DETECTING FEATURES FROM SLICED POINT CLOUDS

Ioannis Kyriazis, Ioannis Fudos and Leonidas Palios

Department of Computer Science, University of Ioannina, Ioannina, Greece

Keywords:

Reverse Engineering, Feature-Based CAD Models, Cross-Sections, Point Cloud, Convex Hull, Voronoi Dia-

gram.

Abstract:

We present a new method for extracting the feature primitives of a 3D object directly from the point cloud of

its surface scan. The objective is to identify a subset of points that provides the same information about the

structure and the topology of the object geometry as the point cloud itself. The entire process is carried out

with the least human intervention possible. The only information we receive as input is the point cloud of the

3D scan of the object.

First, the point cloud is sliced in cross sections. Each cross section consists of a 2D point cloud.

A collection of curve patches is derived for each slice, describing the cross section, and providing a feature-

based CAD model appropriate for further editing. For the extraction of the feature points and the interpolating

curve patches we use properties of the convex hull and the voronoi diagram of the point cloud.

1 INTRODUCTION

Many applications in manufacturing, medicine, geog-

raphy, design, etc. require the scanning of 3D ob-

jects to incorporate them into a computer-based or

computer-aided processing system, with a technique

known as Reverse Engineering. Advanced measur-

ing techniques have been developed to produce a large

amount of points lying on the object surface, i.e. the

point cloud of the object.

We present a method for dividing the point cloud

into several slices, which are processed separately and

provide local information about the object. This infor-

mation is used to extract local features of the object.

Such features may include holes or extrusions on the

object, symmetrical or similar parts, and also scaled,

flipped and generally transformed versions of already

known features.

Several methods have been developed that extract

features from a point cloud. (Jeong et al., 2002) use

an automated procedure to fit a hand-designed generic

control mesh to a point cloud of a human head scan.

A hierarchical structure of displaced subdivision sur-

faces is constructed, which approximates the input

geometry with increasing precision, up to the sam-

pling resolution of the input data. (Au and Yuenb,

1999) use a method that fits a generic feature model

of a human torso to a point cloud of a human torso

scan. The features are recognized within the point

cloud by comparison with the generic feature model.

This is achieved by optimizing the distance between

the point cloud and the feature surface, subject to con-

tinuity requirements. (Amenta et al., 1998) proposed

the crust algorithm, which combines the point cloud

with the vertices of the Voronoi diagram, and com-

putes the Delaunay tetrahedralization of the combined

point set. The triangles where all vertices are sample

points (not voronoi vertices) are considered to form

the object surface. (Attene and Spagnuolo, 2000) use

some properties of geometric graphs. The EMST is

used as a constraint during the sculpturing of the De-

launay tetrahedronization of the data set, and in addi-

tion another constraint is used, the so-called Extended

Gabriel Hypergraph (EGH). These methods are fast

and general but do not provide models appropriate for

CAD use.

Our method uses a subset of the point cloud each

time, which is then used to extract a feature locally.

188

Kyriazis I., Fudos I. and Palios L. (2007).

DETECTING FEATURES FROM SLICED POINT CLOUDS.

In Proceedings of the Second International Conference on Computer Graphics Theory and Applications - GM/R, pages 188-192

DOI: 10.5220/0002082701880192

Copyright

c

SciTePress

This is accomplished by dividing the point cloud into

several slices. These slices contain the same informa-

tion as the initial point cloud - the (x, y, z) coordinates

of the points - with the additional information that the

points of a slice are located near a planar surface that

intersects the object at a specific direction. The points

of each slice can be considered to be co-planar, and

so we can process each slice as a 2D set of points, in-

stead of a 3D object. This provides for more efficient

and accurate local feature extraction.

The local per slice feature representation is then

combined with information provided from several ad-

jacent slices, to reconstruct the global structure and

morphology of the object.

