990.

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

240