DESIGNING AN E-BASED REAL TIME QUALITY CONTROL

INFORMATION SYSTEM FOR DISTRIBUTED

MANUFACTURING SHOPS

Iraj Mahdavi

a

, Babak Shirazi

a

, Maghsud Solimanpur

b

and Shahram Ghobadi

c

a

Mazandaran University of Science & Technology, Babol, Iran

b

Urmia University, Urmia, Iran

c

Iran University of Science and Technology, Tehran, Iran

Keywords: Distributed manufacturing shop, e-based quality control, Information system, Real-time process.

Abstract: Advanced manufacturing systems need to be developed for an enterprise to survive in the increasingly

competitive global market. Statistical e-based quality control approach combines statistical quality analysis

and reporting capabilities with web technology to deliver process optimization solutions. In this paper we

develop a structured profile for statistical e-based quality control to provide the capacity to access required

data anywhere. It helps enterprises to develop customized quality information systems, create and distribute

reports via the internet, and provide real-time display of quality profiles for process monitoring. Quality

engineers and managers have been dependent on information system (IS) departments to secure access to

such data. Statistical e-based quality profile is designed to bridge the gap between the raw data and genuine

quality improvement efforts by providing a powerful web-based solution for real-time quality process.

1 INTRODUCTION

The global diffusion of advanced manufacturing

systems naturally resulted in the needs for distant

product development, which in turn requires the

provision of production information and control on

its procedures across product life cycle. In a

distributed manufacturing shop (DMS), factories

possessing various machines and tools are at

different geographical shop floor, and different

manufacturing capabilities are often selected to

achieve the highest production quality.

Manufacturing operations can be performed by

different machines and tools at different locations.

Distributed manufacturing enables the enterprises to

achieve better product quality, lower production cost

and reduced management risk.

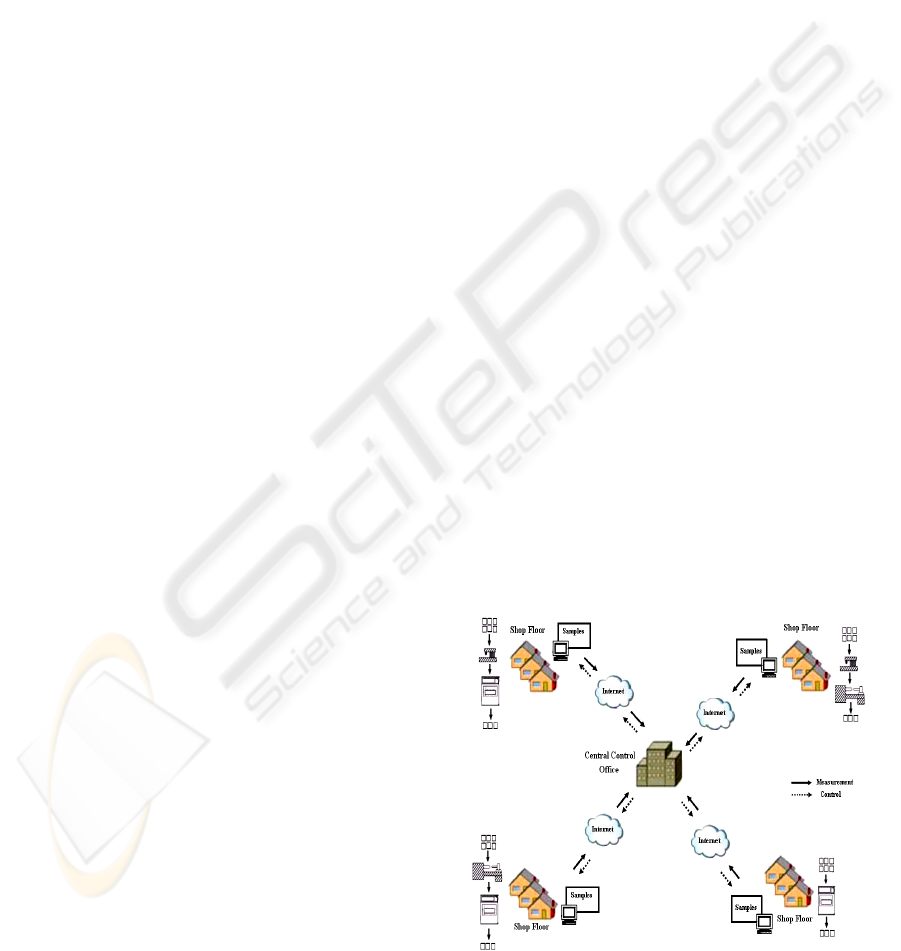

Quality information system (QIS) controls the

quality related information flow between the shop

floors that are combined in a production network in

a geographically distributed manufacturing shops as

shown in Figure 1.