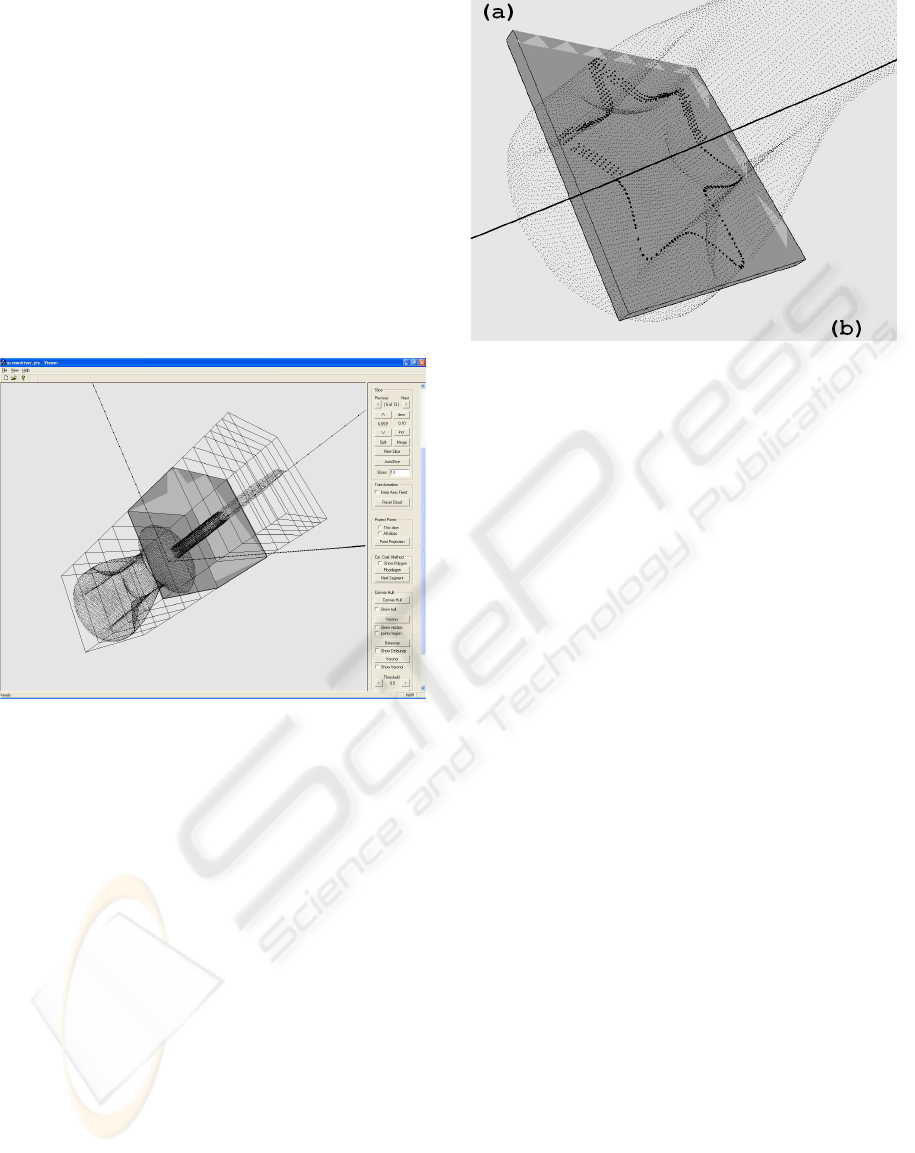

Figure 1: A point cloud can be sliced in any desired direc-

tion. Slice thickness is determined adaptively.

2 SLICING THE POINT CLOUD

A major issue of the point cloud segmentation is

the slicing direction. The direction along which we

choose to divide the object into slices may influence

the process of feature extraction and the resulting

model. To this end we can either align interactively

the object to the desired direction, or seek automati-

cally a transformation of the object that minimizes a

target function, e.g. PCA.