Implementation of a distributed quality

information system requires the data gathering,

processing, storage and distribution among any shop

floors and central control office. In response to this

need, the research community has come with a

solution called e-Based DMS, which is defined as

‘‘an Internet-based computational architecture that

supports the sharing and transfer of knowledge and

information about the product and manufacturing

process amongst geographically distributed shops”

(Rodriguez and Al-Ashaab, 2002; Molina et al.,

1995; Ka Chi Lam and Thomas Ng., 2006).

Figure 1: The distributed manufacturing shops (DMS).

159

Mahdavia I., Shirazia B., Solimanpurb M. and Ghobadic S. (2007).

DESIGNING AN E-BASED REAL TIME QUALITY CONTROL INFORMATION SYSTEM FOR DISTRIBUTED MANUFACTURING SHOPS.

In Proceedings of the Ninth International Conference on Enterprise Information Systems - ISAS, pages 159-163

DOI: 10.5220/0002356701590163

Copyright

c

SciTePress

The aim of this paper is to improve the quality of

production and reduce loss through systematic

tracking and the use of information as continuous

feed-back to production lines by central control

office through a real time quality control information

system (RTQCIS). The proposed paradigm is to aid

quality engineers in distributed shops to send data

and obtain reliable results pertaining to

manufacturing. The RTQCIS architecture also

satisfies all the fundamental requirements for DMS

about statistical quality control in a real time

environment.