Another key issue is to determine the proper thick-

ness for a slice. The points of a very thick slice may

not provide useful information, as we might get many

features tangled together. To avoid this we can split

it into two new slices with reduced thickness. On the

other hand, the points of a very thin slice may be in-

adequate to describe a feature, or the points of two ad-

jacent slices may carry almost the same information,

so we can merge the two slices into one slice with in-

creased thickness. We could also determine the ideal

Figure 2: (a) A slice of the cloud is highlighted. (b) The

points of the slice are projected on a plane parallel to the

slice.

slice thickness adaptively, as described in (Wu et al.,

2004). The distance between two slices can also be

a parameter, but as we do not want to omit any in-

formation from points located between two slices, we

set each slice to start exactly where the previous slice

ends (and there is no empty space between adjacent

slices).

Once we have divided the point cloud into slices,

the points that belong to each slice are projected on

a plane that is vertical to the slicing direction, so we

can use 2D techniques for processing the points of the

slice. Figure 1 illustrates an example of a sliced point

cloud of a Screwdriver, and Figure 2 shows the points

of a slice, and the projected point cloud slice. Figure 1

also shows the interface of the prototype that we have

developed to test our method.

The next objective is to reduce the number of

points, since we can extract the desired information

from only a small point subset. These feature points

are identified with the method described in the next

section.

3 IDENTIFYING FEATURE

POINTS ON A SLICE

The initial point cloud consists of a very large number

of points, depending on the size and shape of the pro-

totype object, and also on the accuracy that was used

to scan the object. The large number of points makes

it difficult to process this raw information. Thus, we

need to reduce the number of points in the cloud while

retaining all the information provided by these points.