2 STATISTICAL E-BASED

QUALITY CONTROL FOR A

DMS

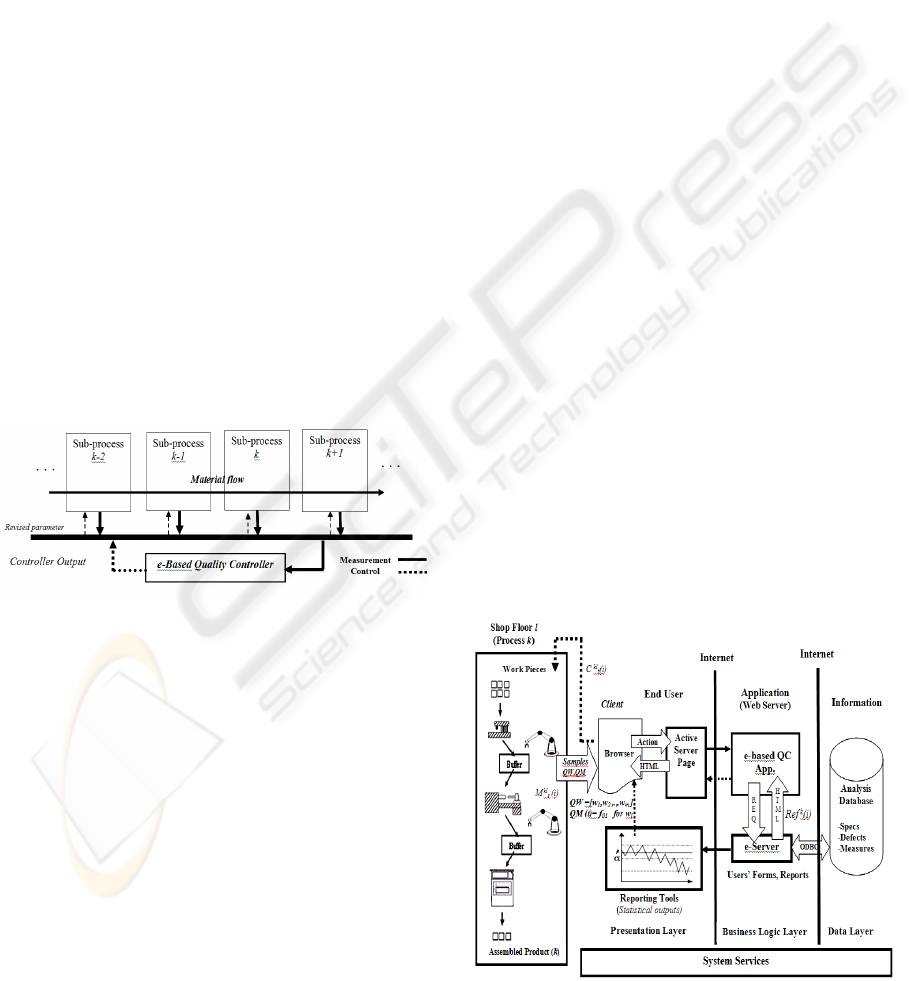

In general, an internet-based manufacturing system

must consist of all processes related to shops

(Sangyoon et al., 2004). The work-pieces in shop are

processed in the sub-processes until the final product

is obtained. In each sub-process the work-piece

quality must be measured. This system must be

connected to internet (or any world-wide

information area network) according to Figure 2.

Figure 2: The model of e-based manufacturing sub-

processes.

Statistical e-based QC has combined statistical

quality analysis and reporting capabilities with

revised policy over web to deliver a process

optimization system that will give everyone in an

enterprise (from the manufacturing floor to the

central executive suite) the information they need to

monitor, analyze, and improve important processes.

Statistical e-based QC must be designed to help

enterprise to bridge the gap between the raw

data and genuine quality improvement. It must

provide a powerful web-based solution for real-time

data to be shared anywhere in the enterprise any

time in a secure environment.

Quality managers have used quality control

systems such as statistical process control,

production part approval process, failure mode

effects analysis, gage calibration and document

control to access key attribute of production process.

Manufacturers currently measure process key

parameter and performance to improve quality in

production (Vijayaram et al., 2006). Statistical e-

based quality control enables continuous quality

improvement through easy and cost-effective access

to quality data. It requires an internet-enabled

software solution to allow individuals to access the

quality data for various analysis. It also needs a

dynamic web-based application that serves as a

quality portal, so that users can easily and cost-

effectively integrate a wide variety of information

for quality improvement.

Any internet-based system architecture is

structured around a three-layered framework:

information, application and end user layer

(Rodriguez and Al-Ashaab, 2005). The end user

layer is connected to the application web server

(application layer), which in turn is connected to the

information databases (information layer). The

application layer consists of two elements: decision

support applications and information management

tools. The web-based interface of the end-user layer

helps users to view and use different decision

support applications and tools. The product data is

produced and used by different engineering

applications throughout the entire production

processes.

For implementing such a system, we need a

client-server architecture that allows the appropriate

database management system (e-Server) to be

connected to the quality control database in

information layer as shown in Figure 3.

Figure 3: Client server architecture.

ICEIS 2007 - International Conference on Enterprise Information Systems

160

Statistical e-based quality controller utilizes

statistical e-server to perform all data access,

transformation, analyses and output creation.

e-Server is a module used for statistical analysis

and seamless integration of new or existing

applications. Users request an action from within the

graphical user interface in a browser (the

presentation layer) by hitting a button, selecting a

menu or completing a form. Once the request is

received by the presentation layer, the presentation

layer (Active Server Pages) handles the request and

directs it to the application (Business Logic

Application layer) for processing. The application

processes the request and determines appropriate

actions needed to complete the request via

interaction between e-based quality control

application and e-server. For computation, analysis

and graphics (SPC charts), the application analyses

data with the help of database to response the

request via ODBC tools. After directing the requests

to this platform, computations performed and results

return in the form of HTML table or data file to the

reporting tools (i.e. accept data from the application,

process the request, generating an SPC chart, and

return the resulting graph in the form of image file

or HTML, check SPC rules and make alarm by

sending rule violation information to the

application).

It should also be able to perform real-time display of

quality control charts to monitor processes. It should

be a flexible, full-featured analysis required for

continuous quality improvement. Data preprocessing

procedure for customer analysis tracks various

online activities of customers. This involves

capturing information about individual user,

constructing logical user “session”, and creating key

terms or variables. For a DMS, our model captures

key terms of the quality information on assembled

products (AP), sub-assembled products (SAP) and

parts or components (P). To implement a

mathematical model of e-QC layer, we present

internal blocks of e-based quality control module as

shown in Figure 4.

In order to supply the controller itself with the

complete information about the current process state,

a detector unit is introduced which receives the

measurement M

kl

t

(i) for frequency of n times, and

passes the state information S

kl

t

(i) to the controller.

The measurement at the end of each sub-process is

received only in the step of the work-pieces that are

passing through and the control output is

determined. (Where k is sub-process number, l is

location number, i is attribute number and t is time

period). The control problem is now to find a

controller output C

kl

t

(i). In general, this may need

a sequence steps until Ref

k

(i) can finally be

reached. A process is called controllable in one step

for any given state S

kl

t

(i), if the measurement M

kl

t

(i) can reach the reference value Ref

k

(i) such that:

Lim | Ref

k

(i) - M

kl

t

(i) | → 0

3 STATISTICAL QUALITY

PROFILE

In this section, a mathematical model is introduced

to provide a real time display of quality profile. The

following notations are considered.

Notations:

w

i

attribute i

M

kl

t

(i) measurements vector at time t in shop

floor l for process k on attribute i

S

kl

t

(i) state information at time t in shop floor l

for process k on attribute i

Ref

k

(i) reference value for process (product) k

on attributes i

f

k

ijl

frequency of quality key attribute i for

process k at location l in product j

LSL

k

(i) lower specification limit for process k on

attribute i

USL

k

(i) upper specification limit for process k on

attribute i

LCL

k

lower control limit for process k

CL

k

central control limit for process k

UCL

k

upper control limit for process k

k

σ

Standard deviation for process k

M number of key attribute

N number of products

P number of locations

T time period duration

C

kl

t

(i) control chart vector [LCL

k

,CL

k

,UCL

k

] at

time t in shop l for process k on

attribute i

The quality information is captured individually for

each part and compiled collectively from the set of

assembled or sub-assembled products. As a result of

tracking the quality of each product, we obtain the

vector of comprehensive key terms or key words on

quality; QW =

[

]

12

,,,

m

ww w⋅⋅⋅

. The quality

information is collected through electronic customer

interaction on the web. We define QM (t) =

DESIGNING AN E-BASED REAL TIME QUALITY CONTROL INFORMATION SYSTEM FOR DISTRIBUTED

MANUFACTURING SHOPS

161

[

]

pnm

ijl

f

××

as a quality space at time t, where f

ijl

is the

frequency of quality keyword i related to product j

and location l. We also define FQM (t) =

[

]

pnm

ijl

××

α

as a fuzzy quality space at time t, where

ijl

α

is a corresponding keyword-product-location

fuzzy membership value as shown in formula (0).

3

111 111

()

ijl ijl ijl ijl

ijl

MN P MNP

ijl ijl ijl ijl ijl ijl

ijl ijl

fff f

f

ff fff

α

=== ===

=××=

∑∑∑ ∑∑∑

(0)

The ratio

1

ijl

M

ijl

i

f

f

=

∑

can be viewed as a reliability value

for quality keyword w

i

in the product-location

incidence matrix, and the ratio

1

ijl

N

ijl

j

f

f

=

∑

as a reliability

value for product j in the keyword-location

incidence matrix, and the ratio

1

ijl

P

ijl

l

f

f

=

∑

as a reliability

value for location

l

in the keyword-product

incidence matrix, and finally

ijl

α

will be the

reliability of quality information in the quality

keyword-product-location space. Tracking by time

could produce a set of fuzzy values:

ijl

α

(T)

=

[

]

ijl

T

ijlijl

ααα

,,,

21

⋅⋅⋅

. This vector shows the

profile of the quality space. For sub-assembled

products (SAP), the final fuzzy value is

{

}

{

}

)(,)(maxmin)( SAPpSAP

ijlijlijl

α

α

α

=

.

Where

)()( SAPp

ijlijl

α

α

∈

as a required

components to SAP. For assembled product (AP),

the final value is considered as:

{

}

{

}

{

}

)(,)(max,)(maxmin)( APSAPPAP

ijlijlijlijl

α

α

α

α

=

,

where

)(P

ijl

α

and

)(SAP

ijl

α

are immediate

predecessor to AP. As for quality key terms, the

formulation (1) is used for an individual location and

formulation (2) for a combination of locations.

T

CL

t

ijl

T

t

α

∑

=

=

1

(1)

for

nj ,,2,1 L=

11

.

TP

t

ijl

tl

CL

TP

α

==

=

∑

∑

(2)

for

nj ,,2,1 L

=

As for quality on total attributes, we consider

formulation (3) for an individual location and

formulation (4) for a combination of locations.

11

.

TM

t

ijl

ti

CL

TM

α

==

=

∑

∑

(3)

for

nj ,,2,1 L

=

111

..

TMP

t

ijl

til

CL

TMP

α

===

=

∑

∑∑

(4)

for

nj ,,2,1 L

=

As a result of tracking the quality profile, the

Equations (5) and (6) are used for obtaining process

control limit.

k

kk

CLUCL

σ

3+= (5)

k

kk

CLLCL

σ

3−= (6)

Where

k

σ

is the standard deviation of process k.