If the points of a slice formed a 2D shape that was

convex then we simply compute the convex hull of

DETECTING FEATURES FROM SLICED POINT CLOUDS

189

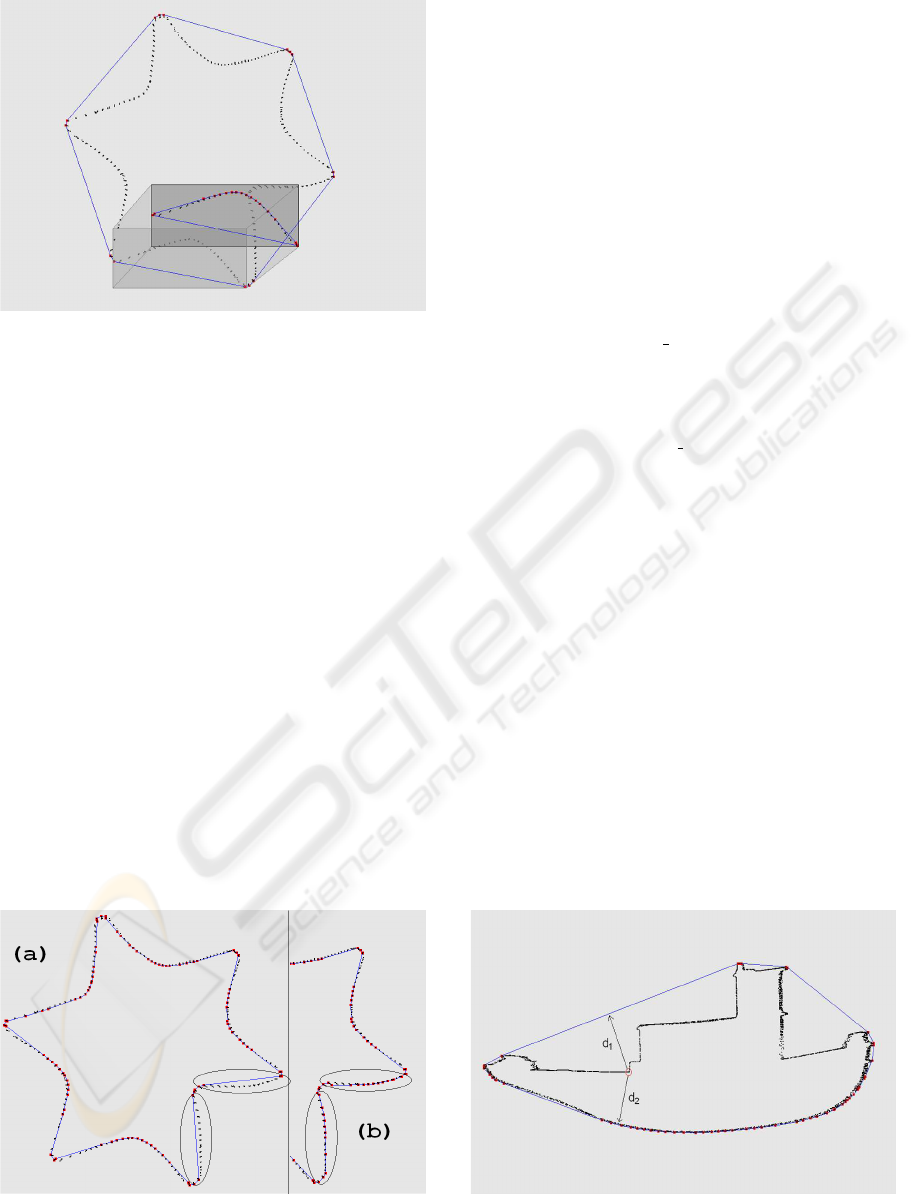

Figure 3: The points in the highlighted region are isolated

and the convex hull of these points is computed to identify

the next set of feature points for the curve.

the points to describe the shape with a polyline con-

sisting usually of much fewer vertices than the points

in the slice. But in general the shape of the points in a

slice is not convex, and thus to interpolate a curve to

these points we need more than just the convex hull of

the points. We always start by computing the convex

hull of the points, to identify some of the points that

will form the curve that best fits our point slice. Now

there are points that are located near the convex hull

(up to a threshold), while other points are still located

far from the convex hull. We partition the points in

regions, one for each line segment of the convex hull.

Some regions may consist exclusively of points near

the convex hull, and other regions consist of points

located far from it. We treat further these remote re-

gions by computing the convex hull of their points,

and then we repeat the same process as for the initial

object (this is illustrated in figure 3). By combining

the initial convex hull with the convex hull of each

region, we get a curve that interpolates the points of

Figure 4: (a) First step of the Convex Hull Method. There

are still some regions where the curve doesn’t fit the points

accurately. (b) Second Step of the Convex Hull Method.

The curve now describes the slice points more accurately.

the slice adequately in most regions. We repeat com-

puting the convex hull for the rest of the regions until

all regions consist of points that are located near the

curve (for a termination criterion see (Said, 2002)).

An example is illustrated in Figure 4.

The method, as applied to a specific slice, is sum-

marized as follows:

Input: a set

P

of points, Slice

i

Output: an ordered set

F

i

of feature points

step 1:

(P

(3D)

i

, L) = slice(i, P)

step 2:

P

i

= project(P

(3D)

i

, S)

step 3:

F

i

= qconvex(P

i

)

step 4: for each region

P

ij

of

F

i

if

avg dist(P

ij

, F

ij

) > e

F

ij

= qconvex(P

ij

) − F

ij

end if

end for

F

i

= F

i

∪ F

ij

if

changes made = true

repeat step 4

end if

step 5: return

F

i

where L is a plane parallel to the slice where we

project the 3D slice. The method described above

works fast and accurately in most cases, but there are

cases in which the curve interpolating the points of

the slice differs significantly from the object we try to

describe. There are two important issues concerning

the points of a slice that might affect the effectiveness

of the interpolating curve. One is the case when one

or more points are assigned to the wrong region of

the curve. One would expect that each point belongs

to the region of the curve which is closest to the point.

But there may be cases in which a point is closest to

one region, but belongs to another region, for exam-

ple the one that is located on the opposite side of the

closed curve (e.g. see Figure 5). To avoid having such

Figure 5: The points in the highlighted area are located

closer to a region other than the one they should be assigned

to (d

2

< d

1

). We use the information of their neighboring

points to assign them to the correct region.

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

190

Figure 6: The convex hull method identifies internal and

external slice points alternatively as feature points. If this

affects the curve significantly, we may have to overcome

the switching effect.

false assignments, we keep track of the previous point

assignments, and if one point is found to be closer to

one region, while its neighbors are closer to another,

we ignore the distance to the closest region and as-

sign the point to the region we assigned the neighbor-

ing points. When the distance is close to zero we can

change region.

Another issue is that the point slice is usually ar-

ranged on a wider area rather than a mere curve. Con-

sidering that the points of the 3D cloud lie on the sur-

face of the object, we would expect the points of a 2D

slice to lie on a curve with no thickness. But since we

allow for slices of certain adaptable thickness, pro-

jecting the points on a plane produces point regions

that form a thickened curve. If the dispersion of the

points is insignificant, the resulting curve would be

suitable. If not, computing the convex hull on each re-

gion would result in selecting external points on some

parts of the slice, and internal points on other parts

(see Figure 6). We call this the internal-external point

switching effect. To overcome this effect we use an

alternative approach, which is described in the next

section.

4 ELIMINATING THE

INTERNAL-EXTERNAL POINT

SWITCHING EFFECT

In cases where the points of a slice cover an area sig-

nificantly wider than the curve we try to extract, we

have to extract those points that describe the object

without information loss. Since we started identify-

ing feature points using the convex hull, our concern

is to identify external points only. To achieve this,

we use a property of the voronoi diagram, called the

largest empty circle. If we compute the voronoi di-

agram for the slice points, each voronoi vertex is a

center for a largest empty circle that is touching three

or more slice points. We can use this property on a re-

gion that consists of points which are located far from

the curve, to identify external points of the region.

First, we choose the farthest voronoi vertex lo-

cated on the opposite side of the curve than the region

points, and locate the three (or more) points that are

on the largest empty circle for this vertex. Since we

chose the farthest voronoi vertex, two of these points

are expected to be the extreme feature points of this

region, which are already known from the previous

step. So we expect one or more remaining points to be

identified as new feature points. This is equivalent to

choosing the third point of the unique Delaunay trian-

gle that the two already known feature points partici-

pate in, considering that there aren’t more than three

co-circular points for this voronoi vertex (if there are

more, the triangle is not unique, but still we can

choose any of the points, or all of them). We iden-

tify these new points as feature points and update the

curve accordingly. We repeat the process, until all

points are located near the curve.

Figure 7: The largest empty circle for the farthest voronoi

vertex is used in each step to identify additional feature

points and update the curve.

By choosing the farthest voronoi vertex every

time, the feature points are expected to be relatively

close to each other, as the curve closes in to the region

points slowly. We can ignore some voronoi vertices

that are too far from the region, and choose a voronoi

vertex that is the farthest within a bounded area. For

example, we can choose that voronoi vertex that is far-

ther from the region, but not farther than e.g. the max-

imum distance of the region points from the curve.

This condition is indicative for the speed of the curve

convergence. If we do not restrict the voronoi vertices

it will take many steps to fully update the curve on this

DETECTING FEATURES FROM SLICED POINT CLOUDS

191

region. The curve will consist of more feature points,

and it will describe the region points more accurately.

On the other hand, if we restrict the voronoi vertices

within a radius, it will take fewer steps to update the

curve, the feature points will be fewer, but the curve

would describe the region points less accurately. We

use this parameter to adapt the curve fitting accord-

ing to user specifications requirement or quality of

approximation guaranties. Figure 7 illustrates the re-

sulting curve in case we choose the farthest voronoi

vertex within a restricted area each time. If we had

chosen the farthest voronoi vertex in each step, the

resulting curve would consist of more feature points.