The controller applies the control chart vector as

given in Equation (7).

],,[)(

kkkkl

t

UCLCLLCLiC = (7)

The statistical reports are drawn graphically by e-

Server on internet browser of shop floor and quality

engineer could achieve the appropriate policy.

4 DISTRIBUTED QUALITY

MANAGEMENT

USING EVOLUTIONARY

ALGORITHM

Quality management for an enterprise wide e-based

QC system focuses on analyzing data to make

decisions that affect future production and revenue.

The analysis includes real-time enterprise wide view

that identifies the levels of operations, and batch

report according to predetermined time period. We

ICEIS 2007 - International Conference on Enterprise Information Systems

162

can apply the evolutionary rule to automatically

modify the structure of e-based quality information.

It updates the quality profile in a dynamic fashion.

The following steps are suggested as an evolutionary

algorithm.

Step 0. Set T=0.

Step 1. Obtain the quality information profile using

e-QC.

Step 2. Apply distributed quality management and

quality decision making policy to modify quality

structure.

Step 3. Implement feasibility analyzer for quality

decision-making.

Step 4. Set T=T+1.

Step 5. Update the e-based quality network profile

and go to step1.

As time passes, new attributes in the quality

information space profile can be generated. In the

newly generated profiles, some attributes may take a

value beyond the lower or upper bound of the range

of variables appropriate for quality decision-making.

Then the feasibility analyzer is used to check the

feasibility boundary of attributes. New attributes are

collected and stored to form a meta-decision

support.

5 CONCLUSIONS

In this paper, we introduced a framework of e-based

quality management and developed a new

formulation that would provide a web-based solution

for real time control of a process. The suggested

logic is useful when we want to use a wide variety of

quality characteristics as key attributes. As a result

of using statistical e-based quality profile, anyone in

an enterprise can contribute to quality improvement

efforts. Web-enabled quality control system will

present an extensive connectivity outside a plant. A

customer’s engineer could tour the plant site and

check the profile online. It is used mostly within a

factory today, but after some advancement, and with

the process in place, access to quality data will be

extended across the supply chain and to customers.

One should be able to obtain information about the

batch s/he ordered and see how it conforms to the

specifications. Based on the research and framework

done in the distributed manufacturing systems, we

developed an analytical approach on e-based quality

control. For a customer interface and reliable and

sustainable information provision, an evolutionary

algorithm is suggested using evolutionary rule. The

prototype of eRTQCIS-DMS has been demonstrated

that quality management data can be captured,

stored, retrieved and disseminated through a web-

based system.

The internet technologies also facilitate the

sharing of quality management information in a

seamless manner. Reports containing consolidated

quality management information can be generated

by eRTQCIS-DMS. With those information and

reports, manufacturer would have a better

understanding about the product quality and

performance evaluation. A mathematical model for

an e-based statistical control on the basis of e-based

quality profile can be elaborated in future

researches.

REFERENCES

Ka Chi Lam, S. Thomas Ng., (2006). A cooperative

Internet-facilitated quality management environment

for construction, Automation in Construction, 15(1),

1-11.

Molina, A., Al-Ashaab, A., Ellis, T., & Young, R. (1995).

A review of computer-aided simultaneous engineering

systems. Research in Engineering Design, 7, 38–63.

Rodriguez, K., & Al-Ashaab, A. (2002). A review of

internet based collaborative product development

systems. Proceedings of the International Conference

on Concurrent Engineering: Research and

Applications, Canfield, UK.

Rodriguez, K. & Al-Ashaab, A.(2005). Knowledge web-

based system architecture for collaborative product

development, Computers in Industry, 56, 125-140.

Sangyoon C., Kyungrai Kim, Yea-Sang Kim. (2004), A

process-based quality management information

system, Automation in Construction, Vol 13, 241– 259

Vijayaram, T.R. , Sulaiman, S. Hamouda A.M.S. , Ahmad,

M.H.M. (2006) , Foundry quality control aspects and

prospects to reduce scrap rework and rejection in

metal casting manufacturing industries , Journal of

Materials Processing Technology, 178(1-3), 39-43.

DESIGNING AN E-BASED REAL TIME QUALITY CONTROL INFORMATION SYSTEM FOR DISTRIBUTED

MANUFACTURING SHOPS

163