The curve would describe the slice points more accu-

rately, but more iterations would be required to fully

update the curve.

The method, as applied to a specific slice, is sum-

marized as follows (following the notation of Section

3):

Input: a set

P

of points, Slice

i

Output: an ordered set

F

i

of feature points

step 1:

(P

(3D)

i

, L) = slice(i, P)

step 2:

P

i

= project(P

(3D)

i

, L)

step 3:

F

i

= qconvex(P

i

)

step 4: for each region

P

ij

of

F

i

if

avg dist(P

ij

, F

ij

) > e

V

i

= qvoronoi(P

ij

)

V

max

= farthest

vertex(V

i

, P

ij

)

F

ij

= largest circle(V

max

, P

ij

)

end if

end for

F

i

= F

i

∪ F

ij

if

changes made = true

repeat step 4

end if

step 5: return

F

i

5 PERFORMANCE

Both the convex hull and the voronoi diagram require

O(nlogn) operations. Apart from computing the con-

vex hull and the voronoi diagram for each region, the

rest of operations require O(n), where n is the number

of points in the cloud. These operations include: (a)

loading the cloud into memory, (b) slicing the cloud,

and (c) projecting the slice points on the slice. Other

operations that require O(n) are (d) selecting the ap-

propriate voronoi vertex for each region, and (e) to

identify the feature points for that region.

To compute the convex hull and the voronoi di-

agram for each region, it would take O(n

j

logn

j

),

where n

j

is the number of points in region j. This

means that we need O(

∑

r

j=1

n

j

logn

j

) operations for

slice i, where r is the number of regions, and

O(

∑

s

i=1

∑

r

j=1

n

ij

logn

ij

) for all slices, where s is the

number of slices. This is also accomplished in

O(nlogn), since

∑

s

i=1

∑

r

j=1

n

ij

= n.

One issue is the number of iterations required to

fully fit the curve to the slice points. It depends on

the shape of the points, and in the worst case it may

require up to O(logn

i

) steps the n

i

points of slice i,

i.e. O(logn) for all slices. In practice, it usually takes

only a few steps. In the example of Figure 4, the re-

sulting curve is satisfactory after the second step.

In conclusion, to derive descriptive curves for all

slices of the point cloud takes O(nlog

2

n) time.

6 CONCLUSIONS

We have developed a method for representing cross

sections (slices) of a point cloud, which will be used

to identify the basic features of the object this point

cloud represents. The information extraction process

consists of several steps, which involve the segmenta-

tion of the 3D point cloud in 2D cross sections, and

the extraction of a descriptive curve for the corre-

sponding point slice. The extraction of the curve is

performed either by computing the convex hull of the

desired regions of the slice points, or by computing

the convex hull and the voronoi diagram of the slice

points, and use the largest empty circle for voronoi

vertices of insufficiently described regions to identify

exterior feature points.

REFERENCES

Amenta, N., Bern, M., and Kamvysselis, M. (1998).

A new Voronoi-based surface reconstruction algo-

rithm. Computer Graphics, 32(Annual Conference

Series):415–421.

Attene, M. and Spagnuolo, M. (2000). Automatic surface

reconstruction from point sets in space. Computer

Graphics Forum, 19(3):457–465.

Au, C. and Yuenb, M. (1999). Feature-based reverse engi-

neering of mannequin for garment design. Computer-

Aided Design, 31:751–759.

Jeong, W.-K., Kahler, K., Haber, J., and Seidel, H.-P.

(2002). Automatic generation of subdivision surface

head models from point cloud data. In In Proceedings

Graphics Interface 2002, pages 181–188.

Said, M. A. (2002). Polyline approximation of single-

valued digital curves using alternating convex hulls.

Computer Graphics and Geometry, 4:75–99.

Wu, Y., Wong, Y., Loh, H., and Y.F.Zhang (2004). Mod-

elling cloud data using an adaptive slicing approach.

Computer-Aided Design, 36:231–240.

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

192